User's Manual of Fiber Laser Chiller

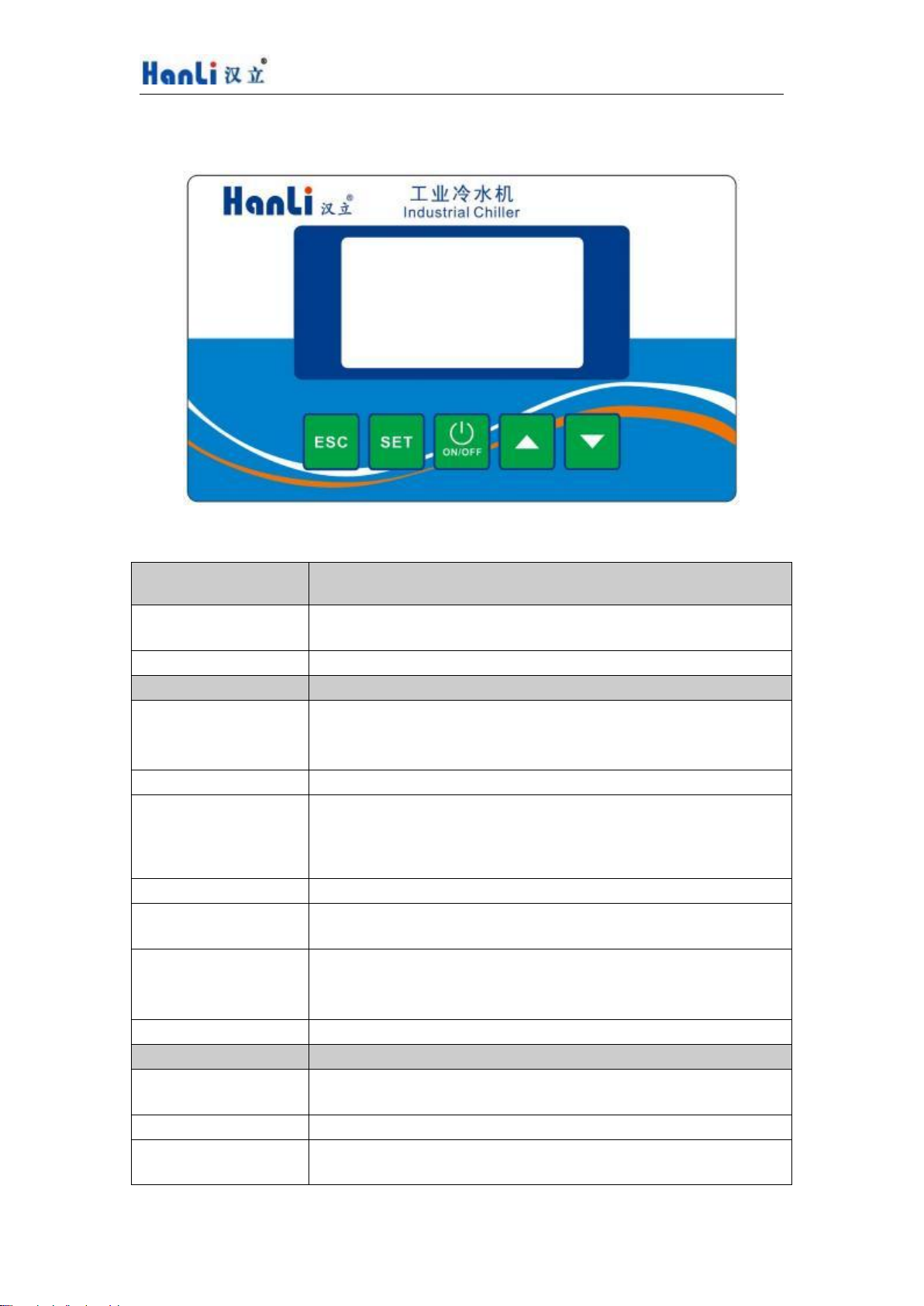

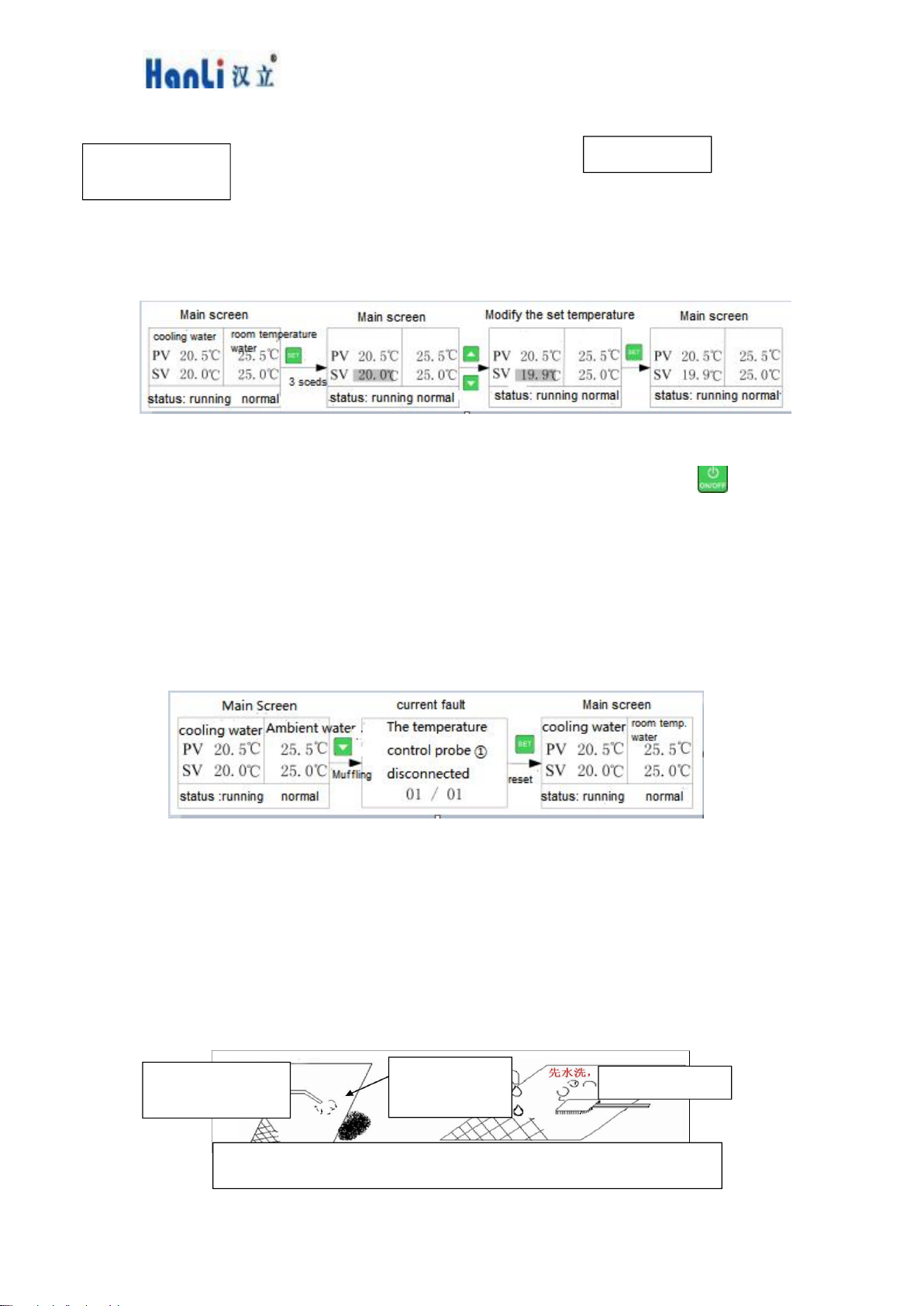

7.3 Power on display

When the split controller unit is powered up, the display shows the software version information

(Fxx/v100 /A00) and after approx. 7seconds it enters the temperature display.

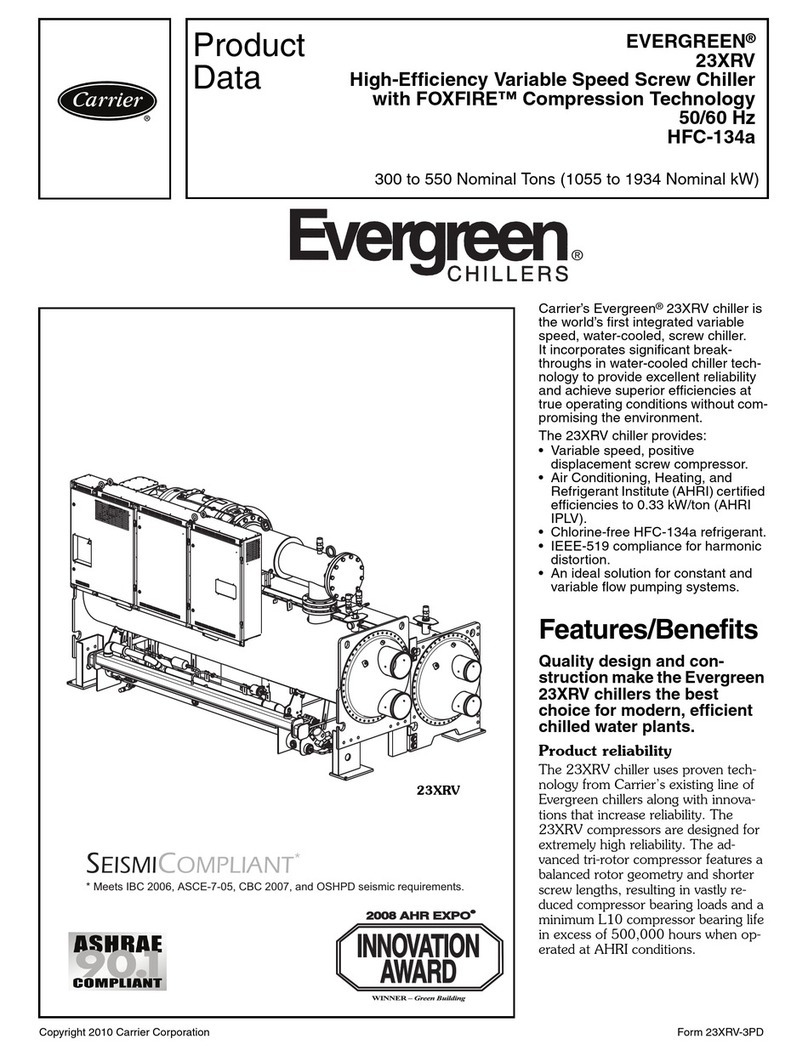

When the LCD controller is in the main interface, press for 3 seconds to switch on the

machine, the status bar of the main interface will show "Running" after switching on the machine;

press again for 3 seconds to switch off the machine, the main interface will show "Stop" after

switching off the machine.

7.4 Temperature display

7.4.1 Split controller temperature display

The display shows the measured water temperature (L.xx.x) for low temperature water by

default.

When the temperature is displayed, press <▼> to switch between the display of the measured

water temperature (H.xx.x), the set water temperature (S.xx.x) and the set temperature difference

(d.xx.x) for normal water, and return automatically after 30 seconds without switching.

Back to the low temperature water interface.

[Note]: L./H./S./d. is the temperature code, xx.x is the temperature value.

