Micatrone MF-PFTT Specification sheet

MF-PFTT

Instruction : mi-261gb_090212

NOTE !

Read the entire instruction carefully before start.

Application

MicaFlex PFTT is a pressure and flow transmitter

with built in PI-controller and a temperature input

which makes it possible to compensate flow mea-

surement for temperature changes.

MF-PFTT can be programmed to activate a purging

unit, MF-PU-2, for automatic cleaning of flow sen-

sors with compressed air on set intervals.

With the four key pad, ¹,¸,PGM and ESC,the de-

sired function is selected as well as setting and scal-

ing is done. The dual row LCD display clearly indi-

cates the selected function.

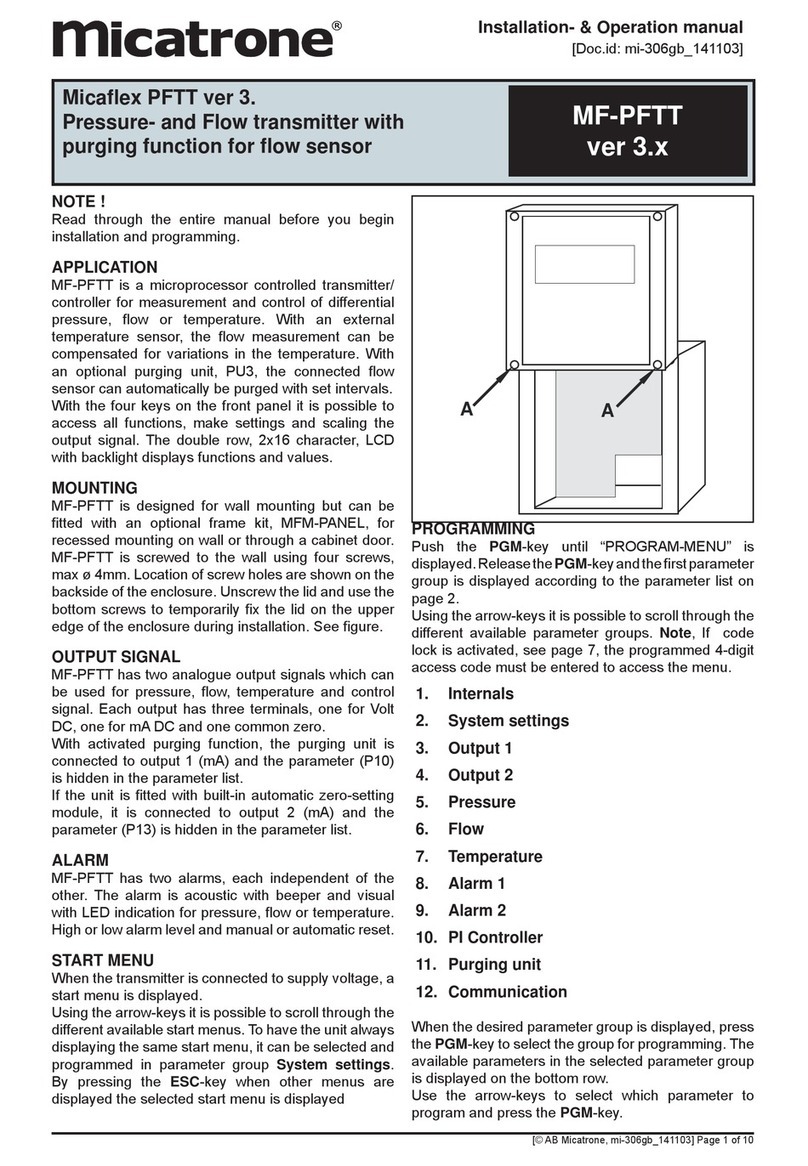

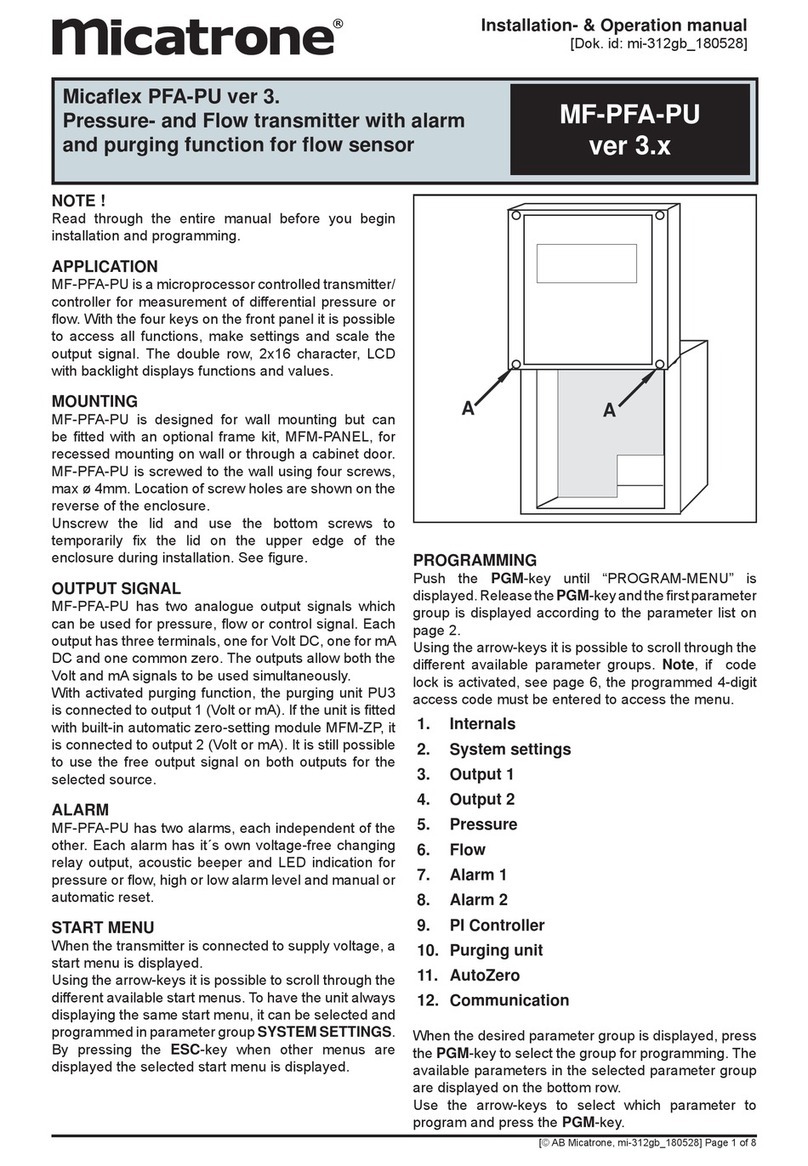

Installation

MF-PFTT is designed to be placed on a wall or for

recessed mounting through a wall or cabin door.

When recessed mounting, a mounting kit,

MFM-PANEL is used. The unit is fixed to the wall by

four screws, max 4 mm. The location of the holes is

shown at the back of the enclosure.

Unscrew the four screws of the front cover and use

the bottom screws to attach the front cover on the

upper end of the casing, see Fig 2. This makes in-

stallation and electrical connection easier.

Connect power supply according to the electrical

connection.

To each front cover the CPU is mounted, since the

I/O calibration of the main circuit board is stored on

the CPU-board, it is not possible to move the front

cover between different units.

Output signal

MF-PFTT has two analogue outputs to be used for

actual value of pressure and flow, temperature,

purging unit or PI-control output for pressure or flow.

VDC or mA output signal must be set by the

DIL-switch (DIL1). The same programming must

then also be done under “Outputs”.

Basic programming instruction

When the power supply is connected a start menu

will be displayed. With ¹¸ it is possible to scroll

through the different start menus. To always have

the same start menu, the selection is programmed

under “System settings”. Pressing ESC when some

other menu is displayed returns to the menu pro-

grammed under “Display”.

Programming

Press PGM until "PROGRAM-MENU" appears. Re-

lease the key and the display shows parameter

group, see table on page 2.

With ¹¸ it is possible to scroll through the parame-

ter groups.

1. Current values

2. System settings

3. Outputs

4. Pressure

5. Flow

6. Temperature

7. PI2 controller

8. Purging unit

9. Communication

10. Internals

When the parameter group to be programmed is

shown, press PGM. The parameters are then

shown, with ¹¸ select the parameter to be pro-

grammed and press PGM.

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

Programmable differential pressure transmitter

for pressure or flow measurement and control

with purging function for flow sensors.

