SKC 224-PCXR8M User manual

Operating Instructions

Universal Sample Pump

Catalog No. 224-PCXR8M

SKC Inc.

863 Valley View Road

Eighty Four, PA 15330

Form #37729 Rev 0804

Table of Contents

Description...........................................................................1

Performance Prole............................................................................................... 2

Operation..............................................................................4

High Flow Applications .......................................................................................... 4

Low Flow Single-tube Applications........................................................................ 9

Low Flow Multiple-tube Applications ................................................................... 14

Maintenance.......................................................................20

Pump Inlet Filter .................................................................................................. 20

Battery Pack Care ............................................................................................... 20

Replacing Battery Pack ....................................................................................... 21

Service Policy ....................................................................22

Parts Descriptions.............................................................24

Replacement Parts.............................................................................................. 26

Optional Accessories........................................................28

Warranty.............................................................................29

MSHA Approval .................................................................30

Indicates a warning or caution.

Indicates a premier feature of the pump.

Notice: This operating instruction may not address all safety concerns (if any) associated with this product and its use.

The user is responsible for determining and following the appropriate safety and health practices and regulatory limitations

(if any) before using the product. The information contained in this document should not be construed as legal advice,

opinion, or as a nal authority on legal or regulatory procedures.

1

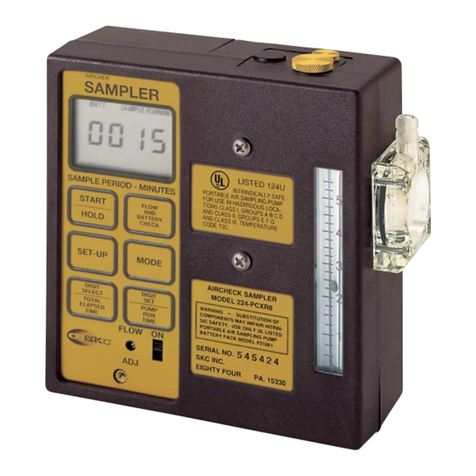

Description

The PCXR8M Universal Sample Pump is a constant ow air sampler suitable for a broad

range of applications. It is ideal for industrial hygiene studies as well as environmental

testing.

