4

ABBREVIATIONS AND EXPLANATIONS

Frequently used abbreviations in this manual include:

Factory-installed additional components are referred to as options

in this manual; factory-supplied but field-installed additional com-

ponents are referred to as accessories.

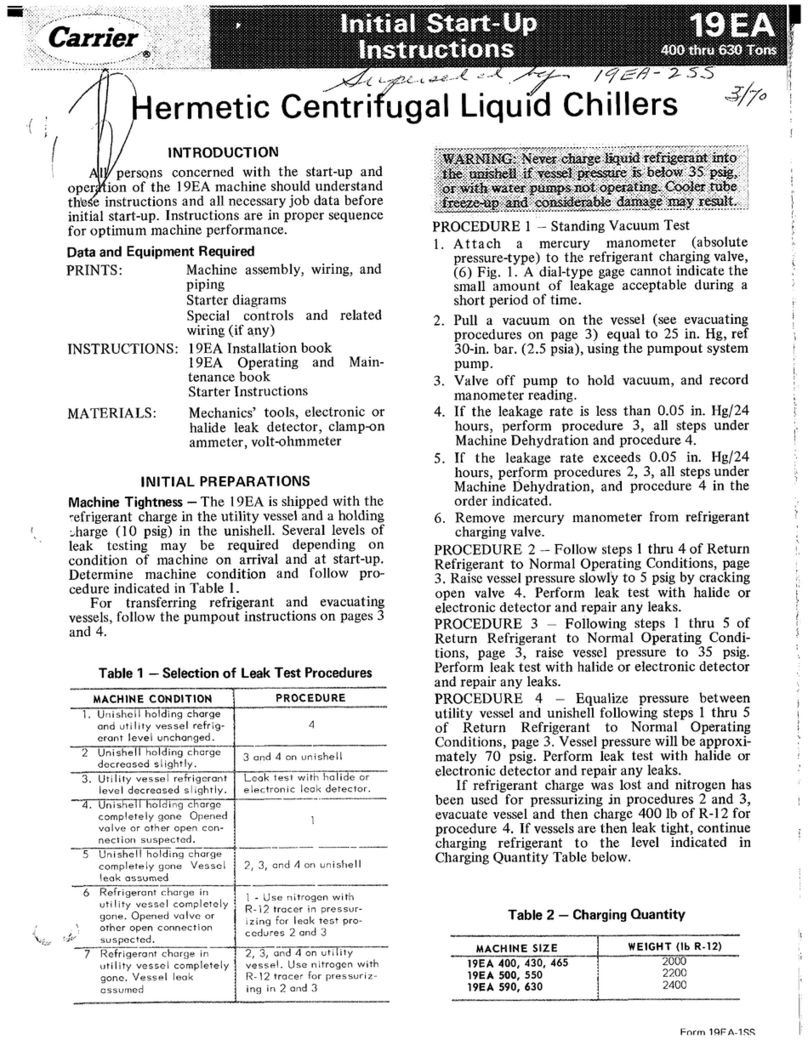

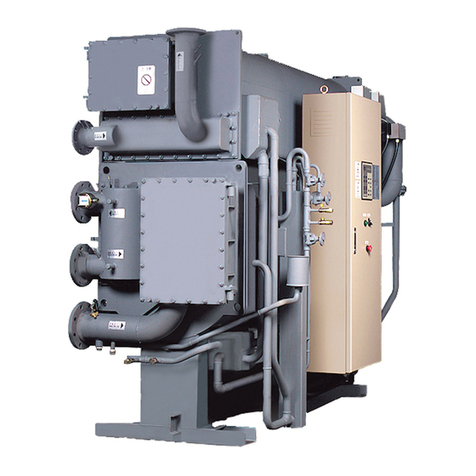

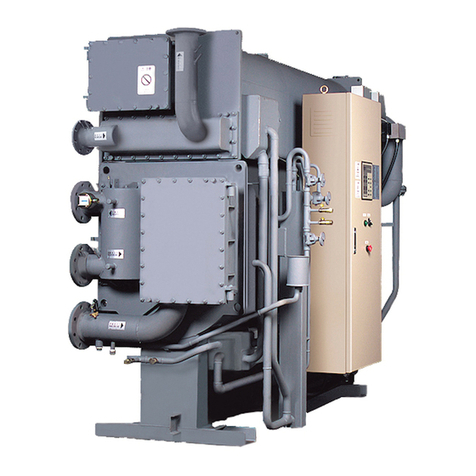

CHILLER FAMILIARIZATION (Fig. 1 and 2)

Chiller Information Nameplate

The information nameplate is located on the left side of the

chiller control panel.