®

Operating and installation manual

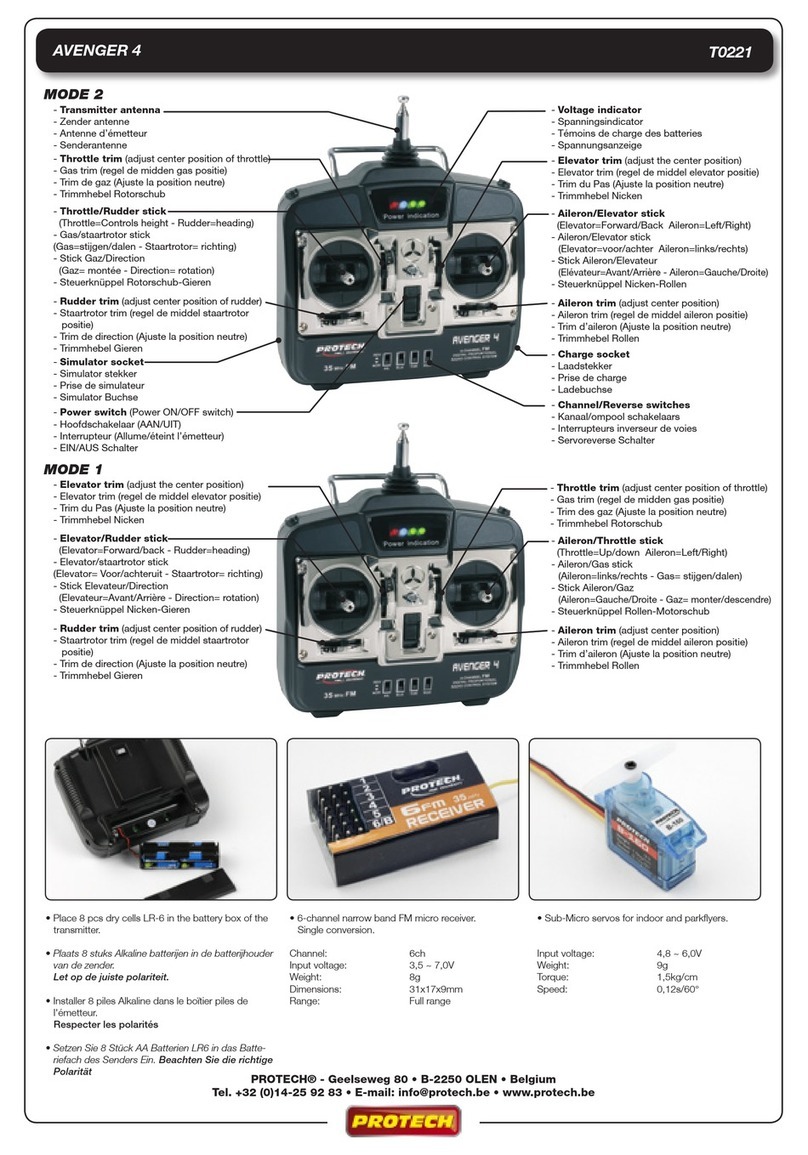

ON

12345

DIL1

J5

D1

L

3

PL1

N-

L+

Output/Utsignal

N-

Ou

t

Ou

t

2

1

Fig 1

DIL 1: 1 on, 2 off volt output 1

3 on, 4 off volt output 2

1 off, 2 on mA output 1

3 off, 4 on mA output 2

AA

Fig 2

Use the front cover bottom screws (marked A)tofixthefront

cover at the enclosures top edge during installation.

Par.no: Parameter Range Value

Internals

0 Prog ver 0.00...9.99

Current values

100 dP -32768...32767

101 Flow -32768...32767

102 PI2 0.00...100.00

103 PI2 CSP -32768...32767

109 Temp -3276,8...3276,7

110 Purging OFF

PRE

CLEAN

POST

PAUSE

TEST

System settings

4 Display dP

FLOW

dP+FLOW

dP+PI2

FLOW+PI2

dP+TEMP

FLW+TEMP

5 Damping[s] 0...9

(hidden) Access code 0...9999

Outputs

19 Output 1 dP

FLOW

PI2

TEMP

CLEAN

20 Signal 1 0..10V

2..10V

0..20mA

4..20mA

21 Output 2 dP

FLOW

PI2

TEMP

CLEAN

22 Signal 2 0..10V

2..10V

0..20mA

4..20mA

Pressure

23 MinCal[Pa] -32768...32767

24 MaxCal[Pa] -32768...32767

25 Unit dP Pa

PaDec

mbar

iwc

26 Min Range -32768...32767

27 Max Range -32768...32767

28 Min Output -32768...32767

29 Max Output -32768...32767

30 Sign dP POS

NEG

Flow

31 Unit flow L/s

m3/s

m3/h

m/s

cfm

32 Max flow 0...32767

Par.no: Parameter Range Value

33 Scale flw 0...32767

34 Set flow 0...32767

92 Compens OFF

ACTUAL

NORMAL 0

Temperature

93 Input OFF

0..10V

2..10V

0..20mA

4..20mA

Pt-100L

Pt-100H

Pt-1000L

Pt-1000H

94 Min Input -30...600

95 Max Input -30...600

PI2 Controller

35 Source OFF

dP

FLOW

36 Mode AUTO

HAND

37 Output DIRECT

REVERSE

52 Temp 1 -30...600

53 SP1 -32768...32767

54 Temp 2 -30...600

55 SP2 -32768...32767

56 SPC OFF

TEMP

39 NZ [%] 1...50

40 P-band 0...9999

41 I-time [s] 0...999

42 BZ [%] 0...100

43 I-time BZ 0...999

96 Min out 0,00...100,00

97 Max out 0,00...100,00

Purging unit

62 Mode OFF

ON

TEST

63 On Time [s] 0...99

64 Pause [s] 30...3600

Communication

47 Adress 1...247

48 Location 0...32767

49 Protocol Comli

50 BAUD 600 b

1200 b

2400 b

4800 b

9600 b

51 Protect NO

YES

2

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

3

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

System settings Outputs Pressure

Output 1

Signal 1

Output 2

Signal 2

dP

0..10V

Flow

Current values

Outputs

Outputs

Outputs

Outputs

AB MICATRONE

dP 48,5Pa

Temperature PI2 controler Purging unit Internals

Scrolls start menus

in the opposite way

Press key until displayed text disappears.

(PGM)

Output %

(PGM)

(PGM)

(PGM)

(ESC)

(ESC)

Scrolls parameter group in the opposite way

Changes between the parameters

according to the parameter list.

Opens parameter group and allows the

parameters to be selected.

Programming position for Unit/Value (Flashes).

Programming of new value. Parameter Unit/Value is flashing.

When programming a number value, each digit is

programmed seperately, until all digits have stopped flashing.

Selection of Unit/Value.

Leaves parameters and returns to Parameter group.

Leaves the parameter group and returns to startmenu.

Always note the programmed data beside the parameter

in the programming protocol for future documentation

PI2

4..20mA

Flow/dP

Auto %

dP

PI2

48,5Pa

15,9%

Flow

PI2

4,80m3/s

20,4%

Flow/dP

Hand %

dP

Flow 4,80m3/s

48,5Pa

AB MICATRONE

Flow 4,80m3/s

Digit programming

Every digit is separately programmed. Press ¸for

1...9, after 9 if negative values are accepted -9...0.

