HARBEN Eliminator VanPack Manual

Harben Inc.

P.O. Box 2250, Cumming, GA 30028

Toll Free: (800)-327-5387 Tel: (770)-889-9535 Fax: (770)-887-9411

email: sale[email protected]m web: www.harben.com

_________________________________________________________________________________________

Operation & Maintenance Manual

Original Instructions

Eliminator Van Pack

903-1315

Section 1 Introduction

Section 2 Scope of Supply

Section 3 Technical Data

Section 4 Operation

Section 5 Routine Maintenance

Section 6 Fault Finding

Section 7 Pump

Section 8 Engine

Section 9 Wiring and Circuit Diagram

Section 10 Parts List / Spares / Auxiliary components

Section 11 Service Documents

Section 12 Warranty & Certification

Section 13 Health & Safety Manual 903-1308

Read the Health and Safety Manual before

operating any equipment. Failure to do so could

cause serious injury or death.

2

Operation & Maintenance Manual for:

UNIT: Eliminator Van Pack R/1 (B11238/A)

ISSUE DATE: 6/20

ISSUE No: 3

AMENDMENTS

Change Changes Date Signature

1 NEW ADDITION 5/20 GT

2 Added Anti-Freeze System Pictures 6/20 GT

3 Updated manual to code 6/20 GT

3

1. Introduction

1.1. Contents

1. INTRODUCTION ........................................................................................................... 3

1.1. CONTENTS ................................................................................................................... 3

1.2. INTRODUCTION ............................................................................................................. 6

1.3. SCOPE OF THIS MANUAL ............................................................................................... 7

1.4. THE ELIMINATOR VANPACK ........................................................................................... 7

1.5. COMPOSITION OF THIS MANUAL..................................................................................... 8

2. SCOPE OF SUPPLY ..................................................................................................... 9

2.1. SCOPE OF SUPPLY ....................................................................................................... 9

2.2. VANPACK ASSEMBLY ................................................................................................... 9

2.3. DETAILED DRAWINGS ..................................................................................................10

3. TECHNICAL DATA ......................................................................................................14

3.1. TECHNICAL DATA ........................................................................................................14

3.1.1. PUMP DATA .............................................................................................................. 14

3.1.2. MAIN COMPONENTS .................................................................................................. 14

3.1.3. ANCILLARIES ............................................................................................................ 14

3.1.4. SERVICES REQUIRED ................................................................................................ 14

3.2. TECHNICAL DESCRIPTION ............................................................................................15

3.2.1. PRIMARY COMPONENTS ............................................................................................ 15

3.2.2. ENGINE MONITORING ................................................................................................ 15

3.2.3. DELIVERY HOSE REEL ............................................................................................... 15

4. OPERATION ................................................................................................................17

4.1. OPERATING CONDITIONS .............................................................................................17

4.2. DAILY CHECKS ............................................................................................................17

4.3. PRE-START CHECKS & BLEED PROCEDURE ..................................................................18

4.4. STARTING THE ENGINE & SETTING THE OPERATING PRESSURE .....................................19

4.5. PRE-START CHECKS & PROCEDURES ...........................................................................20

4.5.1. STARTING THE ENGINE .............................................................................................. 20

4.5.2. CHECKING THE OPERATING PRESSURE WITH A NOZZLE FITTED ................................... 21

4.5.3. CHECKING THE OPERATING PRESSURE WITH A GUN FITTED ........................................ 22

4.6. REMOTE OPERATION STARTING PROCEDURE ................................................................23

4.6.1. STARTING THE ENGINE .............................................................................................. 23

4.7. RAPID SHUTDOWN .......................................................................................................25

4.8. AUTOMATIC SHUTDOWN ..............................................................................................25

4

4.9. HOSE REEL WINDING AND UNWINDING .........................................................................25

4.10. FROST PRECAUTIONS ................................................................................................26