System Components

The main components include the evaporator and condenser

heat exchangers in separate vessels, motor-compressor, refrig-

erant, lubrication package, control panels, PIC6 Touch Screen

HMI, economizer, VFD, and purge system.

Evaporator

This vessel is located underneath the compressor. The evapora-

tor is maintained at a lower temperature/pressure so evaporat-

ing refrigerant can remove heat from water flowing through its

internal tubes. Water flows through the internal tubes to pro-

vide comfort or process cooling.

Condenser

The condenser operates at a higher temperature/pressure than the

evaporator and has water flowing through its internal tubes in or-

der to remove heat from the refrigerant. It contains a metering de-

vice that regulates the flow of refrigerant into the economizer.

Economizer

This chamber reduces the refrigerant pressure to an intermediate

level between the evaporator and condenser vessels. In the econ-

omizer, vapor is separated from the liquid, the separated vapor

flows to the second stage of the compressor, and the liquid flows

into the evaporator. The energy removed from the vaporized re-

frigerant in the economizer allows the liquid refrigerant in the

evaporator to absorb more heat when it evaporates and benefits

the overall cooling efficiency cycle. It contains a float assembly

that regulates the flow of refrigerant into the evaporator.

Motor-Compressor

This component maintains system temperature and pressure

differences and moves the heat-carrying refrigerant from the

evaporator to the condenser. The 19DV utilizes a two-stage

back to back direct drive configuration.

Purge Unit

This is a small independent condensing unit with compressor, sep-

arator, regenerative carbon filters, heater and vacuum pump. The

purge extracts gas from condenser (or from compressor if unit is

not in operation) and purifies it by removing non-condensable

gases and any water vapor that may be present.

Variable Frequency Drive (VFD)

The VFD variable frequency is a voltage source design that

converts line voltage into PWM (pulse width modulating) mo-

tor input for motor speed and torque control.

Refrigerant Lubrication System

This system provides lubrication to the compressor bearing by

means of a refrigerant pump.

Chiller Control Panel

This control panel includes the input and output boards (IOBs),

control transformer, relays, contactors, and circuit breakers. It pro-

vides the power distribution and protection to the electrical com-

ponents installed on chiller and has the following functions:

• Communication with PIC6 touch screen

• Communication with purge panel

• Communication with VFD

• Sensor input and outputs

• Actuators control

• Refrigerant pump control

CAUTION

WHEN FLUSHING THE WATER SYSTEMS isolate the

chiller from the water circuits to prevent damage to the heat

exchanger tubes.

CAUTION

This unit uses a microprocessor control system. Do not

short or jumper between terminations on circuit boards or

modules; control or board failure may result.

Be aware of electrostatic discharge (static electricity) when

handling or making contact with circuit boards or module

connections. Always touch a chassis (grounded) part to

dissipate body electrostatic charge before working inside

control center or use a grounding strap before handling

printed circuit boards.

Use extreme care when handling tools near boards and when

connecting or disconnecting terminal plugs. Circuit boards can

easily be damaged. Always hold boards by the edges and

avoid touching components and connections.

This equipment uses, and can radiate, radio frequency ener-

gy. If not installed and used in accordance with the instruc-

tion manual, it may cause interference to radio communica-

tions. The PIC6 control boards have been tested and found to

comply with the limits for a Class A computing device pur-

suant to International Standard in North America EN 61000-

2/3 which are designed to provide reasonable protection

against such interference when operated in a commercial en-

vironment. Operation of this equipment in a residential area

is likely to cause interference, in which case the user, at his

own expense, will be required to take whatever measures

may be required to correct the interference.

Always store and transport replacement or defective boards

in anti-static shipping bag.

AWG — American Wire Gage

BMS — Building Management System

CCN — Carrier Comfort Network®

DCIB — Digital Control Interface Board

DVM — Digital Volt-Ohmmeter

EC — Envelope Control

ECDW — Entering Condenser Water

ECW — Entering Chilled Water

EMS — Energy Management System

HMI — Human Machine Interface

HVIB — High Voltage Interface Board

I/O — Input/Output

IGBT — Insulated-Gate Bipolar Transistor

IGV — Inlet Guide Vane

IOB — Input Output Board

LCDW — Leaving Condenser Water

LCW — Leaving Chilled Water

LED — Light-Emitting Diode

MAWP — Maximum Allowable Working Pressure

NSTV — Network Service Tool V

OLTA — Overload Trip Amps

PIC — Product Integrated Controls

PPE — Protective Personal Equipment

PWM — Pulse Width Modulating

RLA — Rated Load Amps

RMS — Root Mean Square

SCCR — Short Circuit Current Rating

SCR — Silicon Controlled Rectifier

SIOB — Starfire 2 Input Output Board

TXV — Thermostatic Expansion Valve

VFD — Variable Frequency Drive

VPF — Variable Primary Flow