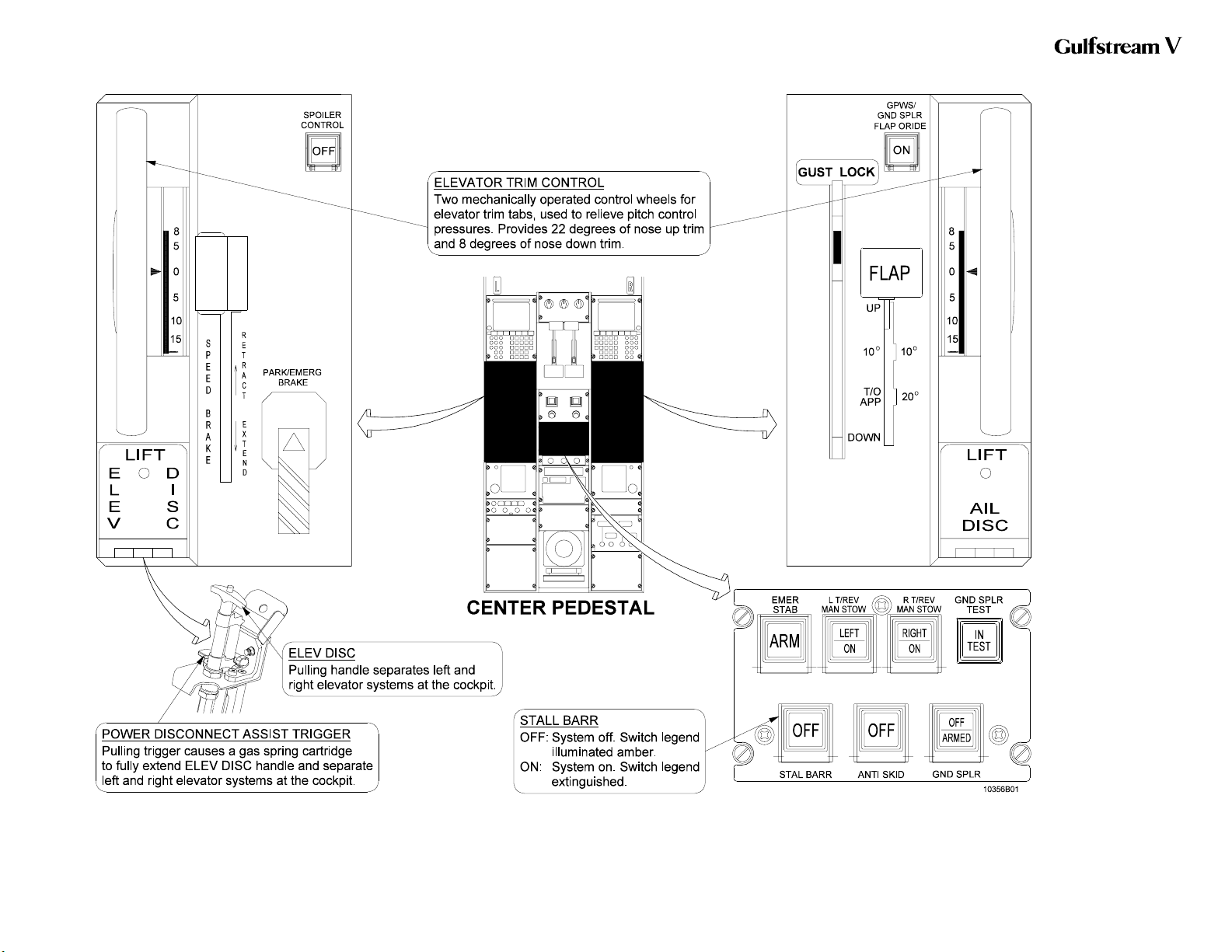

the unlikely event of an immovable elevator, the elevator controls can be

separated by pulling an elevator disconnect handle, located on the cockpit center

pedestal. Once separated, the operable elevator system is identified and used to

fly the aircraft.

