3

Expert PDUEnergy8311 ©2017 GudeAnalog-und DigitalsystemeGmbH

Table of contents

1. Device Description 5

1.1 Security Advice .............................................................................................................. 6

1.2 Content of Delivery ........................................................................................................ 6

1.3 Description ..................................................................................................................... 6

1.4 Installation ...................................................................................................................... 7

1.5 Technical Specifications ................................................................................................ 8

1.5.1 Electrical Measurement ........................................................................................... 8

1.6 Sensor ............................................................................................................................. 9

2. Operating 11

2.1 Operating the device directly ..................................................................................... 12

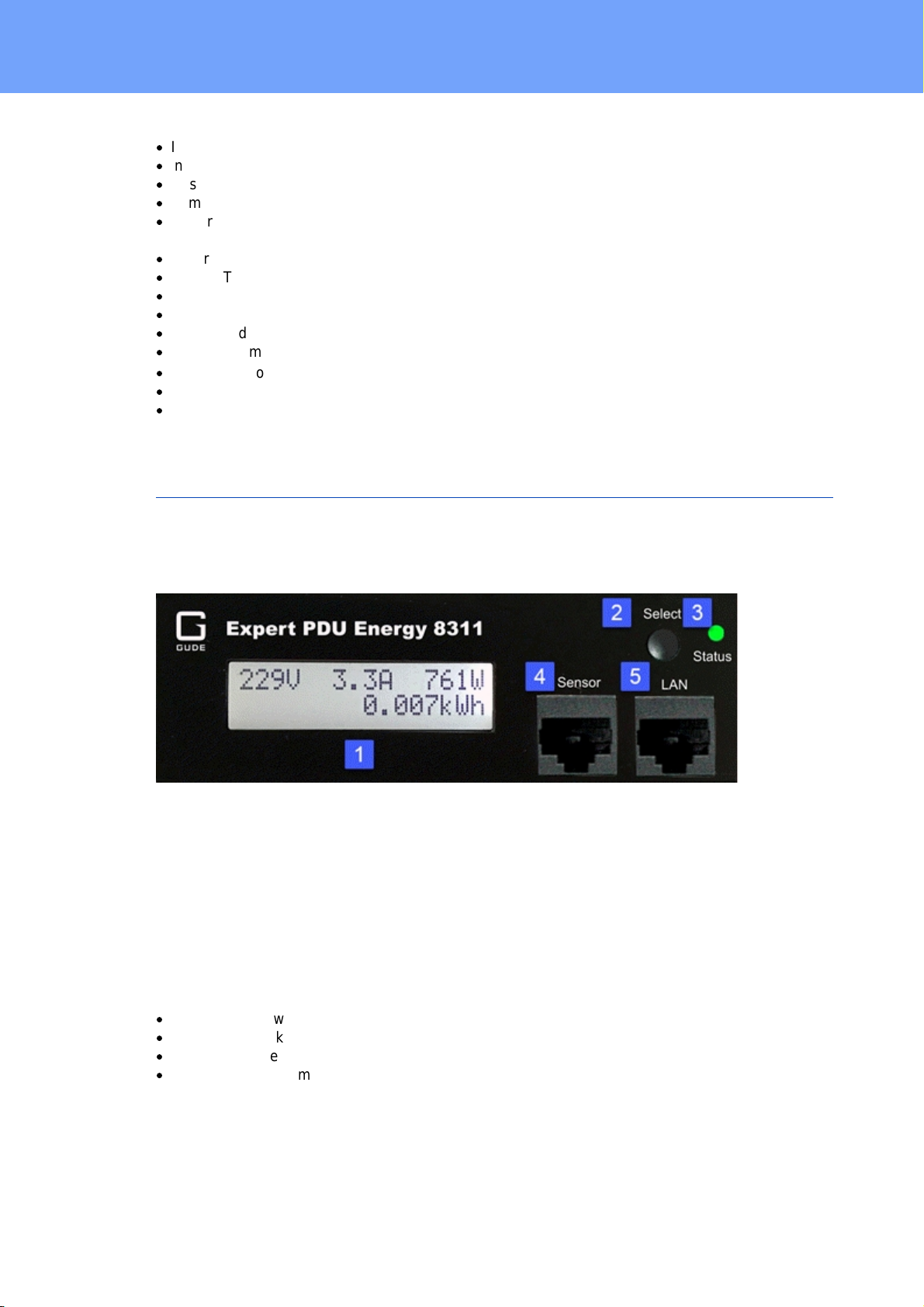

2.2 Control Panel ................................................................................................................ 13

2.3 Maintenance ................................................................................................................ 13

2.3.1 Maintenance Page ................................................................................................. 15

2.3.2 Configuration Management ................................................................................... 17

2.3.3 Bootloader Activation ............................................................................................. 18

3. Configuration 20

3.1 Ethernet ........................................................................................................................ 21

3.1.1 IP Address ............................................................................................................... 21

3.1.2 IP ACL ..................................................................................................................... 23

3.1.3 HTTP ....................................................................................................................... 24

3.2 Protocols ....................................................................................................................... 25

3.2.1 Console ................................................................................................................... 25

3.2.2 Syslog ..................................................................................................................... 26

3.2.3 SNMP ...................................................................................................................... 26

3.2.4 Radius ..................................................................................................................... 28

3.2.5 Modbus TCP ........................................................................................................... 29

3.3 Sensors .......................................................................................................................... 30

3.4 E-Mail ............................................................................................................................ 32

3.5 Front Panel ................................................................................................................... 33

4. Specifications 34

4.1 IP ACL ............................................................................................................................ 35

4.2 IPv6 ................................................................................................................................ 35

4.3 Radius ............................................................................................................................ 36

4.4 Automated Access ....................................................................................................... 36

4.5 SNMP ............................................................................................................................ 37

4.5.1 Device MIB ............................................................................................................. 39

4.6 SSL ................................................................................................................................. 41