Table of Contents

PNEG-1993 CE Compliant E-Series Chain Conveyors - All Models 5

Contents

Chapter 1 Safety .....................................................................................................................................................6

Safety Guidelines .................................................................................................................................. 6

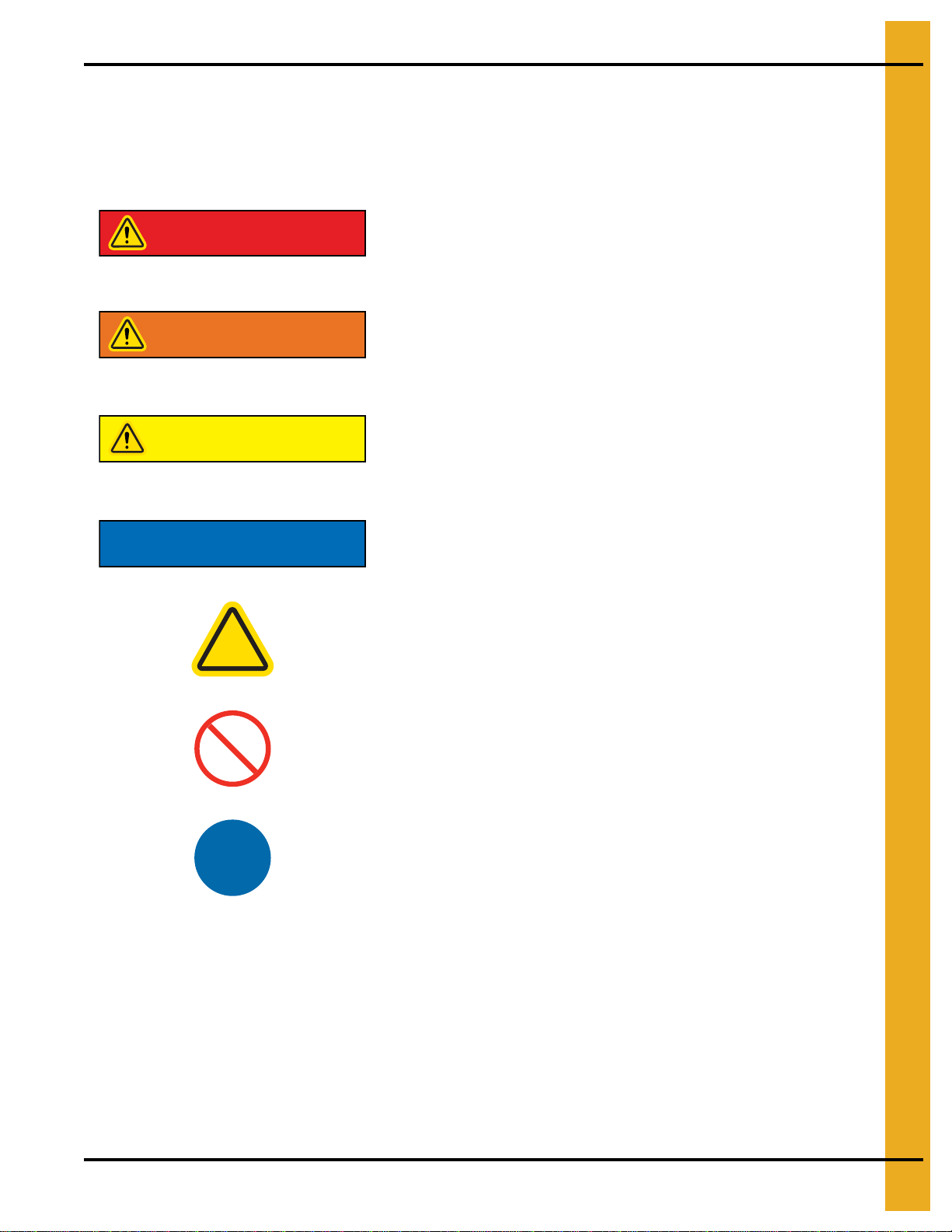

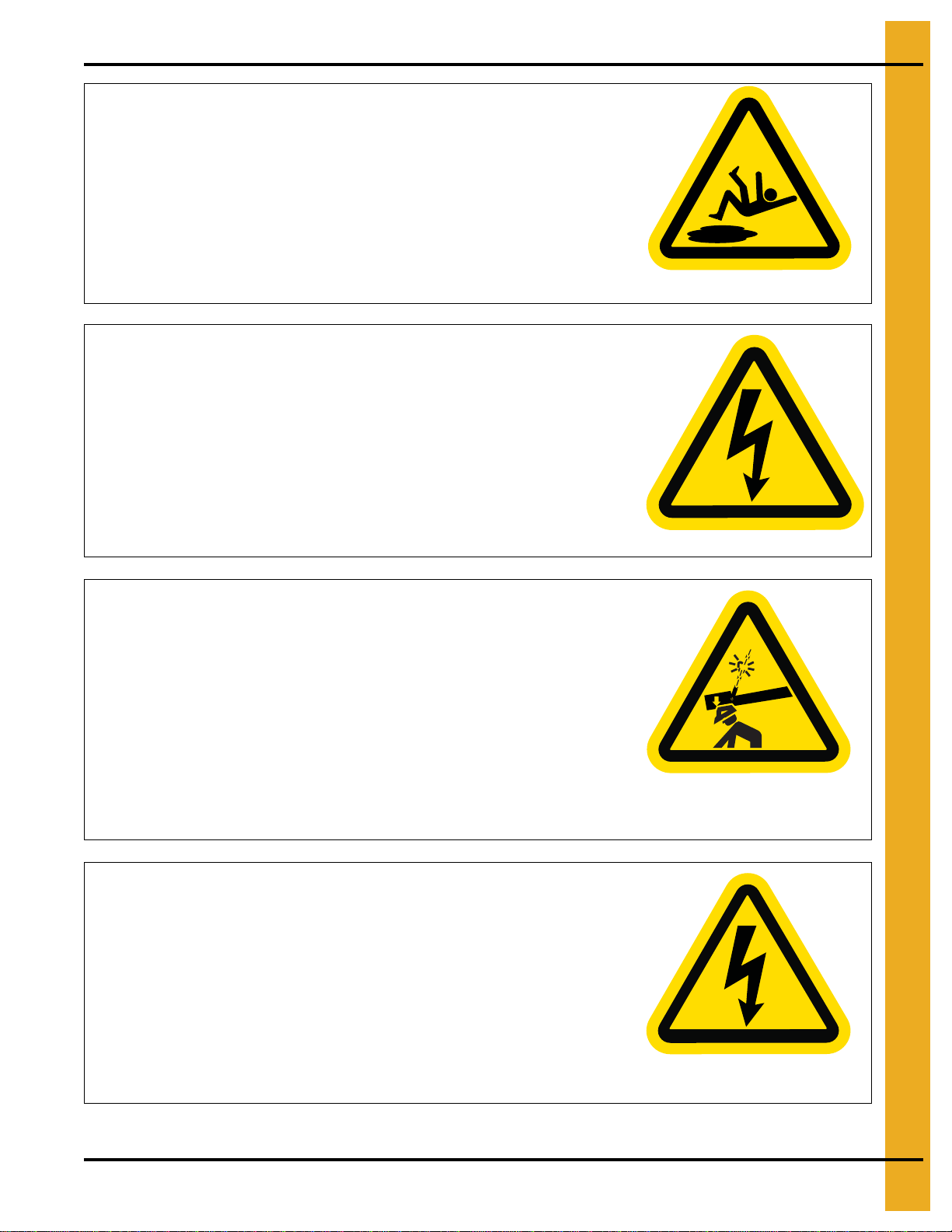

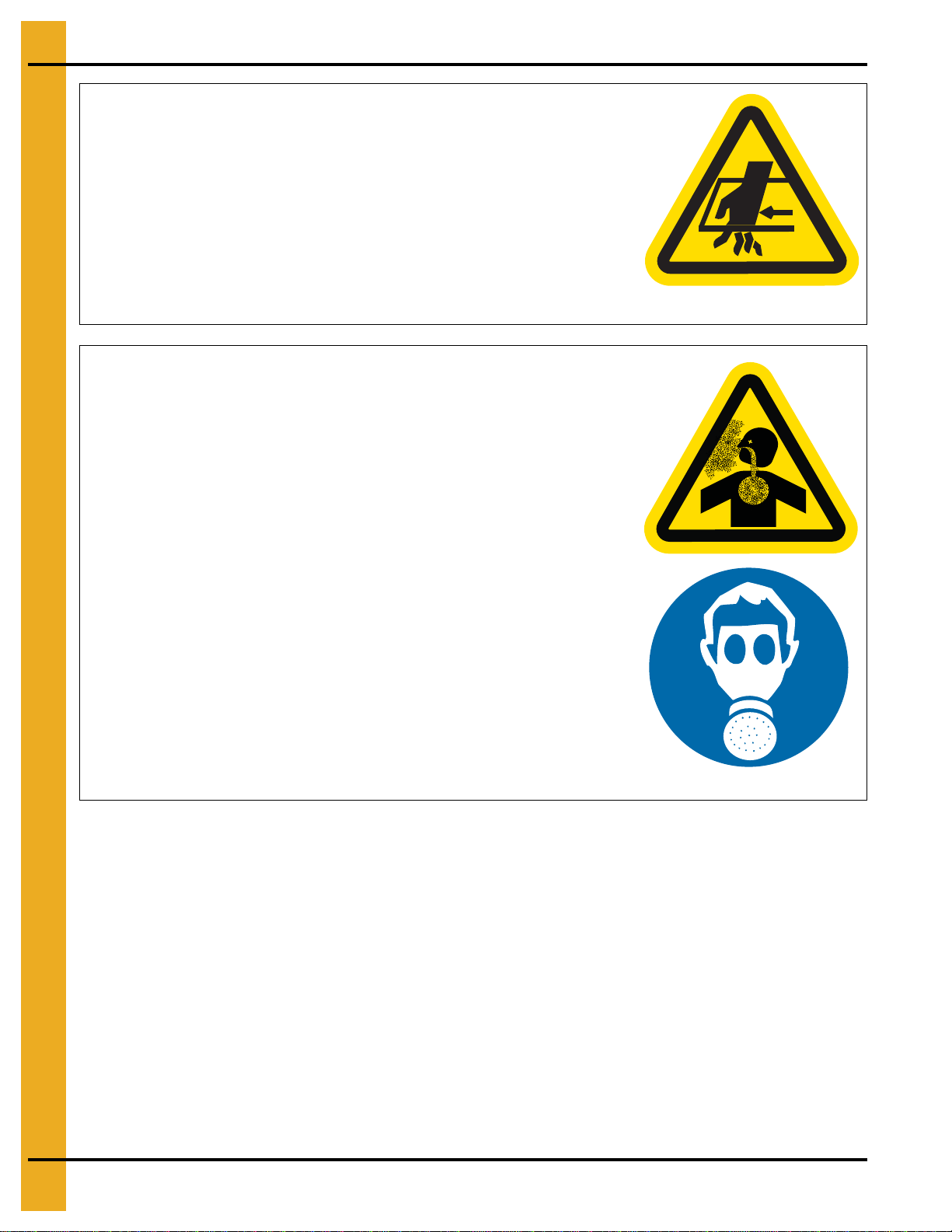

Cautionary Symbols Definitions ............................................................................................................ 7

Safety Cautions ..................................................................................................................................... 8

Safety Sign-Off Sheet ......................................................................................................................... 12

Correct Use ......................................................................................................................................... 13

Correct Installation .............................................................................................................................. 14

Guards ................................................................................................................................................ 15

Electrical Safety .................................................................................................................................. 15

Possible Hazards Inside Grain Bins .................................................................................................... 17

Chapter 2 Safety Decals ......................................................................................................................................18

