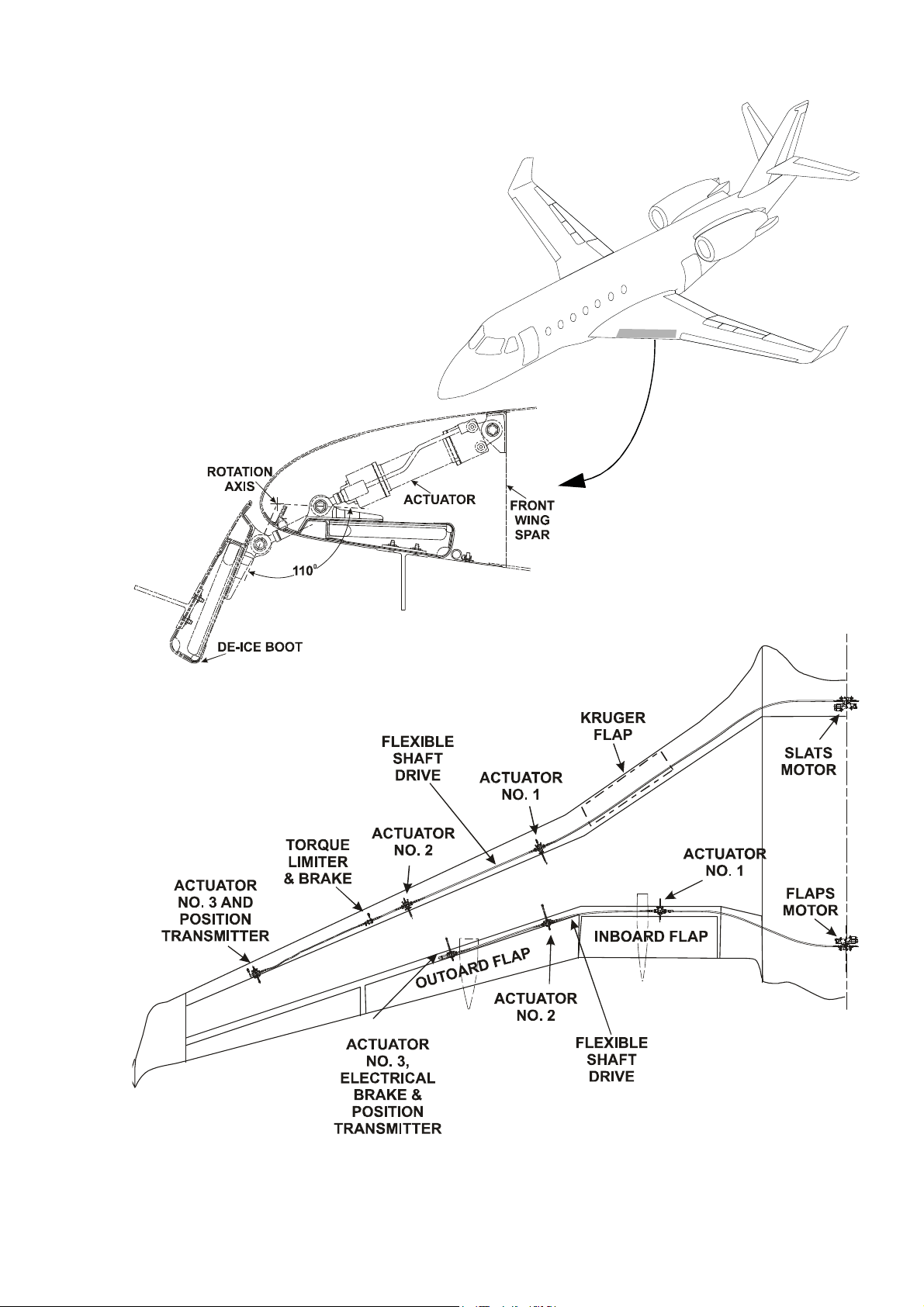

SLATS, KRUEGER AND FLAPS SYSTEMS

Each wing is equipped with two-piece trailing edge flap, one piece

leading edge slat and one piece krueger flap. The flaps and slats are

mounted on and guided by rail and rollers assemblies, driven by

ball-screw linear actuators. The krueger flaps are hydraulically

actuated.

The flaps or slats are operated each by a single electrical rotary

actuator driving a flexible shaft, interconnecting mechanically the

ball-screw actuators of both wings.

The actuators are equipped with torque limiters at each output end to

wing. Electronic controller governs flaps and slats operation and

automatically stops their motion when asymmetry conditions are

created.

