Date:2021.06 Doc No:GSE-M-0001 Ver.A

Installation guide for module

Purpose of this guide

This guide contains information regarding the installation and safe handling of photovoltaic

modules made by Gazioğlu Solar Enerji San. Ve Tic. A.Ş. hereafter is referred to as

“GSE”.

All instructions should be read and understood before installing the modules. The

installation of modules should conform to all the safety precautions in this guide when

installing the modules. The local standards should also be followed in such installations. If

there are any questions, please contact our sales department for further assistance.

Before installing a photovoltaic system, the installer should be familiar with the mechanical

and electrical requirements for such a system. Keep this guide in a safe place for future

reference (maintenance).

The mechanical and electrical installation of modules should consult the corresponding

laws and regulations, such as electrical method, building law.

Scope

PV modules are ideal for charging storage batteries used to power remote homes,

recreational vehicles, boats, telecommunication systems and other electrical applications.

This manual contains important installation, maintenance and safety information. The word

“module” as used in this manual refers to one or more PV modules.

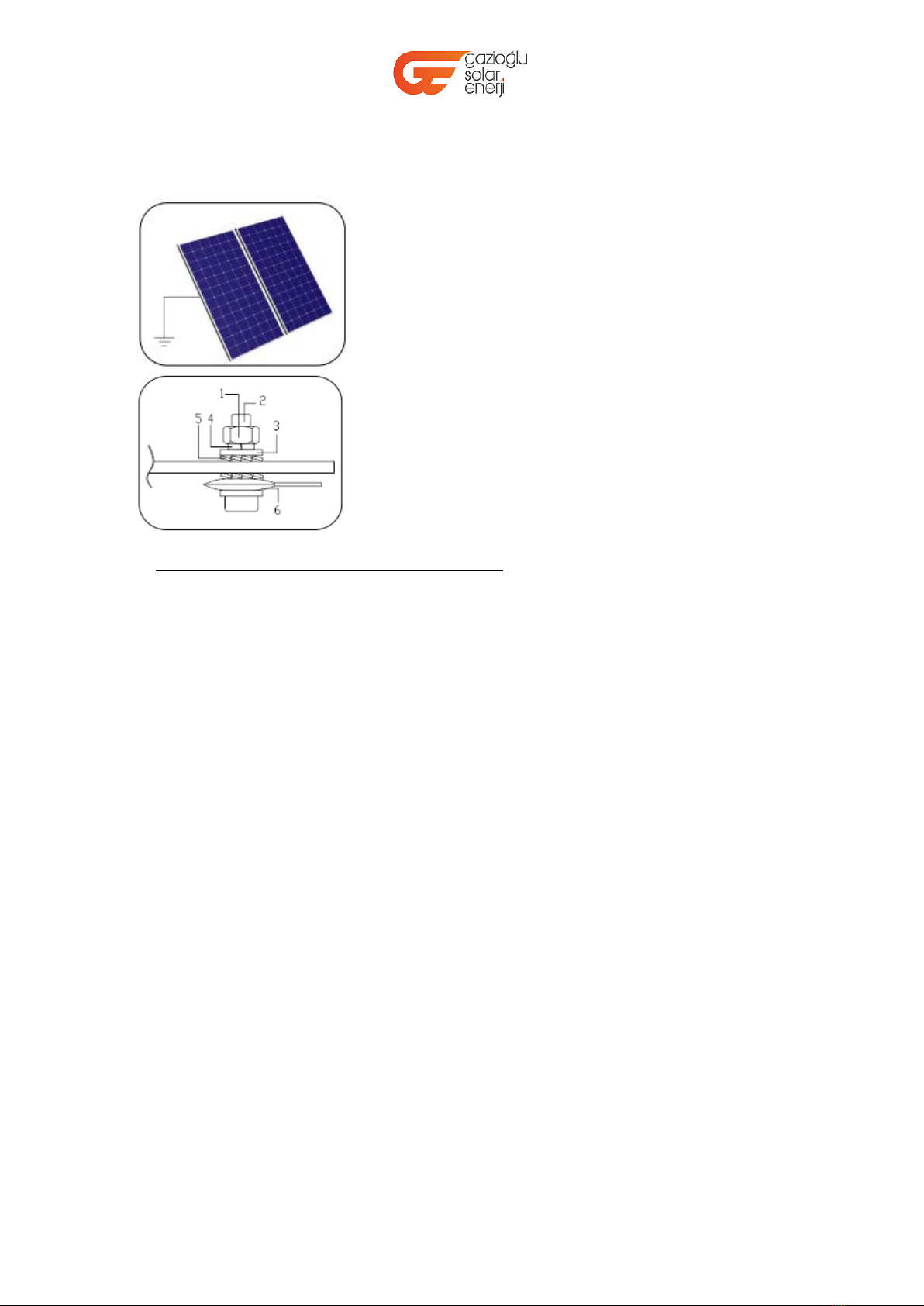

“GSE” modules are designed to fulfill the criteria of protection class II requirements

according to IEC61730-part1.

