handtmann 09513 User manual

Operating manual

Spray ball

09513, 09514, 09515, 09516, 09517

BA_009500.03_EN

1 / 6 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-03-05

1General.............................................................................................................................................................1

2Safety Information............................................................................................................................................2

3Delivery, Completeness, Storage ......................................................................................................................3

4Installation, Operation, Maintenance ...............................................................................................................3

Pos: 1/ Tec hnis ch e D oku ment ati on/Ü ber sc hrift en/ 1./A llg em eines (1) @ 0\mod_1215179088562_20.docx@ 405@ 1 @ 1

1General

Pos: 2/ Tec hnis ch e D oku ment ati on/Ü ber sc hrift en/ 1.1/H er st eller @ 0\m od_ 1215 177521 296_2 0.doc x @ 340 @ 2@ 1

1.1 Manufacturer

Pos: 3/ Tec hnis ch e D oku ment ati on/A llg em eines /H erst ell er o hne EAC @ 1\mod_1445257230549_0.docx@ 9624@ @ 1

Albert Handtmann Armaturenfabrik GmbH & Co. KG

Arthur-Handtmann-Str. 11; D-88400 Biberach

Tel.: +49(0) 73 51/3 42-0; Fax: +49(0) 73 51/ 3 42-44 80

E-Mail: sales.fit[email protected]

Pos: 4/ Tec hnis ch e D oku ment ati on/Ü ber sc hrift en/ 1.1/ B esti mmung sg em äße V er wen dung @ 0\mod_1215178267453_20.docx @ 380@ 2 @ 1

1.2 Proper application

Pos: 5/ Tec hnis ch e D oku ment ati on/A llg em eines /Ver w end ung/ Ver wend ung Spü hkop f @ 4\mod_1551773505710_20.docx@ 34592@ @ 1

Spray balls are used in the food, beverage, pharmaceutical, and chemical industries for the

cleaning of closed systems (vessels, tanks). The systems are cleaned with special cleaning

media, in general within the CIP process.

During installation, operation and maintenance please pay attention to the generally

accepted safety regulations as well as to the operating instructions.

Pos: 6.1 /T ec hnis che D o ku ment ation /Üb ers chr ifte n/1. 1/Mi ss bra uch @ 0\mod_1215178306406_20.docx@ 385 @ 2@ 1

1.3 Misuse

Pos: 6.2 /T ec hnis che D o ku ment ation /All ge mei nes/M iss bra uc h @ 0\mod_1215416013278_20.docx@ 470@ @ 1

Misuse is:

•Application in different operating conditions as intended for the specific type.

•Installation, operation and maintenance by unqualified staff.

•Any unauthorized modification of the valve or a valve component.

•On-observance of the operating instructions.

Any misuse will automatically lead to a loss of right to claim under guarantee as well as

any liability.

Pos: 6.3 /T ec hnis che D o ku ment ation /Üb ers chr ifte n/1. 1/ Sorg falt spfl ic ht @ 0\mod_1215178331000_20.docx@ 390@ 2 @ 1

1.4 Duties of operator

Pos: 6.4 /T ec hnis che D o ku ment ation /All ge mei nes/ Sorg fal ts pflic ht @ 0\mod_1215416250763_20.docx@ 475 @ @1

The operator has to make sure that:

•The valve/component is operated properly and only in functional condition.

•The legal requirements are kept during operation and maintenance.

•Only sufficiently qualified and authorized staff maintain the valve/component.

•The staff responsible for operation and maintenance know and obey the

operating instructions and in particular the safety advice.

•The safety and warning signs remain on the valve/component and are

always legible.