The krueger flaps are powered from the right hydraulic system and

electrically controlled by Flap/Slat Electronic Control Unit (FSECU) and

by SLATS/KRUEGER/FLAPS selector.

Each krueger flap is operated by hydraulic actuator with internal locks

for both extended and retracted positions. The actuators incorporate

limit switches for indication of locked positions.

Slats/flaps/krueger position is displayed on EICAS. Slats/flaps selector

lever is located on the pedestal. When the lever is placed in one of the

flaps angle positions (12°, 20° and 40°), the slats are extended first.

Slats/krueger flaps may also be selected individually (DN position of

the lever).

The slats always extend fully before flaps and krueger flaps start to

extend and, conversely, flaps and krueger flaps always retract before

slats are retracted.

(Continued)

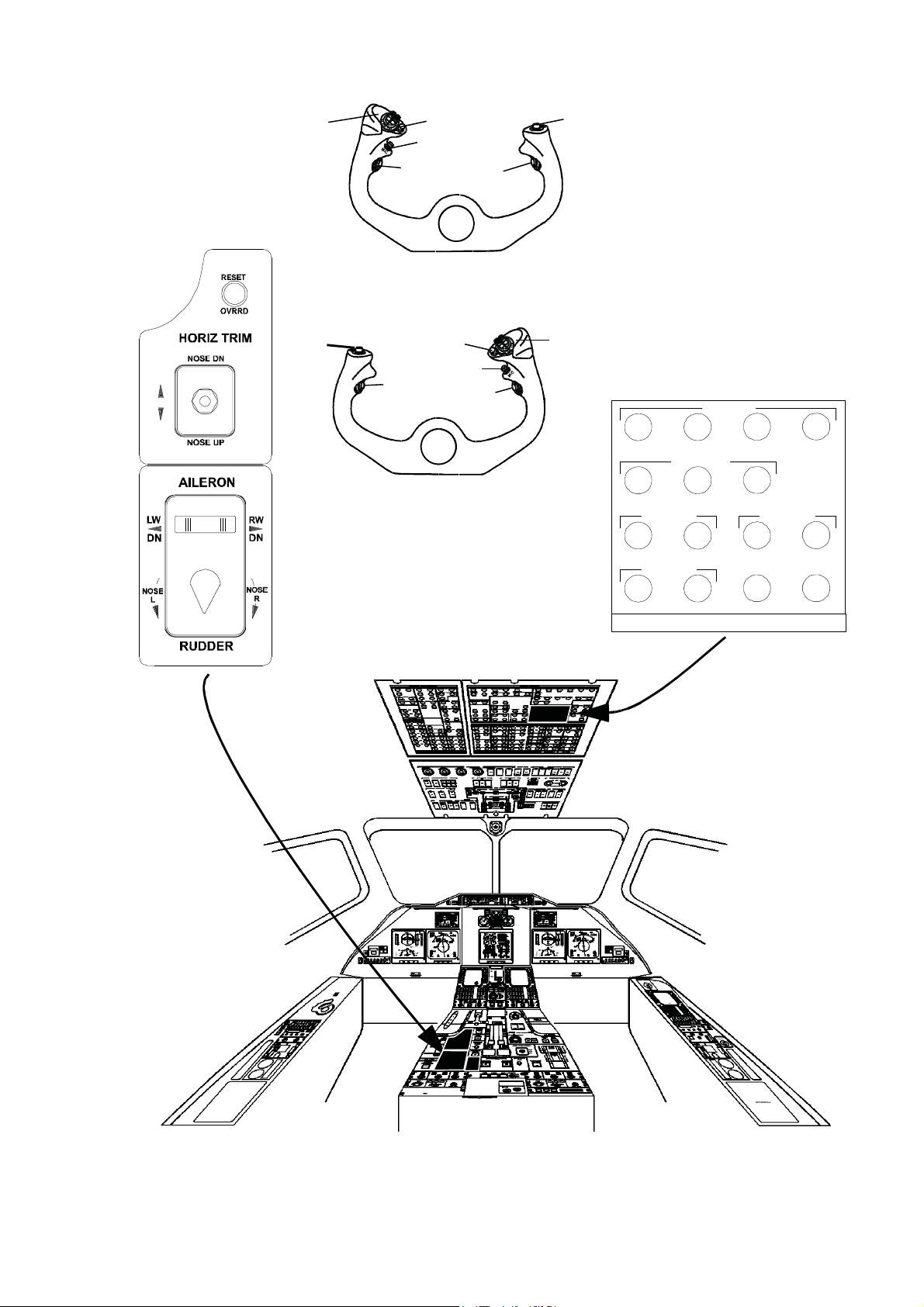

Gulfstream G200 - Trim System