FAUCET INSTALLATION

(Continued)

7

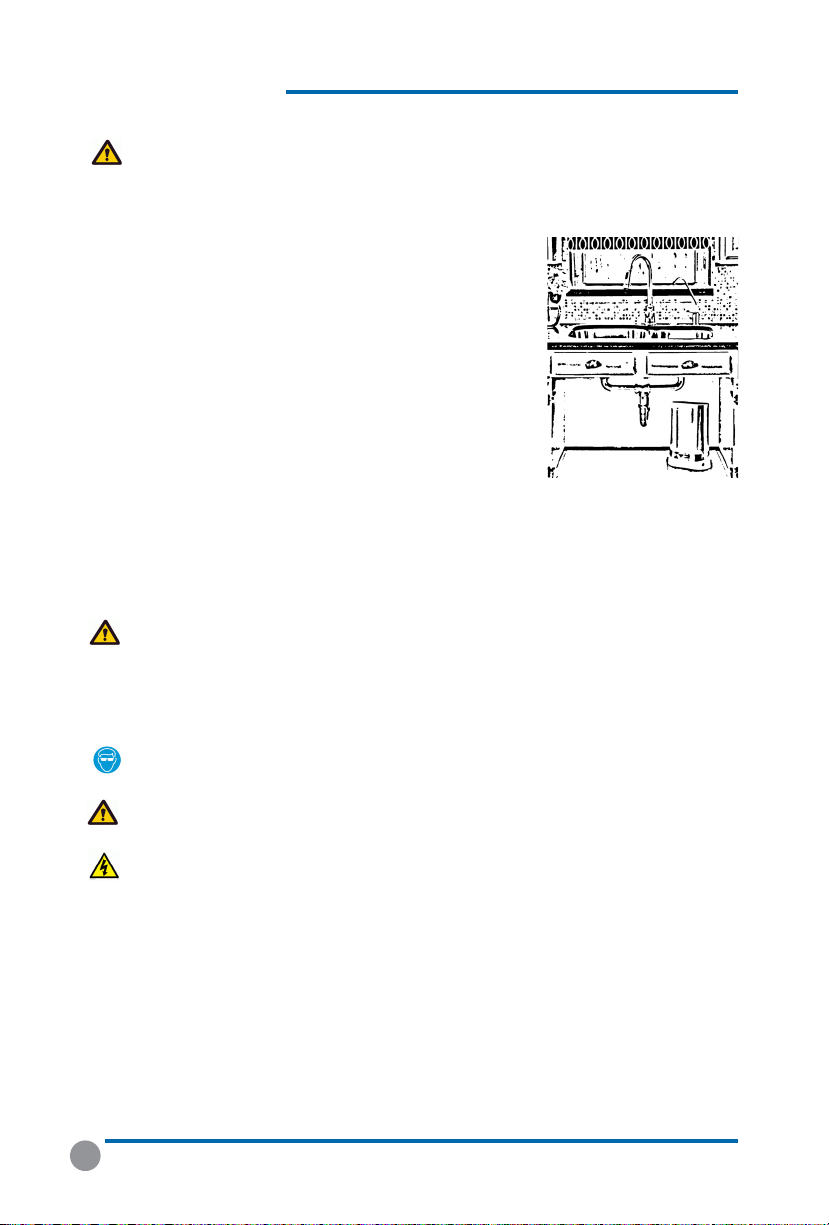

2. REMOVE EVERYTHING FROM INSIDE THE SINK AND SURROUNDING AREA. Place paper

towels in the sink to catch the shavings from the grinding and drilling.

3. Using a cordless drill with a carbide grinding burr, gently grind away enough porcelain or

enamel to more than accommodate the 7/16” (11 mm) drill bit. Approximately the size of a

dime. Enough surface material must be removed to expose the base metal.

CAUTION!!

Porcelain or enamel must be completely removed in the drilling area to prevent

immediate dulling of drill bit.

4. Remove everything from under the sink.

5. Place newspaper or paper towels directly under drilling location in order to catch the

drill shavings.

6. Using the 1/4” (6 mm) drill bit, drill a centering or pilot hole in the center of the desired

faucet location.

NOTE: this centering/pilot hole will make it easier for the 7/16” (11 mm) drill bit to cut through the sink. Operate the

drill slowly and carefully— Especially when the drill bit is about to penetrate the metal. Otherwise, damage to sink

may occur. Use lubricating oil to keep the drill bit cool while drilling.

7. Discard paper towels and newspaper used in sink and below sink. Be very careful not to

drop any shavings in sink or on the oor as they will oxidize and stain surfaces very quickly.

HELPFUL HINT: If you notice any rust spots from dropped shavings you should be able to get rid of them by scrubbing

them with a cleaning chemical.