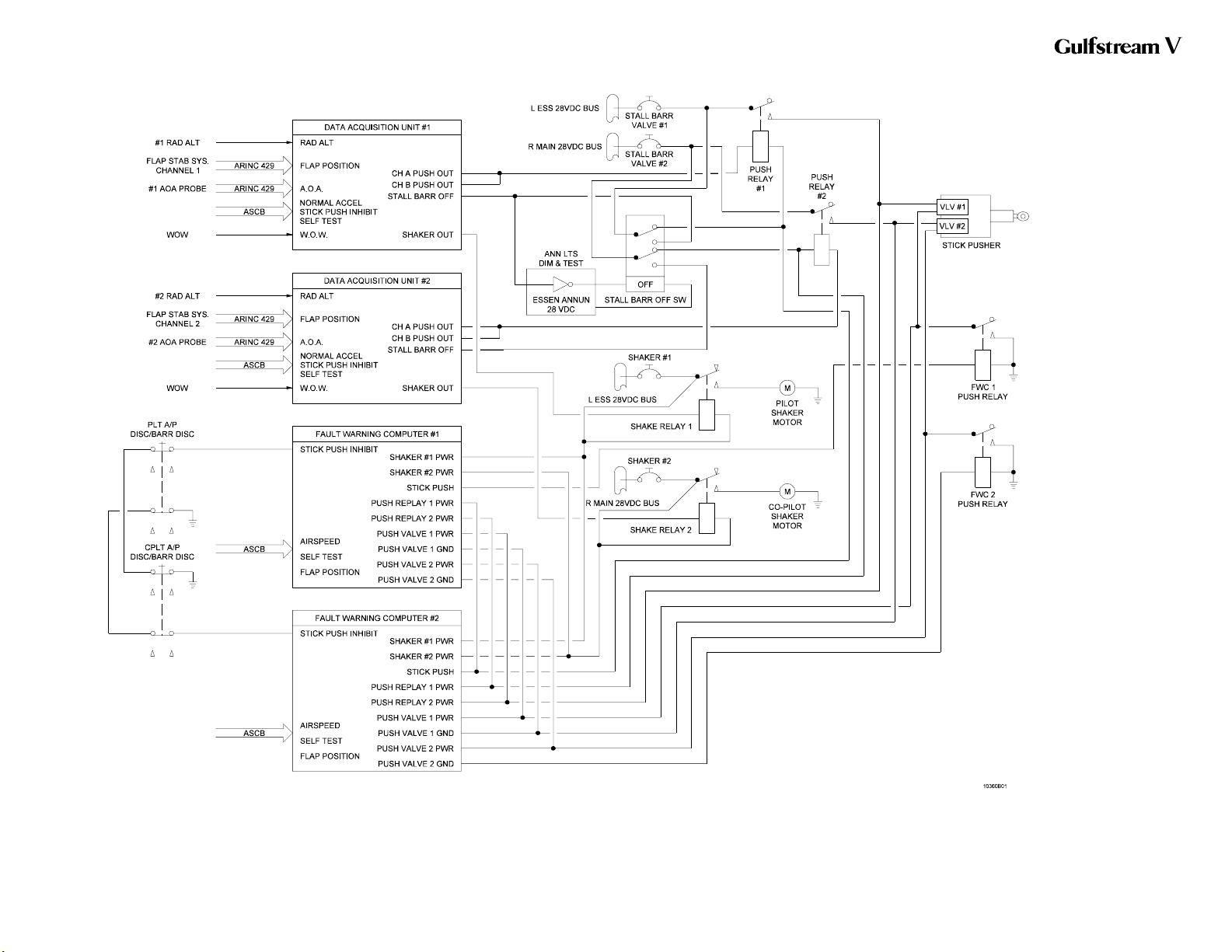

Two stall barrier systems are incorporated into the elevator control system to

prevent a stall by forcing the control columns forward when the crew fails to

respond either to visual indications or to stick shaker vibrations which precede an

impending stall. The stall barrier system is normally left on, but if it is

malfunctioning, the crew can turn the system off, using the STALL BARR switch,

located on the cockpit center pedestal. When a high angle of attack is attained, a

shaker trip point detector activates the control column shaker motors. When a

more severe angle of attack is attained, a pusher trip detector activates its

respective stall barrier pusher.

NOTE:

The control column force can be manually overcome

by pilot or copilot.

2. Description of Subsystems, Units and Components:

A. Automatic Hardover Prevention System:

The elevator actuator incorporates a hardover prevention system which

compares inputs and outputs. If inputs to, and outputs from, the actuator do

not agree, hydraulic pressure to the affected side of the actuator is shut off

and a message is prompted for display on the Crew Alerting System (CAS)

display. The elevators are still operative, but without benefit of the affected

side’s hydraulic boost. The hardover prevention system receives power

from the Left and Right Essential DC bus.

B. Elevator Control Separation System:

(See Figure 4.)

The elevator control systems are dual and separable. In the unlikely event

that a single elevator control system were to become jammed, an elevator

disconnect system provides the means to separate the left and right

elevators from each other. This is accomplished through the use of an

elevator disconnect system, located on the left side of the cockpit center

pedestal and labeled ELEV DISC on its protective cover.

The elevator disconnect system consists of the protective cover, the

elevator disconnect handle (labeled ELEV DISC) and a power assist trigger

(labeled LIFT). If a jammed elevator is detected, the protective cover is

raised and the ELEV DISC handle is pulled. With the handle fully extended,

the pilot’s and copilot’s control columns are separated in the cockpit. The

pilot controls the left elevator and the copilot controls the right elevator. The

immovable elevator side will remain immovable and the movable side is

now free to be used to control the aircraft. The Stall Barrier system remains

functional in this configuration.

If the red power assist trigger was NOT used to actuate the ELEV DISC

handle, the elevator disconnect system can be reset at the discretion of the

flight crew.

If the force required to pull the ELEV DISC handle is too great, the red

power assist trigger, located under the ELEV DISC handle, is pulled. This

OPERATING MANUAL

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Page 6

May 22/01