14 15

At Haltech we make every eort to design and

manufacture fault-free products that perform up to

or above the market expectations. All our products

are covered by a Limited 12 Month Warranty.

Haltech Limited Warranty

Unless specied otherwise, Haltech warrants its products

to be free from defects in material or workmanship for a

period of 12 months from the date of purchase.

If the Haltech product is found to be defective as men-

tioned above, it will be replaced or repaired if returned

prepaid along with proof of purchase. Proof of purchase

in the form of a copy of the original purchase invoice,

receipt or bill of sale which indicates that the product is

within the warranty period, must be presented to obtain

warranty service.

Replacement or repair of a defective product shall con-

stitute the sole liability of Haltech. To the extent permitted

by law, the foregoing is exclusive and in lieu of all other

warranties or representations, either expressed or im-

plied, including any implied warranty of merchantability

or tness. In no event shall Haltech, be liable for special

or consequential damages.

Product Returns

Please include a copy of the original purchase invoice,

receipt or bill of sale along with the unused, undamaged

product and its original packaging. Any product returned

with missing accessory items or packaging will incur ex-

tra charges to return the item to a re-saleable condition.

All product returns must be sent via a freight method

with adequate tracking, insurance and proof of delivery

services. Haltech will not be held responsible for product

returns lost during transit.

Returns of Products Supplied in Sealed

Packaging

The sale of any sensor or accessory supplied in sealed

packaging is strictly non-refundable if the sealed pack-

aging has been opened or tampered with. This will be

clearly noted on the product packaging. If you do not ac-

cept these terms please return the sensor in its original

unopened packaging within 30 days for a full refund.

A sensor or accessory product may be returned after 30

days of purchase (with its sealed packaging intact) for

credit only (no refunds given) and will be subject to a 10%

restocking fee.

Installation of Haltech Products

No responsibility whatsoever is accepted by Haltech for

the tment of Haltech Products. The onus is clearly on

the installer to ensure that both their knowledge and the

parts selected are correct for that particular application.

Any damage to parts or consequential damage or costs

resulting from the incorrect installation of Haltech prod-

ucts are totally the responsibility of the installer.