Digit to be changed is flashing . When all digits are

programmed press PGM and the entire row will

flash. To stop incorrect programming press ESC

and then PGM to execute new programming.

Unit or value programming

Press ¹¸ to change unit/value. When selected

press PGM then the entire row will flash.

Press ESC to return to parameter group.

Press ESC to leave the parameter group and return

to start menu.

Cancel the current programming

It is always possible to stop an incorrect program-

ming with ESC if you have not pressed PGM after

the last digit or unit/value selection.

Programming instruction

We recommend you to follow this instruction.

When any of the start menus is displayed press

PGM until "PROGRAM-MENU" appears. Then re-

lease the PGM key.

1. Current values

100 dP -32768...32767

101 Flow -32768...32767

102 PI2 0.00...100.00

103 PI2 CSP -32768...32767

109 Temp -3276,8...3276,7

110 Purging OFF

PRE

CLEAN

POST

PAUSE

TEST

Shows the actual values and the state of the purg-

ing function.

2. System settings

4 Display dP

FLOW

dP+FLOW

dP+PI2

FLOW+PI2

dP+TEMP

FLW+TEMP

5 Damping[s] 0...9

(hidden) Access code 0...9999

Select the start menu to be displayed.

Select the time constant (damping) for the flow and

pressure measurement 0...9 seconds, normally

1...3 seconds.

Key lock is a hidden parameter if the function is acti-

vated and no code has been entered.

The key lock is to be used when transmitters set-

tings must be protected from unwanted alteration.

The 4-digit code must be entered before accessing

the program and function menu.

For units with built-in control function the code must

also be entered to switch between AUTO and

HAND operation.

Indication of the measured values and operating

state is accessible without entering the code.

At delivery the code is programmed to "0000" un-

less nothing else is agreed to. With factory default

code "0000" the key lock is inactive. I.e no protec-

tion for alternating the settings.

Activating the key lock

To activate the key lock settings must be pro-

grammed into the parameter 'Access code' which is

found below the parameter group 'System settings'.

The code must be different from "0000" unless the

lock will be in-active. After programming a 4-digit

code into the parameter this code must be used to

access the program and function menus.

In-activating the key lock

The key lock can be in-activated by setting the value

of parameter 'Access code' to "0000". Since the set-

ting is done from the program menu the already

programmed code must be known to inactivate the

key lock.

Contact Micatrone if the code has been lost!

Entering code

To access the program or function menu or to switch

between AUTO-HAND function the code must be

entered.

Example to access the program menu:

Press the PGM-key to open the program menu.

Keep the key pressed until following screen ap-

pears.

Release the PGM-key. If the key lock is activated

the following screen appears.

The first digit (0) is flashing to indicate that the first

digit of the code must be entered by using the ar-

row-keys. Press the PGM-key to jump to the second

digit, etc.

When all four digits are entered press a final time

the PGM-key. The entered code is now compared

4

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

MF-PFTT

PROGRAM-MENU

ENTER CODE: 0***

PROGRAM-MENU

with the settings in the parameter 'Access code'. If

they match the program menu is accessed.

The menu is accessible until the ESC-key is

pressed one or several times and the preset start

menu is displayed. Example:

If the code does not match the programmed settings

following screen appears

for a period of 2 second before shifting to the "Enter

code" screen again.

By pressing the ESC-key during the operations the

programming of the code is aborted and the preset

start menu is displayed.

3. Outputs

19 Output 1 dP

FLOW

PI2

TEMP

CLEAN

20 Signal 1 0..10V

2..10V

0..20mA

4..20mA

21 Output 2 dP

FLOW

PI2

TEMP

CLEAN

22 Signal 2 0..10V

2..10V

0..20mA

4..20mA

Select the sources for the two analogue outputs. The

selection is possible between actual value of pres-

sure or flow, PI-control output for pressure or flow,

actual value for temperature measurement and

purging control (CLEAN).

NOTE ! There is only one controller in the unit. The

source for the PI-controller is programmed under

“PI2 controller”.

To measure and control flow or velocity it is neces-

sary to connect the unit to a flow measurement de-

vice mounted in the duct or fan inlet etc.

When controlling the purging function, the signal

output is 0 mA in OFF position and 20 mA in purging

condition. The output signal controls a relay inside

the purging unit, therefore the signal must be set to

mA-output and be programmed for 0...20mA.

Select the output signal for the two outputs, 0/2...10

VDC or 0/4...20 mA. You must also set the DIL-

switch on the circuit board for VDC or mA output.

It is possible to have VDC on one output and mA on

the other.

4. Pressure

23 MinCal[Pa] -32768...32767

24 MaxCal[Pa] -32768...32767

25 Unit dP Pa

PaDec

mbar

iwc

26 Min Range -32768...32767

27 Max Range -32768...32767

28 Min Out -32768...32767

29 Max Out -32768...32767

30 Sign dP POS

NEG

If the unit is used for flow measurement, you do not

need to do any programming under the parameter

group “Pressure”.

MF-PFTT is factory calibrated to a special range.

The range is marked on the label on the right side of

the casing. The calibration is always in Pa. Under

“Pressure” you also find the calibrated range, “Min

Cal” and “Max Cal”. These values are only notes

and are not possible to change.

