–3 –

Subsonic Filter

The VRM series uses a Subsonic Filter to prevent the woofer from reproducing inaudible frequencies.

Subsonic frequencies (known as infrasonic frequencies) are signals below the normal human hearing

range.The subsonic filter reduces the energy of these frequencies and restrains the woofer from operat-

ing outside its optimum linear excursion. This type of electronic control eliminates the mechanical dis-

tortion caused by a woofer traveling beyond its XMAX, improves power handling, increases reliability

and improves sonic performance.

The Result: Improved power handling, increased reliability and improved sonic performance.

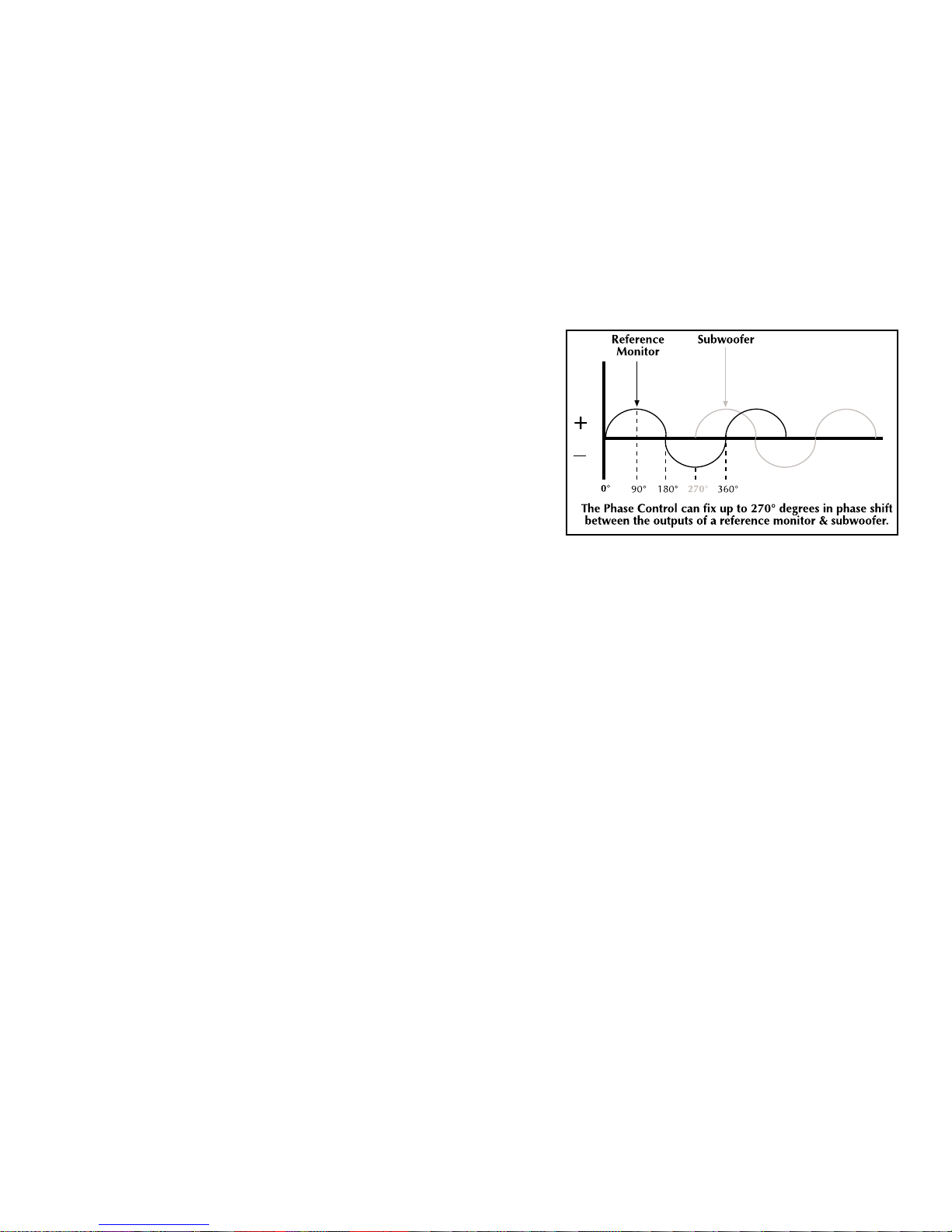

Phase Control

The Phase Control is used to align the arrival time of the sub-

woofer’s output information with satellite monitors. Aligning

both signals will insure that both Subwoofer and reference

monitor information arrive at the listening position at the same

time. This eliminates the possibility of acoustical cancellation

and improves the reproduction of transients in the crossover

region.

The Result: Eliminates phase cancellation and improves tran-

sient response.