Pos: 7/ Tec hnis ch e D oku ment ati on/Ü ber sc hrift en/ 1./S ic herh eit ( 2) @ 0\mod_1215179883656_20.docx@ 409 @ 1@ 1

Spray ball

09513, 09514, 09515, 09516, 09517

BA_009500.03_EN

2019-03-05 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2 / 6

2Safety Information

Pos: 8/ Tec hni sc he D o ku ment ati on/ Sic her hei tsi nfor m atio n/Hi nwei se und Sic herh eit/Hi nweis e und Sic her heit mit AN SI @ 3\mod_1485953336201_20.docx@ 18363@ @ 1

Notice and Safety

The following safety advice is an addition to existing national regulations and laws for

accident prevention. Existing regulations and laws for accident prevention always have to

be adhered to. Pay attention to the specific regulations and laws in your country.

The safety advice does not take into account:

•Coincidences and events that may occur during assembly, operation and

maintenance.

•Local safety regulations in responsibility of the operator.

Basic safety advice

Requirements for a proper function of the valve/component:

•Proper transportation and storage

•Installation and setting into operation by authorized staff

•Operation according to these operating instructions – proper application

•Proper and regular maintenance

WARNING

Warning – general dangers!

To avoid danger for health and life the following safety instructions

strictly have to be obeyed.

•Assembly and setting into operation only by qualified staff.

•Instruction and supervision by the operator.

•Keeping of technical and electrical data as specified in the operating instructions.

•Guarantee the electric safety of external devices.

•Keep legal regulations.

Non-observance may lead to the following dangers:

•Malfunction of the valve/component respectively of the plant.

•Danger for persons due to electrical, mechanical and chemical affects.

•Danger for the environment due to possible leakage of dangerous media.

Pos: 9.1 /T ec hnis che D o ku ment ation /Üb ers chr ifte n/1. /Li ef erung un d Leis tu ng, Lager ung (3) @ 0\mod_1215179940062_20.docx@ 440 @1 @ 1

Spray ball

09513, 09514, 09515, 09516, 09517

BA_009500.03_EN

3 / 6 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-03-05

3Delivery, Completeness, Storage

Pos: 9. 2/ Tec hnisch eD oku mentat ion/B etrie bsanl eitung en/ Liefer ung und L eist ung, Lag eru ng/Lief erung u nd Leis tung , Lager ung @ 0\mod_1215178430359_20.docx@ 316 @ @ 1

•Check the data of the delivery note for factual correctness and the material for

completeness. We regret that money cannot be refunded after purchase.

•Always check the material for transport damages. Possible damages have

to be informed immediately.

•Store the material in a dry place and if possible in its original packaging.

Pos:10/TechnischeDokumentation/Übers chr ift e n/1./ M ont age, Betr ie b, W art ung (4) @ 0\mod_1215179594328_20.docx@ 364@ 1 @ 1

4Installation, Operation, Maintenance

Pos: 11 /T ech nisc he D oku men tat ion/ Be trie bsa nlei tung en/M on tag e, Betri eb, Wart ung/M on tag e/0 950 0/Tec hni sch e D ate n Spr üh kop f @ 4\mod_1551775050996_20.docx@ 34601@ @ 1

Spray balls (static) are used for tank cleaning in the low-pressure range. Tank design and

possible tank internals determine the choice and the position of the spray ball. In

addition, the type and the level of contamination have to be taken into account.

The spray ball distributes the cleaning medium on the inside upper tank wall (see spray

circle Ø).

The tank wall is cleaned by the cleaning liquid flowing down from the tank top.

To guarantee a constant flow, the spray ball must have a minimum flow capacity. With

regard to one meter circumference of the tank and depending on the contamination level,

this capacity is approx. 25-35 l/min.

This results in the required quantity of cleaning media respectively the flow capacity of the

spray ball.

Spray balls are normally used with a cleaning-air-valve combination .

