4.2 Intended use

The Hach EZ-series analyzers are intended for use by individuals who measure multiple water

quality parameters in samples from industrial and environmental applications. The Hach EZ-series

analyzers do not treat or alter water and are not used to control procedures.

4.3 Product overview

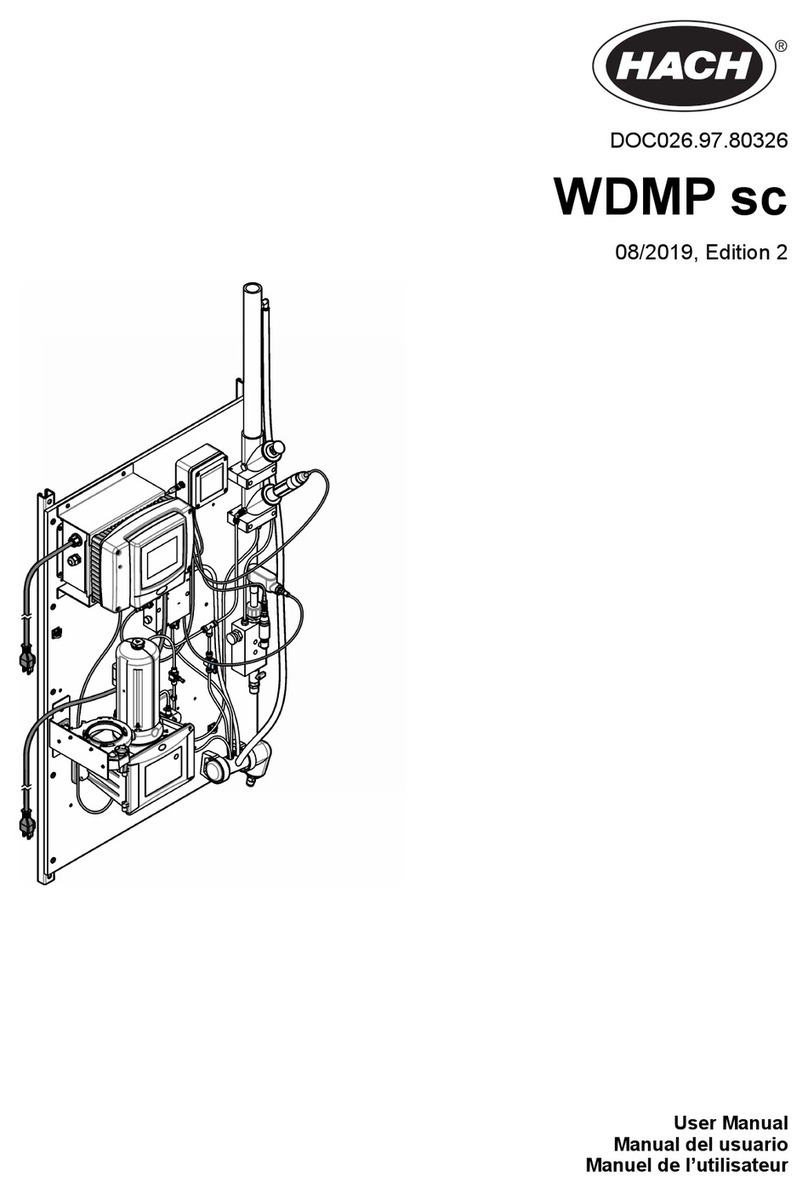

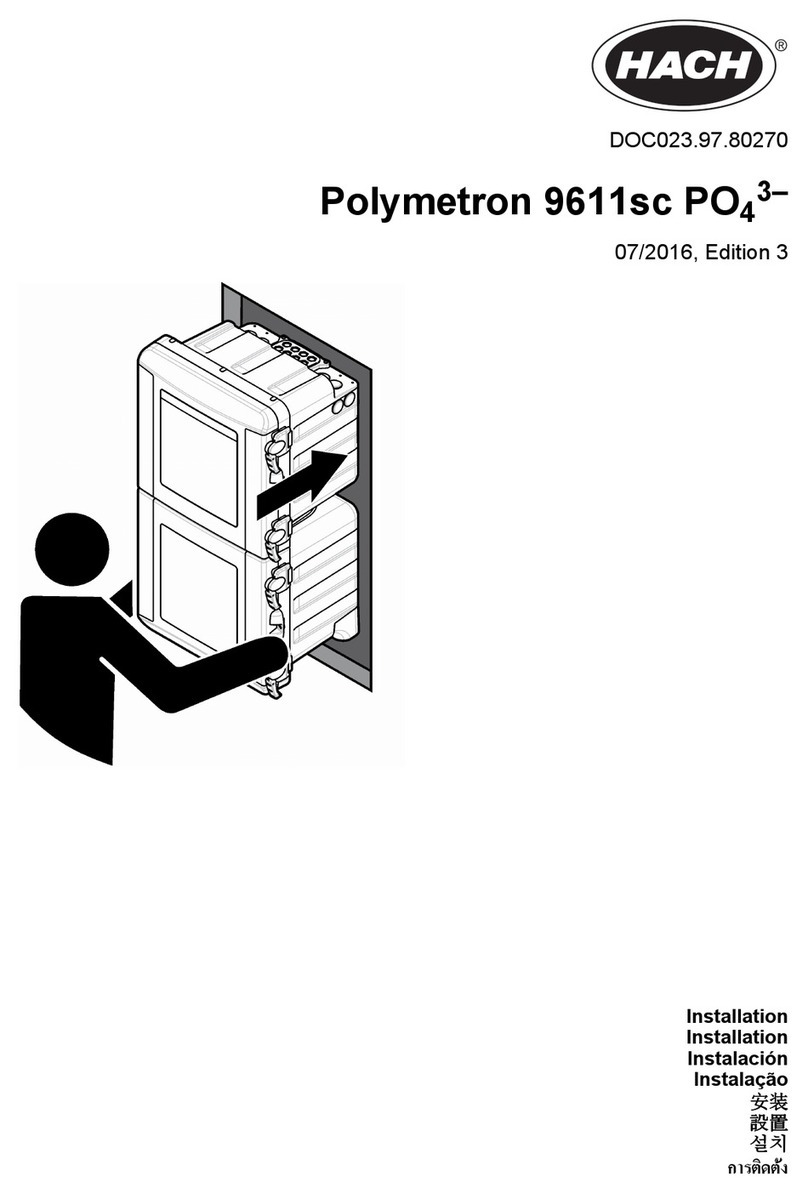

The Hach EZ-series analyzers are on-line analyzers that measure one or multiple parameters in

water samples from industrial and environmental applications. Refer to Figure 1.

The sample line moves the sample into the analyzer. The analyzer uses pumps, valves and syringes

to move the sample and reagents to the measuring cell on the analytics panel. When the

measurement cycle is complete, the analyzer discards the sample through the drain line. The

analysis results shows on the display of the data processing panel. The data processing panel

controls and configures the analyzer. The data processing panel saves the analyzer data (i.e.,

trends , alarms, analysis results and data log files).

A set of reagent bottles is supplied with the analyzer to hold the reagent and solutions. Sample

preconditioning could be necessary based on the analysis technology. Optional sample

