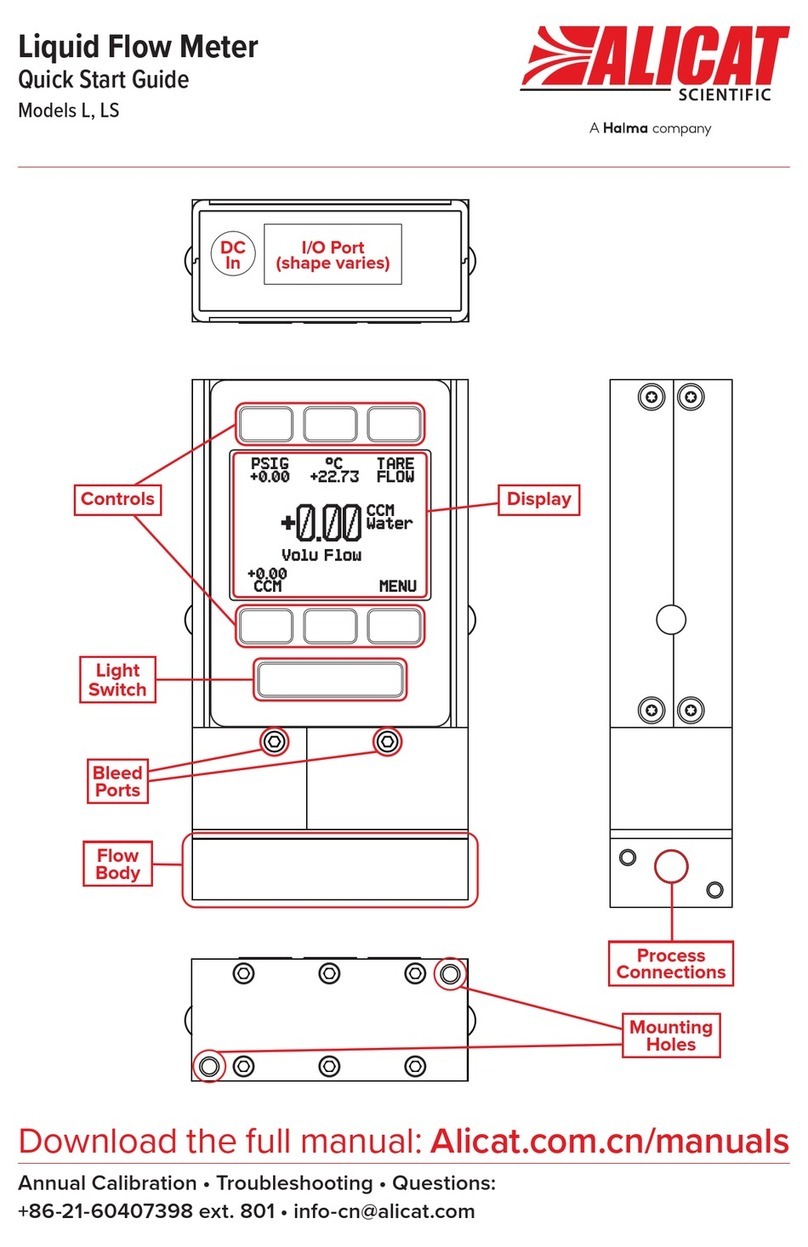

6 Getting Started

Gas Connections

downstream.

Devices ship with plastic plugs seated in the processing ports. To decrease the chance of

the device.

After removing the plugs, immediately connect the device to upstream and downstream

for connections include NPT, SAE, BSPP, and VCR®

have male connections).

prevent leakage around the port threads, but

Pipe dopes or sealants are not recommended on the process connections.

These compounds can cause permanent damage to the controller should they get into

the ow stream.

Maximum Pressure

The maximum common mode pressure is PSIA. Common mode pressure is the

maximum pressure that may be applied simultaneously to both sides of the instrument

without causing damage.

!

Using the ow controller above the maximum specied common pressure

will permanently damage the internal pressure sensors. If the line pressure is above

these limits, use a pressure regulator upstream of the device to reduce the pressure

below 200 PSIA.

Maximum Flow

Commanding a non-zero setpoint prior to applying the pressure will cause the valve to be

fully open and will expose the sensor to any instantaneous changes in pressure, such as

from a snap-acting solenoid valve. For meters and controllers with downstream valves,

pressure.

Power and Signal Connections

Power is supplied to the controller through the DB9 connector on the top of the device.

The table below indicates how to connect the device to power and communication. If your

found at alicat.com/pinouts.

!

Do not power the device until all necessary pins have been properly

connected.

!

Only connect power to pin 7. Connecting power to other pins can permanently

damage the device.

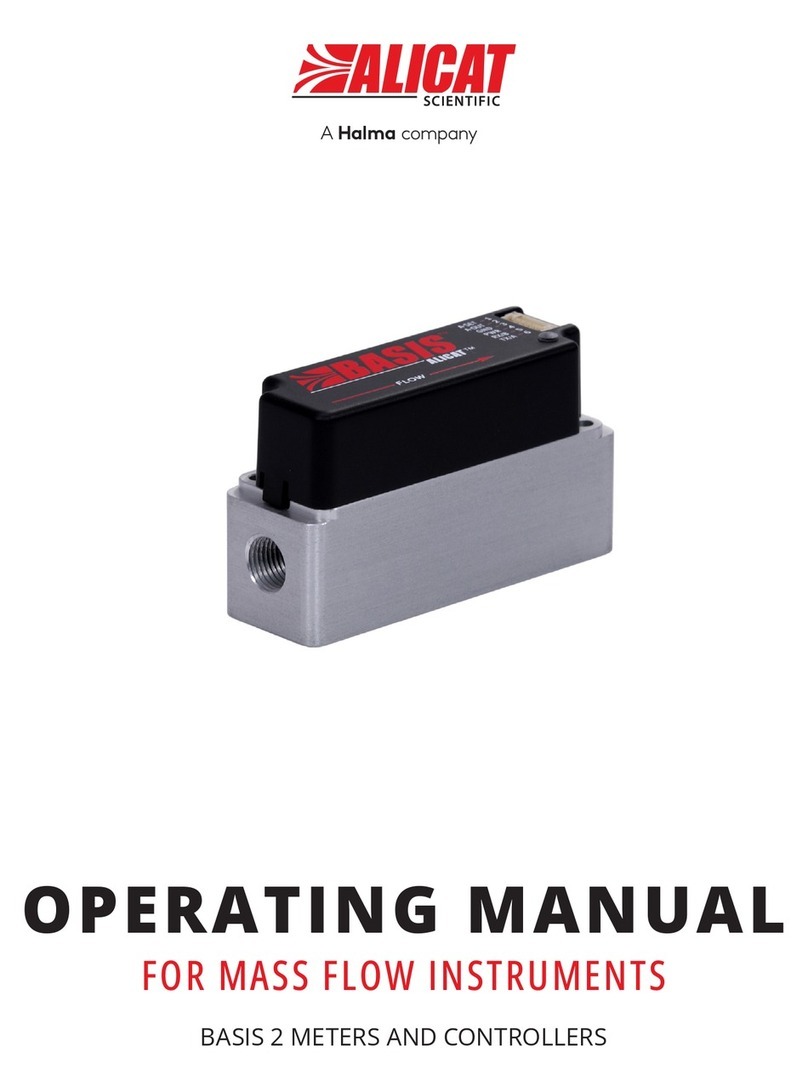

A mass flow controller with male

VCR®-compatible connections.