If you want to change to another unit programme

“Unit dP”. Select Pa, Pa Dec (Pa with decimal),

mbar or iwc (inch water). When programming a new

unit the actual range is shown under “Min range”

and “Max range”. These values are only notes and

not possible to change. To change the range in se-

lected unit or factory programmed unit, programme

“Min output” and “Max output”. The programmed

values shall always be in the selected unit (Pa,

Pa,dec, mbar, iwc). When scaling, note that the ac-

curacy always is in % of the factory scaled range.

Sign for dP

When measuring a negative pressure normally the

MF-PFTT will show the same as measuring a positive

pressure (no sign). When programming “Sign dP” NEG

you get a negative (-) sign before the actual value.

5

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

AB MICATRONE

Flow 12.34 m3/s

INVALID CODE

PROGRAM-MENU

ENTER CODE: 0***

PROGRAM-MENU

AB MICATRONE

Flow 12.34 m3/s

Current values

5. Flow

31 Unit flow L/s

m3/s

m3/h

m/s

cfm

32 Max flow 0...32767

33 Scale flw 0...32767

34 Set flow 0...32767

92 Compens OFF

ACTUAL

NORMAL 0

If the unit isn´t to be used for flow measurement,

nothing has to be programmed under the parameter

group “Flow”.

Programme the unit for flow l/s, m3/s, m3/h, m/s or

cfm (cubic feet / minute).

The basic flow calculation used is made with ÖdP.

To have the display and the output corresponding to

the actual flow or velocity in the selected unit it is

necessary to make some calculations.

Different manufactors of flow measurement devices

have different calculation, but common for all is ÖdP.

Use the actual formula to calculate the max flow for

the factory calibrated measure range. The calcu-

lated flow or velocity at 20 °C is then programmed

under “Max flow” in the selected unit. The flow

range for max. output signal is programmed in

"Scale flw”, e.g. 3,5 m3/s = 10 VDC.

In parameter "Scale Flw", the flow should be en-

tered at actual temperature or in normal flow if tem-

perature compensation is activated. The output sig-

nal is linear compared to the flow or velocity.

NOTE ! If the range is not scaled, the same value in

parameter "Max flow" must also be programmed

into parameter "Scale flw". When scaling the flow,

note that the accuracy depends on the “Max flow”

range.

If adjustment of the displayed actual flow or velocity

must be done, it is possible to do under “Set flow”.

Programme the actual flow coming from a reference

flow sensor or equal.

NOTE ! The programming must be done at the

same time as the reference values are measured

(PGM-key is pressed).

Automatically the “Max flow” programming will be

changed for the new values. If the unit is connected

to a BMS system or equal, the “Max flow” or if

scaled, the “Scale flw” and the output signal must be

programmed in the connecting system.

With the parameter "Compens", the calculated flow

can automatically be compensated for changes in

the air density due to temperature changes. With

the parameter set to "ACTUAL" the flow is calcu-

lated by the current temperature. With the parame-

ter set to "NORMAL 0", the flow will be calculated as

if the temperature was 0 °C.

When the parameter is set to "ACTUAL", the letter

"A" is displayed in front of the selected flow unit, e.g.

Am3/s, and when set to "NORMAL 0", the letter "N"

is displayed in front of the selcted flow unit, e.g.

Nm3/h. This is to indicate that the the flow is calcu-

lated for the current temperature or in normal flow.

6. Temperature

93 Input OFF

0..10V

2..10V

0..20mA

4..20mA

Pt-100L

Pt-100H

Pt-1000L

Pt-1000H

94 Min Input -30...600

95 Max Input -30...600

Within this parameter group, the temperature sen-

sor input is selected. It is possible to use an ana-

logue signal, 0/2...10 VDC or 0/4...20 mA, Pt-100 or

Pt-1000 sensor.

When using an analogue signal the signal must be

scaled in parameter "Min Input" and "Max Input".

Pt-100 and Pt-1000 has two measuring ranges, ei-

ther low (L) or high (H).

The low selection has a temperature range of

-30...80 °C and the high selecting has a tempera-

ture range of 0...600 °C. The setting of parameters

"Min Input" and "Max Input" will automatically be set

for the low or the high range.

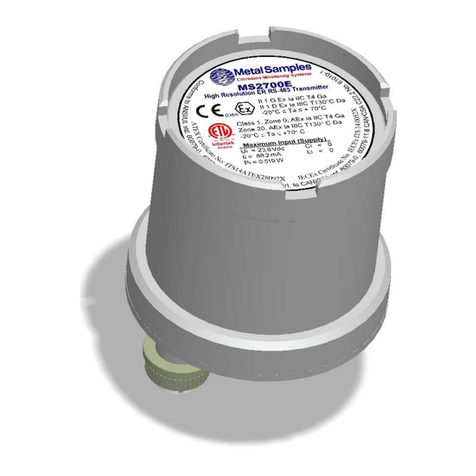

Change the setting of the DIL-switch located in the

upper right corner on the temperature input circuit

board, to correspond with the programmed settings,

VDC, mA, Pt-100 or Pt-1000. See figure on the last

page.

7. PI2 controller

35 Source OFF

dP

FLOW

36 Mode AUTO

HAND

37 Output DIRECT

REVERSE

52 Temp 1 -30...600

53 SP1 -32768...32767

54 Temp 2 -30...600

55 SP2 -32768...32767

56 SPC OFF

TEMP

39 NZ [%] 1...50

40 P-band 0...9999

41 I-time [s] 0...999

42 BZ [%] 0...100

43 I-time BZ 0...999

96 Min out 0,00...100,00

97 Max out 0,00...100,00

6

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

If the PI-controller is not used, you do not need to do

any programming under the parameter group

“PI-controller”.