5. ROUTINE MAINTENANCE ...........................................................................................28

5.1. MAINTENANCE PROCEDURES .......................................................................................28

5.2. GEARBOX LUBRICATING CHART – SPECK NP25 ...........................................................29

5.3. GENERAL TORQUE SETTINGS .......................................................................................30

5.4. DAILY MAINTENANCE ...................................................................................................31

6. FAULT FINDING ..........................................................................................................33

6.1. EQUIPMENT FAULT FINDING .........................................................................................35

6.2. SELECTOR FAULT FINDING ...........................................................................................35

7. PUMP ...........................................................................................................................36

8. ENGINE ........................................................................................................................37

9. CIRCUIT AND WIRING DIAGRAMS ............................................................................38

10. PARTS LISTS / SPARES .............................................................................................42

10.1. INTRODUCTION ..........................................................................................................42

10.2. ORDERING SPARE PARTS ..........................................................................................42

10.3. ACCESSORIES & CONSUMABLES ................................................................................43

10.3.1. ROUTINE MAINTENANCE ............................................................................................ 43

10.3.2. CONSUMABLES ......................................................................................................... 43

10.3.3. ACCESSORIES .......................................................................................................... 43

10.4. PARTS LIST ...............................................................................................................45

10.5. HYDRAULIC DIVERTOR VALVE ASSEMBLY ...................................................................51

10.5.1. RECOMMENDED TOOLS ............................................................................................. 51

10.5.2. SERVICE KITS ........................................................................................................... 51

10.6. TO DISMANTLE ..........................................................................................................52

10.7. TO ASSEMBLE ...........................................................................................................52

11. SERVICE DOCUMENTS ..............................................................................................57

11.1. SERVICE CHECKLIST ..................................................................................................57

11.2. SERVICE LOGBOOK ...................................................................................................58

12. WARRANTY .................................................................................................................59

12.1. WARRANTY OF NEW PRODUCTS: ................................................................................59

12.2. WARRANTY OF SPARE PARTS: ...................................................................................59

12.3. LIMITATIONS OF WARRANTY:......................................................................................61

5

6

1.2. Introduction

Please ensure that you read this Operation & Maintenance Manual in conjunction with the

Health & Safety Manual before operation.

Within this manual, the health and safety risks are highlighted with specific symbols. These

will be referenced to sections within the Health and Safety Manual which you are required to

read. The sections to refer to in the manual will be labelled at the end of the highlighted

statement (Ex. H&S Section 2). There are three symbols that will be used to differentiate the

levels of severity. They are as follows:

o : This is the symbol for . This means that if an accident were to happen,

it would cause minor to moderate injury.

o : This is the symbol for . This means that if an accident were to happen,

it could result in a serious injury or possible death.

o : This is the symbol for . This means that if an accident were to happen,

it will result in death or serious injury. This will only be shown for the most extreme

cases.

It is imperative that these symbols are paid attention to as to avoid any sort of injury.

Notices

Carefully read the notices of this manual because they give important information concerning

safe installation, use and maintenance; familiarise yourself with the workings of the machine

to rapidly switch it off and eliminate pressure.

This manual is an integral and essential part of the product; it must be consigned to the user

to ensure the training/information for personnel.

The manufacturer does not assume responsibility for damage caused to persons, property or

to the machine, in the case of improper use. Carefully preserve this manual for any further

consultation.

Identify the model of your machine by reading the details on the identification plate. Upon

delivery, inspect the machine / accessories for any damage, which may occur during transport.

Always follow the recommended operating procedures. Do not misuse the

equipment as this could result in injury or mechanical breakdown!

7

1.3. Scope of this Manual

This manual provides operation and maintenance instructions for the unit. Where the unit has

been fitted with proprietary components, details of these are also included in this manual.

This manual is compiled to match the Scope of Supply detailed in Section 2. All specifications,

descriptions and parts lists refer only to the components in the version of the unit detailed in

this scope of supply.

