ELECTRO FREEZE Model CS600

184596 1

1 Introduction

The CS600 freezer is designed to produce

soft serve ice cream, ice milk, yogurt, and

similar frozen dairy products, with a product

serving temperature range of 15° to 25ºF (-9°

to -4°C). If such products are prepared from

powdered concentrate, they should be

precooled to 40ºF (4°C) prior to introduction

to the freezer. Use of other products in this

machine is considered misuse (see War-

ranty).

This manual has been prepared to assist

you in the proper operation and general

maintenance of the Electro Freeze

Model CS600 freezer.

Make sure all personnel responsible for

equipment operation completely read

and understand this manual before

operating the freezer. When properly

operated and maintained the freezer will

produce a consistent quality product.

If you require technical assistance, please

contact your local authorized Electro Freeze

Distributor, as follows:

Name:

Address:

Phone:

Forfactoryserviceassistance —contact

H.C. Duke & Son, LLC, Electro Freeze

ServiceDepartmentasfollows.

Phone: 309-755-4553

800-755-4545

FAX: 309-755-9858

((

((

(

2 Note to Installer

This freezer must be installed and

serviced by an Electro Freeze Distribu-

tor or authorized service technician in

accordance with the installation instruc-

tions in this manual.

Verify the weight of the freezer. Ensure a

counter or table of sufficient strength is

used to hold this weight and prevent exces-

sive vibration.

All models require a minimum of 3-inches

(7.6 cm) air space on both sides and back

of the freezer for adequate ventilation.

If this freezer is to be used in a self-service

application, it is recommended that the

machine be fitted with a self-service kit.

