GSK SJT series AC servo motor

2

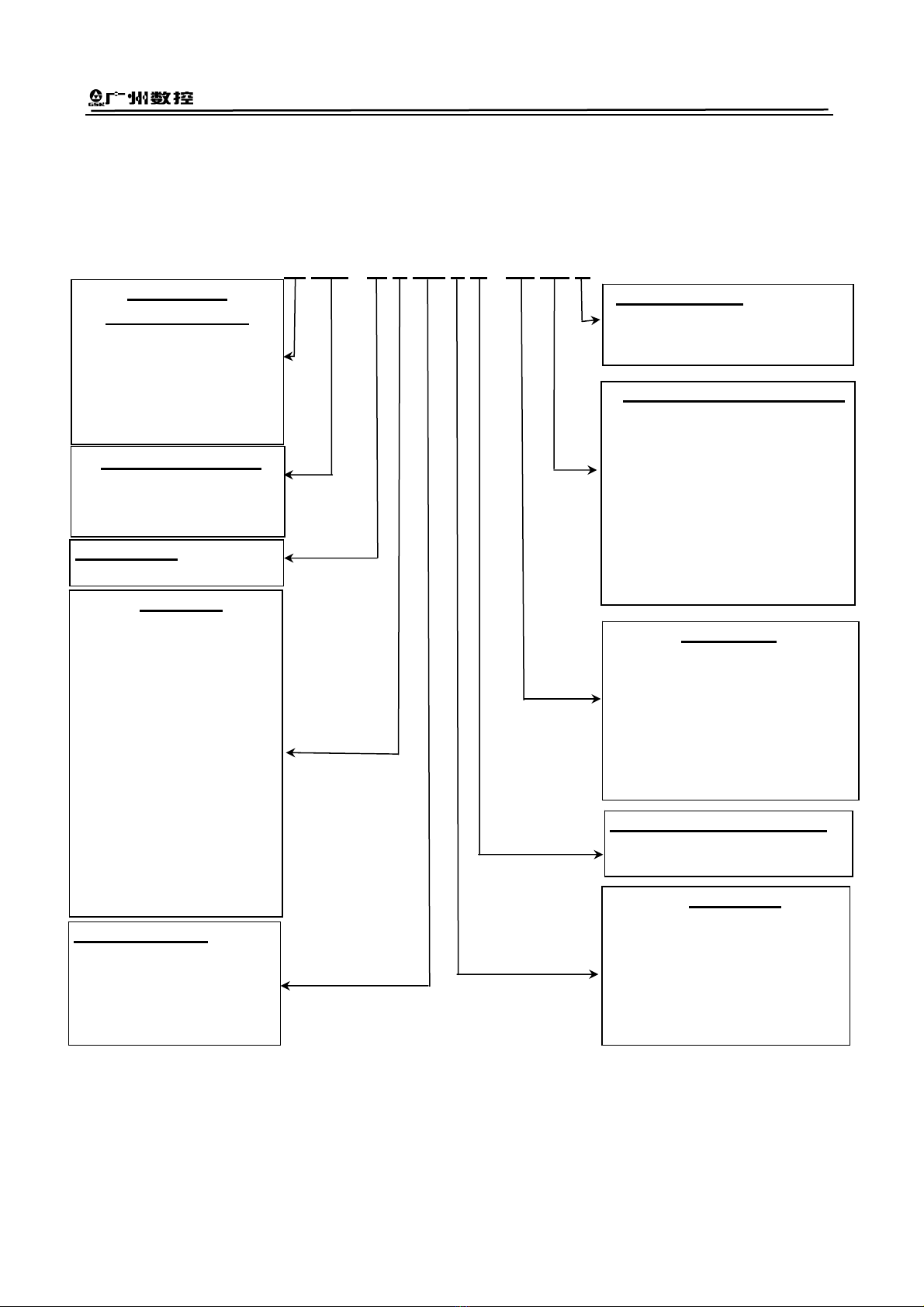

ⅢMODELS of the MACHINE

Example: 80SJT

-

MZ032EH(A4Y1X)

80 SJT - M Z 032 E H(A□Y□X)

Dimension for

installing the flange:

60

80

110

130

150

175

AC servo motor series

SJT Common

SJTG

High precision & speed

SJTR

Dedicated for the robot

Safe brake:

None None

Z Available

Remark: When the power

supply of the safe brake is

DC. (0.9~ 1.1 )×24V, the

interface is 3-cord socket,

the pins 1 and 2 are power

supply terminals (without

pole), pin 3 is the earth one.

When pins 1 and 2 are

connected with the power

supply, the brake doesn’t

operate,; when the power

supply is OFF, it operates.

The safe brake operation

time≤0.1s.

Connection mode

None Industrial (aviation) socket

type

X Cable direct t

e

Shaft end or installation config.

None: Standard shaft end

Y□Special cylinder shaft end

Z□Special cone shaft end

S□Stepped motor installation

configuration

Remark:The digit code is in “□” ,

about the number representing

the special shaft end, refer to the

installation overall figure of the

motor.

Encoder type

A or none Incremental 2500p/r

A1

A2 Incremental 5000p/r

A3 Incremental split-type 2500p/

A4 Absolute 17bit

A4ⅠAbsolute 17bit, Biss treaty

A4ⅡAbsolute 17bit, Smart-Abs

treaty

Rated speed

A 1000 r/min

B 1500 r/min

C 2000 r/min

D 2500 r/min

E 3000 r/min

F 3500 r/min

G 4000 r/min

Zero-speed torque

Remark: It is represented

by three digits, and its value

is in three digits ×10-1 and

its unit is N·m.

Example: 032×10-1=3.2N·m

Input voltage of the drive unit

None 220V

H 380V

Feedback unit

M Photoelectric encoder