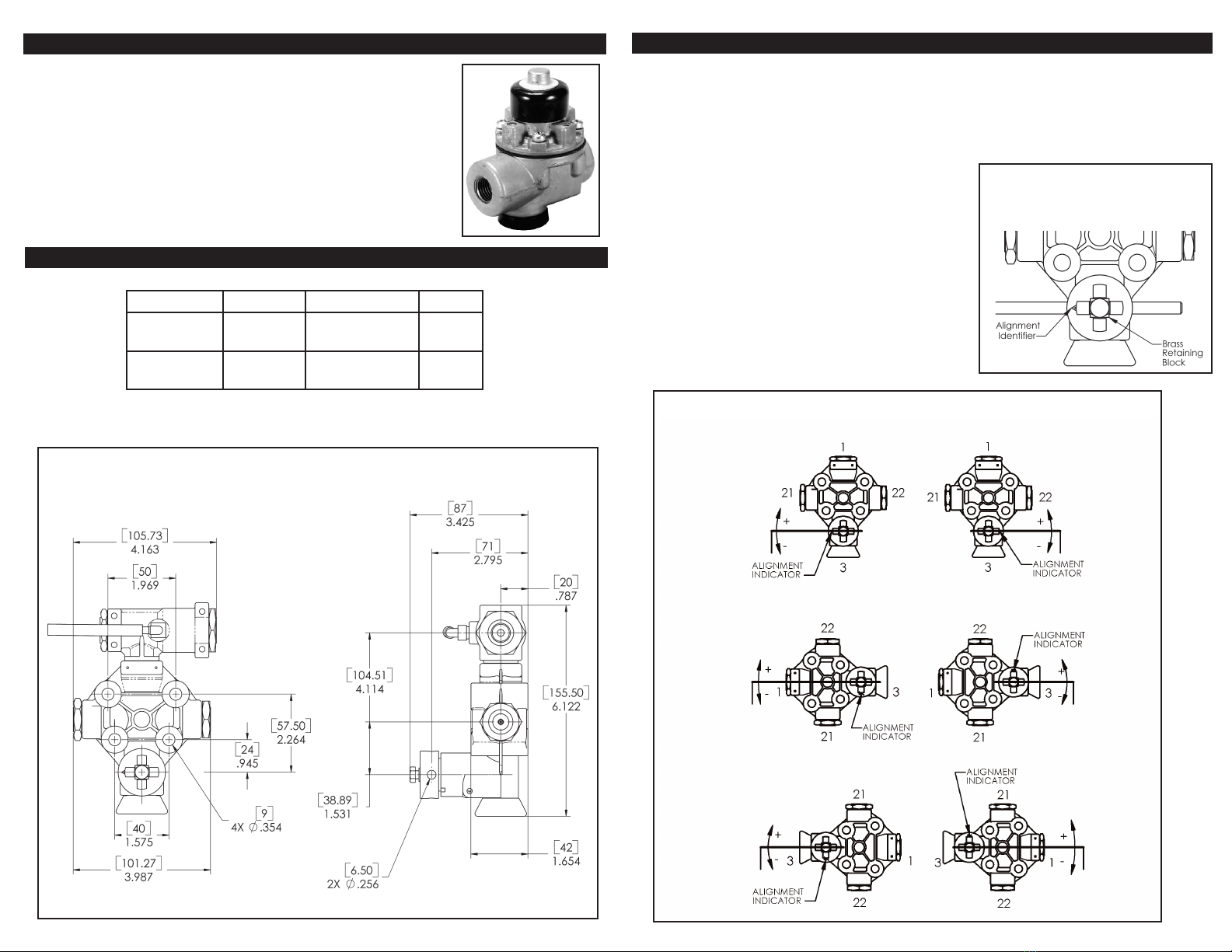

4. Connect the air spring port(s) to the air spring(s) port(s) (as shown in Figure 3)

for either vertical or horizontal position. If only one air spring port is used, other

port must be plugged.

