Crane Terms

Anchor Bolts: Large steel bolts used to mount a base mounted pillar jib crane to the H.S.I. recommended foun-

dation.

Boom: The horizontal beam on which the hoist trolley travels.

Fitting Centers: The distance, centerline to centerline, between two support brackets (fittings) of a wall mounted

jib crane.

Capacity: The maximum live weight that the crane is designed to support.

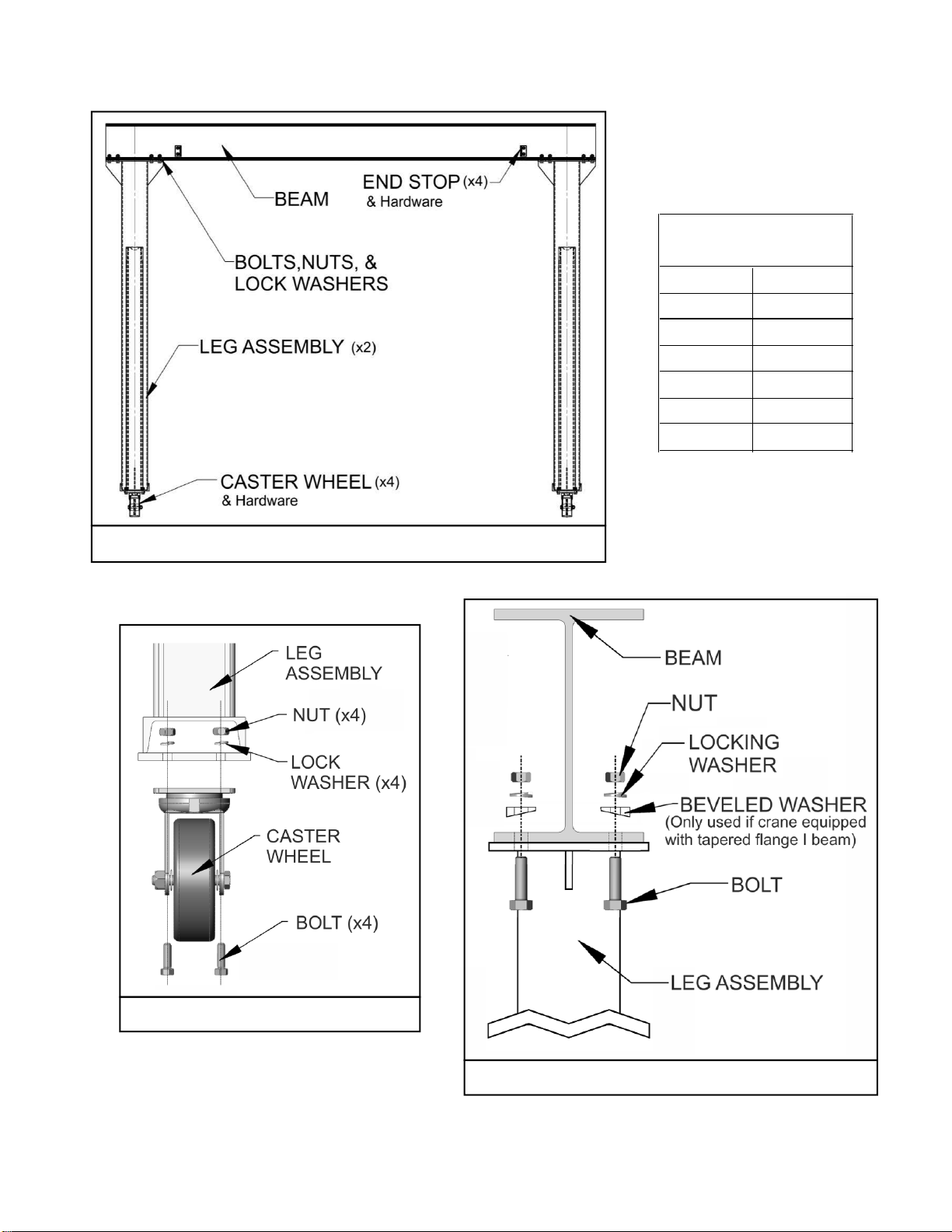

End Stops: Bolted to each end of the boom to prevent the trolley from falling off of the beam.

Foundation: For free standing pillar base mounted jibs. Foundations are used to support the jib and prevent it

from tipping over.

Gussets: Reinforcing plates used to stiffen mast at the base plate.

Head: Houses the roller, and lowers the crushing forces that are imposed on the mast.

Height Under the Boom (H.U.B.): The distance from the finished floor to the underside of the crane boom. To

find the under- boom, take the height of the load, plus the distance the load is lifted, plus the headroom require-

ments of the hoist/trolley and any attachments. Extra room aside from mandatory room needed could be helpful.

Mast: The vertical member of the jib, which supports the crane. Pillar jibs have round pipes as masts.

Overall Height: The highest point of the jib crane (including any hardware). A minimum clearance (usually 3”) is

required from any overhead obstruction.

Hoist: The actual lifting mechanism (powered by electric, air, or manual movement) that hangs from the trolley

that rides on the boom of a jib crane.

Trolley: The mechanism that travels back and forth on the crane boom (powered by electric, air, or manual

movement) which the hoist hangs from.

Overturning Moment: The overturning moment is the force applied to the mounting structure of a sefl-support-

ing pillar jib. This load is created by suspending a load from the boom, and is greatest at full load, at the very end

of the boom.

Rotation Stops: Limits the rotation of a pillar base mounted jib crane boom (which are standard at 360°). Stops

are field welded to the mast.

Span: The span for a pillar base mounted jib crane is the distance from the center of the mast to the end of the

boom. The span for a column mounted crane is measured from the face of the mounting surface to the end of the

boom. The span for a mast type jib crane is measured from the center of the vertical mast to the end of the

boom.

Thrust and Pull: Thrust and Pull are forces applied to a wall/column mounted jib cranes support structure. Thrust

is the pushing force exerted on the structure, and pull is the tensile, or pulling force. Thrust and Pull are equal to

each other (but opposite in direction), and are given for maximum at full load at the end of the boom.

Clear Span: The measurement between the end stops on a crane boom.

Hook Travel: The distance that the hook on the hoist travels.

In order to better understand jib cranes, here are the commonly used terms that are used to specify and design jibs.

5