30312267 Issue 1.08

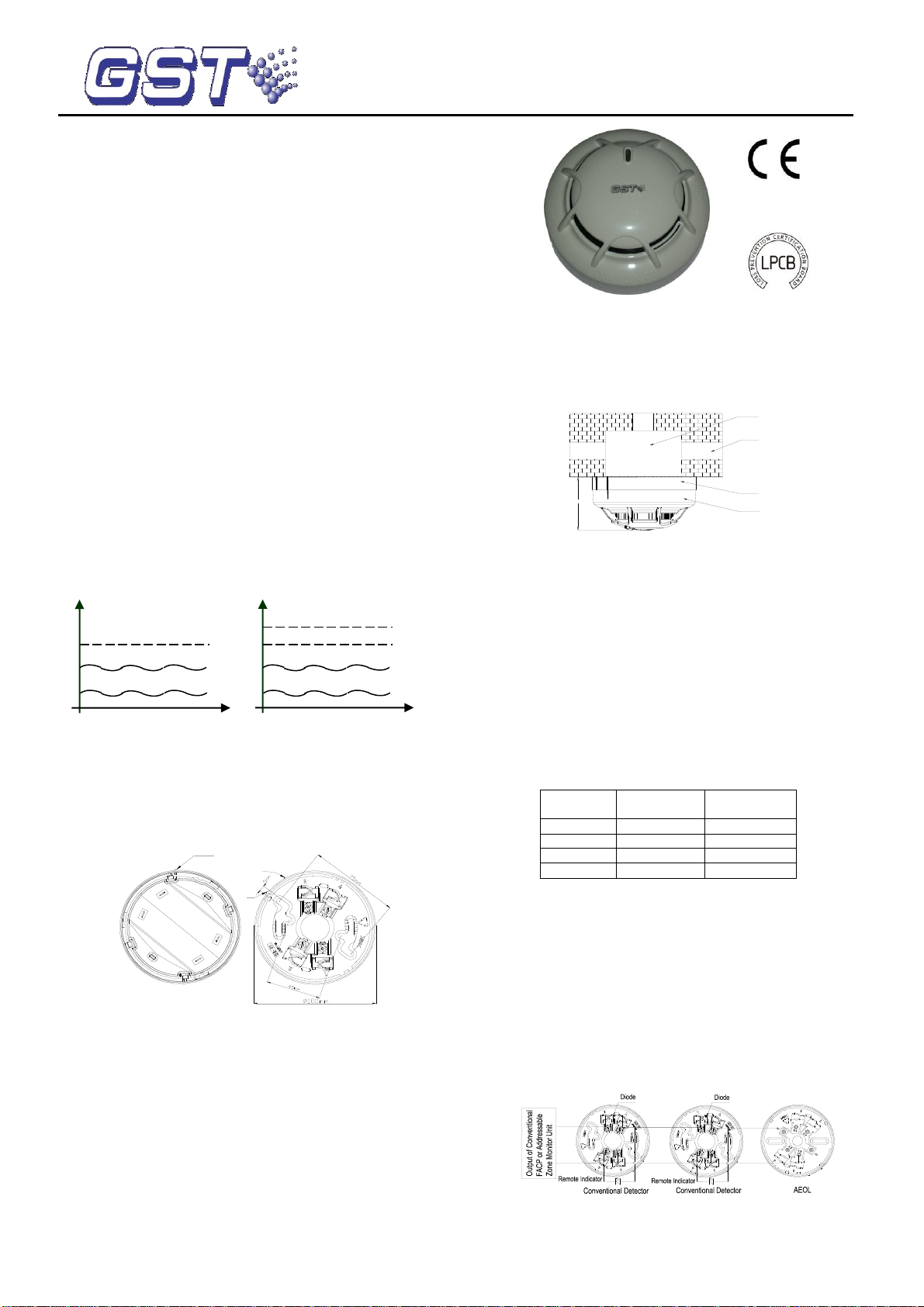

When DP-9907 Active End of Line Unit is not used as the

detector base, a cover should be added to it. The system

connection is shown in Fig.6.

