Table of Contents

PNEG-1204 Enclosed Belt Conveyor 3

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ................................................................................................................................. 6

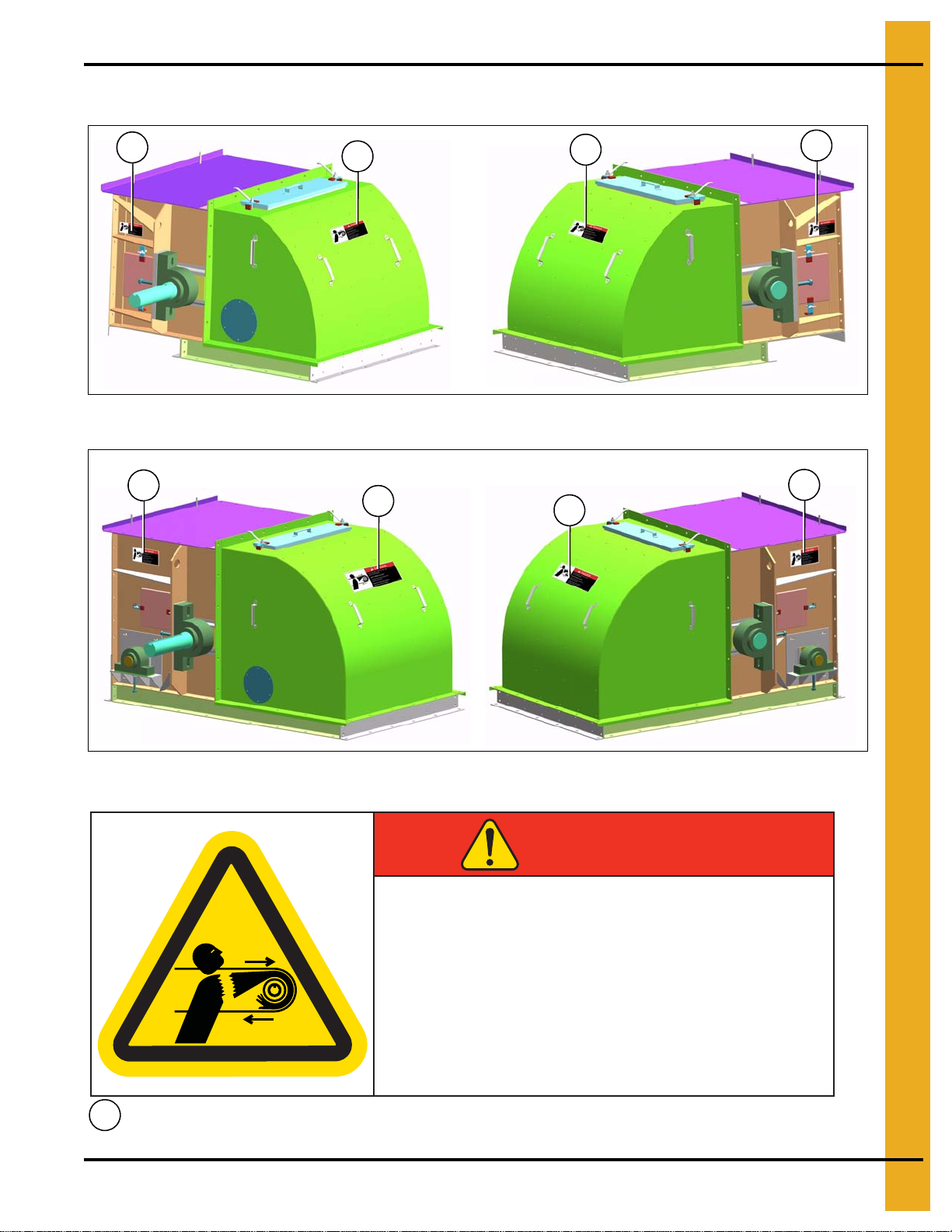

Chapter 3 Decals ....................................................................................................................................................9

Head Section Decal Locations .............................................................................................................. 9

Tail Section Decal Locations ............................................................................................................... 10