Maintenance instructions included in this manual include:

Routine maintenance to be carried out at specific times.

Maintenance of the high-pressure pump.

Repairs to the pump crankcase are not considered maintenance operations as these should

be undertaken only by Harben, their approved agents, or at least competent automotive

engineers.

1.4. The Eliminator Vanpack

Harben® drain vanpacks have been designed to the highest standards so that they will work

safely and reliably for many years. It is important that you take time to read the information

provided in this operation and maintenance manual so that you understand how to make the

most of the vanpack in accordance with the instructions. Harben® vanpacks are powerful

pieces of industrial equipment and should only be operated by competent users who

understand that serious injury or death can occur through misuse.

The Eliminator Vanpack is a highly versatile mobile high-pressure water jetting unit, which

offers the benefits of proven power pack and pump performance with a comprehensive range

of accessories.

Developed for a wide range of water jetting applications, the Unit has been meticulously

designed for safe and efficient use.

Additional accessories can be purchased from Harben®, such as: floor cleaners, jetting guns

and jet pumps which extend the range of work that can be carried out with the jetter. Safety

information relating to individual accessories is provided later in this section.

8

1.5. Composition of this Manual

This manual comprises the following further sections:

Section 2 Scope of Supply

This section defines the scope of supply of the equipment in compliance with the sales order.

Section 3 Technical Data

This section contains technical information about the unit.

Section 4 Operation

This section describes the recommended operating procedures for the unit.

Section 5 Routine Maintenance

This section details recommended routine maintenance requirements for the pump and unit.

Section 6 Fault Finding

Fault diagnosis tables for the pump, engine, and ancillaries.

Section 7 Pump

This section provides details of the pump and gearbox assembly.

Section 8 Engine

This section provides details about the engine.

Section 9 Circuit and Wiring Diagrams

This section includes the Hydraulic, Water and Electrical circuits including engine controller &

wiring loom.

Section 10 Parts List / Spares

How to identify and order spares

Section 11 Service Documents

Service logbook and checklist.

Section 12 Warranty & Certification

Section 13 Health & Safety Manual 903-1308

This manual details health and safety considerations in general and specific to water jetting

equipment.

9

2. Scope of Supply

2.1. Scope of Supply

Unit: ELIMINATOR VANPACK

2.2. Vanpack Assembly

The General Arrangement drawing: 003-295, defines the components of the Eliminator

Vanpack mounted Pump Assembly as follows:

Water is fed from a “mains” supply through a manual low-pressure inlet hose reel into a plastic

water storage tank. The tank supplies the pump with a positive head of pressure via an inline

Hypro strainer that filters the water to approximately 177 microns, (Pump is specified at

200microns)