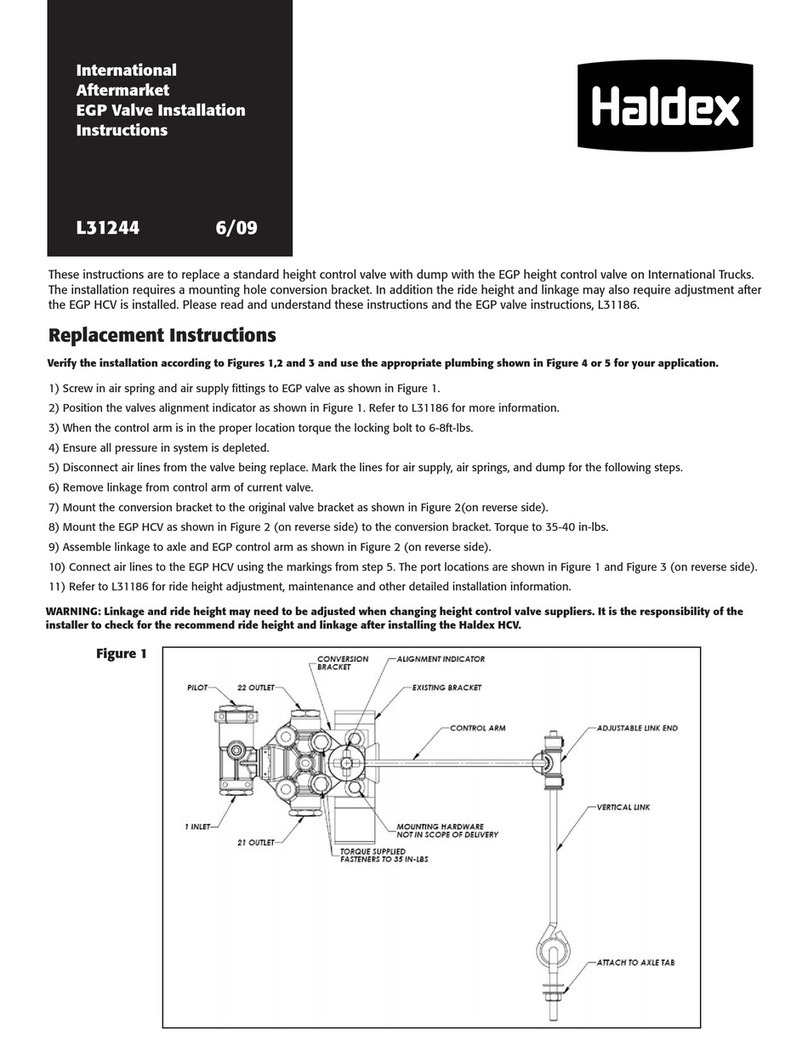

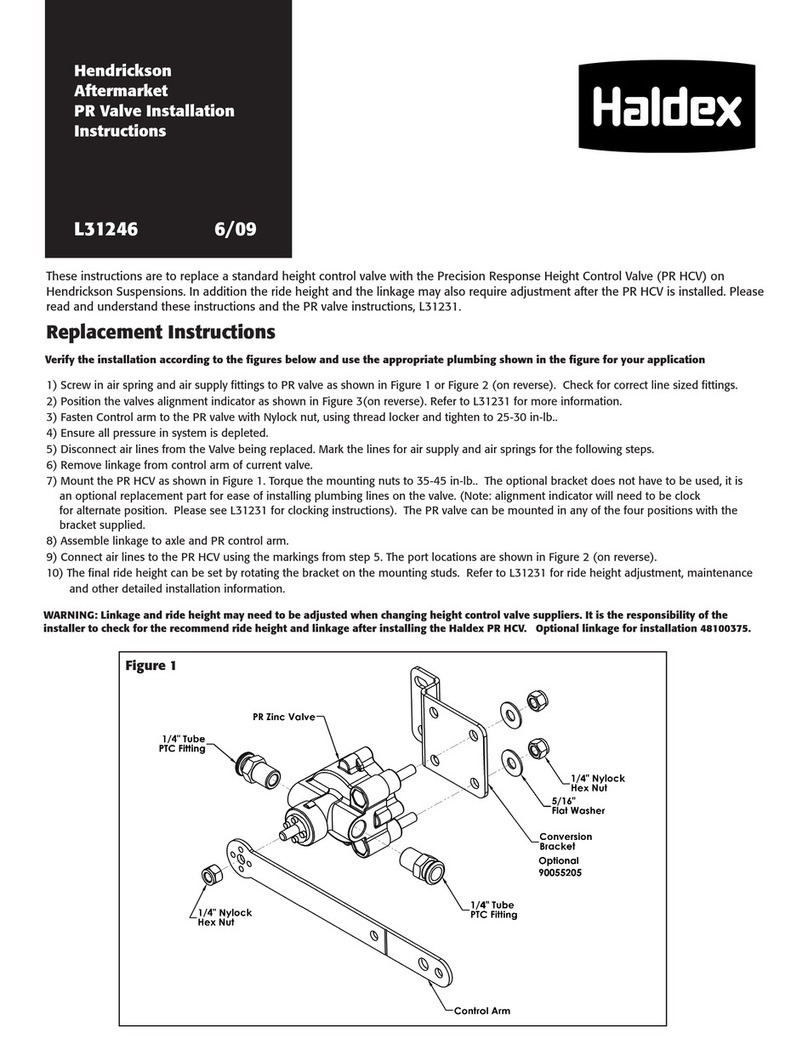

5. Install the EGP control arm. Refer to Figure 2 for proper control arm

installation.

Note: Correct position of the direction arrow on the valve actuator shaft to the

direction of the control arm is critical. Incorrect installation will impair suspension

and vehicle performance. (Refer to Figure 2.)

6. To insure that the control arm is properly installed, temporarily supply air

pressure to the EGP and rotate the control arm up (approximately 20°

above horizontal) and check if air pressure begins to inflate the air spring(s).

If the air springs are not being inflated, recheck the air lines for proper port

connection and the control arm and actuation shaft for proper position.

If the EGP properly inflates the air spring(s), rotate control arm down

(approximately 20° below horizontal) to check if air pressure is being

exhausted from the air spring(s) through the exhaust port of the EPG. Once

it has been determined that the control arm is in the proper position torque the

locking bolt to 6-8 ft/lbs. (Refer to Figure 5).

1. Place vehicle on level ground.

2. Build and maintain a minimum of 70 PSI air pressure.

3. Disconnect the lower anchor of the vehicle link from the axle mount.

4. Place the lever arm into the horizontal position by aligning the arrow and hole

on the shaft with the slot in the housing.

5. Place a 4mm pin in the hole to hold this position temporarily. NOTE: IF THE

VALVE IS OUT OF ADJUSTMENT, THE VALVE WILL BE EXHAUSTING AIR

OR SUPPLYING AIR TO THE AIR SPRINGS.

