YSI ProDSS

Field Procedures 5 18th Edition, 2016

temperature sensor does not need to be

completely dry at its base. Then:

a) Pour a small amount of clean water

(1/8th inch) gently down the side of the

calibration cup.

b) Gently insert the sensor and guard into

the calibration cup and partially tighten

the calibration cup to the bulkhead.

NOTE: Do not fully tighten the cup;

atmospheric venting is required for

accurate calibration. Make sure the DO

and temperature sensors are not

submerged in water.

c) Set the unit aside right side up in the

shade and wait 5 to 15 minutes for

complete air saturation.

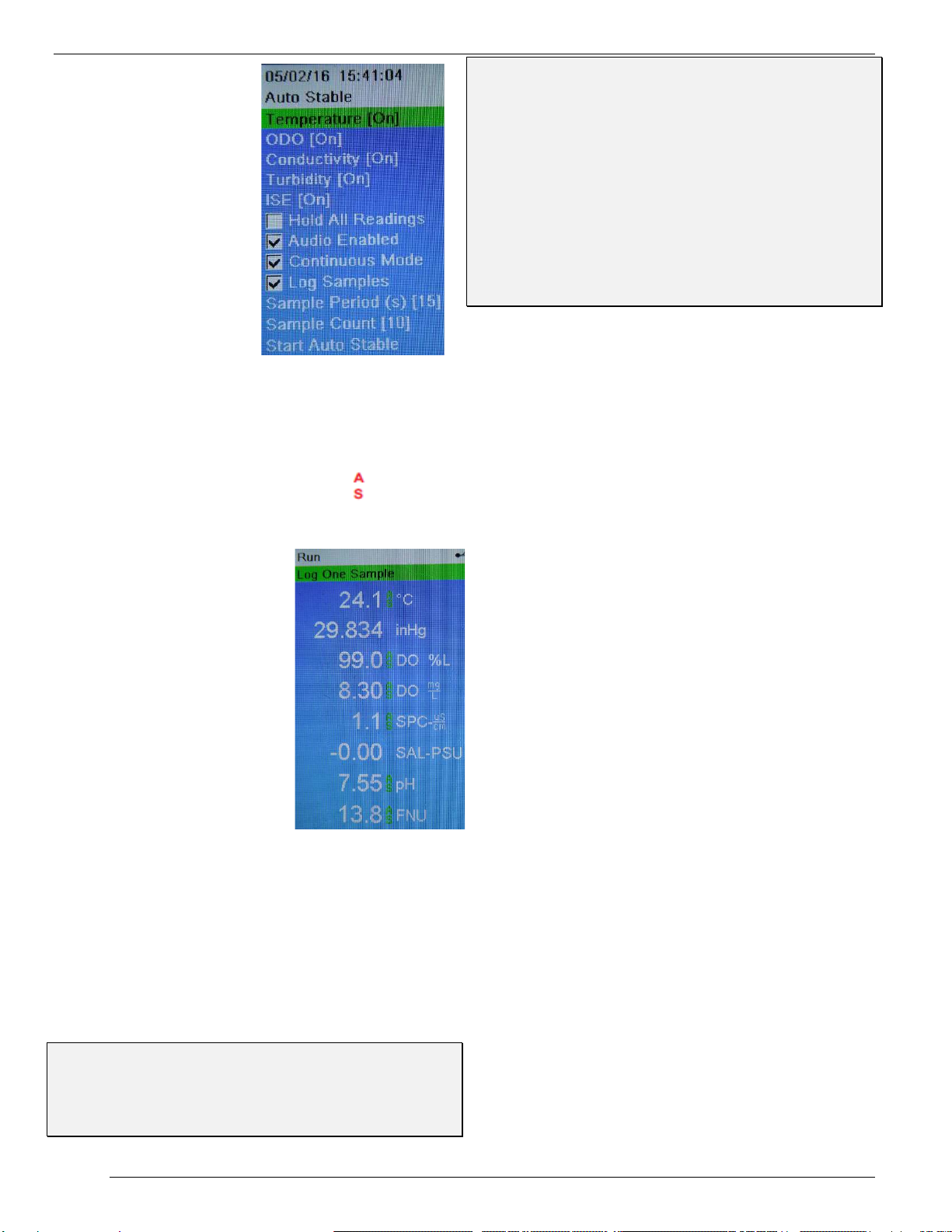

d) Wait for the unit to stabilize to these

criteria: During a period of 2

minutes, both DO % Local and

Temp (°C) stay within ± 0.1 of their

initial readings.

