5

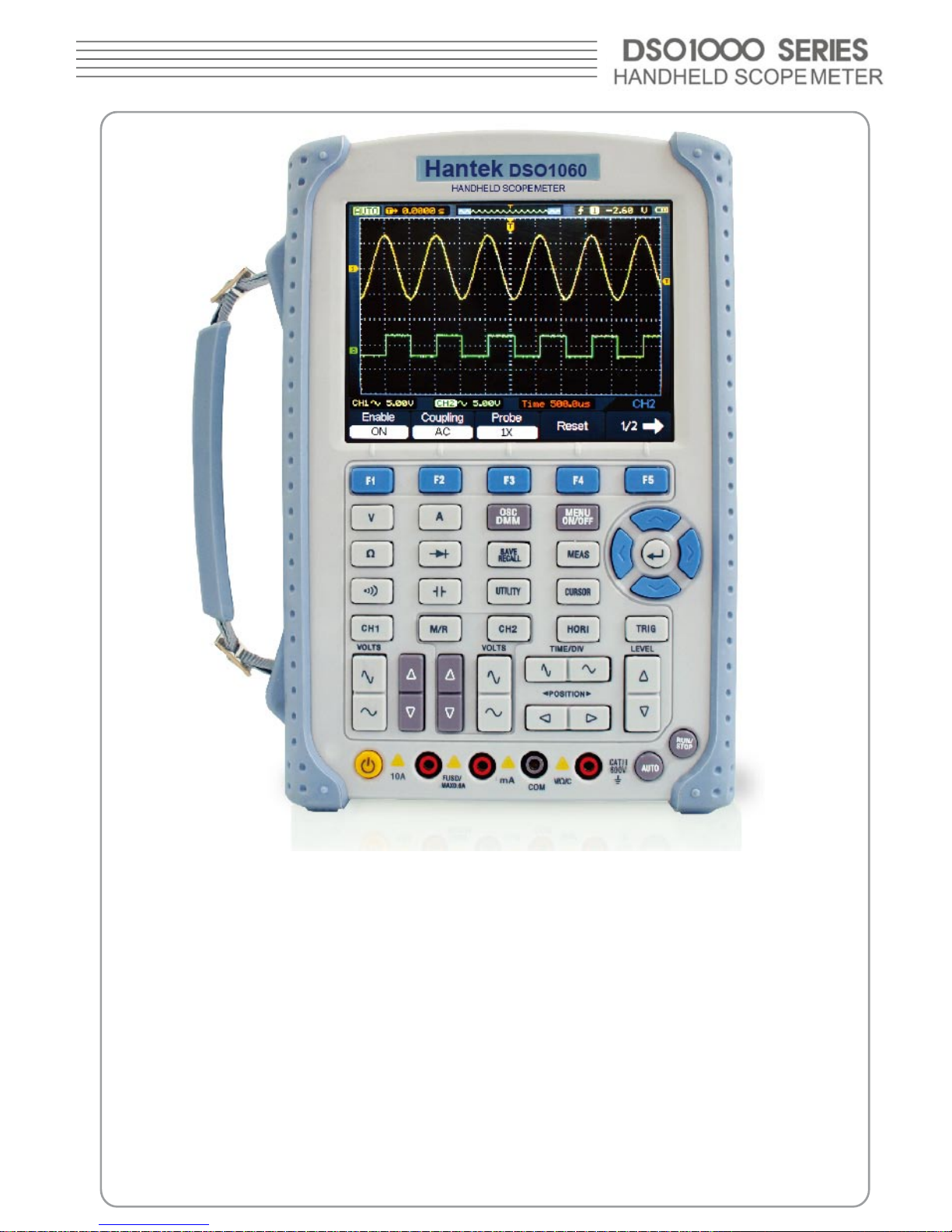

Digital Scope Meters

DSO1000 Series digital scope meters offer exceptional waveform viewing and

measurements in a compact, lightweight package. DSO1000 series is ideal for

production test, eld service, research, design, education and training involving

applications of analog circuit tests and troubleshooting.

Product features:

■ Dual Channel, Bandwidth:

60MHz (DSO1060)

200MHz (DSO1200)

500MHz (DSO1500)

600MHz (DSO1600)

600MHz (DSO1600H)

■ Maximum real-time sampling rate:

150MSa/s (DSO1060)

250MSa/s (DSO1200)

500MSa/s (DSO1500)

1GSa/s (DSO1600)

2GSa/s (DSO1600H)

■ Memory depth:

32K points (Single Channel), 16K points (Dual Channels)

■ Color TFT LCD, 320×240 pixels resolution.

■ USB storage and printing supports, rmware upgrade via USB interface.

■ Adjustable waveform intensity, more effective waveform viewing.

■ One-touch automatic setup, ease of use (AUTOSET).

■ 15 Waveforms, 15 setups, supports CSV and bitmap format.

■ 22 Automatic measurements.

■ Automatic cursor tracking measurements.

■ Waveform recorder, record and replay dynamic waveforms.

■ User selectable fast offset calibration.

■ Built-in FFT function, Frequency Counter.

■ Pass/Fail Function.

■ Addition, Subtraction, Multiplication and Division Mathematic Functions.

■ Advanced trigger types include: Edge, Pulse width.

■ Multiple Language User Interface.

■ Pop-up menu makes it easy to read and easy to use.

■ Built-in multi-language help system.

■ Easy-to-use le system supports Multi-Language characters le name

input.

■ Selectable 20 MHz bandwidth limit;