Table of content

II

Table of content

1 Overview.......................................................................................................................................... 1

1.1 General information................................................................................................................ 1

1.2 Technical data.......................................................................................................................... 1

1.3 Mounting instructions............................................................................................................. 2

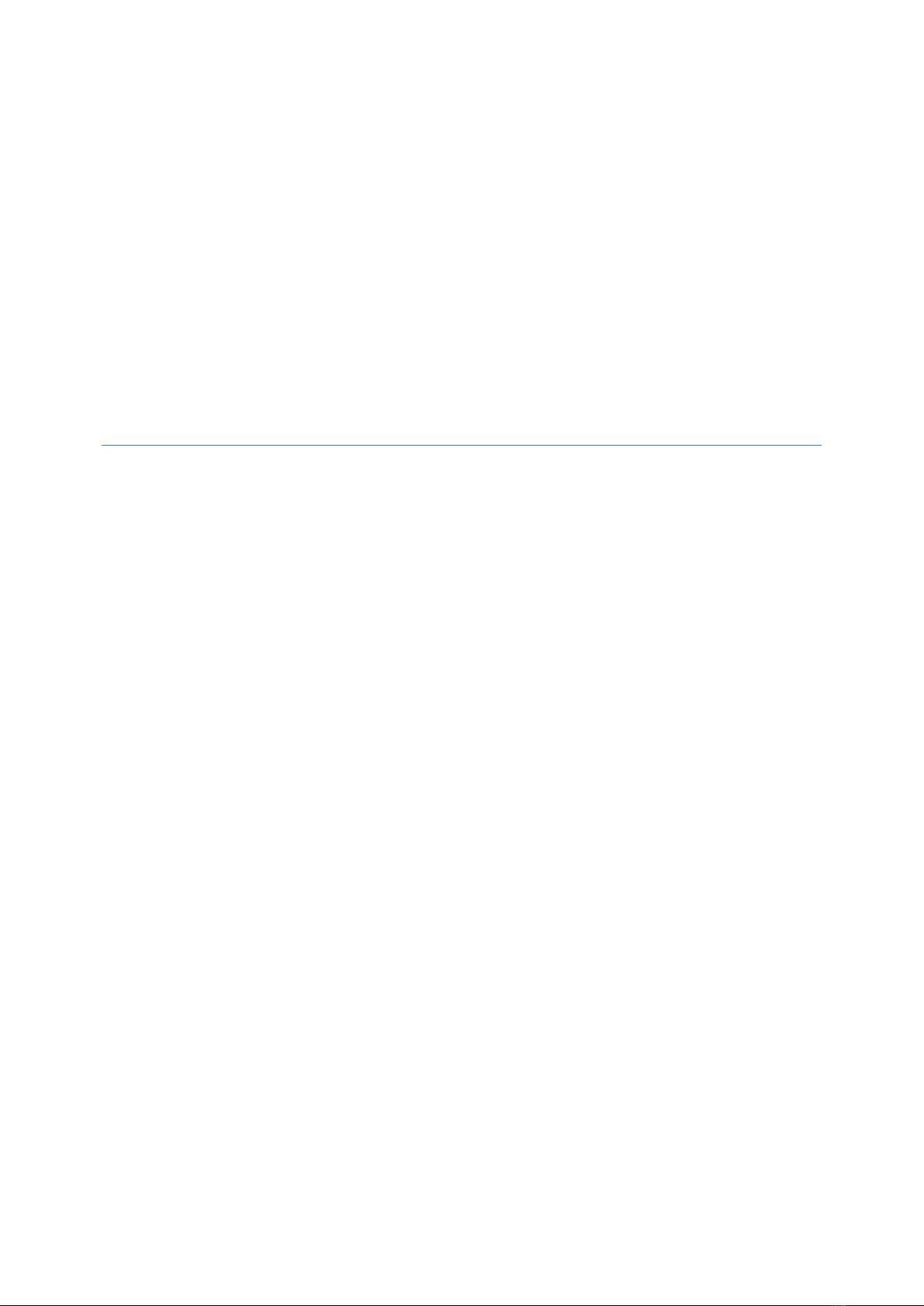

1.3.1 Inserting into the tightening system ............................................................................... 2