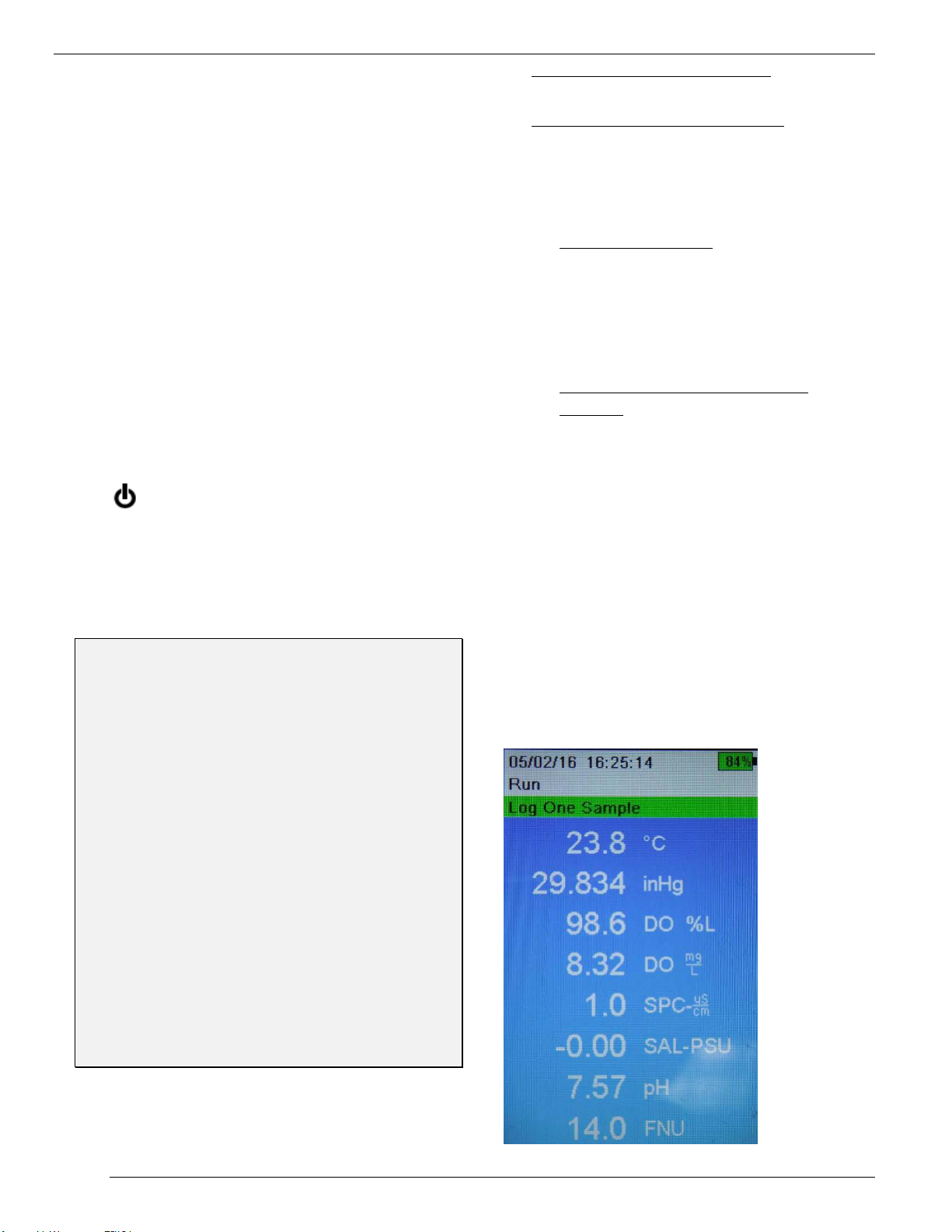

e) In Local DO% mode, the meter should

read 100% ±2%.(If it does not, try

unscrewing the sensor guard and

carefully dabbing the DO sensor tip with

a Kimwipe, then test again.)

f) Record the reading.

6. Record the meter number.

7.

If you are not submitting the data to Clallam

County

, record the latest calibration dates

for all parameters. Select the

File

button,

View GLP

, and scroll to see when the

instrument was last calibrated for each

parameter.

COMMON SENSE AND EXPECTED RANGES:

Please compare your readings with the expected

ranges on the datasheet. If you’re outside the

expected range, consider re-sampling or

troubleshooting with your fellow samplers. A couple

of common problems:

Conductivity readings <25 µS: You might not

have held the probe completely underwater. Try

taking another set of readings.

Turbidity readings <0: This is probably a sign of

contamination during zero calibration at the office;

report the problem to staff, who can re-run the zero

calibration without having to re-run the other

turbidity calibration settings.

8. If you performed replicates, check the

“Water Chemistry—General” protocol to see

if your pairs of readings are within the

acceptable precision limits; resample as

needed.

9. Record time and full initials of the

sampler; this should be someone who has

been properly trained (see “Quality

Assurance” protocol).

10.Turn off the meter (hold the Power

button), make sure the calibration cup is on

tight, and place the unit in the field bag.