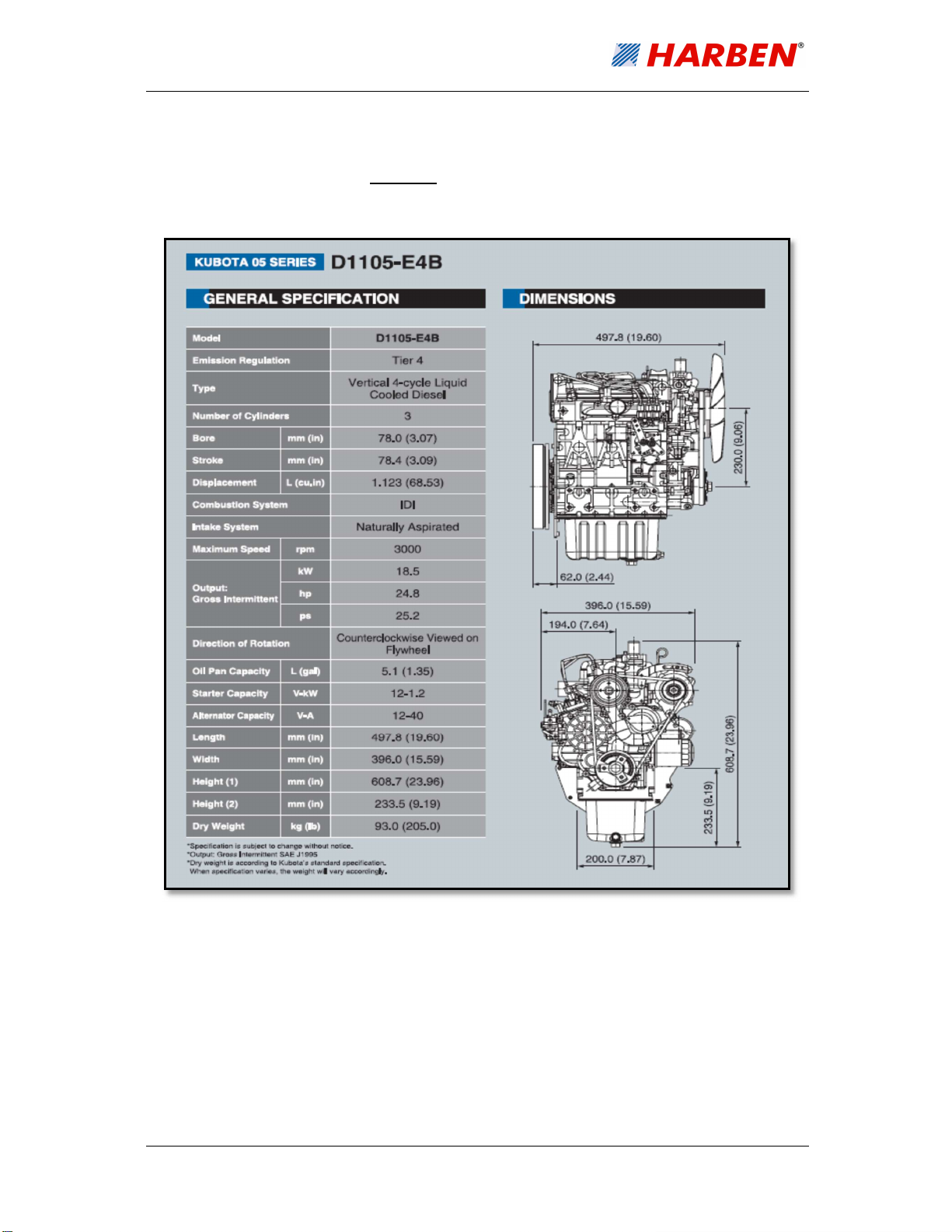

The Speck high-pressure plunger pump is driven by a Kubota D1105-E4B-EU-X1 18.5kW

Stage 5 C-TXT industrial diesel engine through a Speck NP25 gearbox.

The water is directed by an electrically controlled Hydraulic diverter valve, to a hydraulically

driven hose reel c/w 300’ of ½” hose, or at low pressure ‘dumped’ back to tank.

The system is protected from over pressurisation by means of a Hawk safety relief Valve.

The system pressure can be adjusted by means of a Speck UL221 Unloader Valve.

The engine and system pressure can be monitored at the control panel situated at the rear of

the van.

10

2.3. Detailed Drawings

Detailed drawings and parts lists for the above components are provided as follows:

The Speck Pump is detailed in Section 7.