The modules are qualified for protection class II: Hazardous voltage (IEC61730: higher

than 50V DC; EN61730: higher than 120V), hazardous power applications (higher than

240W) where general contact access is anticipated (Modules qualified for safety through

EN IEC61730-1 and -2 ).

Disclaimer of liability:

The installation techniques, handling and use of this product are beyond company control.

Therefore, “GSE” does not assume responsibility for loss, damage or expense resulting

from improper installation, handling or misuse.

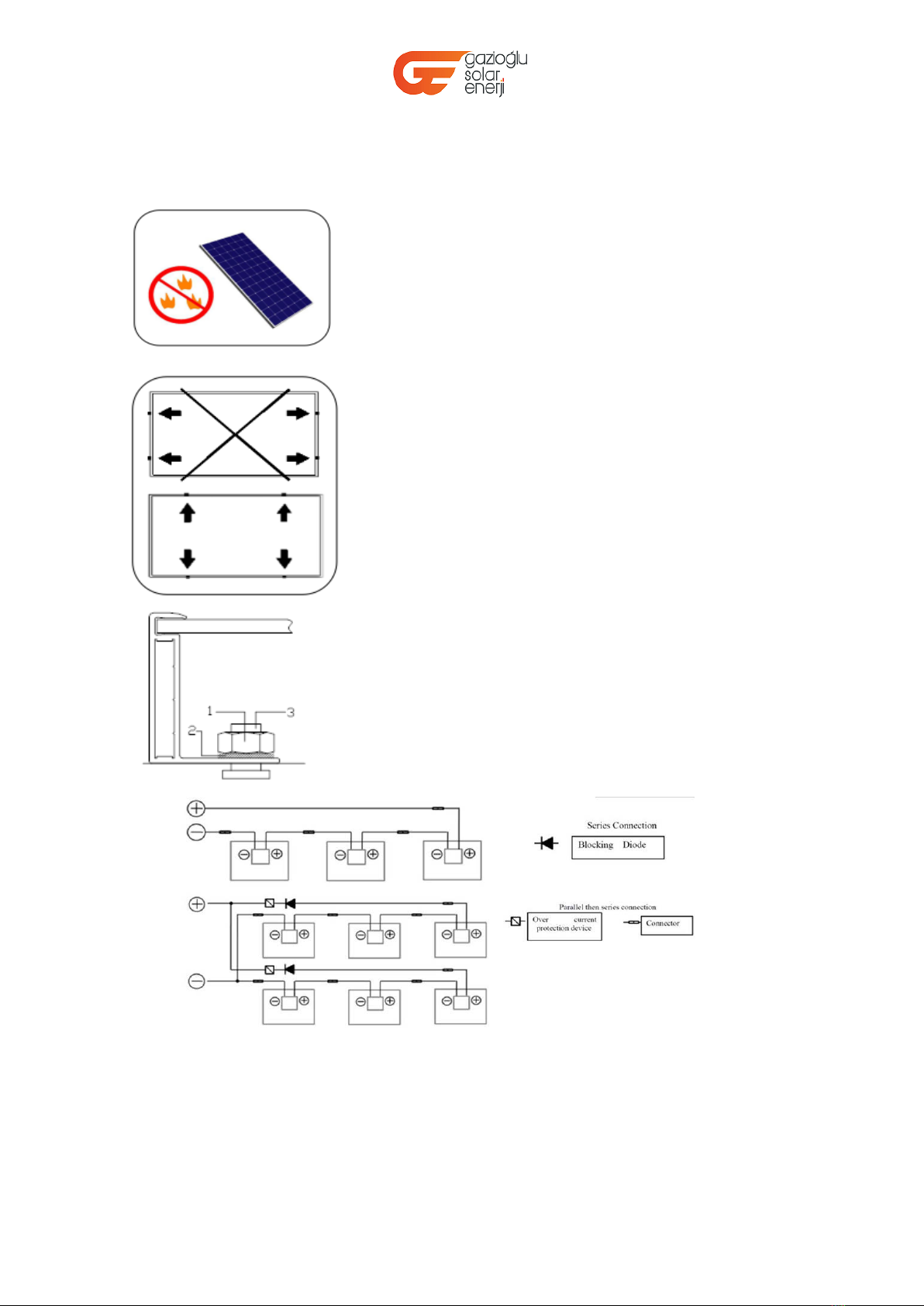

General Safety Information

Ensure that the module is used only in applications for which it is suitable (see “Installing

Modules”). All work on a PV system (installation, setup, maintenance) must be carried out

only by appropriately qualified and authorized engineers.

The appropriate DIN standards, construction rules and safety instructions must be followed

during installation.

Warning!

PV modules generate electricity as soon as they are exposed to the sunlight. One