1.3.2 Connecting with the SMpdp/IMpdp module .................................................................. 2

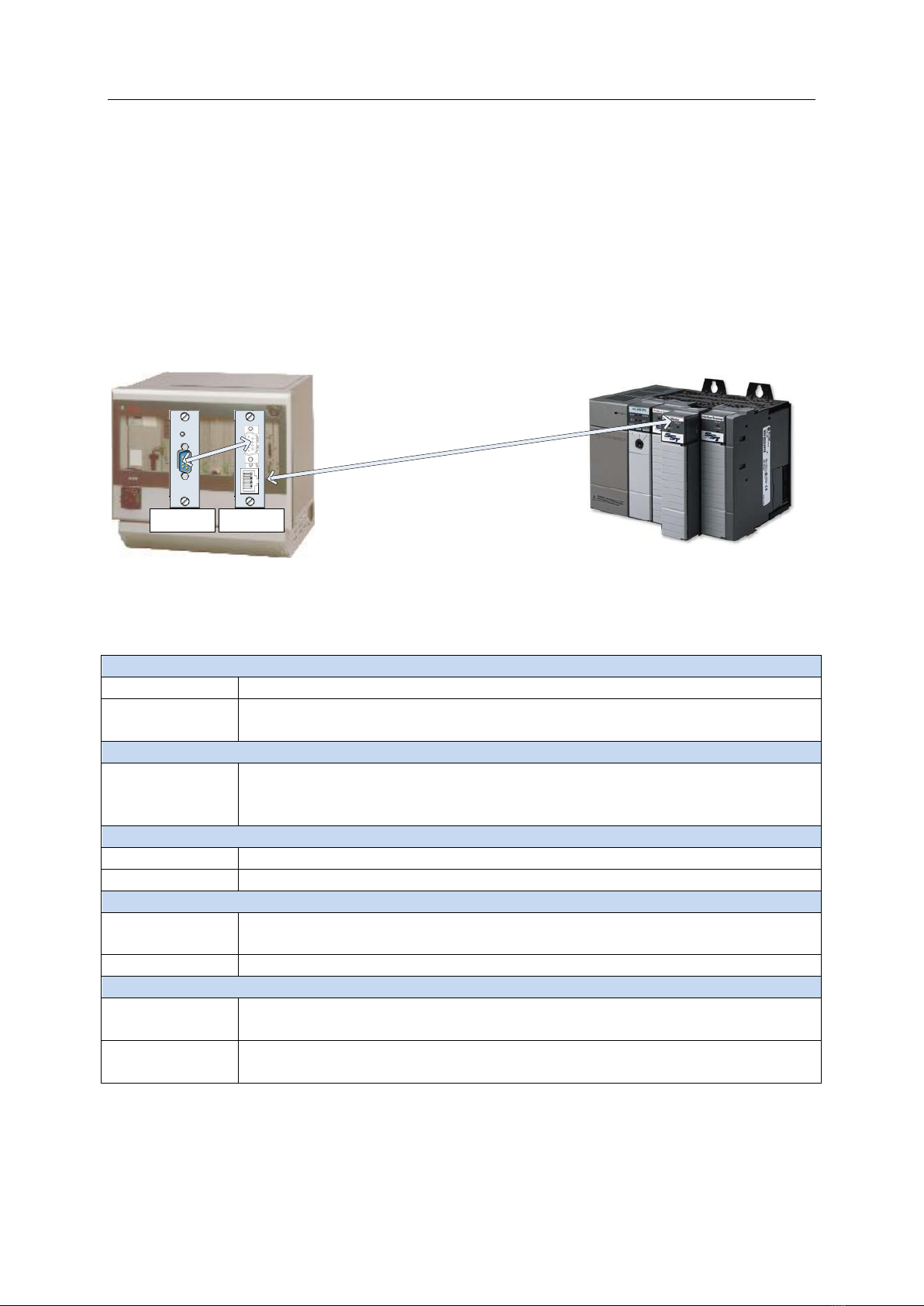

1.4 Interfaces................................................................................................................................. 2

1.4.1 X1 IMpdp/SMpdp ............................................................................................................ 2

1.4.2 X2 Ethernet...................................................................................................................... 3

1.4.3 Diagnostic LED’s A/B........................................................................................................ 3

2 Configuration................................................................................................................................... 3

