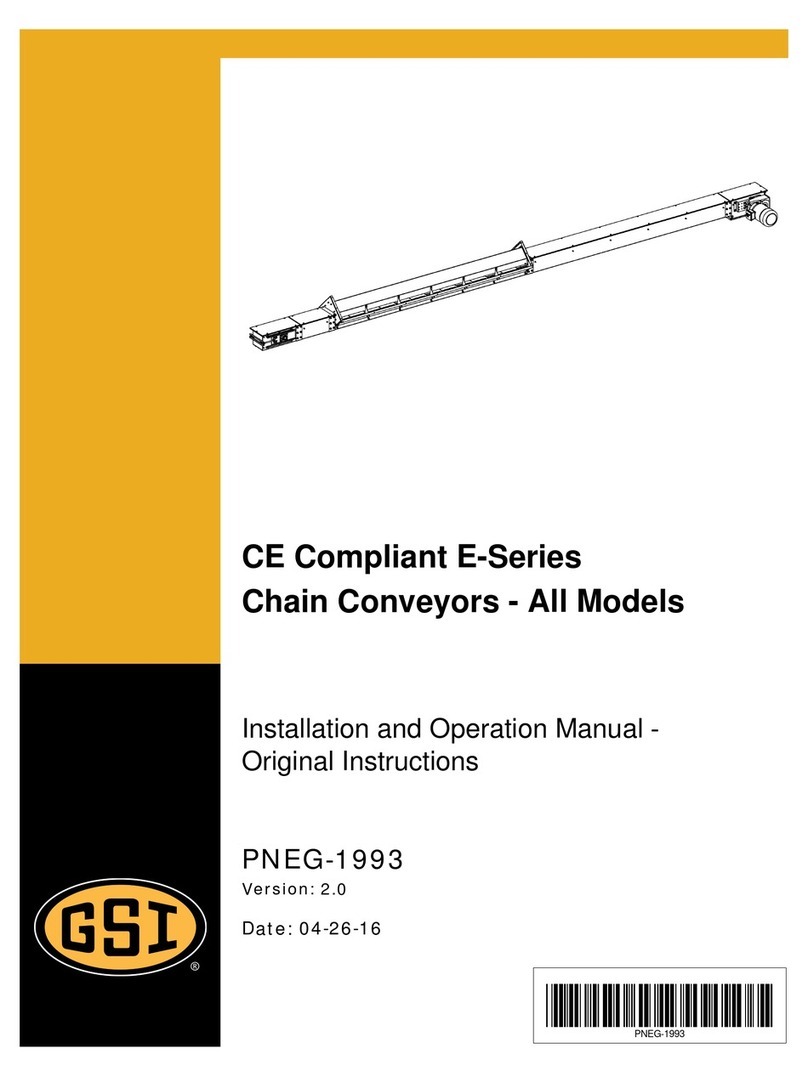

GSI Group II Series User manual

PNEG-1043

SeriesII

26"and32"Tall

En-Masse Chain Conveyors

Installation and Operation Manual

PNEG-1043

Date: 12-21-20

2 PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors

Equipment Information

Use of the Equipment Information page will help you identify your equipment incase you need to call your

dealer or installer. This information should be filled out and kept on record.

Equipment Information

Model Number: ______________________

Serial Number: _______________________

Date Purchased: _____________________

Dealer/Distributor Name and Phone Number:

___________________________________

___________________________________

___________________________________

___________________________________

GSI Material Handling

1004 E. Illinois St.

Assumption, IL. 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Table of Contents

PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors 3

Contents

Chapter 1 Safety .....................................................................................................................................................4

Safety Guidelines .................................................................................................................................. 4

Safety Sign-Off Sheet ........................................................................................................................... 5

Chapter 2 Safety Decals ........................................................................................................................................6

Head Section Decal Locations .............................................................................................................. 6

Tail Section Decal Locations ................................................................................................................. 7

Chapter 3 General Precautions ............................................................................................................................8

Chapter 4 Inspection .............................................................................................................................................9

Receiving Inspection ............................................................................................................................. 9

Pre-Installation Preparation ................................................................................................................... 9

Chapter 5 Installation ..........................................................................................................................................10

Head and Tail Assembly ..................................................................................................................... 10

Intermediate Trough Section Assembly .............................................................................................. 10

Cover Assembly Installation ................................................................................................................ 12

Inlet Assembly and Installation ............................................................................................................ 12

Drag Chain Assembly Installation ....................................................................................................... 13

Installing Shaft Mount Reducers ......................................................................................................... 14

Torque Arm Bracket Installation .......................................................................................................... 15

Chapter 6 Care and Maintenance .......................................................................................................................16

Storage ................................................................................................................................................ 16

Welding ............................................................................................................................................... 16

Motor ................................................................................................................................................... 16

Support ................................................................................................................................................ 17

Clearance ............................................................................................................................................ 17

Discharge ............................................................................................................................................ 17

Chapter 7 Options ................................................................................................................................................18

