Operation Manual

4

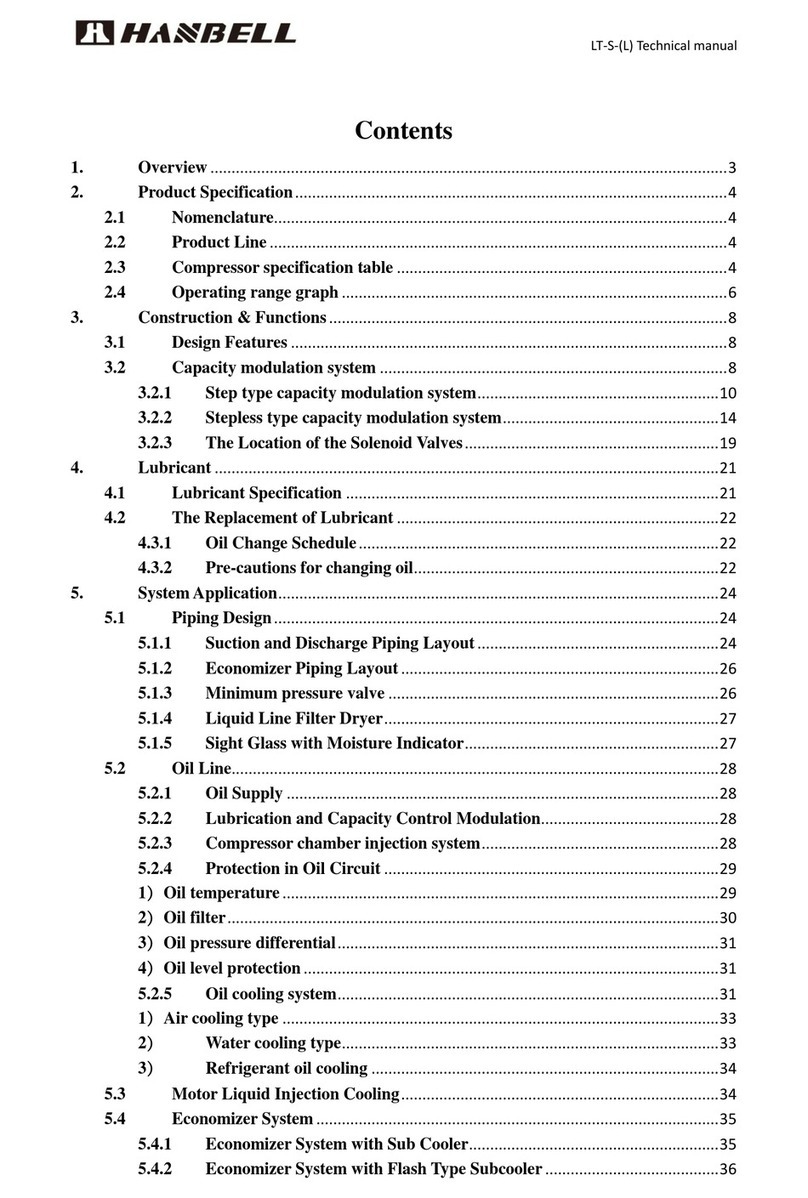

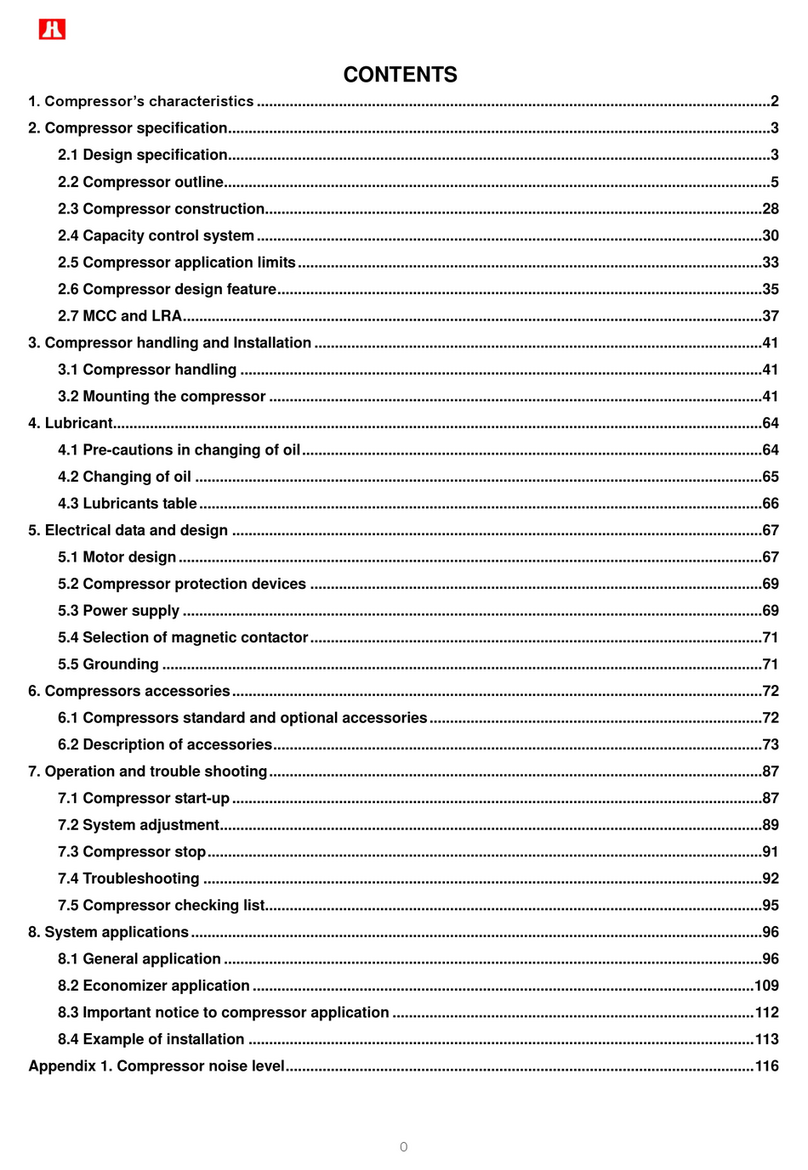

CONTENT

1. General provisions..................................................................................................................................... 5

1.1 Models................................................................................................................................................ 5

1.2 Identification....................................................................................................................................... 5

1.3 Precautions in using............................................................................................................................ 5

1.4 Use the compressor properly.............................................................................................................. 7

1.5 Sale and after service.......................................................................................................................... 7

2. Safety........................................................................................................................................................... 8

2.1 Employee qualification and training .................................................................................................. 8

2.2 Safety Instructions.............................................................................................................................. 8

2.3 Safety instructions for operation ........................................................................................................ 8

2.4 Safety instructions for maintenance, repair and assembly ................................................................. 8

3. Description of scroll compressor and spare parts...................................................................................... 10

3.1 Description of scroll compressor...................................................................................................... 10

3.2 Scroll air end structure ..................................................................................................................... 10

3.3 Scroll air end operating..................................................................................................................... 10

3.4 Oil-free scroll air end technical data ................................................................................................ 11

4. Direction for installation............................................................................................................................ 12

4.1 Power supply.................................................................................................................................... 12

4.2 Installation place .............................................................................................................................. 12

4.3 Cautions for user.............................................................................................................................. 12

4.4 Preparation before operation ............................................................................................................ 12

4.5 Control system.................................................................................................................................. 13

4.6 Maintenance..................................................................................................................................... 14

4.7 Trouble shutting................................................................................................................................. 17

5. Exemption and Statement.......................................................................................................................... 19

Appendix 1 Maintenance and replacement diagram for scroll compressor..................................................... 20

.