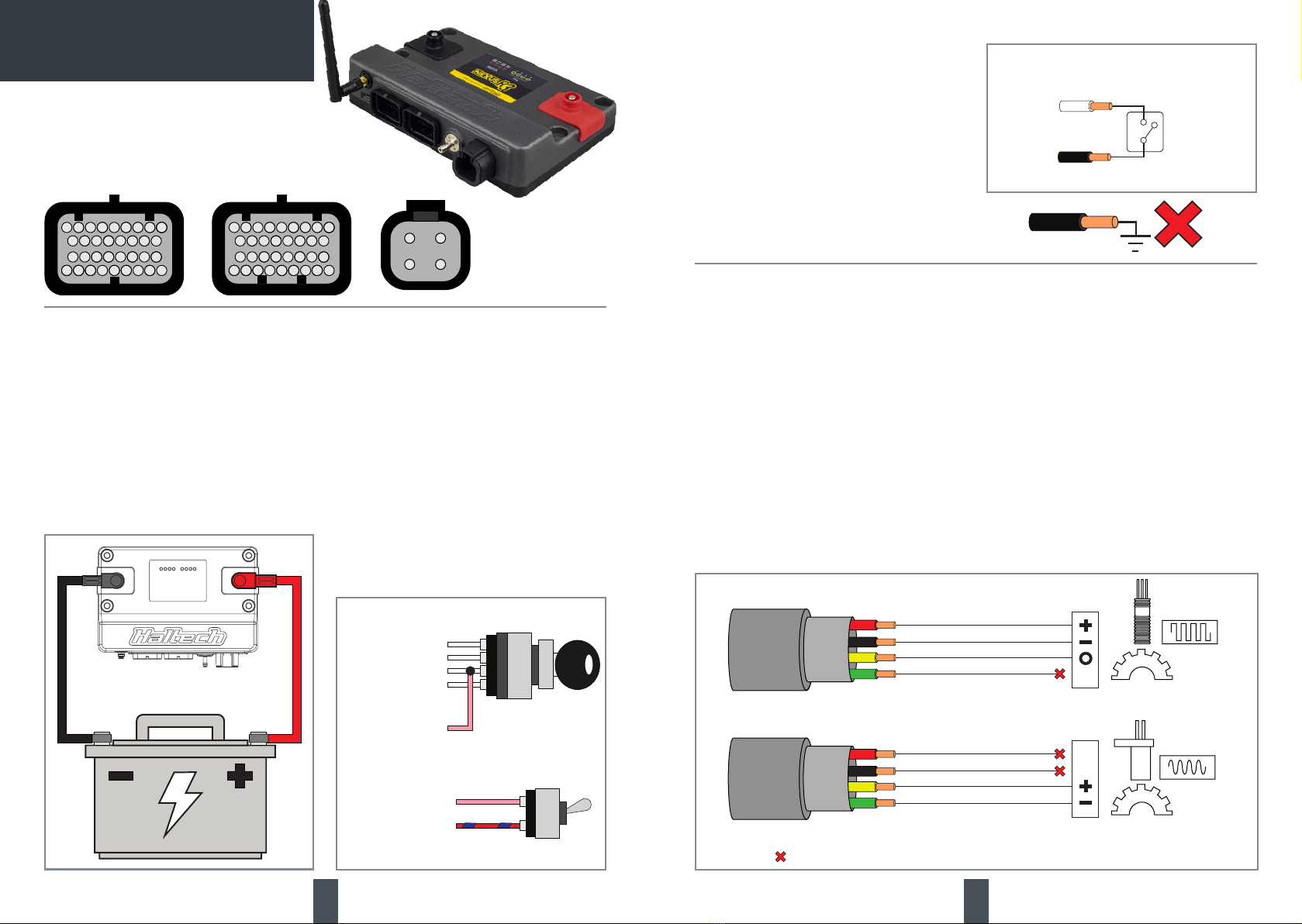

Always disconnect the battery when doing electrical

work on your vehicle. Avoid sparks, open ames or use

of electrical devices near ammable substances. Do not

run the engine with a battery charger connected as this

could damage the ECU and other electrical equipment.

Do not overcharge the battery or reverse the polarity of

the battery or any charging unit. Disconnect the Haltech

ECU from the electrical system whenever doing any

welding on the vehicle by unplugging the wiring harness

connector from the ECU.

After completing the ECU installation, make sure there is

no wiring left un-insulated. Uninsulated wiring can cause

sparks, short circuits and in some cases re. Before at-

tempting to run the engine ensure there are no leaks in

the fuel system.

All fuel system components and wiring should be mount-

ed away from heat sources, shielded if necessary and

well ventilated. Always ensure that you follow work-

shop safety procedures. If you’re working underneath a

jacked-up car, always use safety stands!

_____________________________________________

Haltech O-Road Usage Policy

In many states it is unlawful to tamper with your vehicle’s

emissions equipment. Haltech products are designed

and sold for sanctioned o-road/competition non-emis-

sions controlled vehicles only and may never be used on

a public road or highway.

Using Haltech products for street/road use on public

roads or highways is prohibited by law unless a specif-

ic regulatory exemption exists (more information can be

found on the SEMA Action Network website www.sema-

san.com/emissions for state by state details in the USA).

It is the responsibility of the installer and/or user of this

product to ensure compliance with all applicable local

and federal laws and regulations. Please check with your

local vehicle authority before purchasing, using or install-

ing any Haltech product.