11

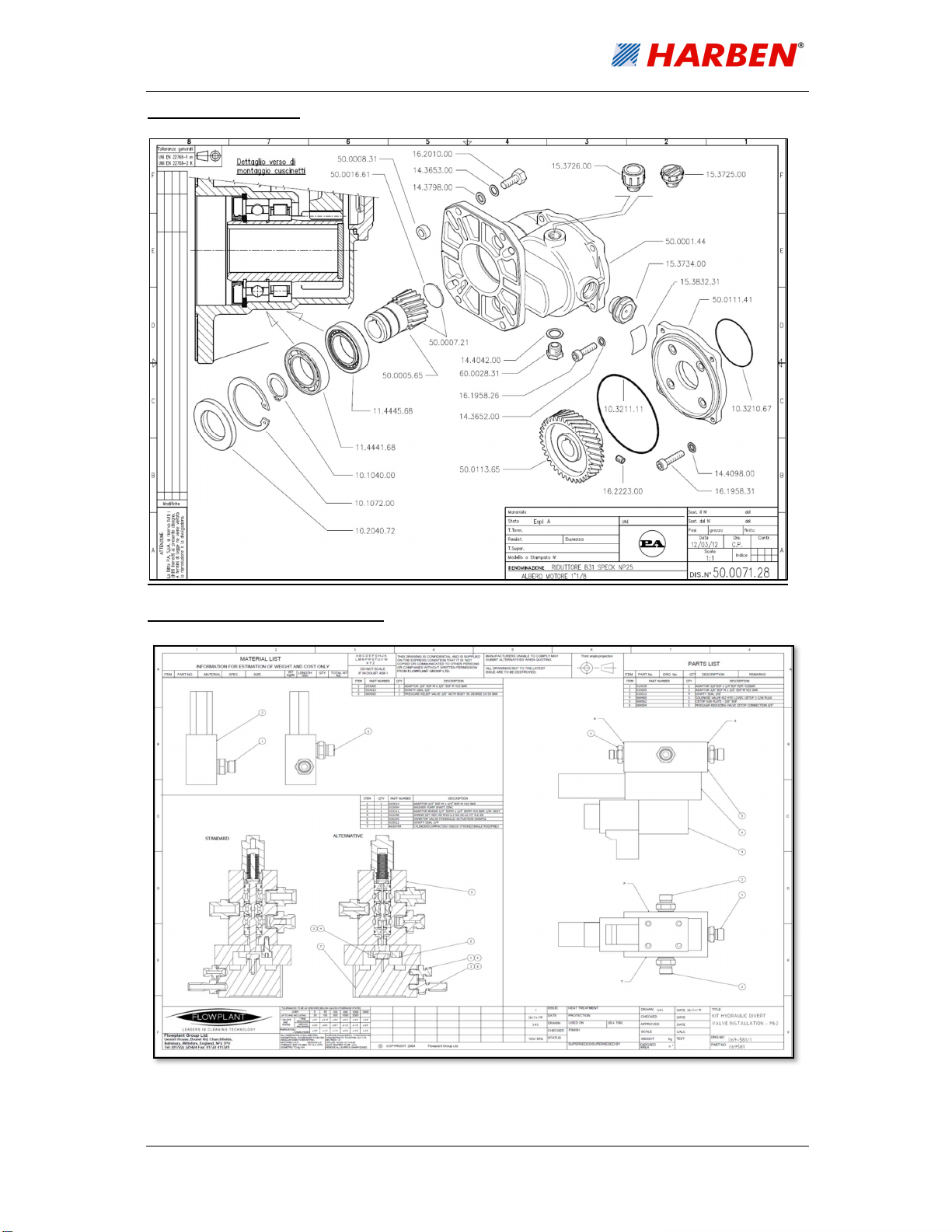

NP25 Gearbox Detail

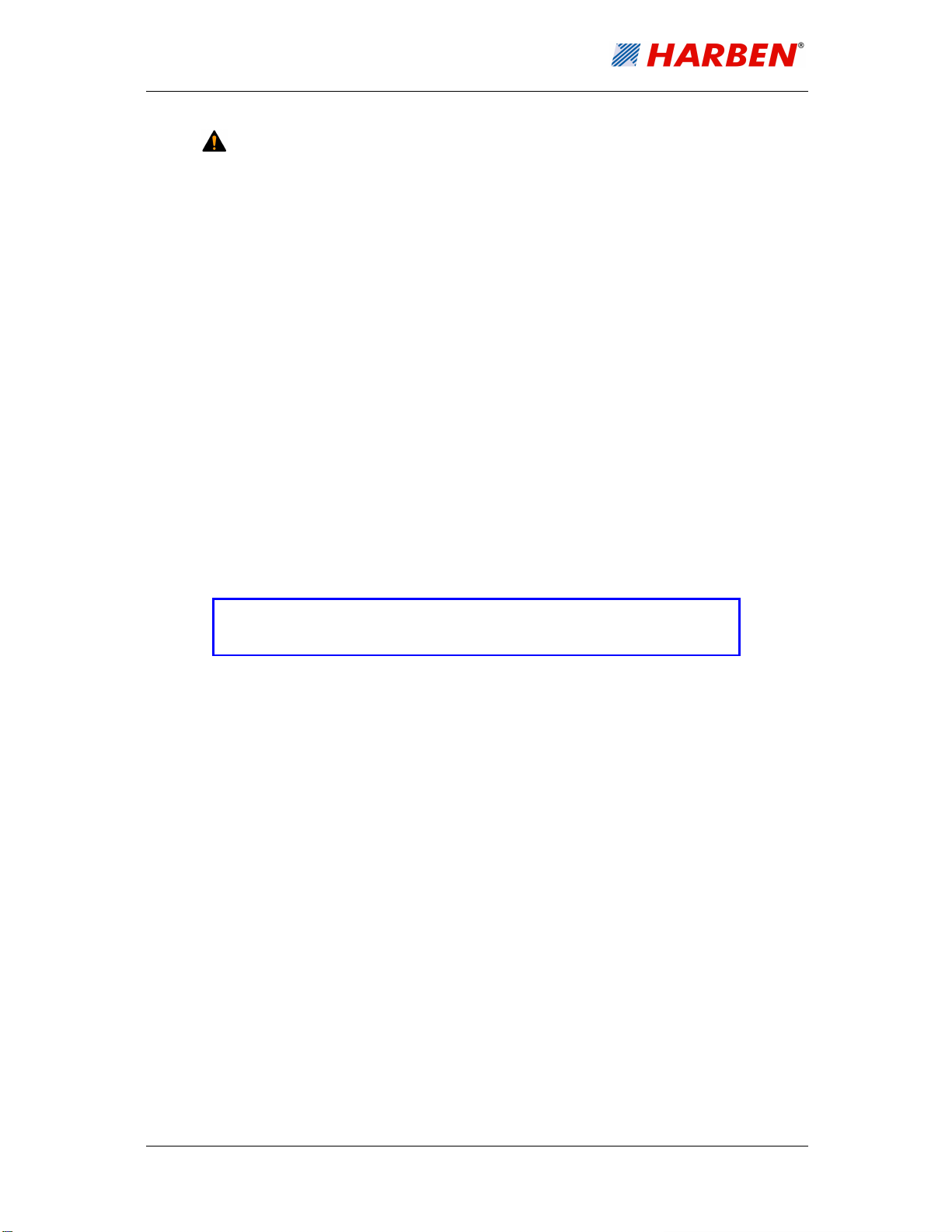

Hydraulic Diverter Valve 069-581

12

Hawk Safety Relief Valve 035-401

13

Speck Unloader Valve UL221 035-185

14

3. Technical Data

3.1. Technical Data

3.1.1. Pump Data

PUMP TYPE Speck NP25/54-200 [positive displacement]

Number of cylinders 3

Power rating (nominal) 22.5 hp

Plunger diameter 25mm

Crankshaft speed 1450rpm

Maximum pressure 200

Normal operating pressure 200 bar [2900psi]

Flow rate Up to 54 L/min

Crankcase lubrication Splash / Gravity

Crankcase oil capacity 0.24 USG

Recommended crankcase oil ISO VG 220 or SAE 90 Gear oil.

Valves Identical suction & discharge.

NPSH Input 10 bar max. Suction head -0.3 bar.