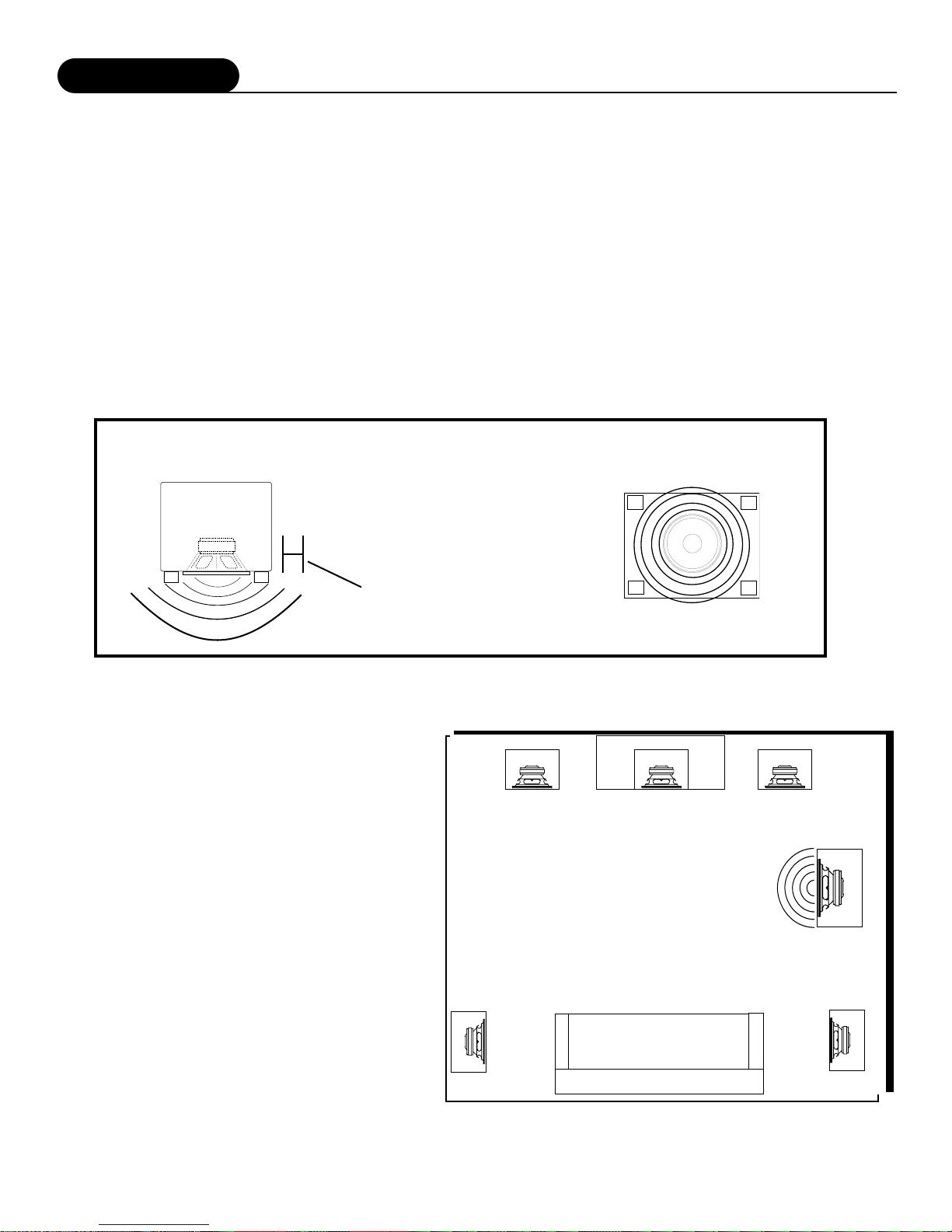

Speaker Level Inputs

Does your receiver have only speaker level outputs? No problem! Hafler’s Speaker Level Input circuitry

converts the speaker line outputs (high level) from your receiver into pre-amp line inputs (low level) for

your VRM amplifier. This allows compatibility with a variety of receivers as well as the ability to retrofit

your new Hafler subwoofer into existing systems without the need for external adapters.

Santoprene Rubber Surround

Santoprene is a very durable and temperature tolerant material which provides a consistent support

necessary for the linear motion of the speaker cone. In addition, the damping capabilities eliminate

the transmission of sonic disturbances between the cone and the frame of the speaker. This greatly

improves the accuracy of the woofer’s low frequency response.

The Result: Improves woofer’s low frequency response.

Aluminum Voice Coil Former

The transducers voice coil former is black anodized aluminum for highly efficient thermal transfer.

Another method of producing voice coils is with Kapton®formers. Although this material is very resis-

tant to heat, any heat generated by the transducer is “trapped”on the copper voice coil windings.

HAFLER uses aluminum voice coil formers because aluminum acts like a “heat sink”and helps dissi-

pate heat away from the voice coil. This allows winding high temperature copper wire in multiple lay-

ers for improved efficiency.

The Result: Improves power handling by efficiently dissipating heat.