Fig. 6

When the detector is connected with conventional fire alarm control

panel or the addressable zone monitor unit from GST, if a 4.7KΩ

terminal resistor is connected to the end of output loop, then DB-01 base

is used. The system connection is shown in Fig. 7.

Fig. 7

When a remote indicator connects with a few of detectors, a diode

1N5819 needs connecting with Terminal 4 of the orientation base in

series and with anode of the remote indicator. Either DB-01 or DB-01D is

used depends on which DP-9907 Active End of Line Unit or 4.7KΩ

terminal resistor is connected. The system composition is shown in Fig. 8.

Fig. 8

Output loop of the addressable zone monitor unit can be connected with

up to 15 conventional field devices. The addressable zone monitor unit

features loop checking. When the loop is broken, the addressable zone

monitor unit will send fault signal to fire alarm control panel. When any

field device in the output loop is removed, the addressable zone monitor

unit reports fault. If a DP-9907 Active End of Line Unit is connected, it will

not affect the normal operation of other field devices.

Testing

Before testing, please ensure that the detector has been installed

correctly and powered up. After 10 seconds, testing can begin.

1. The detector must be tested after installation and periodical

maintenance.

2. Testing method

1) Magnetic test

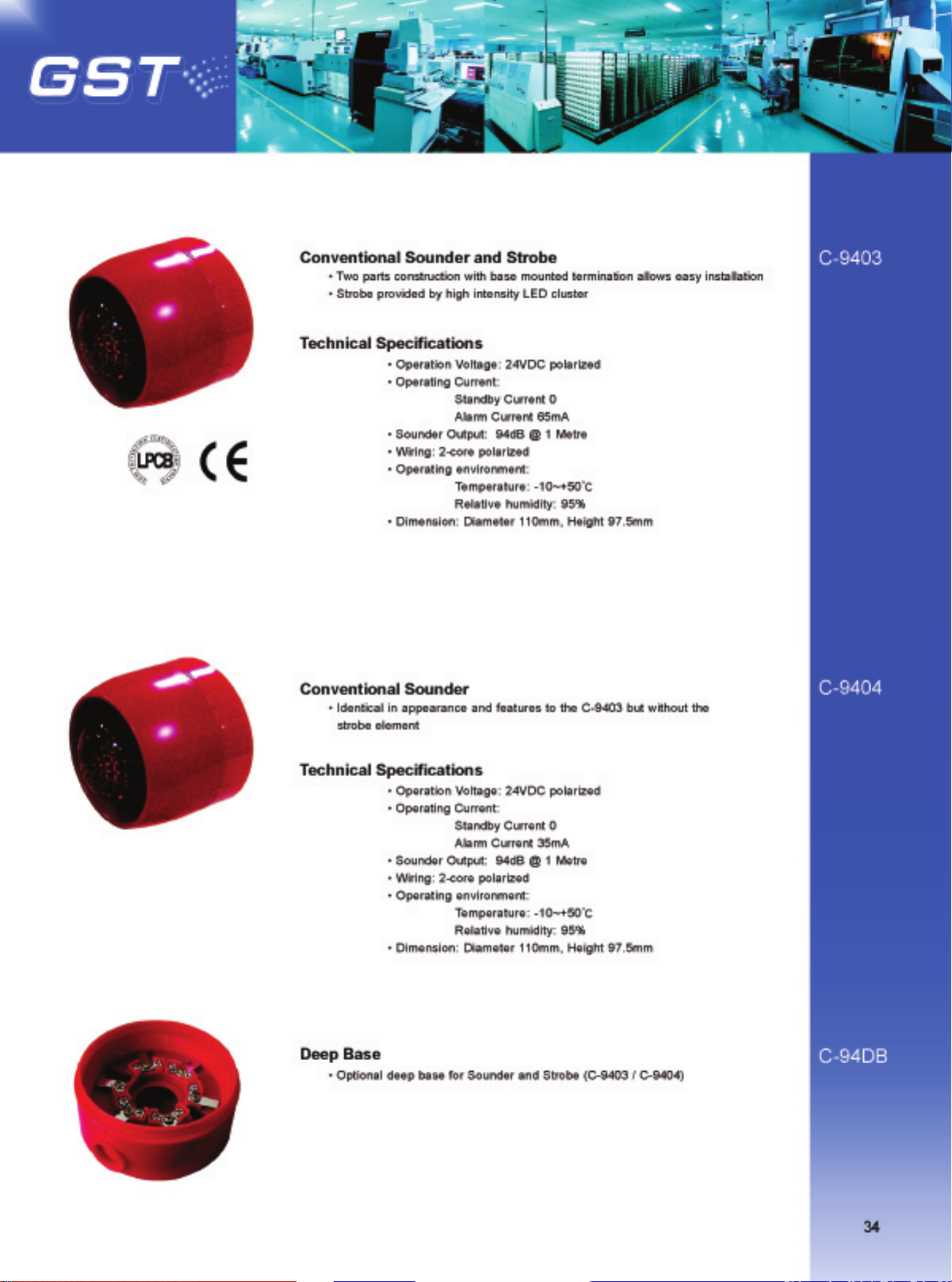

Magnetic test zone is shown in Fig. 9. Put the magnet of commission tool

close to that of the detector and hold on for a few seconds until the

detector generates alarm.

Fig. 9 Fig. 10

2) Smoke test

Taking a cotton rope burning without flame close to the detector, blow the

smoke into the detector until the detector generates alarm.

3. After testing, cut power for 10 seconds at least and reset the detector.

Notify the proper authorities that the system returns to normal state.

Clean the failure detector in the test according to Maintenance, and test it

again. If it is still fail to pass, please return it to repair.

Maintenance

1. The detector should be installed just before commission and kept well

before installation, taken corresponding measures for dust-proof,

damp-proof and corrosion-proof.

2. The dust cover cannot be removed until the project has been plunged

into usage. Otherwise it can’t alarm normally.

3. Clean the detector at least once a year to ensure normal operation of

the system.

4. If nuisance alarms are often found of the detector on site, the sensing

chamber should be cleaned and replaced when necessary.

