1

Table of Contents

I. GENERAL SAFETY INFORMATION .....................................................................................................................3

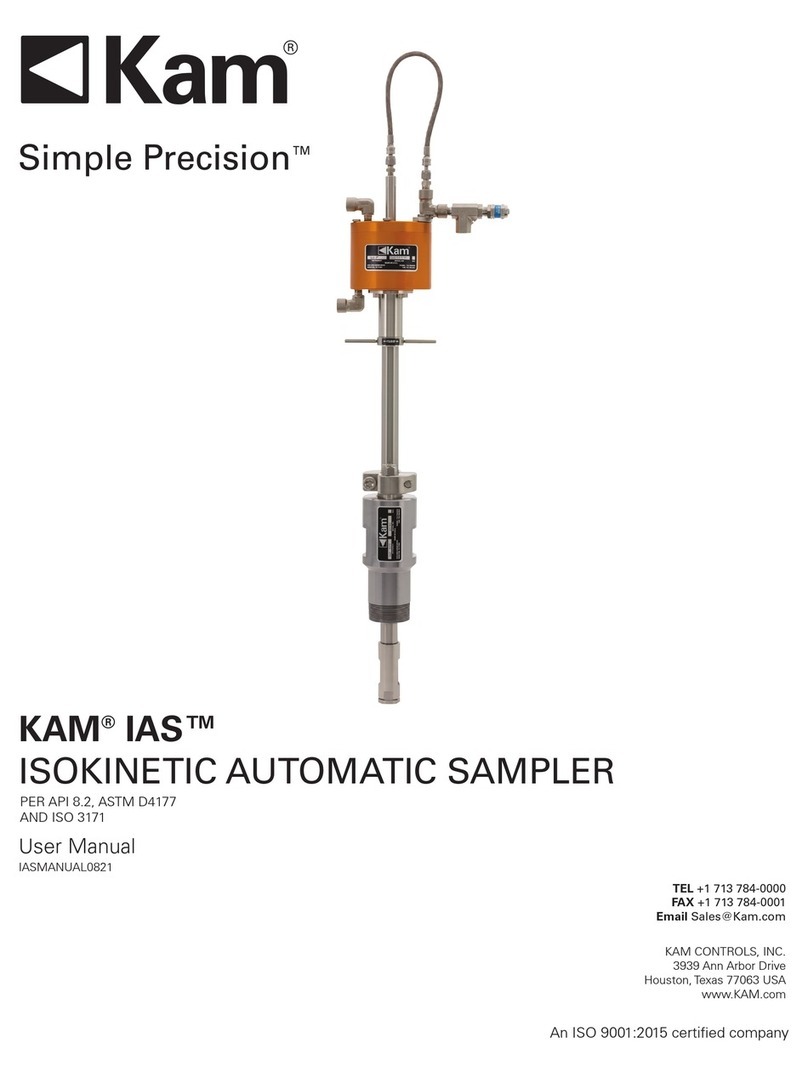

II. GENERAL INFORMATION ...................................................................................................................................5

2.1 System Description .................................................................................................................................5

2.2 Optional Features ...................................................................................................................................6

2.3 Material Sampled....................................................................................................................................6

2.4 Sampler Construction .............................................................................................................................6

III. GENERAL INSTALLATION REQUIREMENTS ....................................................................................................7

3.1 Receiving Inspection...............................................................................................................................7

3.2 Pre-Installation Preparation ....................................................................................................................7

3.3 Location ..................................................................................................................................................7

3.4 General Mounting Guidelines .................................................................................................................7

3.4.1 Factory Pre-Mounted Sampler.............................................................................................................8

3.4.3 Field-Mounted Sampler Using Weld-On Plates ...................................................................................8

3.5 Material Sample Transport Lines............................................................................................................9

3.6 Controller Location..................................................................................................................................9

3.7 System Wiring.......................................................................................................................................10

3.7.1 Electrical Power Requirements, System............................................................................................10

3.7.1.1 Controller ........................................................................................................................................10

3.7.1.2 Clutch Solenoid Coil........................................................................................................................10

3.7.1.3 Drive Motor .....................................................................................................................................10

IV. OPERATIONS AND ADJUSTMENTS................................................................................................................11

4.1 Control Components And Their Functions............................................................................................11

4.1.1 POWER OFF/ON Switch S-2 ............................................................................................................12

4.1.2 SAMPLING MODE Switch S-3 (Automatic/Manual) ..........................................................................12

4.1.3 MANUAL SAMPLING Switch S-4 ......................................................................................................12

4.1.4 CONTINUOUS SAMPLING Switch S-5.............................................................................................12

4.1.5 POWER Pilot Light.............................................................................................................................12

4.1.6 SAMPLING Pilot Light........................................................................................................................12

4.1.7 Digital Display Timer T-1 (Standard)..................................................................................................13

4.1.8 Digital Display Counter C-1 (Optional)...............................................................................................14

4.1.9 Printed Circuit Board..........................................................................................................................15

4.1.9.1 Main Fuse .......................................................................................................................................15

4.1.9.2 Motor Fuse......................................................................................................................................15

4.1.9.3 PC Board Fuse F3 ..........................................................................................................................15

4.1.9.4 Motor Timer Switches (Tens & Ones).............................................................................................15

4.1.9.5 Solenoid Timer Switches (Tens & Ones)........................................................................................16

4.1.9.6 Motor LED Indicator........................................................................................................................16

4.1.9.7 Solenoid LED Indicator ...................................................................................................................16

4.1.9.8 Mode Select Switch ........................................................................................................................16

4.1.9.9 Terminal Strip..................................................................................................................................16

4.1.9.10 115V/230V Switch.........................................................................................................................17

4.2 Sampler Mounted Electrical Components.............................................................................................17

4.2.1 Limit Switch........................................................................................................................................17

4.2.2 Drive Motor ........................................................................................................................................17

4.2.3 Clutch Solenoid..................................................................................................................................18

V. MAINTENANCE AND REPAIR ...........................................................................................................................19

5.1 General Maintenance............................................................................................................................19

5.2 Periodic Inspection................................................................................................................................19

5.3 Lubrication ............................................................................................................................................19

5.3.1 Auger & Auger Tube Spur Gears.......................................................................................................19

5.3.2 Gear Reducer ....................................................................................................................................20

5.4 Mechanical Repair Procedures.............................................................................................................20