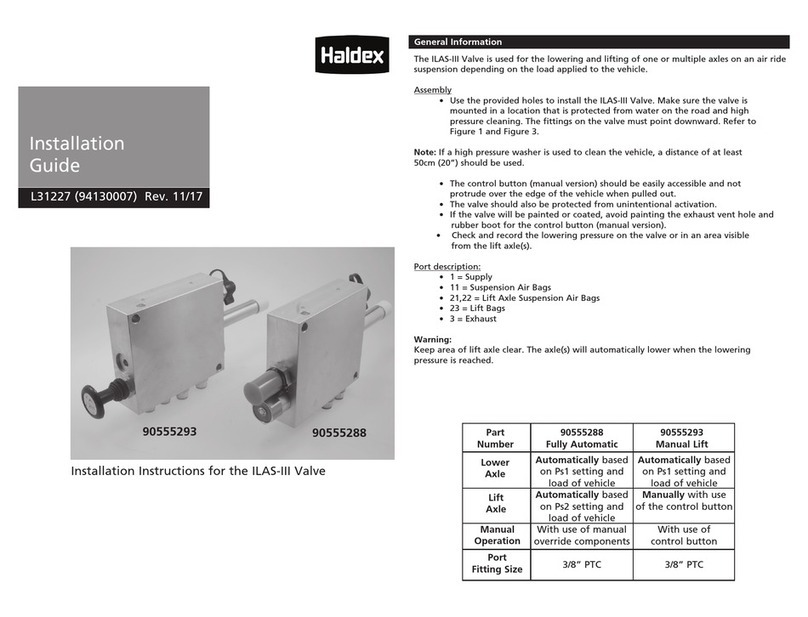

General Information

The Haldex ILAS III Valve is used to lower and lift one or more axles on a vehicle. The ILAS III Valve activates

the lift axle as the load is applied to the vehicle. This is achieved by the Ps1 and Ps2 pressure settings in

the valves. The Ps1 pressure setting lowers the axle(s) to the ground and is found on both the Automatic

(90555288) and Manual (90555293) Valves under the yellow cap. The adjustment to Ps1 is made by using

the ILAS Wrench (904053001). The Ps2 pressure setting is used for returning the axle to the up position and

is only found on the Automatic Valves. The Ps2 adjustment is located underneath the red cap and can be

