3

C O N T E N T S:

Safety Precautions...............................................................4

A. Overview of the Machine............................................5

B. Main Usage and Features.............................................5

C. Main Specications........................................................6

D. Transmission System.....................................................7

D.1 Main Transmission System.......................................8

D.2 Feeding System............................................................8

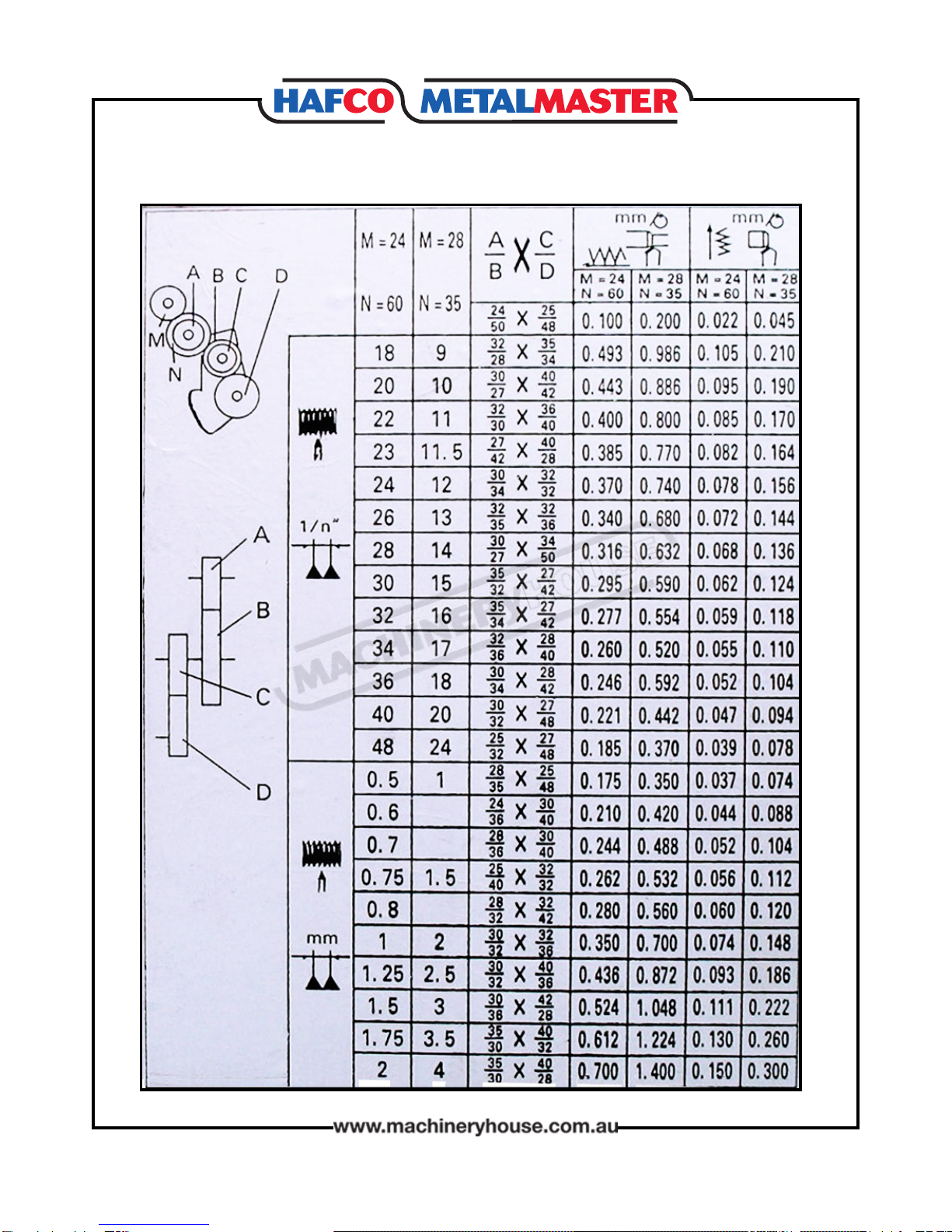

D.2.2 Threading....................................................................9

Change Gears.........................................................9

Thread Chart........................................................10

D2.3 Setting The Cutting Tool With Spindle

Centerline............................................................................11

E. Installation And Adjustment Of The Lathe.........12

E.1 Installation....................................................................12

E.2 Adjustment Of The Lathe........................................13

E.2.1 Adjustment Of Main Spindle..............................13

E.2.2 Adjustment Of Clearance Between The Top

Slide, Worktable And Cross Slide.................................13

E.2.3 The Adjustment Of The Locking Handles Of

TheTailstock........................................................................14

F. Operation.........................................................................15

F.1 Illustration Of The Operation Parts......................15

F.2 Speed Changing Of The Main Spindle...............16

G. Lubrication.....................................................................16

Lubrication Points.............................................................17

Table Of Lubrication Points...........................................17

H. Wiring Diagram.............................................................18

Spare Parts...........................................................................19