417

1.The filter or connector is obstructed.

1 The related switch has not been

turned on.

.

2. The voltage of the machine is not

normal or stable.

3 The related indicator light flashes

abnormal.

.

1 Switch on the related motor switch..

2 Make sure the machine is working with

stable volatge.

.

3 Turn off the power, and then, turn it on

again.

.

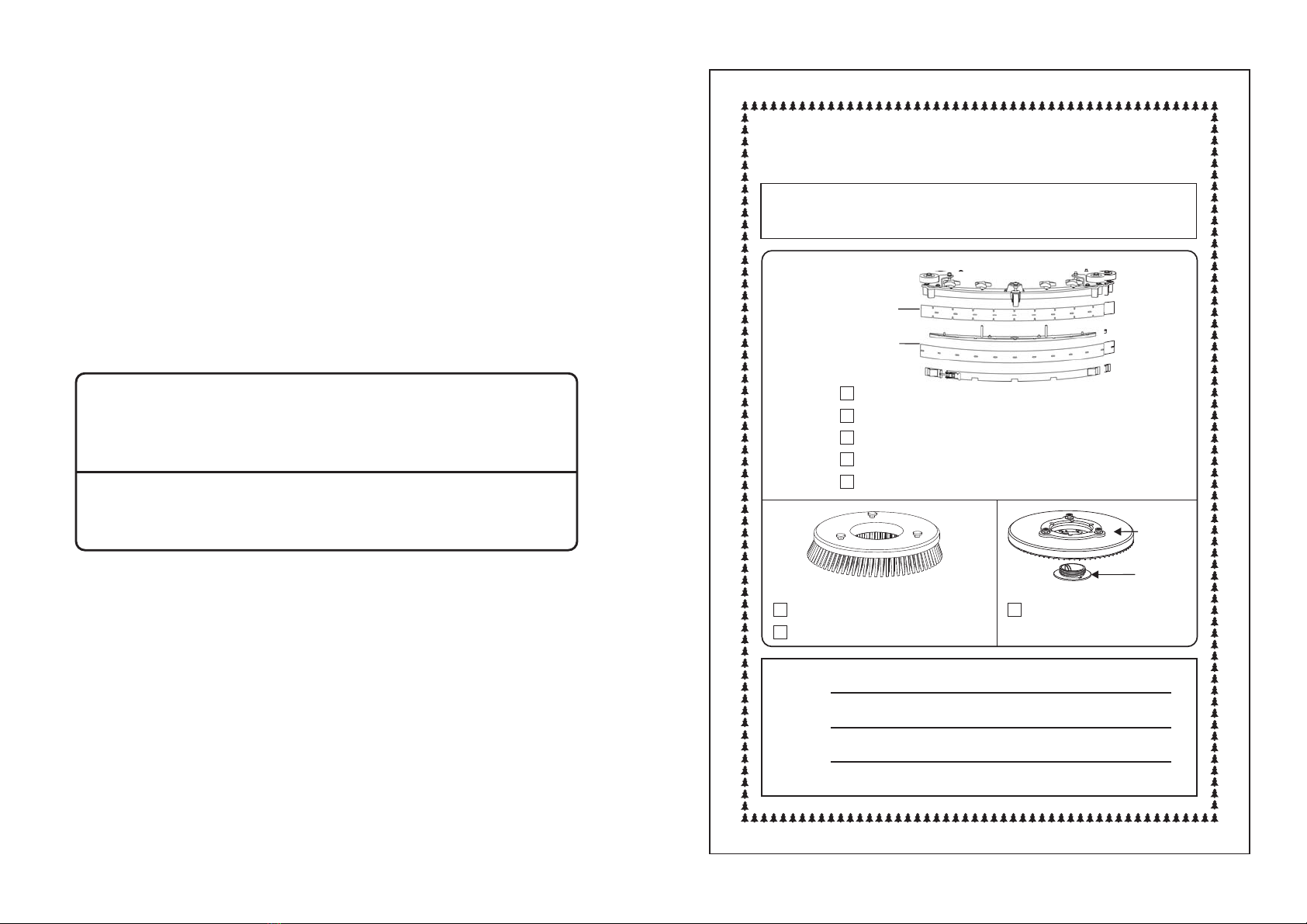

2 Control panel buttons

and indicator lights display.

. Operation control

1

2

5

4

3

OPERATION INSTRUCTIONS

Description of control components

1.Handle Control the direction of

the machine.

3.Key switch The whole power switch.

Control all the function

buttons.

4.Squeegee lever Lift up it to ascend the

squeegee;

release it to

descend the squeegee.

5. Pedal Step on it rightward to

descend the brush;

it leftward and

to raise the

step

on release

it brush.

Control panel

MAINTENANCE GUIDE

Trouble shooting

Note: Before contacting the repair agent or our customer service department,

please check the followings for possible solutions.

Note:

Problem Cause Solution

The motor

does not run.

No water

come out

or the water

flow is small.

Vacuuming

is weak.

The terminal poles

of the batteries

become hot or

fused.

Water suction

power is weak.

The machine

could not

clean

thoroughly.

1.The machine socket has not been

socket.

connected well with the battery

The control panel’s

LED indicator light

do not blink.

1.Connect the machine socket well with

the battery socket.

2.The floor being cleaned is too dry.

Solution supply is insufficient when

cleaning a new building for the first

time.

3.The solenoid valve or the sprinkling

motor is obstructed. The sprinkling

indicator light blinks.

1.Remove the filter and the connector

and clean them.

2.When the ground is too dry, sprinkle

some water on it before cleaning

water.

3.Clean the solenoid valve and the

sprinkling motor.

4.Check whether the solenoid valve is

short-circuited,the sprinkling motor

is working.

1.The seal ring of the recovery

tank lid failed.

2. The hose clip loosened.

3. The vacuum motor loosened.

4. The suction hose is obstructed.

5. The suction hose is broken.

1.Attach the seal strip properly.

2.Check the hose clip and install it

properly.

3.Open the silencer lid, make sure

the motor is installed correctly

and properly.

4.Clear out the air inlet and outlet.

5.Repair the suction hose.

1.The cable are not tightly

screwed.

1.Tighten the screw.

1.The suction hose is obstructed.

2.There are foreign objects in the

squeegees.

3.The squeegee is excessively

worn out.

4.The height of the squeegee is

not suitable.

5.The vacuum motor does not run.

1.Remove the foreign objects.

2.Remove the foreign objects

3.Use another side of the squeegee

or replace the squeegee.

4.Adjust the height of the squeegee.

5.Check the motor.

.

1.Check the motor.

2.Use a special effect detergent and

sprinkle it on the floor.

3.Replace the brush.

4.Remove the foreign object.

1.The brush motor doesn’t run.

2.The dirt is too stubborn.

3.The brush is excessively worn

out.

4.The brush is obstructed by a

foreign object.

4.The solenoid valve or the sprinkling

motor is too protective.

Suction

button

③

⑥

④

②Power gauge

Manual/Auto

button

⑦

Sprinkling button

Scrubbing/

Assembling

button

⑤

①Removing

button

Key switch

Guangdong Baiyun Cleaning Group Co.,Ltd