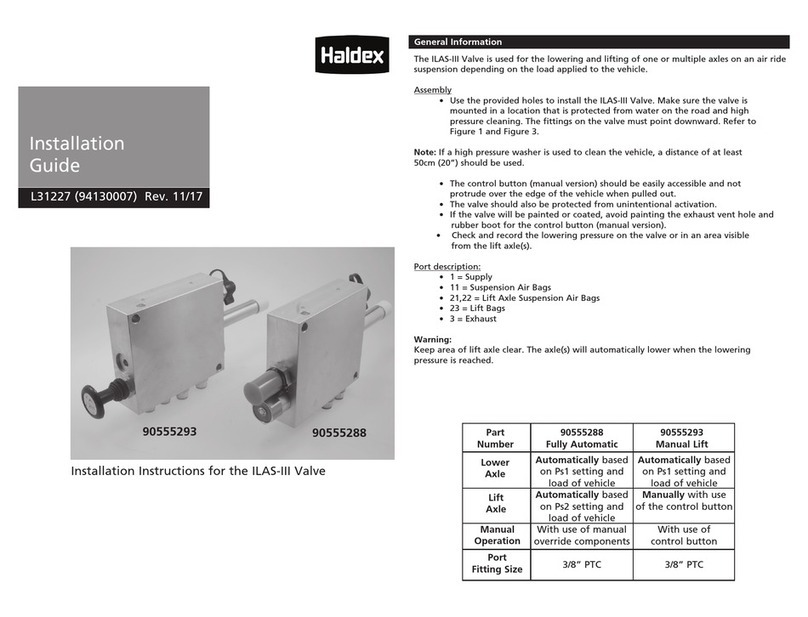

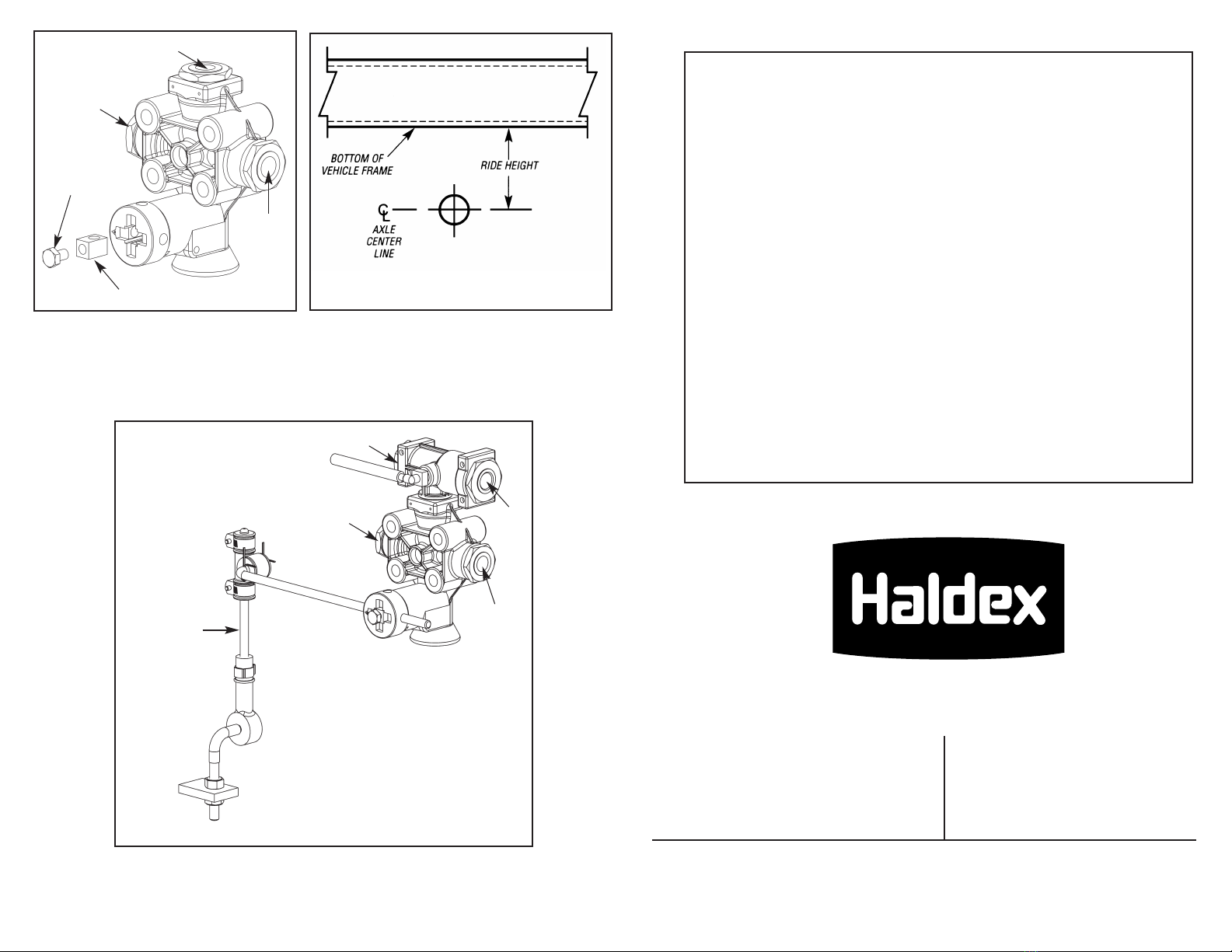

6. Remove rubber cap, loosen the locking nut. (Figure 4)

7. Using a screw driver, turn the adjustment screw clockwise until the valve will

begin supplying air to the air bags. (Figure 4)

8. Turning the adjustment screw counter-clockwise, count the number of turns

until the valve begins to exhaust air.

9. Turn the adjustment screw clockwise 1/2 the number of turns between filling

and exhausting to set proper neutral position.

10. Treat the lock nut with Loctite 290 or equivalent and tighten it hand tight,

using the screw driver to maintain neutral position.

11. Replace rubber cap.

SETTING THE NEUTRAL POSITION

Figure 3.

12. Insert the lower anchor of the vertical link to the axle mount, loosen the jam

nut(s) and turn until the vehical kink is free from binding.

13. Remove the 4mm pin holding the neutral position.

14. Install and tighten the lock washer and nut.

Figure 4.

Locking

Nut

Adjustment

Screw

Rubber

Boot