Contact your Electro Freeze Distributor or

H. C. Duke & Son, LLC. for this kit.

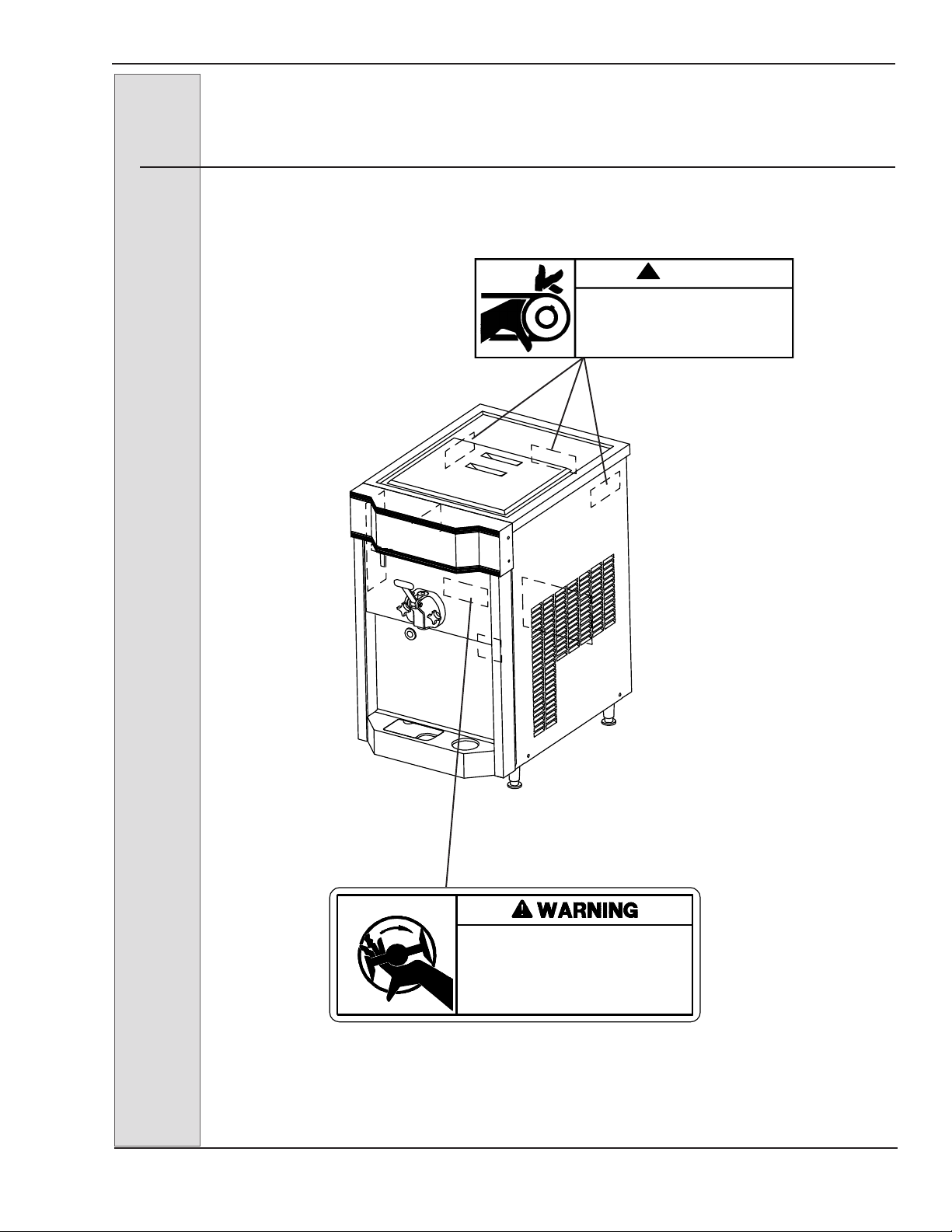

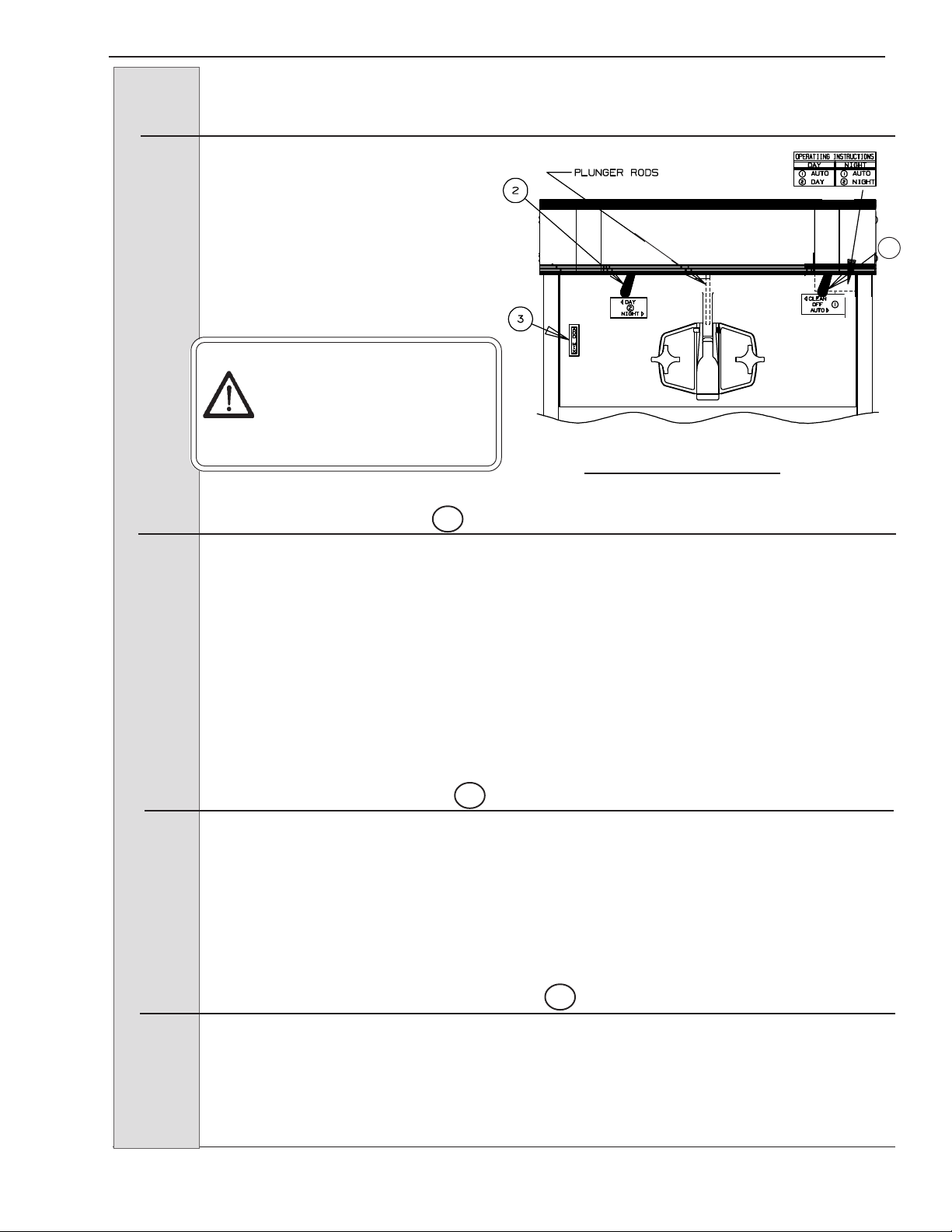

Test the operation of the head safety switch

prior to placing the freezer in service. See

Section 12, Routine Maintenance, Monthly.

After installation the warranty registration

card must be completed and returned to

validate the warranty.