3.1.2. Main Components

Prime Mover Kubota D1105-E4B-EU-X1 18.5kW Stage 5 C-TXT

Drive Gearbox Speck NP25 Reduction box (2.176:1)

3.1.3. Ancillaries

Water Tank Capacity 88 gals. (400 litres)

Supply Water Filter N05105 Hypro line strainer / 177 micro mesh

Pressure Gauge Digitally Displayed

Safety Relief Hawk (Automatic SRV)

3.1.4. Services Required

Mains Water Supply Positive head.

Note: Water pH value of 5 to 9 is recommended.

15

3.2. Technical Description

3.2.1. Primary Components

The primary components of the Eliminator Vanpack are as follows:

A prime mover in the form of a Kubota 3-cylinder water-cooled diesel engine which

drives a Speck NP25 type high-pressure pump.

The pump can raise the water pressure up to 2900psi (200 bar).

A hydraulically driven hose reel 300 ft of 2 wire braid high-pressure hose with either a

nozzle or gun attachment to deliver the high-pressure water to the selected working

site.

A plastic water tank, acting as a reservoir, ensures the water is settled and non-

turbulent, discharging a smooth lamina flow of uninterrupted air free supply, a positive

head of pressure to the pump inlet and maximising the pumps full potential. The tank

can be filled via the inlet reel by connecting to a mains inlet water supply

o NOTICE: Turbulent water will cause the pump to run unevenly and cause

excessive wear due to cavitation.

Water is diverted to the hose reel either using a 12VDC hydraulic diverter.

A Hypro 177Micron mesh inline strainer is fitted to the suction line between the tank

and the pump inlet.

Note: This is a critical component which ensures that no contaminants are drawn into the

pump inlet. This filter must be inspected and cleaned daily, if it becomes blocked it will cause

the pump to cavitate.

3.2.2. Engine Monitoring

Engine oil pressure and engine coolant temperature, together with alternator charge rate are

continuously monitored. Activation of the engine pressure or temperature switches will cause

an engine shutdown and the respective ‘FAULT’ to be displayed on the control unit.

Alternator failure will be displayed on the control unit.

3.2.3. Delivery Hose Reel

The hose reel drum on which the delivery hose is wound is driven by a powerful OMR315

hydraulic motor directly coupled to the hose reel hub. Hydraulic power is obtained from a

hydraulic gear pump driven from the engine P.T.O. (See below)

16

Note: 050-324 Hydraulic gear pump detail: -

(Ratio 0.844/1.00, Output 4.35 cc/rev, direct mounting, theoretical discharge volume @

3000rpm = 3 gpm, max speed 3200rpm, max pressure 1707psi)

The speed and direction of the reel is controlled by a manual lever-controlled spool valve c/w

safety relief and flow control, this is situated just below and right of the high-pressure hose

reel.

17

4. Operation

4.1. Operating Conditions

Operators of water jetting equipment should be fully conversant with the Water Jetting

Association ‘Code of Practice for the Use of High-Pressure Water Jetting Equipment’,

hereafter referred to as 'The Code of Practice'. A copy of The Code of Practice is available

upon request.

Please ensure that you read this Operation & Maintenance Manual in conjunction with the

Health & Safety Manual before operation.

4.2. Daily Checks

Carry out all daily checks. Full maintenance checks are detailed in Section 5 - Routine

Maintenance.

They are:

Pump oil level

Gearbox oil level

Water filter cleanliness

Engine oil level

Engine coolant level

Tank water level & Cleanliness

Diesel level

Anti-freeze level

Radio Remote fully charged

18

4.3. Pre-start Checks & Bleed Procedure

1. WARNING! In cold weather check that machine is not frozen before starting (see

Antifreeze section 4.11). Serious injury can occur from ice bullets. (H&S Sections 3

and 7)