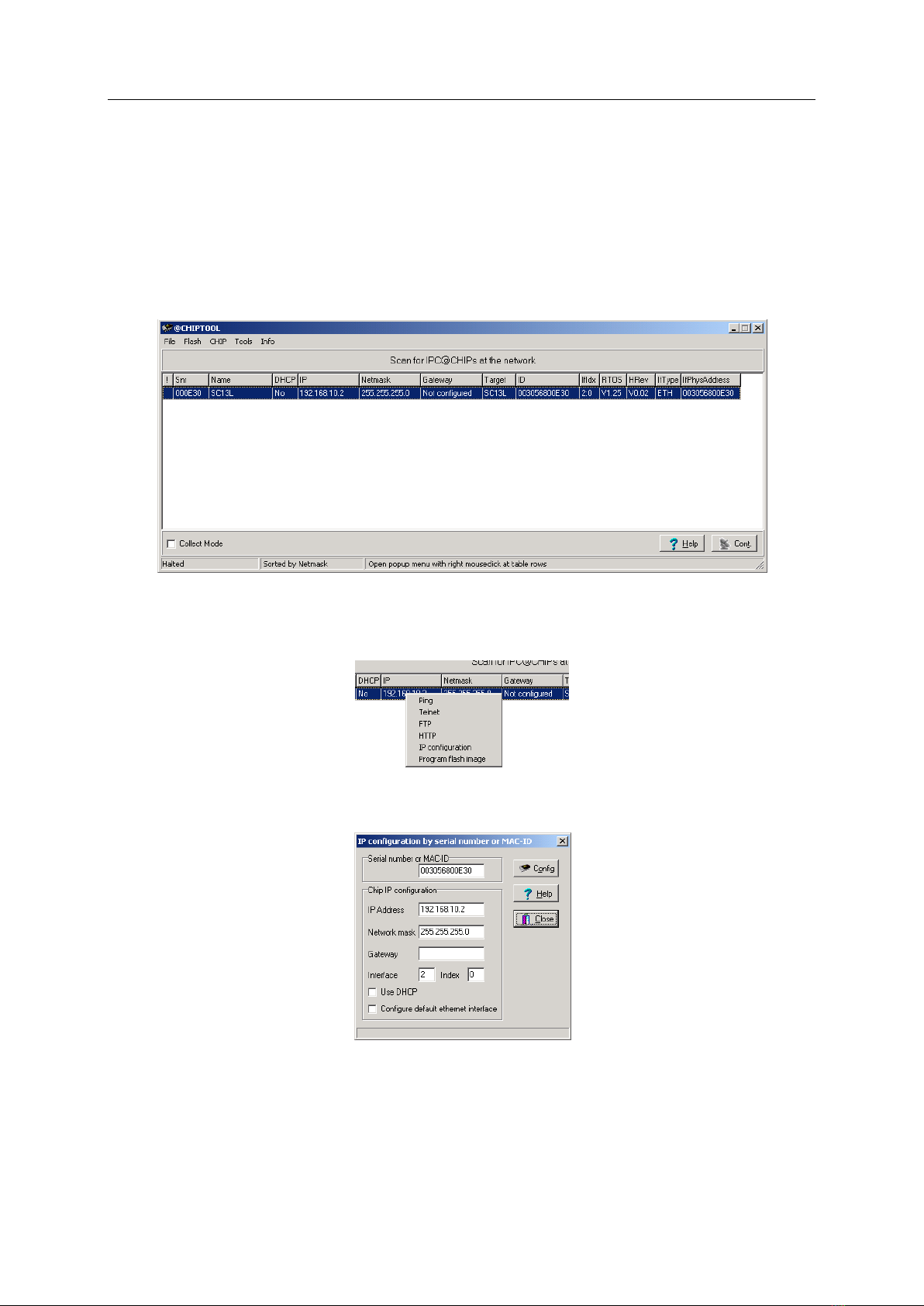

2.1 BG02-EIP configuration ........................................................................................................... 3

2.1.1 BG02-EIP factory defaults................................................................................................ 3

2.1.2 Changing settings ............................................................................................................ 4