WARRANTY CERTIFICATE

WIRING NOTES

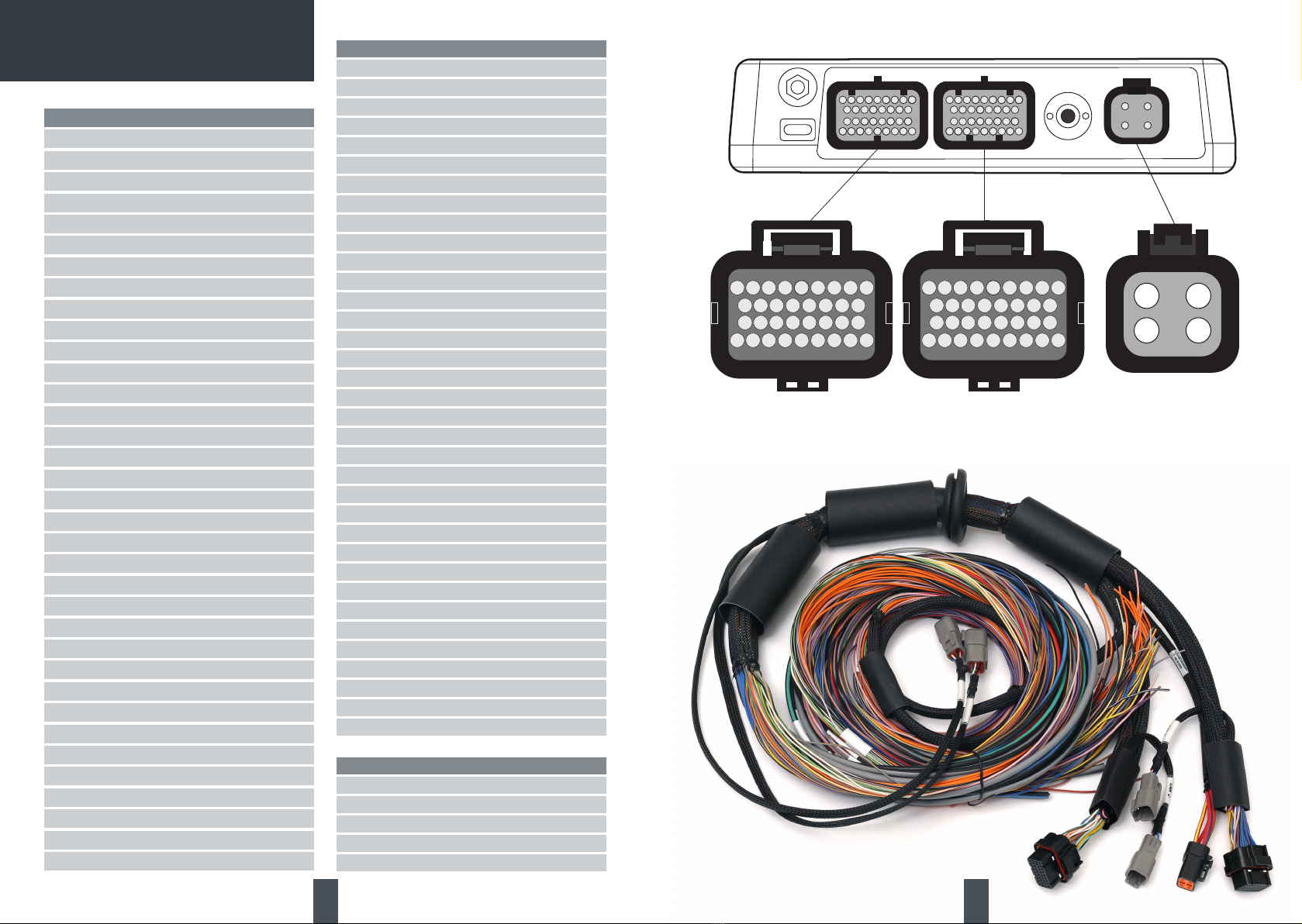

CONNECTOR A

Pin Function Colour Notes

A1 INJ 1 Blue _______________

A2 INJ 2 Blue/Black _______________

A3 INJ 3 Blue/Brown _______________

A4 INJ 4 Blue/Red _______________

A5 INJ 5 Blue/Orange _______________

A6 INJ 6 Blue/Yellow _______________

A7 INJ 7 Blue/Green _______________

A8 INJ 8 Blue/Violet _______________

A9 DPO 1 Violet/Black _______________

A10 PGND OUT Black _______________

A11 PGND OUT Black _______________

A12 DPO 2 Violet/Brown _______________

A13 IGN SW IN Pink _______________

A14 DPO 3 Violet/Red _______________

A15 DPO 4 Violet/Orange _______________

A16 DPO 5 Violet/Yellow _______________

A17 DPO 6 Violet/Green _______________

A18 HBO5 (12V) Pink/Red _______________

A19 HBO 1 Brown/Black _______________

A20 HBO 2 Brown/Red _______________

A21 HBO 3 Brown/Green _______________

A22 HBO 4 Brown/Pink _______________

A23 CAN1H White _______________

A24 CAN1L Blue _______________

A25 HBO6(12V) Pink/Brown _______________

A26 +12V LOW Red/Blue _______________

A27 IGN 1 Yellow/Black _______________

A28 IGN 2 Yellow/Red _______________

A29 IGN 3 Yellow/Orange _______________

A30 IGN 4 Yellow/Green _______________

A31 IGN 5 Yellow/Brown _______________

A32 IGN 6 Yellow/Blue _______________

A33 IGN 7 Yellow/Violet _______________

A34 IGN 8 Yellow/Gray _______________

Notes:

CONNECTOR C

Pin Function Colour Notes

C1 TRIG+ Yellow ______________

C2 TRIG - Green ______________

C3 HOME + Yellow ______________

C4 HOME - Green ______________

C5 SPI 1 Gray/Brown ______________

C6 SPI 2 Gray/Red ______________

C7 SPI 3 Gray/Orange ______________

C8 SPI 4 Gray/Yellow ______________

C9 +8V Orange/White ______________

C10 AVI 1 White ______________

C11 AVI 2 White/Yellow ______________

C12 AVI 3 White/Gray ______________

C13 AVI 4 White/Violet ______________

C14 AVI 5 White/Green ______________

C15 AVI 6 White/Orange ______________

C16 AVI 7 White/Black ______________

C17 AVI 8 White/Brown ______________

C18 AVI 9 White/Red ______________

C19 SPI 5 Gray/Pink ______________

C20 SPI 6 Gray/L.Green ______________

C21 CAN2H White ______________

C22 CAN2L Blue ______________

C23 Knock 1 Black/Blue ______________

C24 Knock 2 Black/Green ______________

C25 +5V Orange ______________

C26 SGND A Black/White ______________

C27 AVI 10 L.Green ______________

C28 AVI 11 L.Green/Black ______________

C29 WB Heater+ Gray ______________

C30 WB Input Yellow ______________

C31 WB Pump Red ______________

C32 WB Nernst Black ______________

C33 WB Heater- White ______________

C34 WB Cal Green ______________

Notes:

CONNECTOR E

Pin Function Colour Notes

E1 INJ 12V Red/Blue ______________

E2 IGN 12V Red/Yellow ______________

E3 25A-HCO 3 Red/Orange ______________

E4 25A-HCO 4 Red/Green ______________

Notes: