5 Ver. 1.0

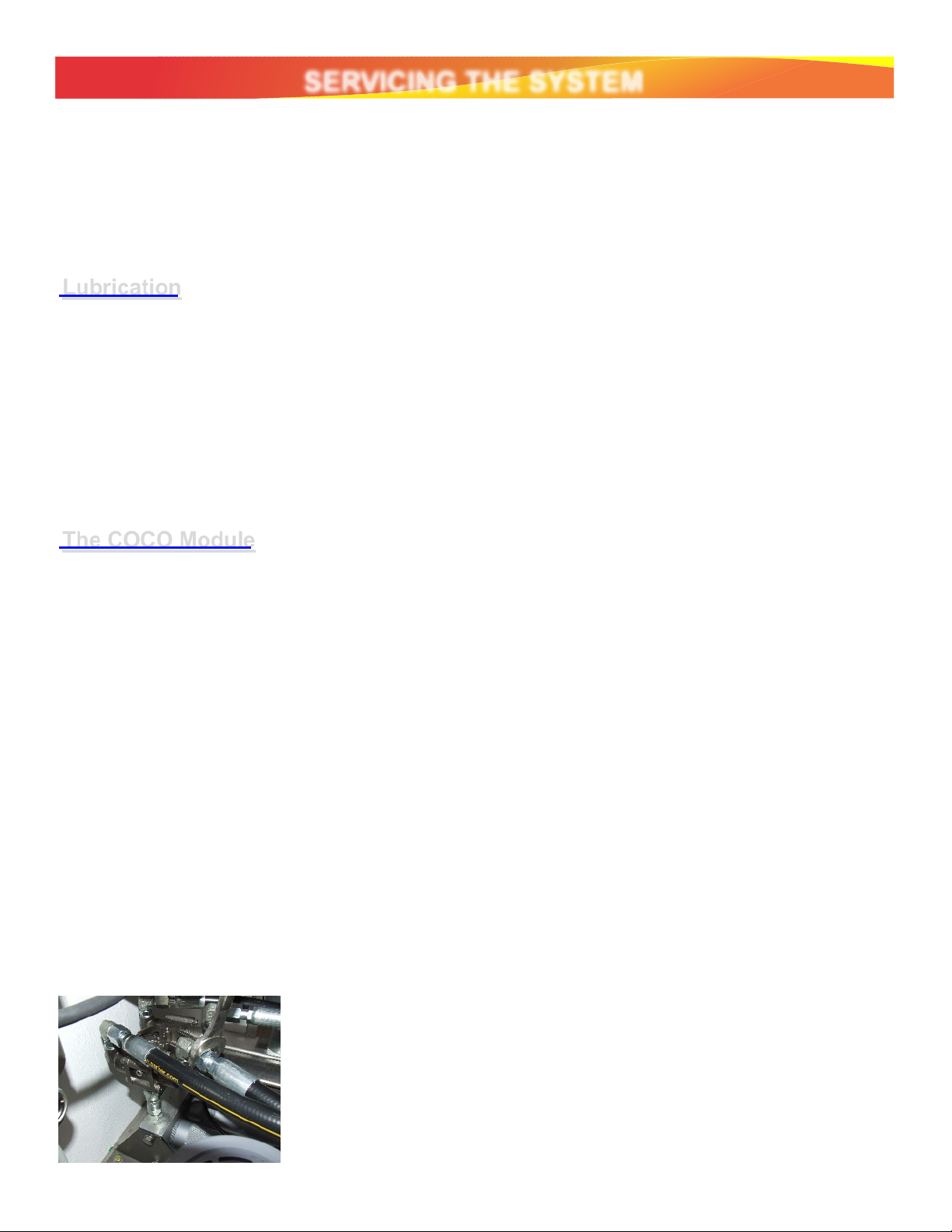

WARNING! The CD150 contains moving parts which are by definition wearing parts. Critical components are

wearing from the moment the system is energized. It is absolutely essential that this wear be anticipated and

monitored to assure proper ratio dispensing. Key personnel must become familiar with the following procedure

for monitoring the wear of metering seals, for if it does not become routine, improperly metered material will

result.

The frequency with which the performance of the seals should be checked varies with the abrasiveness of the

fillers within the product being dispensed, as well as the volume of resin being dispensed. Normally, once each

week of operation is sufficient to detect any ratio error before it becomes significant. However, if the results are

critical, monitoring should be more intense. The ratio check is a three step procedure.

