ELECTRO FREEZE Soft Serve Model GEN-2080

185240 3

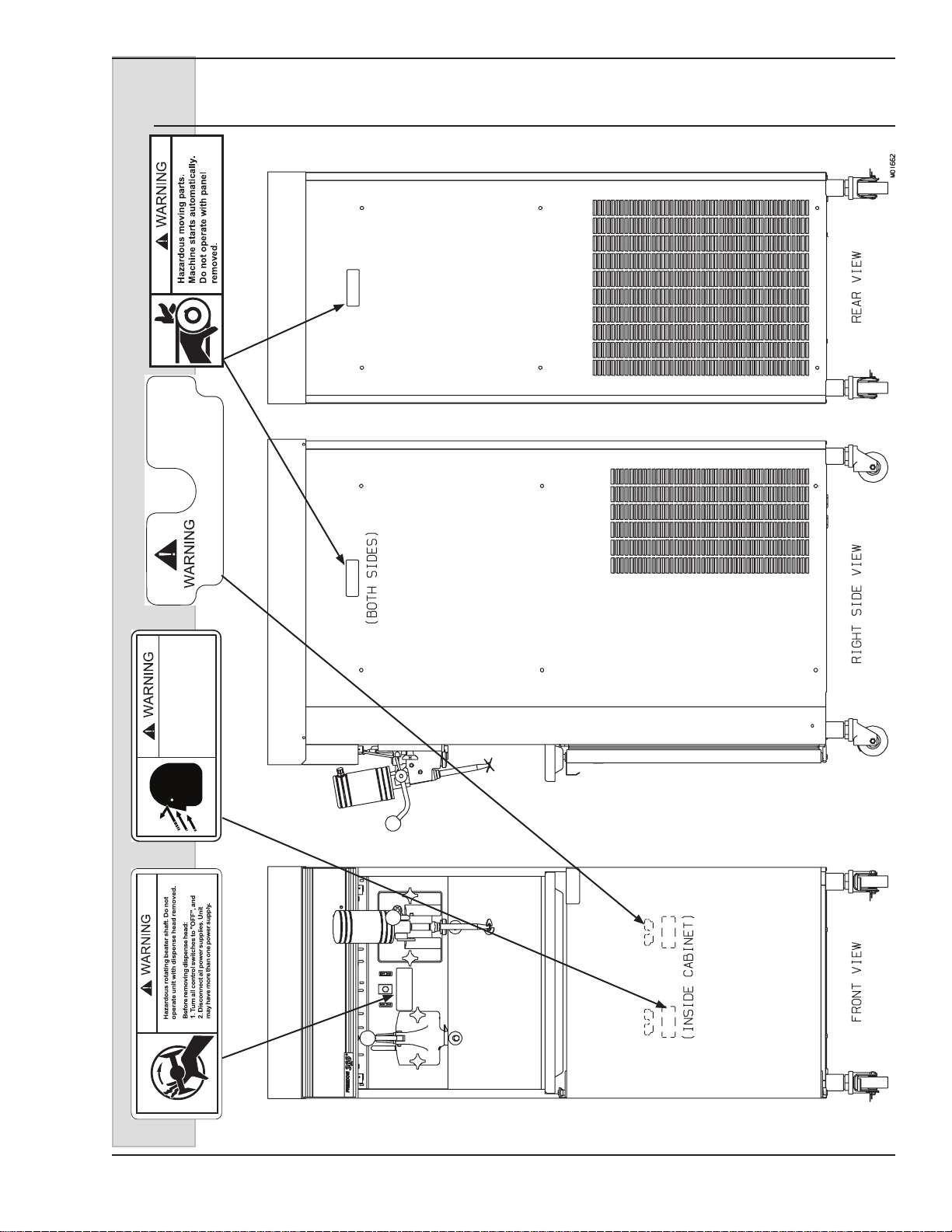

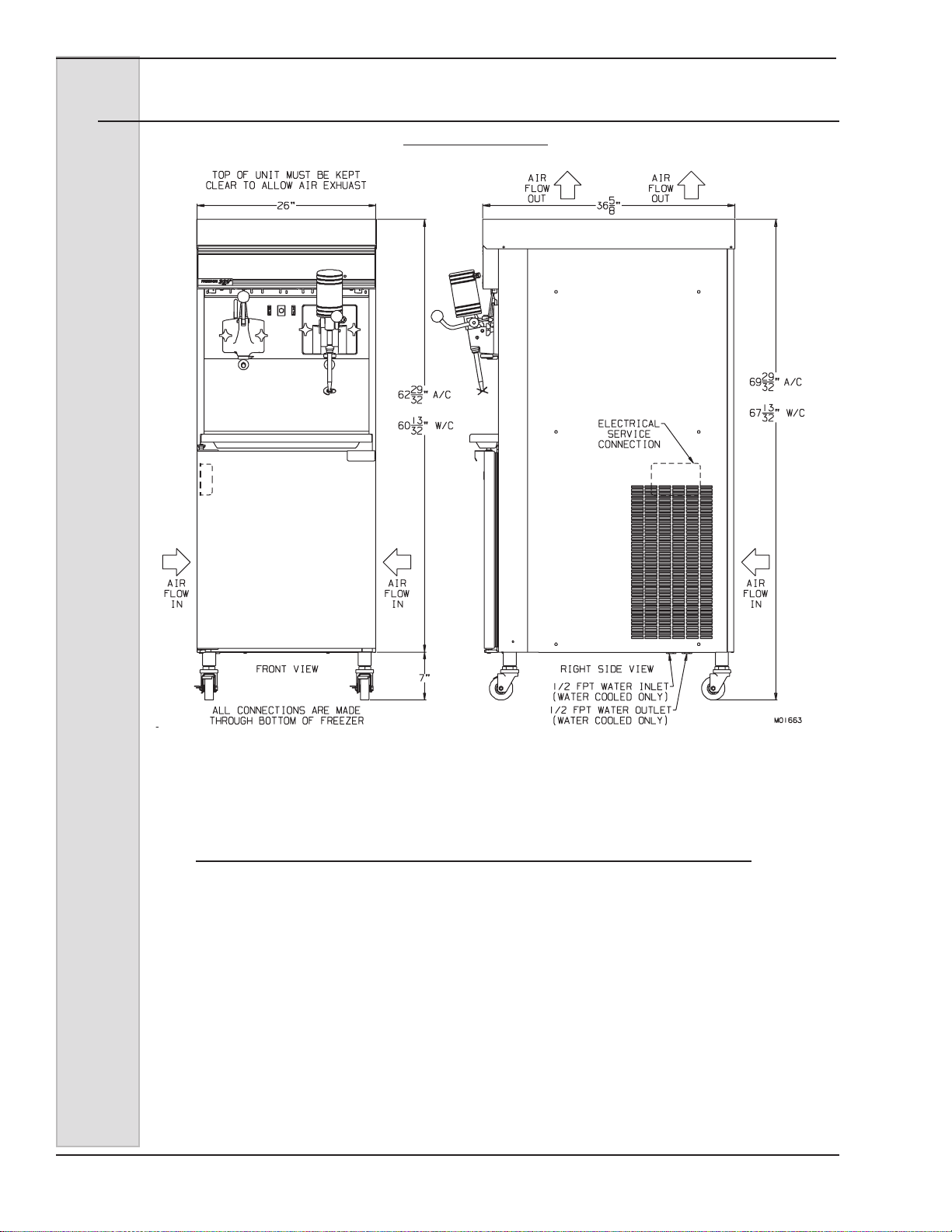

2. Where codes permit, we

recommend that the freezer be installed

on casters and have exible water and

electrical connections for service and

cleaning ability.

3. All models require a minimum 6

inch (15 cm) clearance on either the side

panels or the rear panel for adequate

ventilation. Freezers designed with top air

discharge require that at least 18 inches

(45 cm) above the top panel be free of

obstructions. Anything blocking ventilation

of the freezer (including cone dispensers)

will reduce the efciency of the freezer.

4. Water cooled models will require

a 1/2 inch MPT water inlet and water

waste connection. Both condensers are

2.3 Electrical Requirements

2.2 Installation (continued)

3. Refer to the wiring diagram

provided for proper power connections.

4. Electrical connections are made in

the junction box located mid-level behind

the left side panel.

5. Use a exible connection when

permissible. All materials and connections

must conform to local codes and the

National Electrical Code.

6. For 3 phase freezers, beater shaft

rotation must be clockwise as viewed

from the front of the freezer.

2.4 Electrical Connections

1. Double freezers with two

compressors require one power supply for

each side of the freezer. Each side of the

freezer operates independently.

2. Check the data plate for fuse