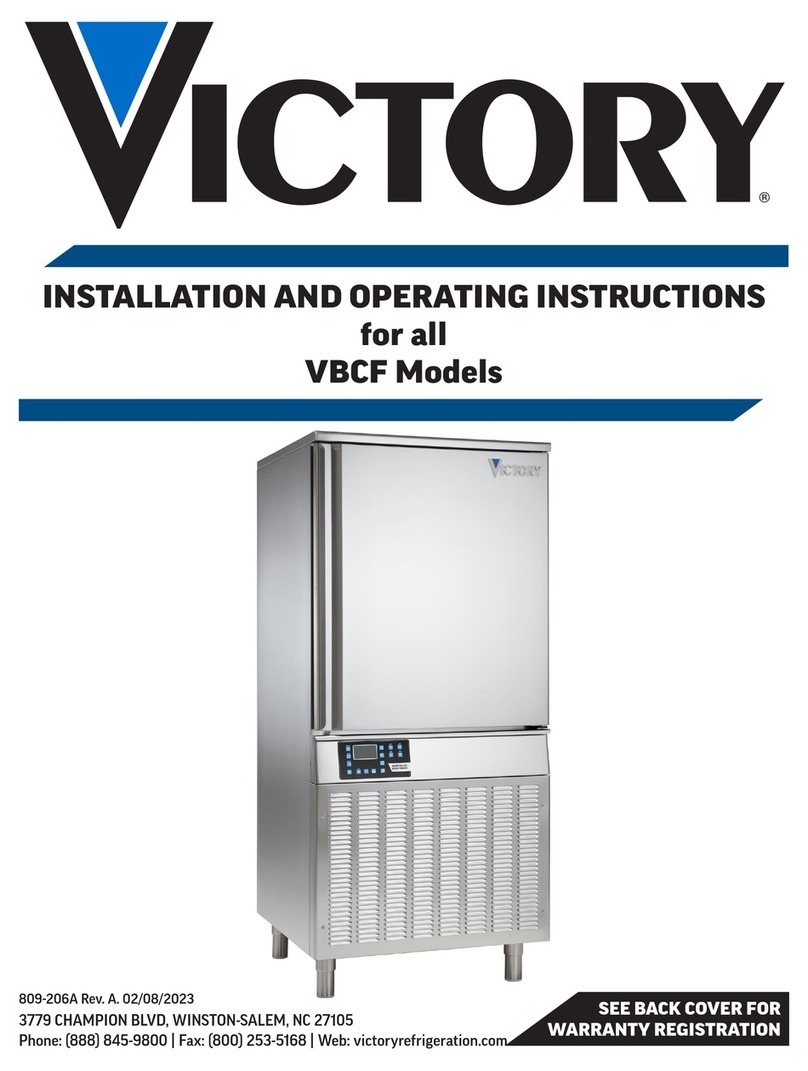

7.4.2 Integrated controller temperature display

The PV zone shows "actual temperature" and the SV zone shows "set temperature".

7.5 Parameter setting

7.5.1 Parameter setting of the split controller

In the non-fault state, press <▲>+<▼> at the same time to enter the low temperature water

setting temperature setting interface, the setting temperature xx.x is displayed flashing, at this time

the setting temperature can be modified by pressing <▲> or <▼> keys.

If no key operation is performed for 5 seconds after setting, the system will automatically save

the set value and exit the setting state.

Normal water set temperature = [Low temperature water set temperature] + [F01 Normal water

temperature difference], to change this ,you need to modify the factory parameter [F01 Normal

water temperature difference].

In the temperature display, press the <▲>+<▼> keys simultaneously for 5s to enter the

manufacturer's parameter setting status, the factory set parameters are generally not adjusted, if you

need to adjust, please seek the chiller manufacturer's agreement.

During the selection of the manufacturer's parameters, press <▼> to select the parameter item,

press <▲> to enter the parameter setting and exit the manufacturer's parameter setting after 15s of

operation without pressing the key (the display shows the parameter item).

For parameter setting, the parameter value can be modified by <▲> or <▼>, after 5S of

keyless operation or by pressing <▲>+< ▼> to return to the parameter selection and save (the

display flashes to show the parameter value).