MF-PFTT has a PI-controller specially made for

pressure and flow control. The controller has two

programmable integral times.

The controller could be programmed as a standard

PI-controller, but in most of the applications to-

gether with pressure and flow control we recom-

mend to program it as an integral controller without

P-band. There are two programmable I-times.

Outside a desired limit on both sides of the set point

it is possible to have a shorter I-time and inside the

limits a longer I-time.

Programming

Select source: dP, FLOW or OFF.

Select mode: AUTO or HAND, Normally AUTO.

Select output to be: DIRECT or REVERSE.

Normally reverse (if the pressure or flow is higher

than the set point the output signal will decrease).

Programme the set point "SP1" in the earlier pro-

grammed unit for dP or Flow.

Allowed limits are:

dP Pressure/Min Out .. Pressure/Max Out.

FLOW 0 .. Flow/Scale flw.

With the parameter "SPC", the set value can be

compensated for temperature changes. Select

"TEMP" to automatically have the unit to change the

set value between two different linear values.

Selecting "Temp 1" will use "SP1" as the set value.

Selecting "Temp 2" will use "SP2" as the set value.

Current set point value can be read in parameter

group "Current values" and parameter "PI2 CSP".

Programme the neutral zone NZ 1...50 % of the se-

lected pressure or flow range, normally 1...5%. The

NZ is in % of the scaled pressure or flow range with

half of the neutral zone on each side of the set point.

P-band

Normally not used for pressure and flow control.

I-time

When programming as an I-controller there are two

possibilities.

1. The same I-time over the whole range. Nor-

mally used. Program BZ = 000 and I-time BZ

= 000. The I-time should normally be longer

than the time for the dampermotor etc to go

frommintomax.

2. Shifting between two I-times. The reason for

working with two I-times is often that outside a

set pressure or flow limit you want to have a

fast response and inside a slow response (see

Fig 3). BZ: limit for switching I-time.

BZ is in % of the scaled pressure or flow

range. Half the Bz is on each side of the set

point. If the control output is not entering a

stable position, increase the I-time, you could

also try to increase the neutral zone.

Min out & Max out

The output signal from the PI-controller kan be lim-

ited within a specified range. The range is pro-

grammed in percent into parameter "Min out" and

"Max out".

Example: If "Min out" is set to 30,00 and "Max out" is

set to 75,00, the output signal will be limited to

3,00...7,50 V (with 0...10 V setting) or 8,8...16,0 mA

(with 4...20 mA setting).

Hand position

Return to start menu and select the menu displaying

the PI-controller together with either the pressure or

flow value.

“Flow / dP”

“Auto 50.00 % “

Press PGM, “Auto” will shift to “Hand” and make it

possible to set the output in % with ¹¸ .

To return to “Auto” press PGM.

To return to start menu press ESC.

8. Purging unit

62 Mode OFF

ON

TEST

63 On Time [s] 0...99

64 Pause [s] 30...3600

The purging function can be programmed in three

different states, OFF, ON or TEST -mode. "OFF" will

result in a inactivated mode. In "ON" mode the purg-

ing function is activated and cleaning will be per-

formed with even intervals. If the parameter is set to

"TEST", the purging function is active and will per-

form constantly. This is used to check the purging

function.

In parameter "On Time" it is possible to set the time

for each interval to be during purging. The time is

programmed in seconds. Parameter "Pause" is

used to set the time between each purging. This pa-

rameter is also programmed in seconds, 3600 sec-

onds = 1 hour.

During the pause, the LED "Normal" is lit. Measure-

ment and control are in operation. Two seconds be-

fore the purging begin, the LED "Normal" goes out

and the measurement is stopped with the latest

read value stored and the control output signal is

frozen at the current level. When the purging begin,

7

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

DP/Flow

BZ

BZ

Setpoint NZ

NZ

1

2

I-time BZ

I-time I-time

sec.

Fig 3

I-time, Itime BZ, BZ and NZ

the LED "Clean" is lit and the purging control signal

to the purging unit is activated.

After completed purging interval, the LED "Clean"

goes out and after an additional 5 seconds the mea-

surement and control output is restored. The LED

"Normal" is lit and a new "Pause" time begin.

Technical Data

Indicator: Alphanumeric LCD

2 rows, 2 x 16 characters

Pressure range: see label on the unit

Flow ranges: l/s: 0...32767

m3/s: 0...327,67

m3/s: 0...32767

m/s: 0...327,67

cfm: 0...32767

Accuracy : < ± 0,5 % of pressure range

Temperature drift: < ±0,5 % /10 °C

Time delay: 0...9 sec.

Temp. input: Sensor Pt-100, Pt-1000 and

0/2..10 VDC, 0/4..20 mA

Outputs: Two analogue outputs

0/2...10 VDC, 0/4...20 mA

selectable and scaleable

Ambient temp: 0...50 °C'

Power supply: 24 VAC ±15 %

20...32 VDC

Power

consumption: 3 VA

Housing class.: IP 65

Electric connections

-rigid wire

-flexible wire

1x2,5mm

2/ terminal

1x1,5mm

2/ terminal

Cable entry: 2 x M16x1.5mm

(cable glands not included)

Dimensions WxHxD: 122 x 120 x 90mm

Conformity:

-EMC

-LVD

SS-EN 50081-1

SS-EN 50082-2

SS-EN 610101-1

Maintenance

Check the zero point every 6:th month.