8. Coverthedrilled hole withyour nger BE VERYCAREFUL NOT TOCUT YOURSELFONSHARP

EDGES! Rinse sink then scrub with cleaner to prevent any rusting from shavings and to

prepare for faucet installation. Plug hole again while rinsing o cleaner. Hole must be

plugged in order to avoid water dripping below into sink cabinet, which may cause damage.

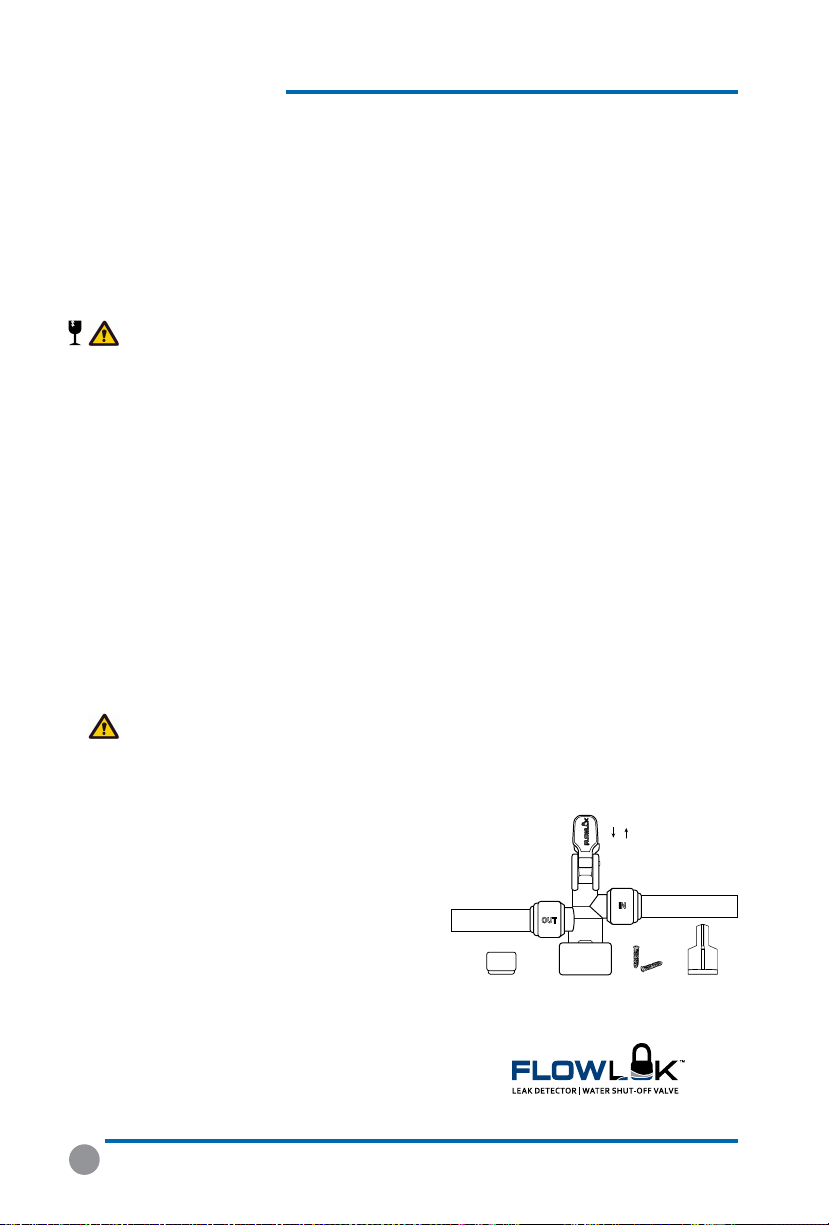

9. Remove faucet from package.

For steps 10-14 refer to DIAGRAM B on page 8.

10. Slip the small, thin rubber gasket over the faucet shank. Next slip the chrome trim plate

(escutcheon plate) over the faucet shank. Finally, slip the large, thin rubber gasket over the

faucet shank.

11. Take the faucet spigot and insert it into the faucet base in the hole next to the faucet

handle. Push the faucet spigot in until it stops.

12. Place the faucet shank complete with only hardware installed in step 11 though the drilled hole.

13. From under the sink slip the large, black plastic, locating washer over the faucet shank.

Next, slip the lock washer over the faucet shank followed by the thin chrome nut.

14. While holding the faucet assembly above the sink tighten the chrome nut below the sink

with an adjustable wrench. Tighten the chrome nut until the faucet assembly does not move.

CAUTION!!

DO NOT OVERTIGHTEN THE CHROME NUT. Overtightening can cause damage to

the sink or faucet assembly.