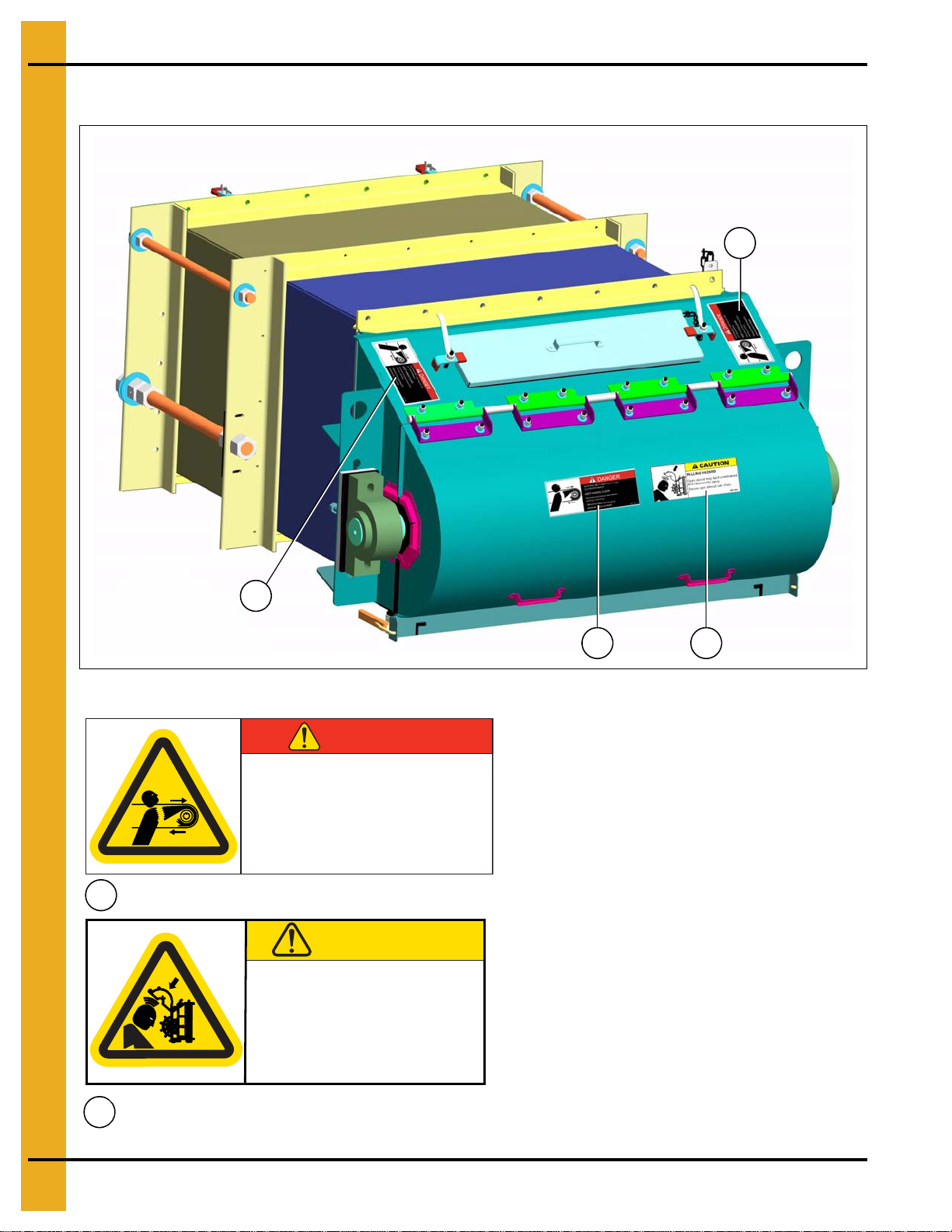

Loader Section Decal Locations ......................................................................................................... 11

Intermediate Section Decal Locations ................................................................................................. 12

Belt Guard Cover ................................................................................................................................ 13

Chapter 4 Conveyor Assembly ...........................................................................................................................14

Conveyor Assembly Overview ............................................................................................................ 14

Intermediate Section Installation ......................................................................................................... 15

Cover Installation ................................................................................................................................ 18

Loader Installation ............................................................................................................................... 20

Chapter 5 Motor Assembly .................................................................................................................................22

Motor and Shaft Torque Arm II Installation ......................................................................................... 22

Motor and Torque Arm II Reducer Installation .................................................................................... 24

Chapter 6 Belting Assembly ...............................................................................................................................29

Finding Belt Centerline ........................................................................................................................ 29

Squaring the Belt End ......................................................................................................................... 30

Check the Squareness of the Belt Cut ................................................................................................ 31

Installation of Belt ................................................................................................................................ 32

Splicing the Belt .................................................................................................................................. 33

Belt Tension ........................................................................................................................................ 37

Belt Tracking ....................................................................................................................................... 38

Chapter 7 Loading ...............................................................................................................................................41

Spouting .............................................................................................................................................. 41

Spouting Location ............................................................................................................................... 42

Belt Conveyor Loading ........................................................................................................................ 43

Chapter 8 Options ................................................................................................................................................44

Motion Sensor Option (Whirligig - WG1-4B) ....................................................................................... 44

Pressure Plug Switch Option .............................................................................................................. 45

Chapter 9 Start-Up ...............................................................................................................................................46

Starting Conveyor ............................................................................................................................... 46

Secure Shroud During Maintenance ................................................................................................... 46

Chapter 10 Care and Maintenance .....................................................................................................................47

Bearings ............................................................................................................................................ 47

Welding .............................................................................................................................................. 47

Motor ................................................................................................................................................. 47

Support .............................................................................................................................................. 47

Storage .............................................................................................................................................. 48

Chapter 11 Troubleshooting ...............................................................................................................................49

Chapter 12 Appendix 1 - Reference Information ...............................................................................................50

Chapter 13 Warranty ............................................................................................................................................51