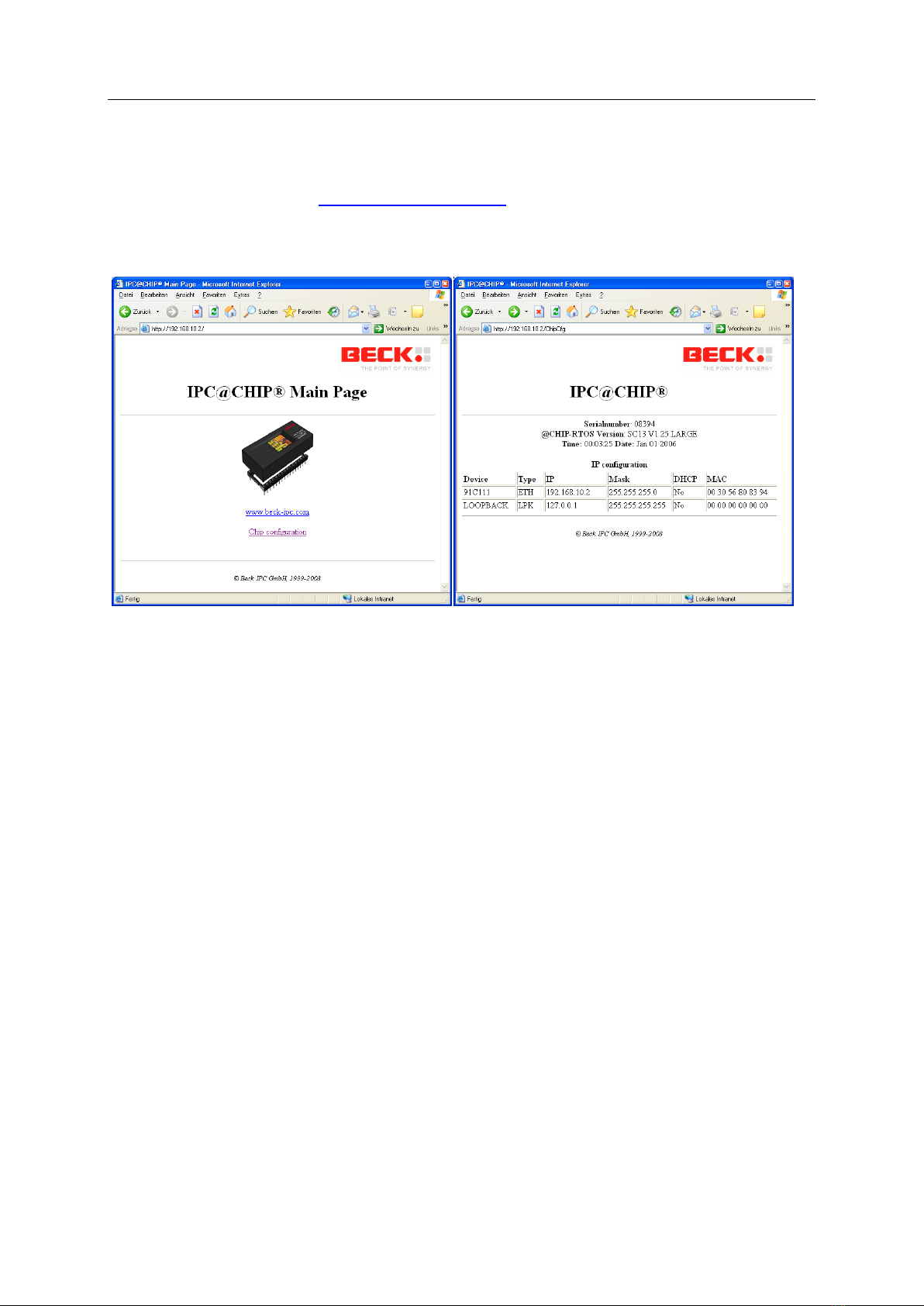

2.1.3 Web browser access........................................................................................................ 5