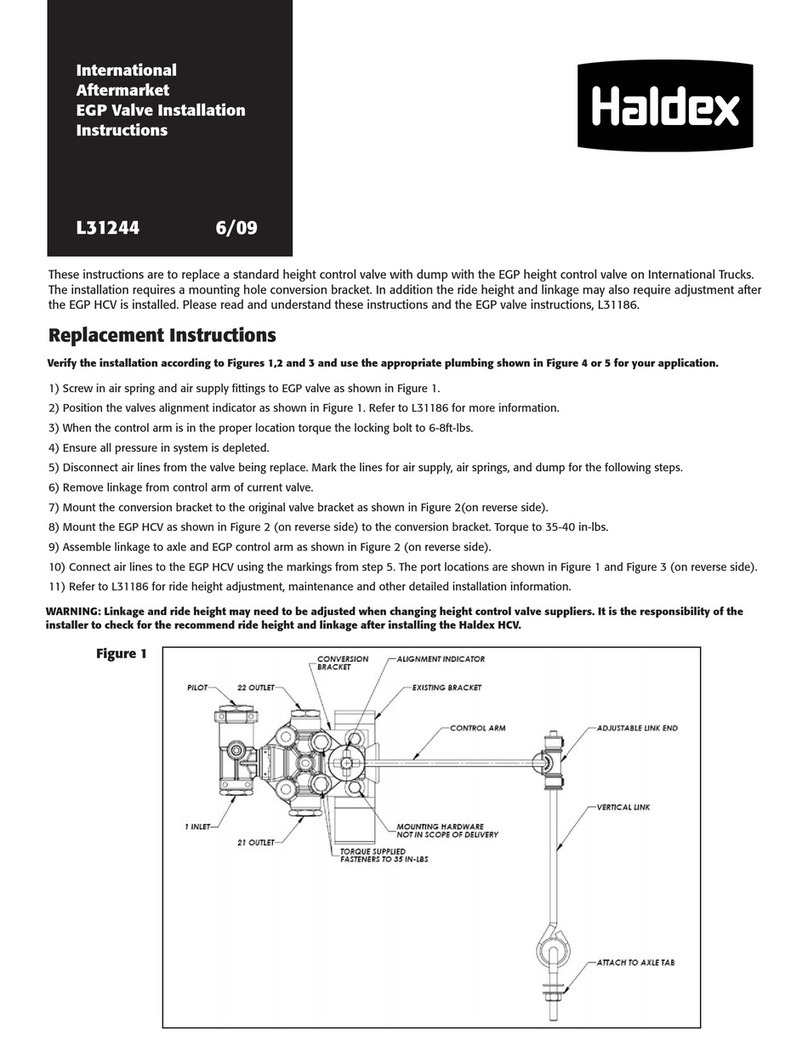

adjusted by hand. Refer to Figure 1 for the Automatic port locations and Ps1 and Ps2 adjustment features.

Refer to Figure 2 for the Manual port locations and the Ps1 adjustment feature. The following instructions

will define the correct procedure to set Ps1 and Ps2 pressure settings and how to check that the valve is

functioning properly.

Prior to setting Ps1 and Ps2 pressures,

you must first determine pressure in the

air suspension system as follows:

1. Determine the pressure in the air

suspension at max. load with the

axle in the up position and also with

the axle in the down position.

2. Determine the pressure in the air

system at empty or no load with the

lift axle in the down position and

again with the lift axle in the up

position.

These four pressure readings will

show the range of pressures the air

suspension is moving through and

will assist in setting the ILAS III Valve

properly for the vehicle.

Note: Before choosing the set points

for the Ps1 and Ps2 familiarize yourself

with local and state (or providence) reg-

ulations that may require a lift axle to

be lowered or raised at a specified load

weight. To determine these set points, a

pressure reading at the desired trigger

load will be needed.

ILAS III Instructions

for Adjustment of

Ps1 and Ps2

L31248 9/09

Ps2 Adjustment for ILAS III Automatic Only

Note. The Ps2 setting of the valve must be higher than the unloaded air bag pressure of the trailer

with all axles on the ground. If this guideline is not followed the Ps2 will not activate and the

axle will remain down.

1. The ILAS III factory setting for Ps2 is approximately 20 PSI. If adjustment is necessary, remove red can

and with fingers back out white nut until face of nut is at the end of the threads. DO NOT REMOVE

WHITE NUT FROM STUD! The Ps2 has a setting range of 10 PSI to 45 PSI, this is dependent on the Ps1

set point. See Figure 5 on previous page for the adjustable range of the valve.

2. Connect a regulated air pressure line to port 11 and set at 80 PSI. Connect the gauge and air switch

to the test port. Close air switch and allow the two gauges to equalize (may take several minutes to

equalize). The Ps1 setting must trigger in order to adjust the Ps2 setting.

3. Once the two gauges are equalized to the same pressure (80 PSI), regulate the pressure down to the

new desired Ps2 setting pressure. May take several minutes to equalize again.

4. To change the Ps2 setting accurately, the test port gauge must equal the regulated pressure gauge

of Port 11 – EXTREMELY IMPORTANT for precise setting of the valve. Once equalized pressure is

reached between both gauges (may take several minutes), very slowly turn the adjustment nut in

(turn to the right) until the exhaust of the valve is heard. Stop the adjustment when the exhaust

is heard. The valve is now set precisely to the regulated pressure that was supplied to Port 11.

Repeat Steps 1-6 from the Functional Check to verify that the Ps2 setting is at the desired

pressure setting.

NOTE: When making an Automatic ILAS III valve adjustment to the Ps1 setting or PS2 setting, this

may result in changes to other settings. Example: An adjustment to increase Ps2 could cause an

increase in Ps1. Always Repeat Steps 1-6 from the Functional Check to verify the settings are

correct before operating the vehicle.

