8

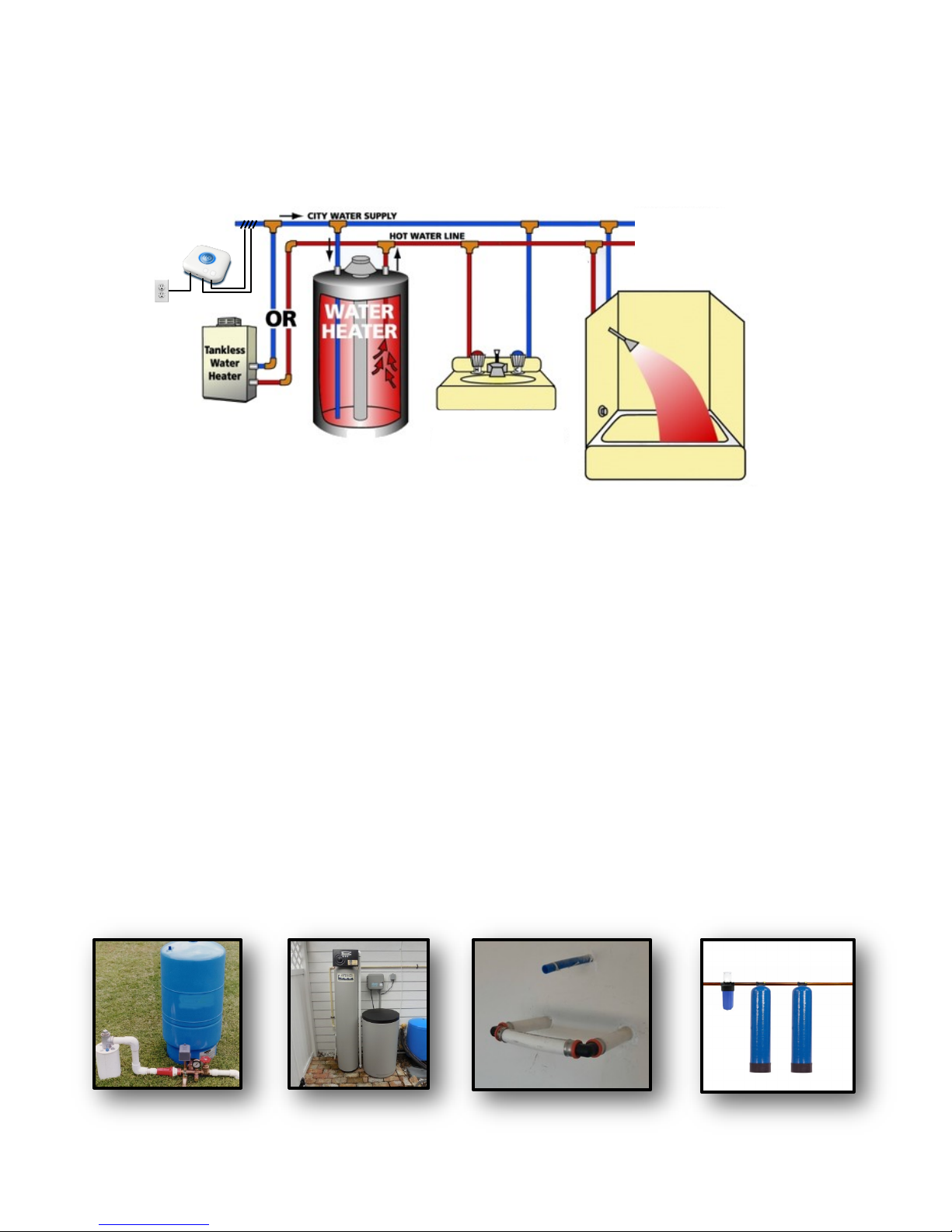

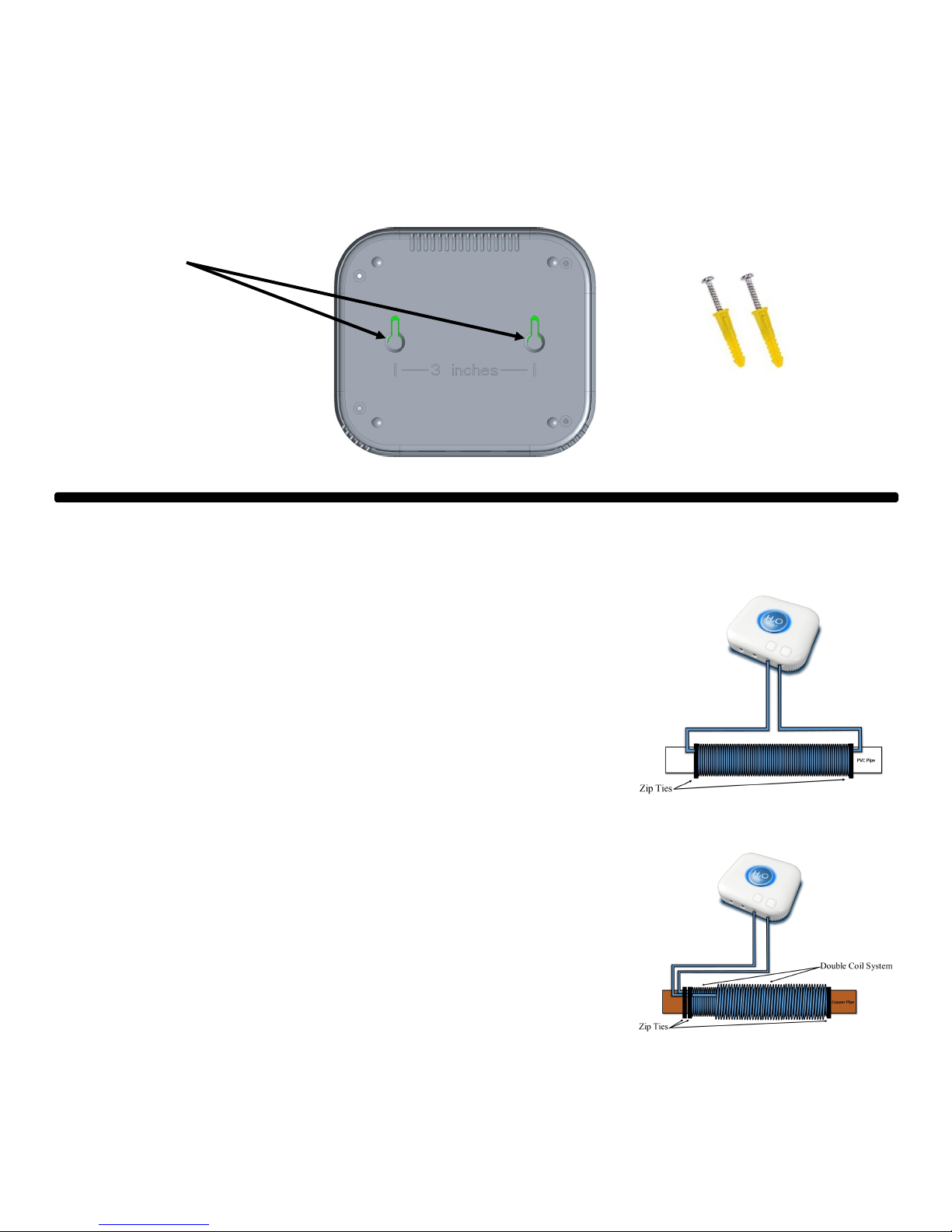

Connecting Induction Coil

1. Upon compleon of installing the inducon coil, the two wires leading from the inducon coil must be

connected to the control module.

2. You will need to strip approximately .5” of the wire insulaon from each wire.

3. There are two illuminated holes in the boom of the control module to receive the stripped wire ends.

4. To insert the coil wires into the control module there are two illuminated push buons located on the

front of the control module. Press down on the buons one at a me to insert each of the wires into the

control module.

5. Once the buons are released with the wire inserted this will lock the wire into the receptacle. Give the

wire a gentle tug to make sure wires are connected properly.

6. When roung inducon coil leads back to the control module make sure they are not twisted together or

touching each other as much as possible.

7. Make sure the two wires coming from the inducon coil are no longer than 10’ in length. These lines can

be cut shorter to desired length needed.

Features and Notifications

Example of wire with

the insulaon removed

The Elite Max i comes equipped with four color illuminaon and sound nocaons.

1. The buons on the front and wire receptacle holes on the boom of the control module will illuminate

a white light to aid with the installaon of the coil wires.

2. The logo halo will stay solid red unl a coil is detected. Once the coil is detected the logo halo will go to

solid green.