Inspection Ports .................................................................................................................................. 18

Plug Relief Door .................................................................................................................................. 18

Slack Chain Assembly ........................................................................................................................ 19

Chapter 8 Optional Carry-Over Bars ..................................................................................................................21

Carry-Over Bars - Reversing Conveyor .............................................................................................. 21

Chapter 9 Troubleshooting .................................................................................................................................22

Chapter 10 Warranty ............................................................................................................................................23

4 PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors

1. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

1. Safety

PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors 5

Safety Sign-Off Sheet

As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe operating

and safety procedures for this auger. This sign-off sheet is provided for your convenience and personal

record keeping. All unqualified persons are to stay out of the work area at all times. It is strongly

recommended that another qualified person who knows the shut down procedure be in the area in the

event of an emergency.

Date Employee Name Supervisor Name

6 PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors

2. Safety Decals

Head Section Decal Locations

DC-972

WARNING

Moving parts can crush

and cut. Keep hands

clear. Do not operate

without guards in place.

Failure to do so could

result in serious injury.

GSI Group 217-226-4421

Moving parts can

crush and cut.

Do not operate with

guard removed.

Disconnect and lockout

power before servicing.

Keep hands clear

.

DC-997

The GSI Group 217-226-4421

DANGERDANGER

WARNING

EXPOSED CONVEYORS

Moving parts can cause

serious injury.

Lockout power before

removing covers or inspection

door.

GSI Group Inc. 217-226-4421 DC-1230

Moving parts can

crush and cut.

Do not operate with

guard removed.

Disconnect and lockout

power before servicing.

Keep hands clear.

DC-996The GSI Group 217-226-4421

WARNING

1

2

3

4

Decal 3 outside

Decal 4 inside

Decal 3 Outside

Decal 4 Inside

2. Safety Decals

PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors 7

Tail Section Decal Locations

DC-972

WARNING

Moving parts can crush

and cut. Keep hands

clear. Do not operate

without guards in place.

Failure to do so could

result in serious injury.

GSI Group 217-226-4421

Moving parts can

crush and cut.

Do not operate with

guard removed.

Disconnect and lockout

power before servicing.

Keep hands clear

.

DC-997

The GSI Group 217-226-4421

DANGER

DANGER

Moving parts can

crush and cut.

Do not operate with

guard removed.

Disconnect and lockout

power before servicing.

Keep hands clear.

DC-996

The GSI Group 217-226-4421

WARNING

1

Decal 3 Outside

Decal 4 Inside

3

4

8 PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors

3. General Precautions

1. Read and understand the Operator’s manual BEFORE operating the unit.

2. Keep all safety shields and devices in place.

3. Keep all covers in place.

4. Make certain everyone is clear of the equipment before operating.

5. Keep hands, feet and clothing away from moving parts.

6. Shut OFF and lock out all power to adjust, service, clean or unclog the unit.

7. Keep off the equipment at all times.

8. Keep children, visitors and all untrained personnel away from the machine

when in operation.

9. Do not operate electric motor equipped units until motors are properly grounded.

10. Disconnect power on electrical driven units before resetting motor overloads.

11. Do not repetitively stop and start the drive in order to free a plugged condition.

“Jogging” the drive in this manner can damage the conveyor and/or

drive components.

CAUTION

PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors 9

4. Inspection

Receiving Inspection

Carefully inspect the shipment as soon as it is received. Verify that the quantity of parts or packages

actually received corresponds to the quantity shown on the packing slip. Any discrepancies should be

clarified immediately. Please remember that any damage or missing parts must be noted on the bill of

lading at the time of delivery. Report any damage or shortage to the delivering carrier as soon as possible.

GSI’s responsibility for damage to the equipment ends with acceptance by the delivering carrier.

Save all paperwork and documentation furnished with any of the en-masse conveyor components.

Pre-Installation Preparation

Familiarize yourself thoroughly with this manual and all the conveyor parts. Read the Operator’s manual

and all safety signs before using or servicing equipment. Taking the time to do so will aid in the assembly

of the conveyor.

Remove all banding and crating material. Arrange the conveyor components so that they are

easily accessible.

Locate sturdy items to serve as blocking. (i.e. wood blocks, saw horses, etc.) Blocking is used to support

the conveyor sections above the ground to help in assembly. Locate and place the conveyor sections

on the blocking in order, starting with the head section and concluding with the tail section.

10 PNEG-1043 Series II 26" and 32" Tall En-Masse Chain Conveyors

5. Installation

Head and Tail Assembly

The head and tail sections of the chain conveyor are shipped pre-assembled direct from the factory.

Intermediate trough sections may come factory pre-assembled or unassembled. The order will serve

as a reference to how the trough section will arrive. If you have any questions, please refer to the

order confirmation.

Figure 5A Head Assembly Figure 5B Tail Assembly

Intermediate Trough Section Assembly

Figure 5C Typical Intermediate Trough Section Assembly

Other manuals for II Series

1

Table of contents

Other GSI Group Accessories manuals