Retrieving data from the meter

Retrieving from the meter’s data files:

Select the

File

button and select View Data and

Show Data. (If no data is displayed, make sure

you have the right date and time entered at the

bottom.) Find the bottom row for the site you

want, which should be the last set of data

recorded when you hit Enter to log your reading

at that site.(If you took a field replicate at this

site, this last row will be those replicate

readings; you’ll have to scroll back up a bit to

find your primary sample readings.) To see the

data readings for each parameter, hit the Right

Arrow key to scroll.

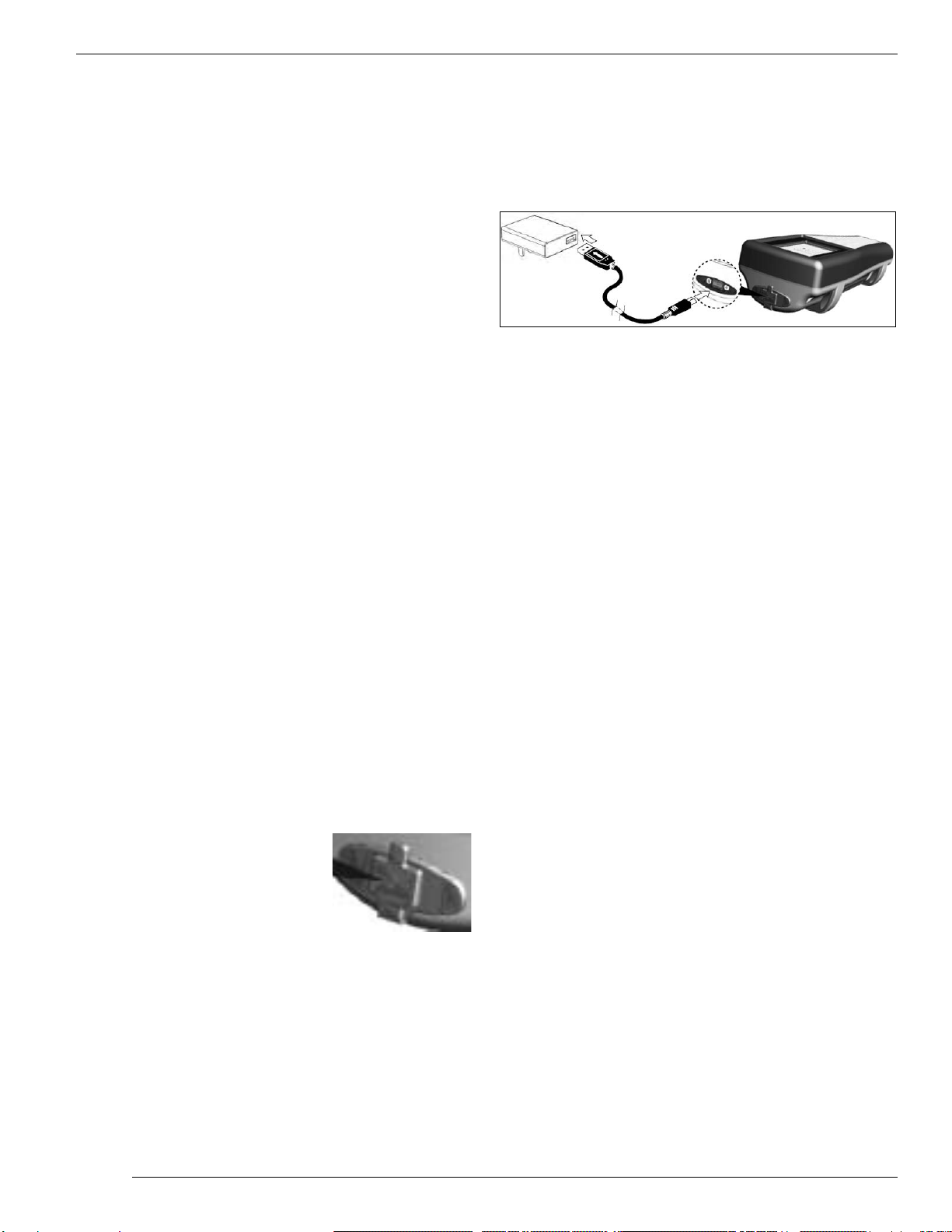

Retrieving from computer upload: Connect the

meter via its USB cable to a computer with

KorDSS software loaded, and open KorDSS.

Wait for the data in the meter to upload

automatically. Then, on the Home Screen,

choose “View Logged Data” and “Search.”

Choose your search criteria, then in the Results

screen, select the datasets you want to view,

and hit “Accept.” Go to “Dashboard” tab and

view and record your readings. (You may have

to convert units in some cases, due to glitches

in the KorDSS software.) You can Print these

data sets or upload them to a .csv file. To find

other data sets, choose “Search” again.

Storage for >1 week

Use expired pH 4 buffer as a storage solution to

improve the life of the pH probe. Pour enough

pH 4 buffer in the calibration cup so the ends of

the sensor modules are all submerged when the

sensor assembly is oriented with the sensor

ends down. Store the unit in this orientation.