CE Mark and Rating Plate ................................................................................................................... 20

Chapter 3 Installation ..........................................................................................................................................21

Pre-Installation Preparation ................................................................................................................. 21

Head and Tail Identification ................................................................................................................. 22

Assembling an Un-Assembled Intermediate Section .......................................................................... 23

Assemble Conveyor Sections ............................................................................................................. 24

Chain Installation ................................................................................................................................. 28

Gear Motor Installation ........................................................................................................................ 30

Chapter 4 Electric Operated Gate Installation ...................................................................................................31

Overall Head Gate and Intermediate Gate Dimensions ...................................................................... 31

Cut Trough Bottom for Intermediate Gate ........................................................................................... 32

Motor Bracket Installation for Head Gate and Intermediate Gate ....................................................... 33

Limit Switch Installation of Head Gate and Intermediate Gate ............................................................ 34

Install Gate to Trough Bottom of Intermediate Gate and Head Gate .................................................. 36

Flipping the Shaft to Change Gate Drive Side .................................................................................... 37

Slack Chain Detector and Plug Switch ................................................................................................ 38

Chapter 5 Electrical Installation .........................................................................................................................39

Chapter 6 Reducer Lubrication ..........................................................................................................................41

Lubricant Table ................................................................................................................................... 43

Start-Up and Break-In ......................................................................................................................... 44

Chapter 7 Maintenance ........................................................................................................................................45

Chapter 8 Optional Components ........................................................................................................................46

‘Whirlygig’ Motion Sensor .................................................................................................................... 46

Chapter 9 Troubleshooting .................................................................................................................................47

Chapter 10 Warranty ............................................................................................................................................49