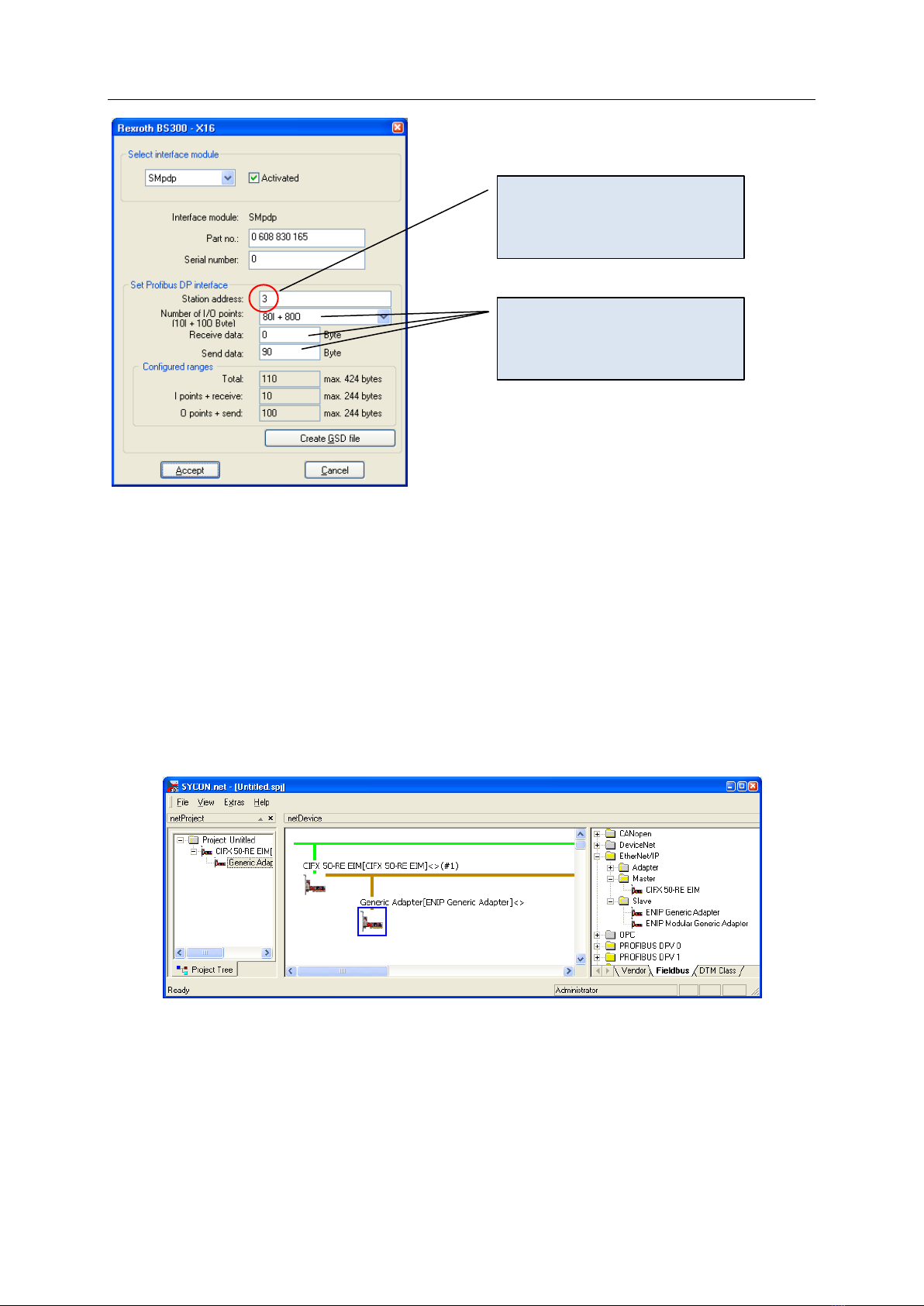

2.2 Configuring the tightening system .......................................................................................... 5

2.3 Ethernet/IP Scanner Configuration ......................................................................................... 6