3. The solid green logo halo illuminaon will turn blue to nofy that the Elite Max i is funconing properly.

At this point the buon and coil hole illuminaon will turn o.

4. If in the event the logo halo illuminaon goes to red there is an power issue to the control module.

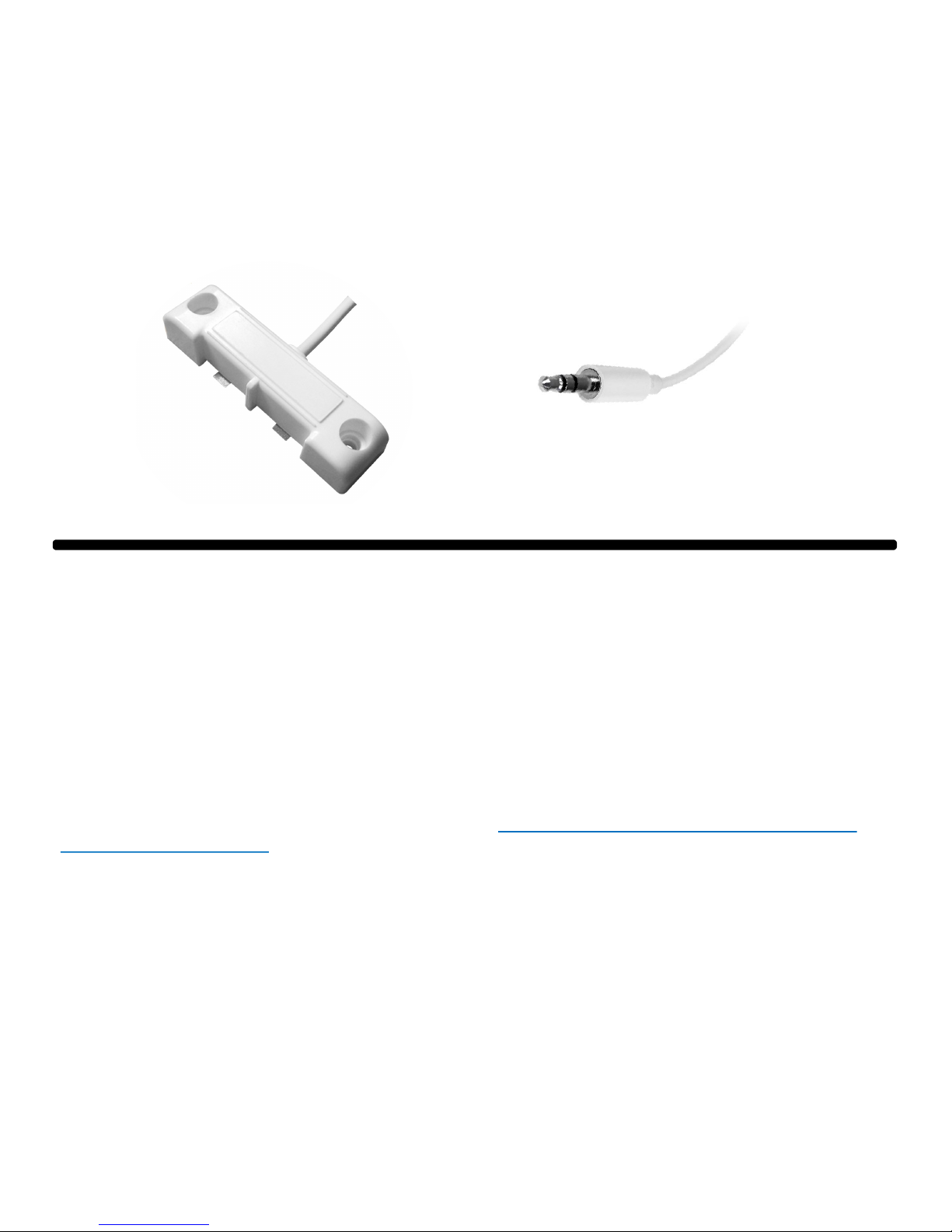

5. The Elite Max i is equipped with an oponal water leak detecon module.

6. In the event the water leak detecon module detects a leak an audible buzzer will sound and the logo

halo will blink red unl the water leak is reced.

Illuminated buons

and holes for wire

inseron

Solid red logo illuminaon indicates

an power issue or no coil detected,

blinking red indicates water leak

When the coil is connected

and unit is funconing proper-

ly, logo illuminaon will go

from solid green to solid blue