size, wire ampacity and electrical

specications.

tied together so that one water inlet and

one water waste is all that is required.

The connections are found on the bottom

under the compressor mounting area

and are tagged “Water Inlet” and “Water

Waste.” A manual shut-off valve should be

installed in the water inlet line at the time

of installation. The water pressure must

be above 35 psig (241 kPa) and below

140 psig (965 kPa) for proper operation.

5. Place the freezer in the nal

location and level by adjusting the legs or

casters so that it is level side-to-side and

the front is approximately ¼ inch lower

than the rear (to allow proper drainage of

the freezing cylinder).

2. Supply voltage must be within

+ 10% of voltage indicated on the

nameplate. Also, on three-phase

systems, voltage between phases must

be balanced within 2%. (More than a 6

volt difference between any two voltage

measurements at 208-230 volts indicates

a possible imbalance.) Request your local

power company to correct any voltage

problem.

3. An easily accessible main power

disconnect must be provided for all poles

of the wiring to the freezer.

1. Always verify electrical

specications on the data plate of each

freezer. Data plate specications (see

Figure 3-1) will always supersede the

information in this manual.

CAUTION

To prevent acciden-

tal electrical shock, a

positive earth ground is

required.

CAUTION

To prevent accidental elec-

trical shock, a positive earth

ground is required.