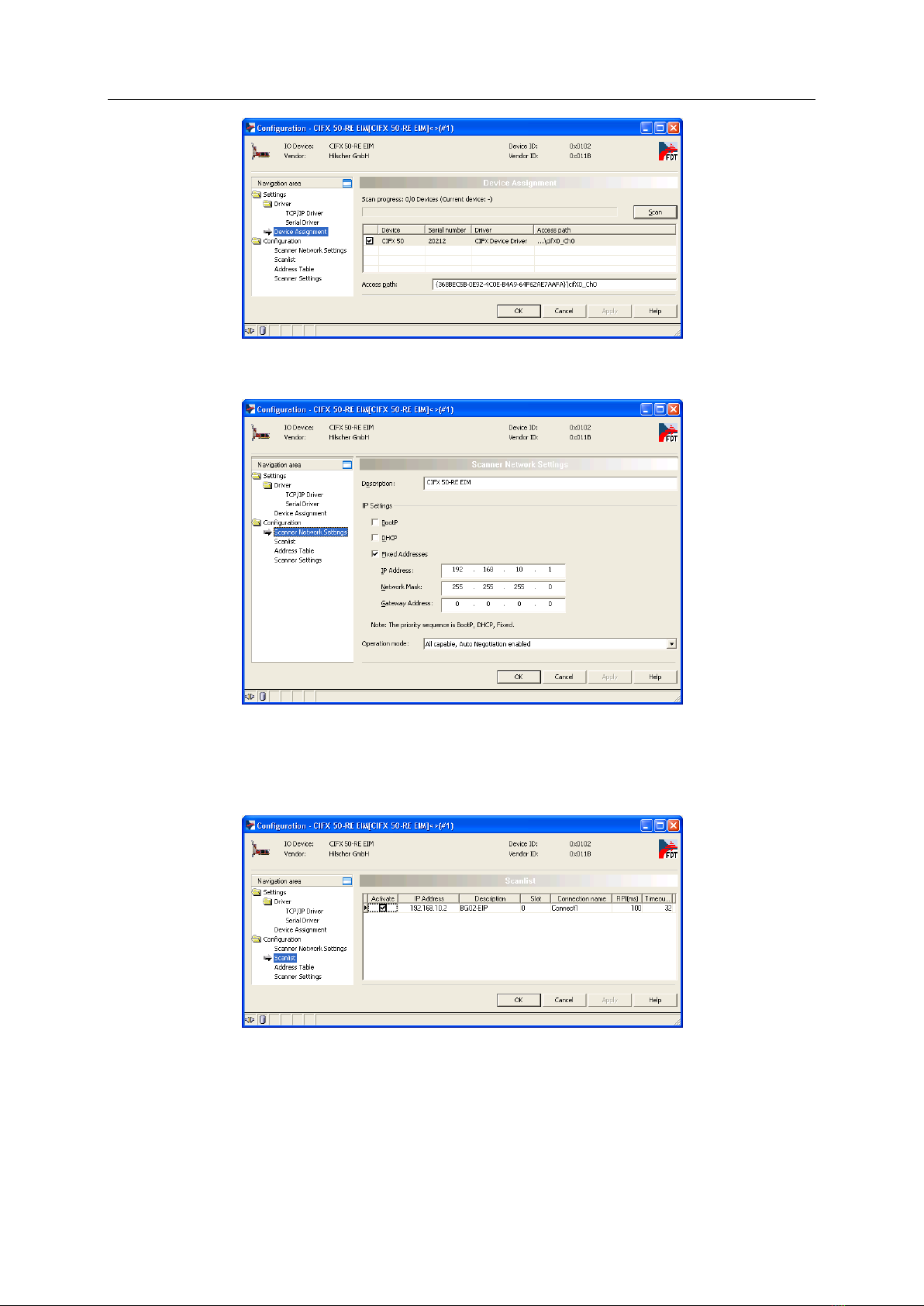

2.3.1 Configuration with Hilscher Sycon.NET........................................................................... 6

2.3.2 Configuration with ControlLogix ..................................................................................... 9

3 EtherNet/IP adapter functionality................................................................................................. 10

3.1 Message Server ..................................................................................................................... 10

3.2 Process Data Mapping........................................................................................................... 10

3.2.1 Input data (PLC BG02 KE)..................................................................................... 11

3.2.2 Output data (KE BG02 PLC).................................................................................. 11

3.3 Behaviour on errors............................................................................................................... 13

3.3.1 Ethernet/IP errors ......................................................................................................... 13

3.3.2 Profibus errors............................................................................................................... 13

4 Reference ...................................................................................................................................... 14

4.1 Operation details and timing................................................................................................. 14

4.2 EtherNet/IP CIP Object Classes ............................................................................................. 15

4.2.1 Identity Object Class (Class code 0x01)......................................................................... 15

4.2.2 Message Router Object Class (Class code 0x02) ........................................................... 16

4.2.3 Assembly Object Class (Class code 0x04) ...................................................................... 16

4.2.4 Connection Manager Object Class (Class code 0x06).................................................... 16

4.2.5 TCP/IP Object Class (Class code 0xF5) ........................................................................... 16

4.2.6 Ethernet Link Object Class (Class code 0xF6) ................................................................ 16

4.3 Firmware update ................................................................................................................... 16