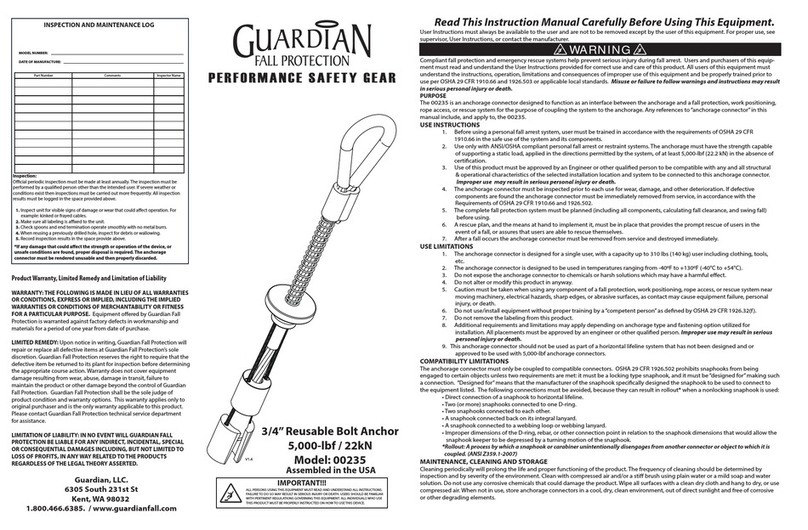

Assembly Instructions

Safety Stations

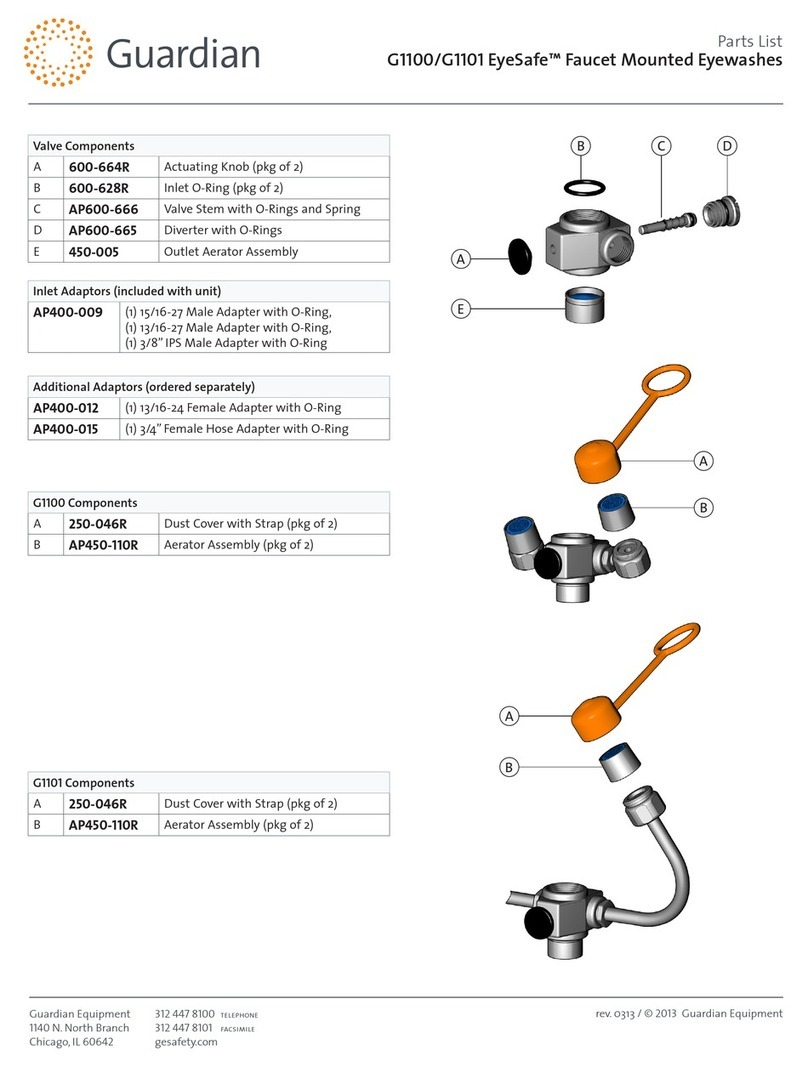

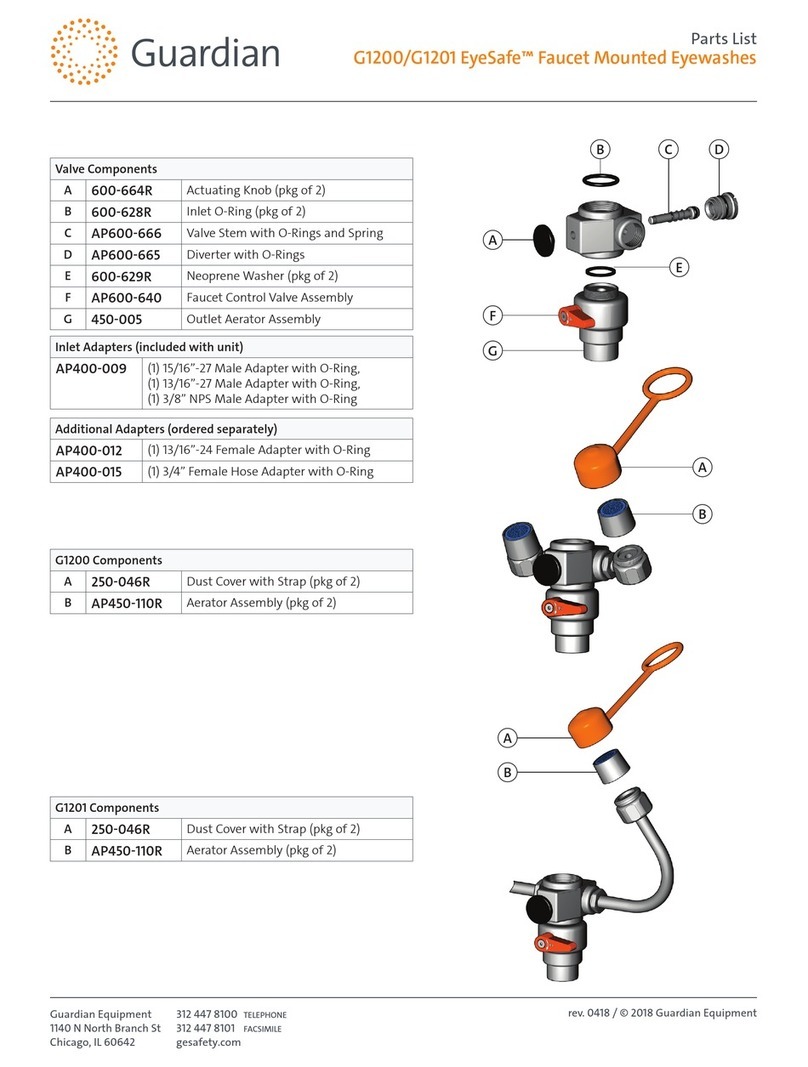

A

B

C

O

P

Q

R

D

E

F

G

H

I

JKLMN

32” Nipple

16 5/8” Nipple 22” NIPPLE

10 1/2”

Nipple

8 7/8”

Nipple

Safety stations are designed for easy assembly in the field.

Essentially, these units are assembled from the “bottom up”,

as described below:

1. Assemble floor flange (A), 1 1/4” IPS x 6 1/4” nipple (B),

and plugged outlet tee (C). If unit has a foot treadle, the

floor flange and treadle are pre-assembled. Position foot

treadle for proper access by users, and tee for connection

to drain. IMPORTANT: Plugged tee (C) must be oriented with

plugged end down to assure proper drainage.

2. Assemble 1 1/4” IPS x 16 5/8” nipple (D) and frame

assembly (E). Position frame assembly for proper access by

users.

3. Assemble 1 1/4” IPS x 32” nipple (F) and inlet tee (G).

Position tee for connection to supply. If the top vertical

inlet will be employed, plug tee with supplied 1 1/4” IPS

square head plug.

4. Assemble 1 1/4” IPS x 22” nipple (H) and 1 1/4” x 1” IPS

reducing inlet tee (I). Position tee forward for proper

location of shower. If the back horizontal inlet will be

employed, plug tee with supplied 1 1/4” IPS square head

plug.

5. Assemble 1” IPS x 8 7/8” nipple (J), emergency shower

valve (K), 1” IPS x 10 1/2” nipple (L), elbow (M), and shower

head (N).

6. Place cupped, stainless steel washer (O), rubber gasket (P),

and bowl (Q) onto waste receptor. Center components to

assure a watertight seal.

7. Thread drain plate (R) down onto mounting shank as far

as possible. If neccessary, rotate bowl clockwise to draw

drain plate down onto mounting shank.

8. Thread eye or eye/face wash spray head assembly onto

mounting shank. Position outlet heads for proper access

by user.

9. Secure entire unit to floor and/or wall for stability.

10. If unit has foot treadle, connect foot treadle chain to

valve/handle assembly.

11. Attach orange plastic pipe wrap and sign.

Notes:

1. All threads are tapered pipe and require pipe joint

compound or Teflon tape to assure watertight connection.

2. If unit is furnished with corrosion-resistant powder

coating, care must be taken to avoid damaging finish

during assembly. For best results, a strap wrench should

be used.

3. Test the entire unit for proper operation.

4. The use of dielectric unions is required when connecting

to copper supply to avoid premature corrosion.