2. Only operate the machine in a well-ventilated area. (H&S Sections 3, 8, 9, and 12)

3. Park next to suitable clean water supply on a level ground.

4. Ensure vehicle handbrake is applied. (H&S Sections 3, 11, and 13)

5. To fill water tank, connect to water supply. The water will fill the tank via the inlet hose

reel when the tank is full it will flow out the overflow. (NOTICE: To comply with water

authority bylaws never fill the tank by putting a hose directly inside)

6. Feed the end of the high-pressure hose through the hose trace on the swinging arm

in front of the hose reel. Do not fit the nozzle or gun at this point! (H&S Section 3, 6,

and 16)

7. In order to avoid an interruption to the jetting operation please ensure that the hand

held ‘radio control unit’ is fully charged, this is to ensure the radio signal is at full

strength and not compromised while the unit is being operated in ‘remote’ mode.

NOTICE: Do not drop the handheld “radio control unit” (RCU) down a manhole

as this could cause it permanent damage. Please use the lanyard provided.

19

4.4. Starting the Engine & Setting the Operating Pressure

The Vanpack is supplied with a Radio Control System allowing One-man operation ‘OMO’ in

accordance with the 'Single Person Operation’ as detailed in The Code of Practice.

Starting procedures are provided for 'Local' operation where water to the high-pressure hose

is controlled by the operator using the Control unit at the machine, and for 'remote' operation

where water to the high-pressure hose is controlled by the hand-held radio control unit ‘RCU’.

While the remote-control facility is provided for single person jetting operation, it should be

noted that initial pressure check must be made at the pump set. Hence, even with the 'remote'

enabled, all initial pressure checks must be made

Either:

With a single operator and ‘radio control unit’ (RCU) adjacent to the pump set and with

the nozzle secure in a drain or pipe or the gun firmly held in the hand.

Or:

With two people, one at the pump set and one in charge of the nozzle or gun.

Once the required operating pressure has been set, remote operation can be safely conducted

by one person using the handheld ‘radio control unit (RCU)

Tank water level

Ensure you have an adequate water supply and that the water tank is at least ½ full. The

machine WILL NOT RUN if the water tank is empty, this will be indicated by an on-screen

warning on the control panel, clearly marked as ‘low water’ as well as an audible warning. It

is preferable to have a full tank of water and provide the pump with a good positive head.

NOTICE: Do Not allow unfiltered water into the pump

20

4.5. Pre-start Checks & Procedures

4.5.1. Starting the Engine

Pre-start Checks

Ensure the open-ended high-pressure hose is in a safe position, preferably within sight of the

operator at the control panel.

Indirect Injection Diesel Engine Key Start Module Operating Procedure

1. Rocker Switch (Bottom Right of Panel) is the Master On/Off (0)

2. In position (1) (On) auxiliary circuits will be energized, screen will be illuminated.

3. Enter the 4-digit PIN using the up and down arrows to select numbers and the enter

button to select

4. Momentarily press the Green button on the Controller, this will automatically run

through pre-heat and prestart When cold. Engine will start automatically and idle at a

pre-determined engine rpm. **Water will now be circulating through the pump and be

diverted back the water tank

This manual suits for next models

1

Table of contents

Other HARBEN Water Pump manuals

Popular Water Pump manuals by other brands

Wilo

Wilo Yonos MAXO Installation and operating instructions

GORMAN-RUPP

GORMAN-RUPP SFDV3A Installation, operation, and maintenance manual with parts list

BGS technic

BGS technic 1609 instruction manual

KSB

KSB Amarex N series Installation and operating manual

SKC

SKC 224-PCXR8M operating instructions

Grundfos

Grundfos HYDRO MPC instructions

Ingersoll-Rand

Ingersoll-Rand NM2304B-X-X Operator's manual

Becker

Becker U 5.200 operating instructions

FLOWTECH

FLOWTECH flowpress WMDA Operation and maintenance manual

Taconova

Taconova TACOFLOW2 PURE 15 Installation and operating instructions

Bestway

Bestway SALUSPA S100105 owner's manual

Trotec

Trotec TGP 1025 ES operating manual