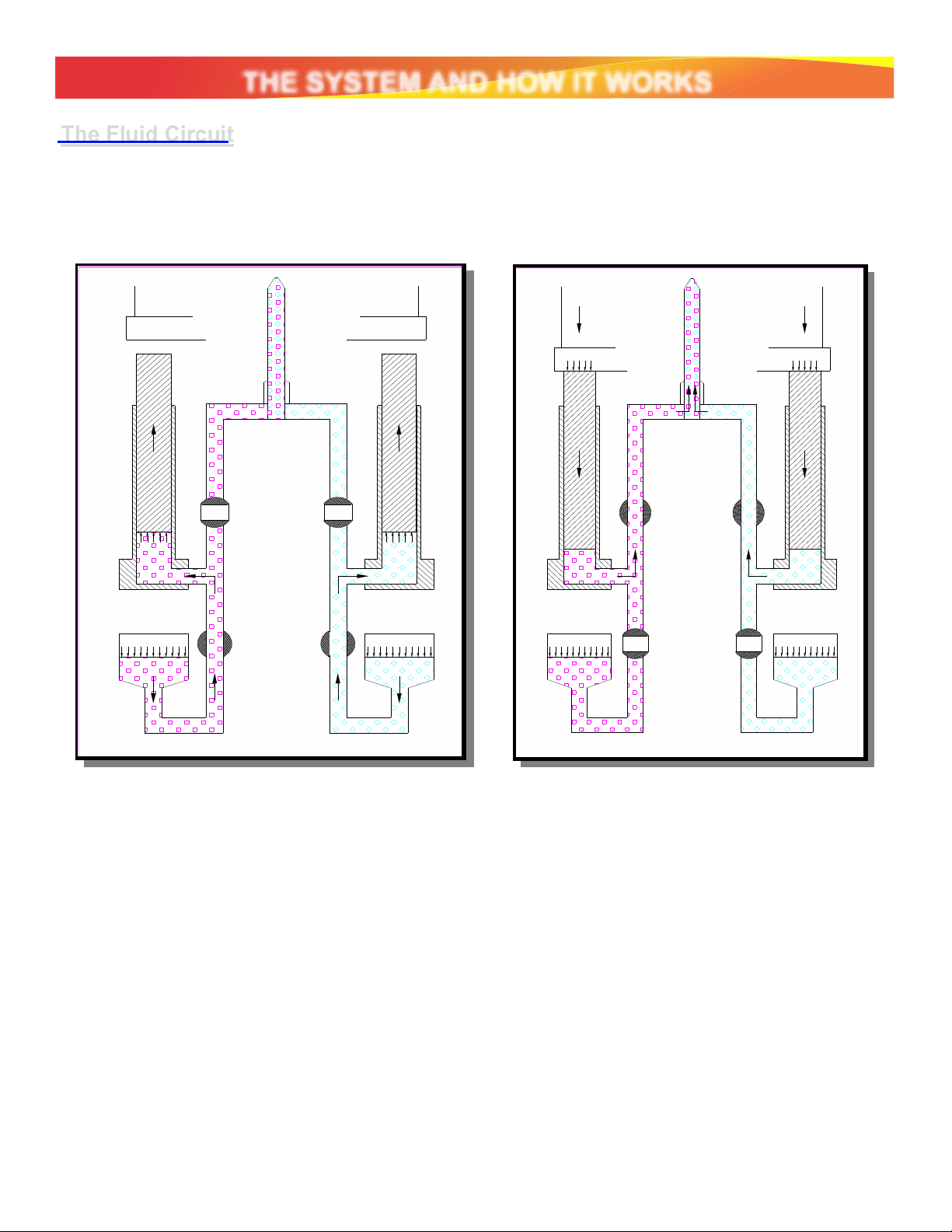

Stage I: To determine if the COCO outlet valve seals are leaking in the direction of normal flow.

1. With air connected to the dispenser, switch the dispenser “OFF”. (This will open the inlet valves

and close the outlet valves)

2. Energize the transfer system.

3. Remove the dispense hoses or static mixer from the outlet valves.

4. Wipe the outlet fittings and place a towel or rag beneath them.

5. Wait at least five minutes and observe the fittings for any indication of leakage.

6. If seepage has occurred, replace the leaking seals. ( This would indicate failure of the outlet valve

seals.)

7. If no seepage has occurred then move on to Stage II

8.

Stage II: To determine if the COCO inlet valve seals are leaking in the direction of normal flow.

1. Turn the pressure regulator counterclockwise until it stops.

2. Flip the dispenser switch to the “ON” position. ( This will open the outlet valves and close the inlet

valves)

3. Repeat steps 4 and 5 from Stage I.

4. If seepage has occurred replace the leaking seals. (This would indicate failure of the inlet valve

seals.)

5. If no seepage has occurred move to Stage III.

Stage III: To determine if the COCO inlet seals are leaking in the direction opposite of normal

flow.

1. Tightly cap the outlet fittings

2. De-energize the transfer system.

3. Disconnect the material supply hoses from the dispenser.

4. Turn the dispenser regulator knob clockwise to the maximum pressure available.

5. Wipe the inlet fittings clean and place a towel beneath them.

6. Wait at least five minutes and observe the fittings for any indication of leakage.

7. If seepage has occurred, replace the leaking seals. (This would indicate failure of the inlet seals.)

8. If no seepage has occurred, the ratio assurance check is complete.

Operation

Ratio Assurance Test