4.Theinstrumentisguaranteedtokeepingoodrepairfor12monthsexceptthe

probe.

5.Donotusetheinstrumentininappropriateconditions.

6.Ifyoufindthevalueoftestingwereerrorinthestatusofmeasurement,youcould

loosenthehandleoftheprobetoadjustthescrewoftheresistancetinily.Ifdon’t

ensurethattheinstrumentisoperatedcorrectlydescribedbelow,therewouldbe

errororMistake.

7Don’tattempttorepair,ordisassemble,andanyreconstructthisinstrument.

8Useonlyrecommendedpoweraccessories.

9Don’tconnecttheterminalsoftheouterpowersupplyreversely.theinnerisplus,

theouterisMinus.

10Don’tdropthisinstrumentortheprobedownground.It’llbedamagedbystrong

vibration.

11

Donotallowhandsorotherobjectswithdirttotouchtheprobe.

12Avoidusing,placingorstoringtheinstrumentinplacessubjecttostrongsunlightor

hightemperature,soastohumidity,water,oil,rustair,vibrationandothers.

13Itwouldbeusedtotemperaturerangeorstoreupneedtocomplyasappointment.

14

You

shouldnotmovingtheinstrumentrapidlybetweenhotandcoldtemperatureto

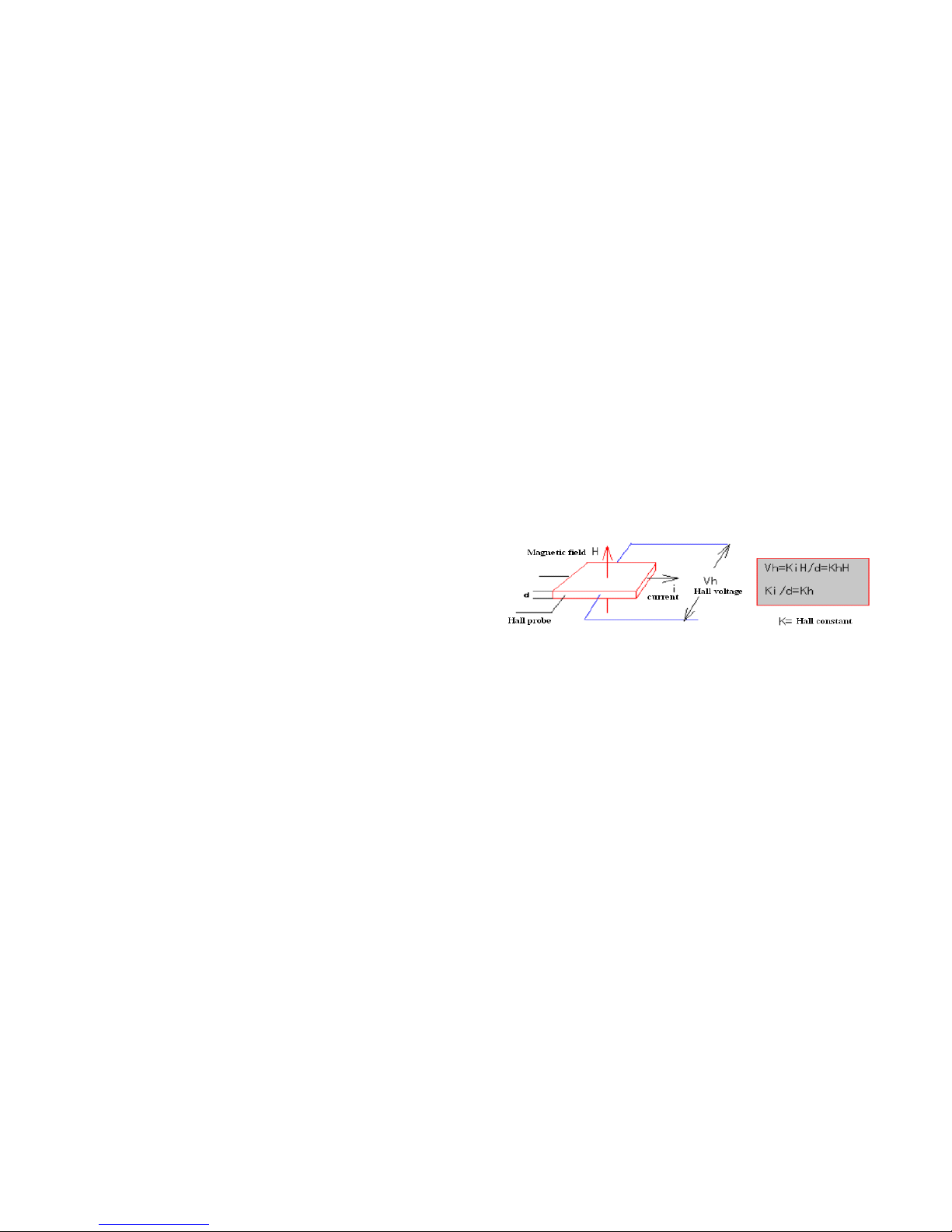

Working Working Working WorkingPrinciple Principle Principle Principle

ThisseriesofinstrumentsusesensorswhicharemadeaccordingtoHallEffect.

Thecircuitadoptsprecisionconstantcurrentsource,amplifierwithlowdriftandhigh

stabilitypowersupply.ItiscontrolledbytheSCM.Finallymeasuredvalueisdisplayed

bydigitalvoltmeterwitha4½LED.

1)PrincipleofHallEFFECT

Whenplacingthesemiconductorcarryingcurrentinthemagneticfield

axialtothecurrentdirection,thesemiconductorwillgeneratetransverse

galvanomagneticphenomenon,namelygenerateelectromotiveforceinthe

directionaxialtothemagneticfieldandcurrent,whichisHallEffect.Hall

Effectcanbeexplainedwithclassicalgalvanomagnetictheory.Generally,Hall

voltageUHisexpressedas:

UH=RHIB0/d=RHIIB0

Ofwhich:d—thethicknessoftheHalldevice

RH—Hallconstant

RHI=RH/d—ConstantoftheHalldevice

2

13