Spray ball

09513, 09514, 09515, 09516, 09517

BA_009500.03_EN

2019-03-05 Albert Handtmann Armaturenfabrik GmbH & Co. KG 4 / 6

Type 09513 - horizontal tank, perforation 180° to the top

DN capacity [m³/h] 1.5 - 2.0 bar Ø spray circle [m]

10 1.5 – 2.0 1.0

25 12 – 14 3.0

32 16 – 18 4.0

50 25 - 29 6.0

Type 09514 - horizontal tank, perforation 180° to the bottom

DN capacity [m³/h] 1.5 - 2.0 bar Ø spray circle [m]

25 13 – 15 3.0

32 17 – 19 4.0

50 23 - 27 6.0

Type 09515 - vertical tank, perforation 220° to the top/*240° for DN 10

DN capacity [m³/h] 1.5 - 2.0 bar Ø spray circle [m]

10* 3.0 – 3.5 1.0

25 15 – 17 3.0

32 22 – 25 4.5

50 30 - 35 6.0

65 56 – 64 10.0

Type 09516 - vertical tank, perforation 220° to the top

DN capacity [m³/h] 1.5 - 2.0 bar Ø spray circle [m]

50 43 - 50 10.0

Type 09517 - vertical tank, perforation 360°

DN capacity [m³/h] 1.5 - 2.0 bar Ø spray circle [m]

10 3 - 4 1.0

50 48 - 55 8.0

65 60 - 67 10.0

Pos: 12 /T echni sch eD okum entati on/Ü bersc hrift en/1. 1/Mon tagehi nweis e @ 0\mod_1215178399000_20.docx@ 395@ 2 @ 1

Spray ball

09513, 09514, 09515, 09516, 09517

BA_009500.03_EN

5 / 6 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2019-03-05

4.1 Assembly instructions

Pos: 13 /T ech nisc he D oku men tat ion/ Be trie bsa nlei tung en/M on tag e, Betri eb, Wart ung/M on tag e/0 950 0/M ontag e 09500 @ 4\mod_1551776480620_20.docx@ 34610@ @ 1