a) Open the top cover of detector, and draw out the sensing

chamber by slightly lifting its two sides using a straight

screwdriver, as shown in Fig. 10.

b) Clean the sensing chamber by alcohol cotton swab clipped by

tweezers, and also by clear water and brush. Please note not

to leave any cotton in the chamber.

c) Install the sensing chamber and top cover back.

5. Before cleaning, notify the proper authorities that the system is

undergoing maintenance and will temporarily be out of service. Disable

the zone or system undergoing maintenance to avoid unwanted alarms.

6. The detector should be tested again after cleaning and re-installing.

7. Protect the metal component on the PCB against damp and improper

distortion.

8. Fire simulation test should be made to the detector at least once half a

year.

Specification

Red, periodically flash once in polling when

the status is set to “ON”; don’t illuminate when

the status is set to “OFF”. Periodically flash

twice in fault or sensing chamber dirty;

illuminate in alarming.

Polarity-sensitive output, directly connecting

with remote indicator (built in 10k resistor in

series, max. output current is 2mA); don’t

illuminate when in normal; flash in alarming.

Instant power down (10s Min, 1.0VDC Max

The sensitivity can be set by hand held

programmer. There are two sensitivity levels:

level 1 (default), level 2.

Two-wire, polarity sensitive.

Ingress Protection

Rating

Diameter:100mm Height: 44.5mm (without

base)

WEEE Information

2012/19/EU (WEEE directive): Products marked with this

symbol cannot be disposed of as unsorted municipal waste in

the European Union. For proper recycling, return this product

to your local supplier upon the purchase of equivalent new

equipment, or dispose of it at designated collection points.

Limited Warranty

GST warrants that the product will be free from defects in design,

materials and workmanship during the warranty period. This warranty

shall not apply to any product that is found to have been improperly

installed or used in any way not in accordance with the instructions

supplied with the product. Anybody, including the agents, distributors or

employees, is not in the position to amend the contents of this warranty.

Please contact your local distributor for products not covered by this

warranty.

This Data Sheet is subject to change without notice. Please contact GST for more information or questions.

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei, P. R. China 066004

Tel: +86 (0) 335 8502434 Fax: +86 (0) 335 8502532

service.gst@fs.utc.com www.gst.com.cn