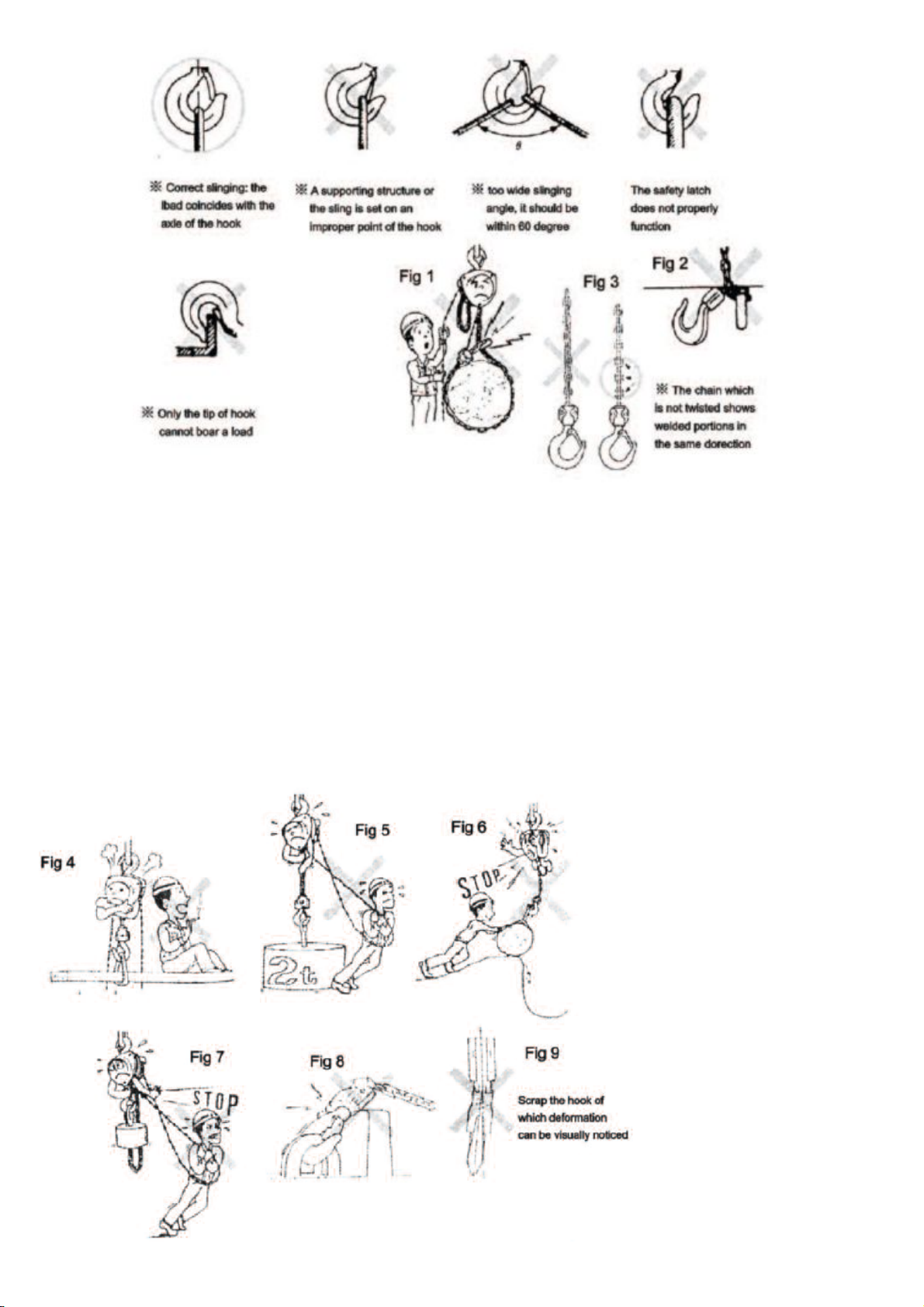

avoided. The hook clearly deformed as shown in Fig. 9 should be scrapped and exchanged with a new and genuine one.

11. Always take care with the manipulation of the hand chain. It should be avoided that the hand chain will be abruptly jammed when it is manipulated

with or without a load or a load is lifted by means of another power. In this case, the hand chain will be partially deformed or damaged.

11.

5. Inspection and Maintenance

5.1 Daily Inspection

●For daily operation, be sure to carry out the following checks prior to operation.

●In case of any abnormality or concern, stop operating the hoist until and take proper counter-measures by ,a specialist possessing

enough knowledge of the unit or by a dealer of GT products.

●Do not allow continuous running of the unit under abnormal conditions as it is very dangerous and might lead to a severe accident.

1. Check if the end of the load chain without hook (chain stopper pin end ) is fixed correctly. Check to see if the chain stopper pin is not deformed and

that it rotates smoothly.

1.

2. Are firm connections made between the top hook and the hoist body, the body and the load chain, and the load chain and the bottom hook

respectively?

2.

3. Are visually ,no deformations of the top and bottom hooks noticed?3. 4. Are any parts missing? Are no severely deformed portions noticed of any part ?4. 5. Is the load chain well lubricated? Does it show any remarkable damages ,deformations or wear marks ?5. 6. Check whether the hand chain runs easily and smoothly on operation and that a smooth ratchet sound is heard during lifting.6.

●Immediately stop operating the chain hoist and make a full repair of it, when such abnormalities as mentioned above (item 1 through 6)

are found.

5.2 Periodic inspection

In case of and functionality trouble and/or any abnormality, stop operating the hoisting unit and take proper counter measures by a specialist , competent

repairer possessing enough knowledge of the unit or by a dealer of GT products. It may happen that the load chain and the hooks fall in a dangerous state even

if they show no remarkable changes in their function. It is therefore indispensable to make a periodic measuring check based on “the Methods for Maintenance

and Inspection” as stated in this information brochure.The periodic inspection should be normally made once a month or in line with the legal requirements of the

country that the unit is being used within . Exchange damaged or deformed parts only with new ,authorised ones.

6. The Methods for Maintenance and Inspection

●Do not use parts of and /or the chain hoist over the limit of its designed use.

●If any worn parts are found in excess of the standard limit of use as stated below in carrying out the daily and periodic voluntary inspections, they

should be replaced.

●When replacing load chains, be sure to use the load chain manufactured by us. Load chains manufactured by any others are not applicable with this

unit.

6.1 Checking the load chain and its lifetime.

It is important to carefully inspect the whole chain. For checking the elongation, measure the inner length of 5 links with a vernier caliper as the sketch shows. It

is normally sufficient to check the links in a distance of approx. every 50cm but check them by making the measuring distance shorter when the elongation of

the chain is close to the limitation for use stated in Table 2 , so that none of them will exceed the limitation for use. Exchange the load chain with a new one, if it

is found by visual checks to be clearly influenced by higher temperatures or to be clearly deformed or worn . Furthermore, do not weld at any point near or on

the load chain or the hoist itself.

Limitation of the deformed load chain for use (Table 2)

Rated load (kg) Linkdiameter- Px5mm(new

chain) Limitation of Px5(mm) for use

250 Ø4x60 61.2

500 Ø5x75 76.5

1,000 Ø6x80 81.6

1,500 Ø7x105 107

2,000 Ø8x120 122

3,000 Ø10x140 142.8

3,000 Ø7x105 107