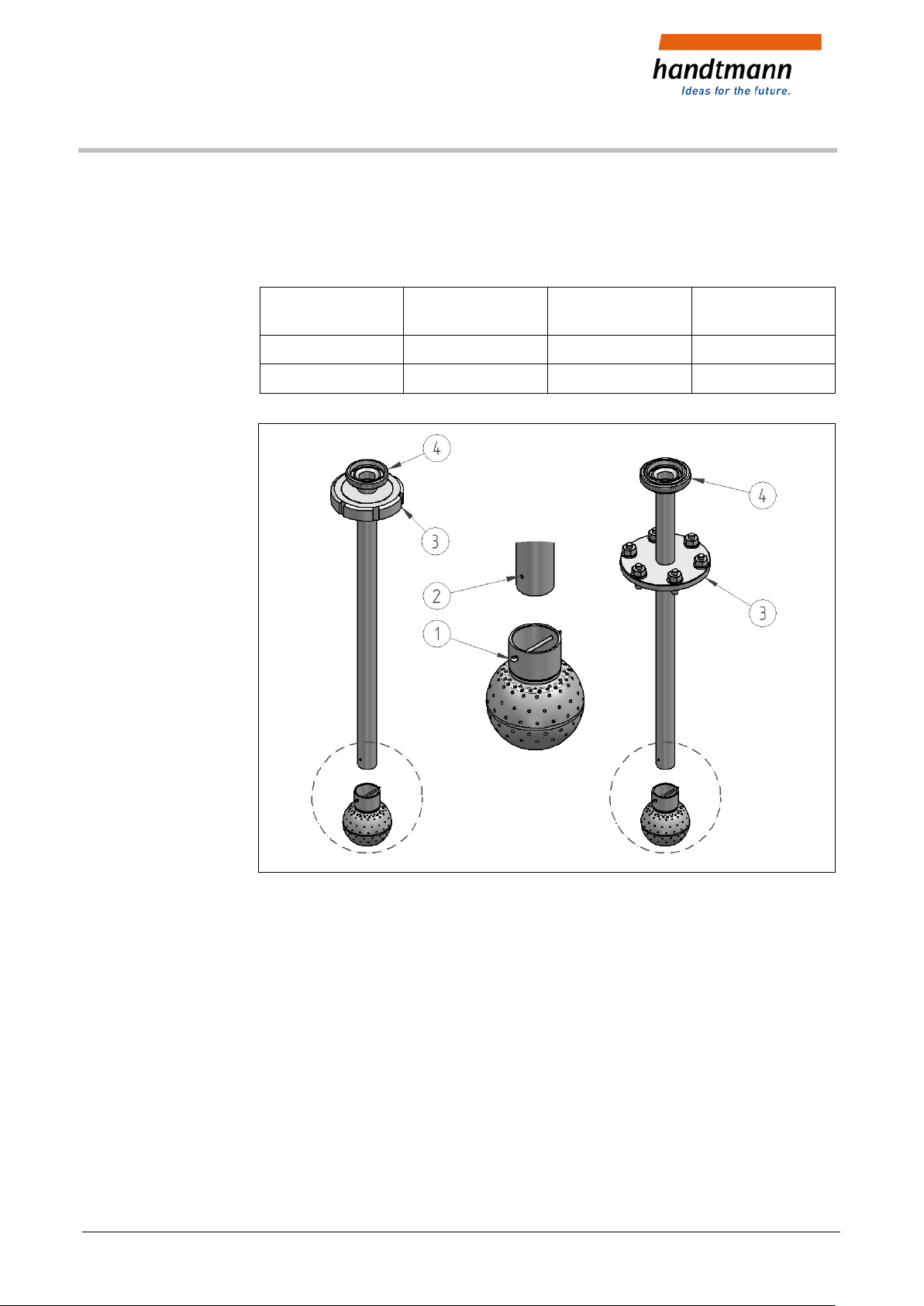

The spray ball will be connected with a split-pin to aspecial mounting tube. If necessary,

the complete unit (mounting tube and spray ball) can be dismounted.

Mounting tube Spray ball /DN DIN thread Flange connection

Dome cap

09601 25 - 50 x

09605 50 - 65 x x

1 Split-pin 2 Split-pin bore hole

3 Tank connection 4 CIP connection

Pos: 14 /T echni sch eD okum entati on/Ü bersc hrift en/1. 1/Betri ebshi nweis e @ 0\mod_1215178541671_20.docx@ 400 @ 2@ 1

Spray ball

09513, 09514, 09515, 09516, 09517

BA_009500.03_EN

2019-03-05 Albert Handtmann Armaturenfabrik GmbH & Co. KG 6 / 6

4.2 Operation

Pos: 15 /TechnischeDokumentation/Betriebsanleitungen/Montage,Betrieb, Wartung/Betrieb/09500/Betriebshinweise95000@ 4\mod_1551779581698_20.docx@ 34628@ @ 1

CIP:

•Tank diameter should be smaller than the spray circle diameter.

•Chose spray ball capacity from the table.

•Liquid pressure at the spray ball 1,5 - 2,0 bar.

•Cleaning time depending on contamination level.

•Cleaning temperatures acc. to operating conditions.

•Draining of the detergents has to be guaranteed.

WARNING

Warning – General dangers!

Splash hazard by caustic, acid and other media

– Do not open tank/vessel during CIP.

Pos: 16 /T echni sch eD okum entati on/Ü bersc hrift en/1. 1/War tungs hinwei se @ 0\mod_1215765605303_20.docx@ 653 @ 2 @ 1

4.3 Maintenance

Pos: 17 /T echnis che Do kumen tation/ Betr iebsanl eitu ngen/M ontag e, Betri eb, War tung/ Wartu ng/95 000/War tung 95 000 @ 4\mod_1551780417185_20.docx@ 34637@ @ 1

Basically, the spray balls are maintenance-free (material stainless steel)

CAUTION

Caution – damage to components!

However, due to mineral sediments or insufficient water quality, a reduction of the bore

hole cross sections is possible.

– Any maintenance only at depressurized system.

– Maintenance if necessary, at least once a year.

– During maintenance pay attention to the assembly and safety instructions.

=== En de der Lis te für T extmar ke Inhal t= ==

This manual suits for next models

4

Table of contents

Other handtmann Industrial Equipment manuals