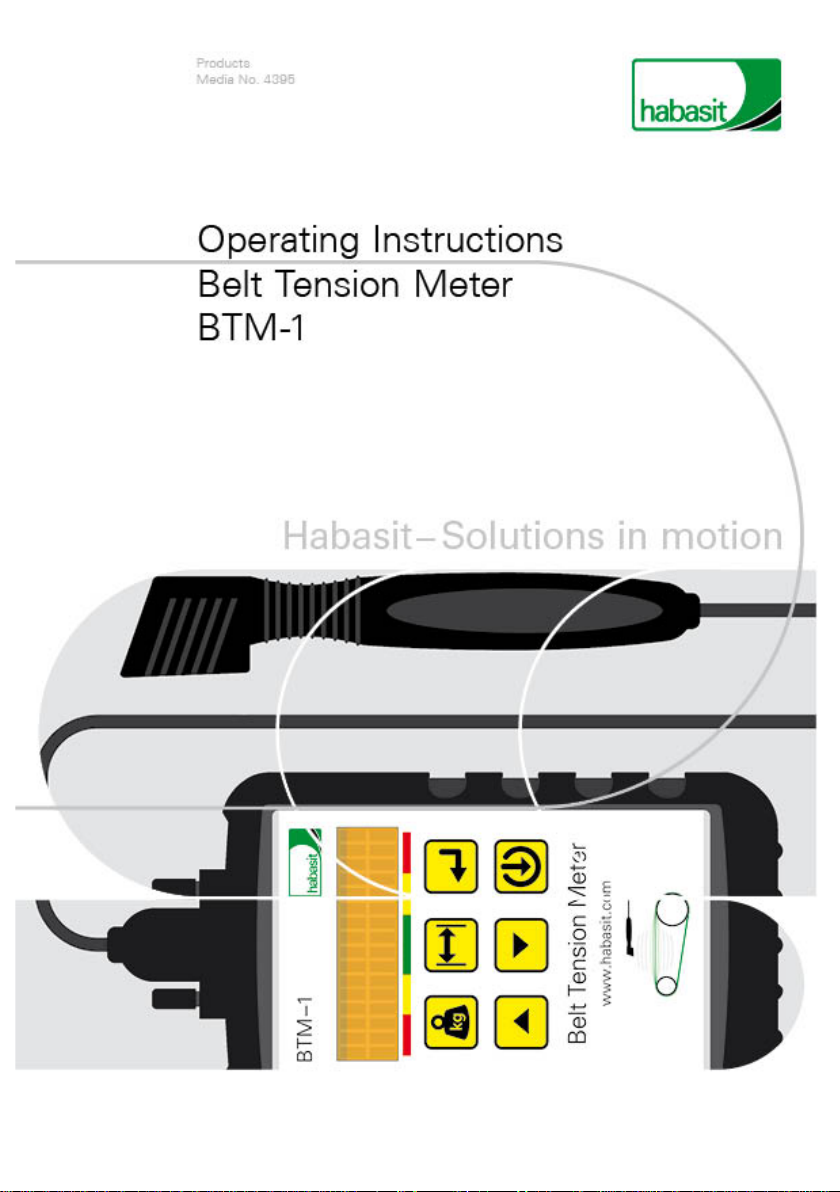

Operating instructions – Belt tension meter BTM-1

Version 1.0

3

Contents

Introduction................................................................................................... 4

Safety guidelines................................................................................ 4

Notes on batteries/rechargeable batteries......................................... 5

Care Instructions................................................................................ 6

Maintenance....................................................................................... 6

Disclaimer .......................................................................................... 6

Intended use ...................................................................................... 7

Delivered items .................................................................................. 7

Product advantages........................................................................... 7

Preparation measures.................................................................................. 8

Connecting the measurement probe.................................................. 8

Operational elements................................................................................... 8

Operating buttons .............................................................................. 8

Checking Calibration.................................................................................... 9

Operation.................................................................................................... 10

General information on "belt tension“ .............................................. 10

Measuring procedure....................................................................... 11

Positioning of the measurement probe............................................ 12

Belt Selection................................................................................... 13

How to get belt weight information?................................... 13

Step by Step: .............................................................................. 14

Procedure: .................................................................................. 14

Input of calculated value in the BTM-1............................... 14

Measurement Procedure ................................................................. 15

Storing measurements..................................................................... 16

Calling up stored measurements..................................................... 16

Procedure: .................................................................................. 16

Switching off the instrument........................................................ 16

Specifications ............................................................................................. 17

Menu structure ........................................................................................... 18

Problem solving.......................................................................................... 19