preconditioning panels are available for the sample line.

There are different analyzer series available with different measurement technology and measured

parameters:

• EZ 1000 series—On-line colorimetric analyzers for general water analysis (chemical parameters)

and nutrient analysis (i.e., nitrate, phosphate, ammonia)

• EZ 2000 series—On-line colorimetric analyzers with digestion for general water analysis (chemical

parameters) and nutrient analysis (i.e., nitrate, phosphate, ammonia)

• EZ 3000 series—On-line ion-selective (ISE) analyzers for general water analysis

• EZ 4000 series—On-line titrimetric analyzers for general water analysis (chemical parameters)

• EZ 5000 series—Multiparametric on-line titrimetric analyzers for general water analysis (chemical

parameters)

• EZ 6000 series—On-line voltammetry analyzers for heavy/trace metal analysis (e.g., Ag, As, Cr,

Hg, Pb, Se)

• EZ 7x00 serires—On-line analyzers for industrial applications (e.g, COD, TOC, Total Nitrogen,

Total Phosphorus, volatile fatty acids FOS/TAC, influent toxicity, international bitternes units,

Adenosine Triphospahte)

The EZ-analyzer has different options such as: Sample detection, level detection for reagent bottles,

remote Start/Stop, auto-validation, auto-calibration, auto-cleaning, RS232 and Modbus.

8 English