Troubleshooting

Test port gauge does not respond after waiting several minutes:

§Check with soap and water for leaks around all fittings connected to the test port.

§If an adapter is being used over the metric M16x1.5 thread verify that the white check valve is

being engaged by the adapter. If the check valve is not engaged, no air will pass by the gauge.

§Check to see if adequate air is being supplied to the regulator and Port 11.

Ps1 can not be set correctly:

§Perform a Functional Check to verify that the Ps1 triggers and is above the desired set point

use the adjustment wrench to turn in (turn to the right) the adjustment nut until it stops.

DO NOT TORQUE! Back nut out four turns.

§Verify that the desired Ps1 set point is within the adjustable range from 45 to 75 PSI.

Ps2 can not be set correctly:

§Perform a Functional Check to verify that the Ps1 has been triggered prior to the adjustment of Ps2

and that the current Ps2 setting is below the desired Ps2 setting.

§If an adjustment is made to both Ps1 and Ps2 the settings may change slightly as one is

dependent on the other. If needed repeat setting procedures until the desired settings are

achieved.

United States 816.891.2470

Canada 519.621.6722

Mexico 52.81.81569500

L31248

US 9/09

Web Only

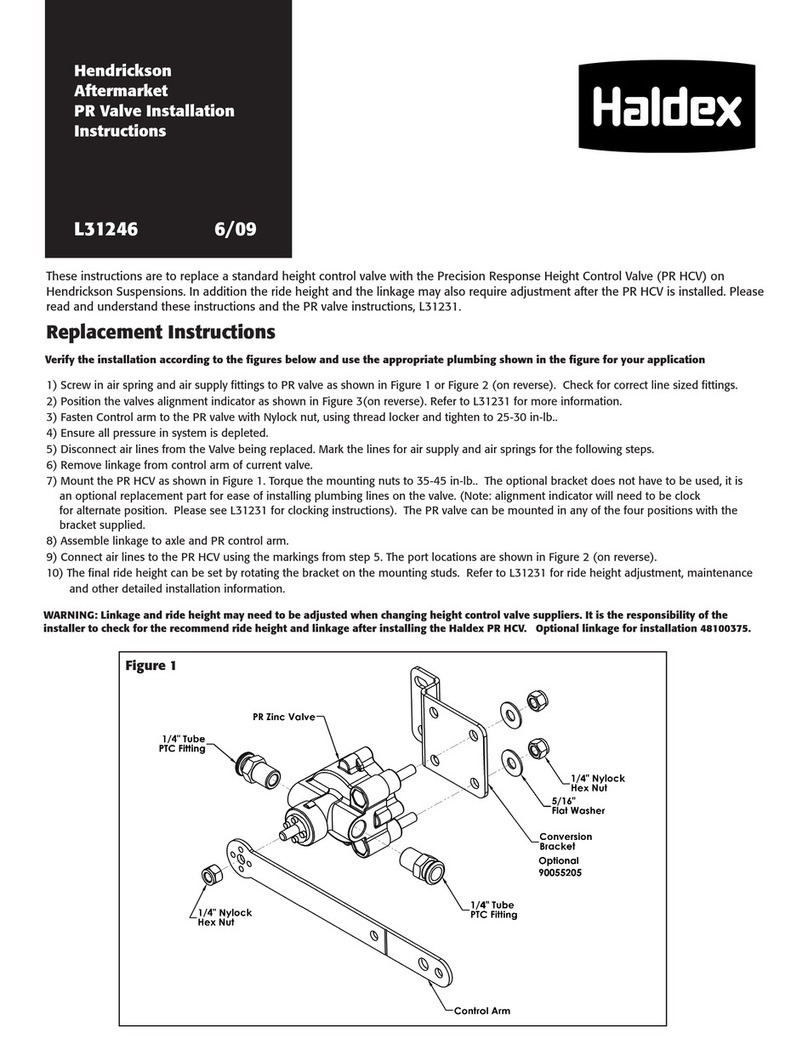

Figure 1

Figure 2