Zero setting of the pressure transmitter

Disconnect the pressure tubes or set the manifold

valve in the calibration position.

With the startmenu displayed, press simultanously

both the keys ¹¸ until the display shows:

ZERO OFFSET

Release the keys when the display shows:

ZERO OFFSET

ADJUSTING

When zero set is ready, the unit displays

ZERO OFFSET DONE

and automatically returns to start menu.

Electrical connection:

Input type for temperature sensor

DIL-switch located in top right corner on PCB.

Volt:

mA:

Pt-100:

Pt-1000:

8

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

AB Micatrone Telephone: +46 8-470 25 00

Åldermansvägen 3 Fax: +46 8-470 25 99

SE-171 48 SOLNA Internet: www.micatrone.se

web reference - http://www.micatrone.se/prod_detail.php?lang=gb&id=53

LN-N-

Out 1

Out 2

24 VAC

20...32 VDC

11 12 13 14

Pt-100

Pt-1000

mA

Volt

+

ON

12345

H1

R22

R3

R5

R24

R21

C11

E4

R10

R17

R13

AC1

C1

C12

R25

IC1

D1

R26

ON

12345

ON

12345

DIL1

C5

R16

R4

R1

R11

R19

C9

R6

C10

R7

R23

K

2

0

0

ON

12345

ON

12345

ON

12345

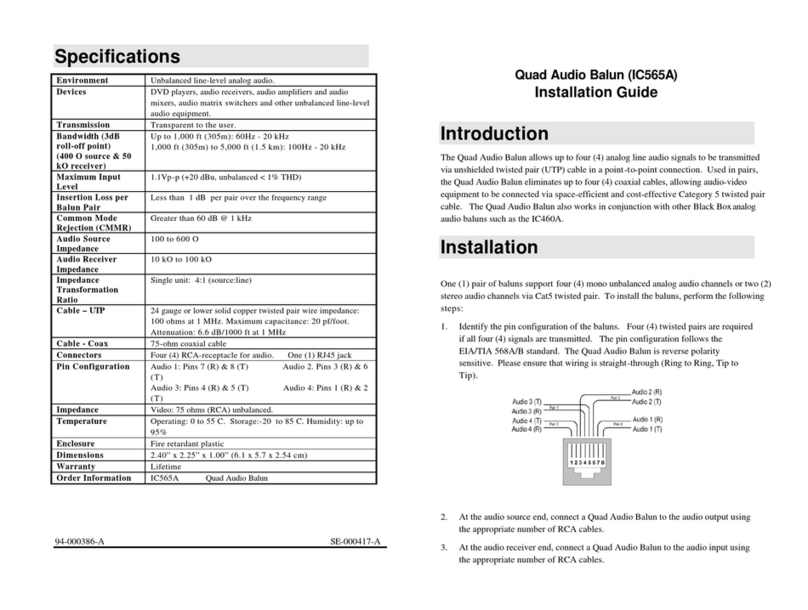

Other Micatrone Transmitter manuals

Popular Transmitter manuals by other brands

Hollyland

Hollyland Mars 4K quick guide

Nautel

Nautel VS1 Operation and maintenance manual

Emerson

Emerson PENBERTHY MGT-362 Installation, operation and maintenance instructions

Knick

Knick Stratos Multi E401N user manual

Metal Samples

Metal Samples MS2700E Operator's manual

MuxLab

MuxLab 500056-PRO Quick installation guide

Siemens

Siemens Sitrans LU-180 operating instructions

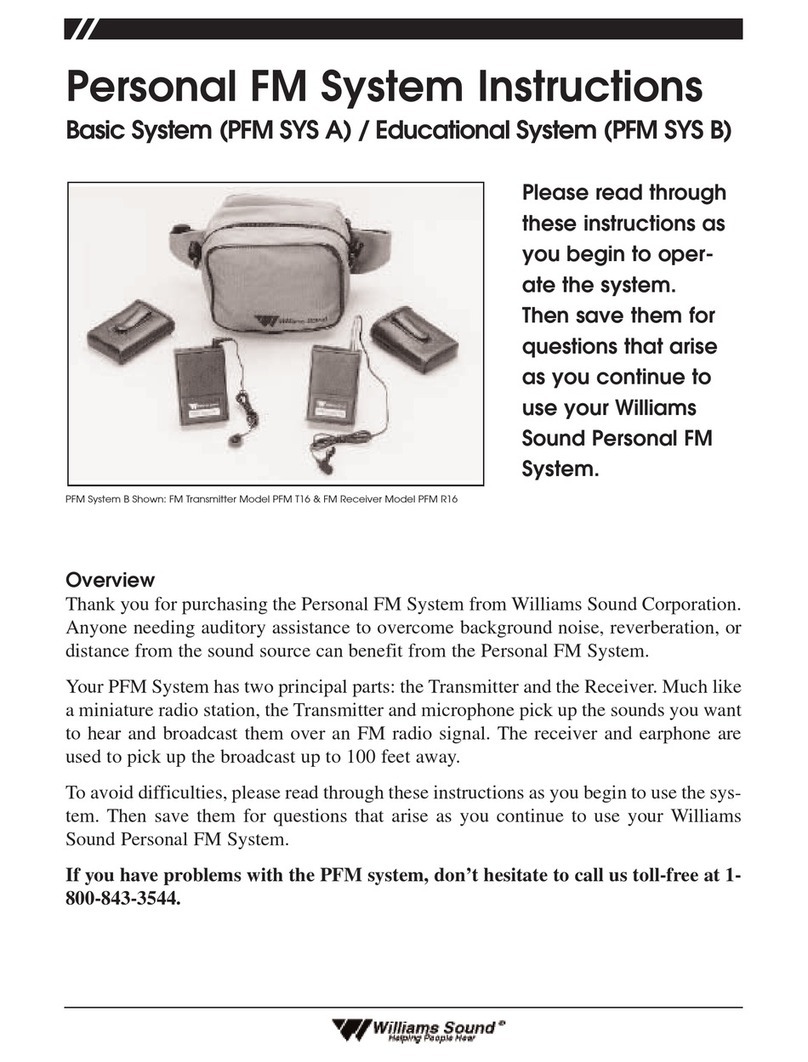

Williams Sound

Williams Sound PFM SYS A instructions

MISURA

MISURA MCAST user manual

Nautel

Nautel VS300 Operation and maintenance manual

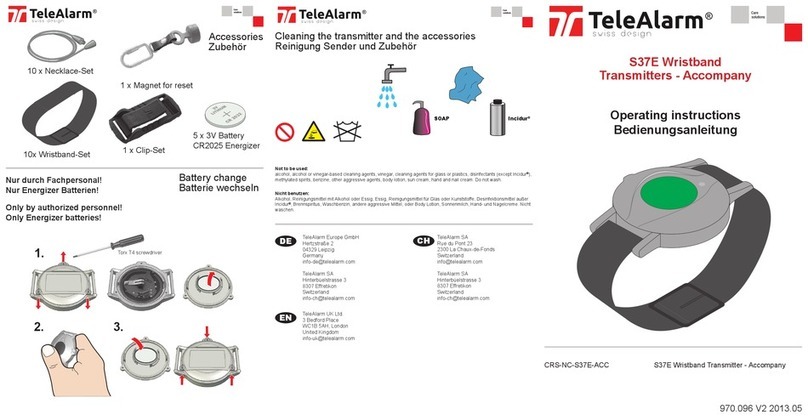

TeleAlarm

TeleAlarm S37E operating instructions

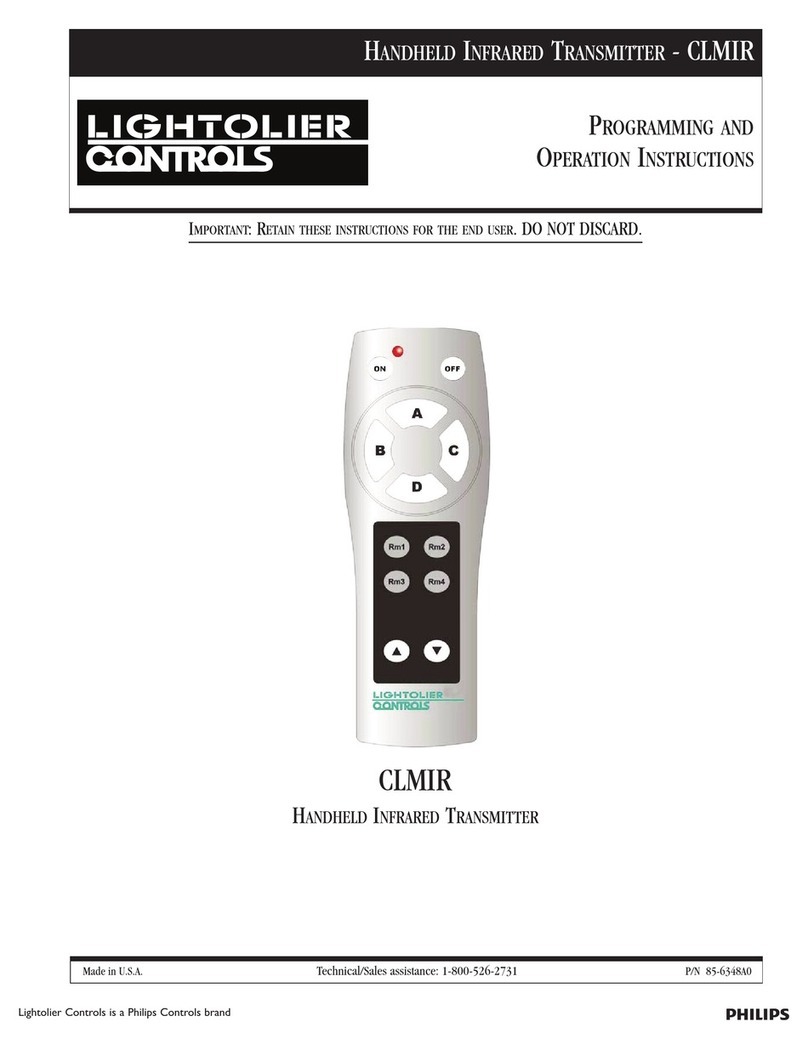

Philips

Philips Lightolier Controls CLMIR Programming and operation instructions