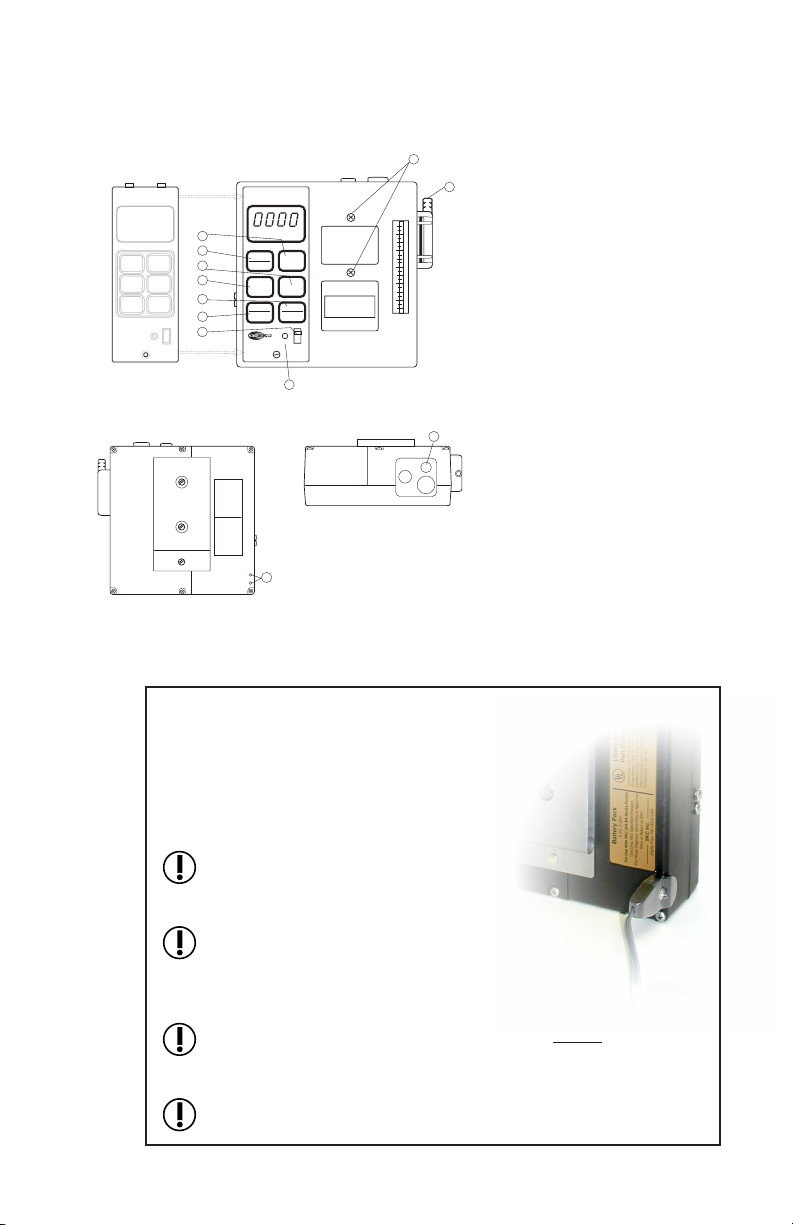

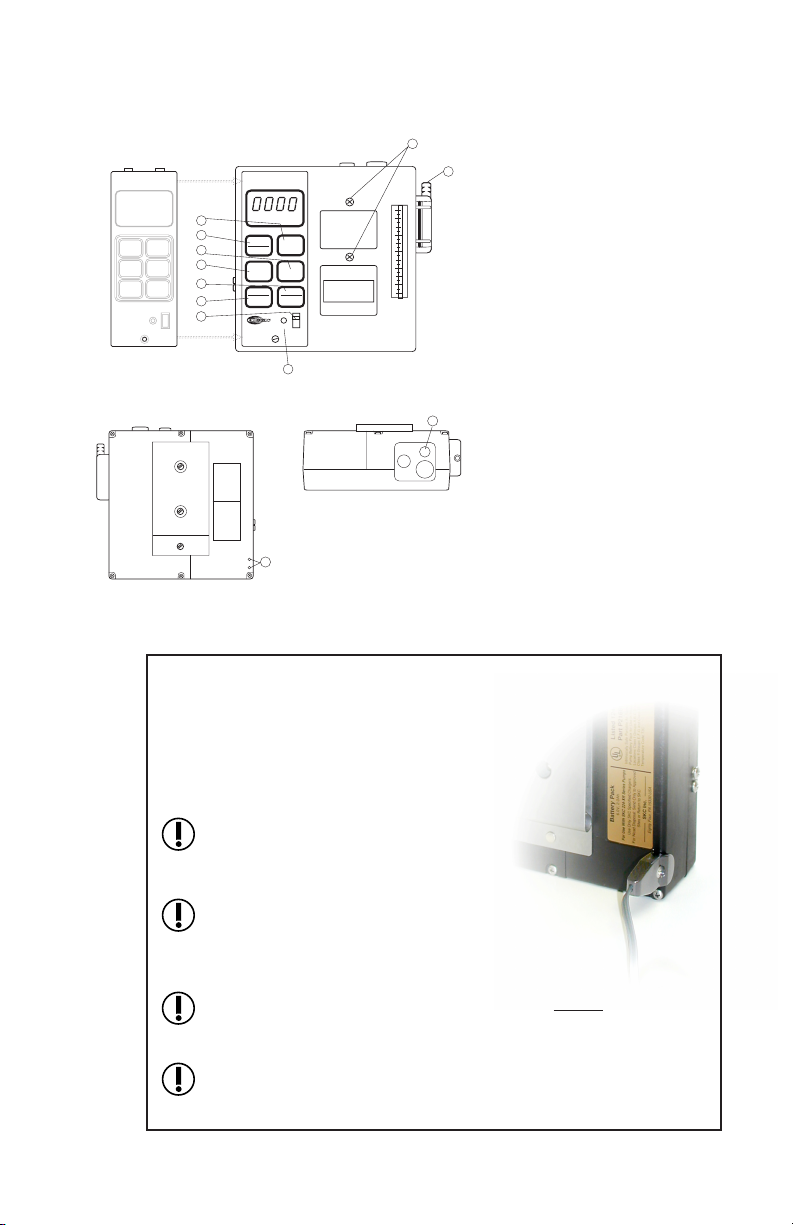

Low Flow Regulator

(beneath cap screw)

allows pump to be switched

from high to low ow.

Durable RFI-shielded Case

provides protection from radio

frequency interference

between 27 and 1000 MHz.

Rechargeable NiCad Battery

provides continuous 8-hour

operation on a single charge.

Built-in

Particulate Trap

in see-through

housing

protects pump.

Built-in Rotameter

provides a visible check

of relative ow rate during

sampling from 0.5 to 3 L/min.

Accessory Mounting Screws

allow sampling accessories

such as impinger holders

to be secured to pump.

Recessed Flow Adjustment

adjusts ow rate between

1000 and 3000 ml/min.

Digital LCD

shows run time, set times,

battery check, and

fault functions.

Touch Keypad

for programmable

functions

On/Off Switch

Tamper-resistant Cover

prevents changes to settings.

PCXR8M Universal Sample Pump

2

Performance Prole

Flow Range: ......................... 1000 to 3000 ml/min

(5 to 500 ml/min requires adjustable low ow holder)

Weight: .................................. 34 oz (964 gm)

Dimensions: ........................ 5.1 x 4.7 x 1.9 in (13 x 11.9 x 4.8 cm)

Compensation Range: ....... 1000 ml/min at 40 inches water back pressure

2000 ml/min at 40 inches water back pressure

3000 ml/min at 22 inches water back pressure

Flow Control: ....................... Holds constant ow to ± 5% of the set point

Run Time: ............................. 8 hrs minimum at 3000 ml/min and 20 inches water back pressure;

dependent on media used

Flow Indicator: ..................... Built-in ow indicator with 250-ml division; scale marked at 1, 2, 3, 4,

and 5 L/min

Power Supply: .................... MSHA approved when used with rechargeable NiCad battery pack,

2.0-Ah capacity, 4.8 V, Cat. No. P22434 only. Recharge battery

pack in fresh air only.

Charging Time: .................... ≤ 6 hrs with PowerFlex Charger

Operating Temperature: .... -20 C to 45 C (-4 F to 113 F)

Storage Temperature: ........ -40 C to 45 C (-40 F to 113 F)

Charging Temperature: ..... 5 C to 45 C (41 F to 113 F)

Operating Humidity: .......... 0 to 95% Relative

Protect sample pump from exposure to water and weather.

Multiple-tube Sampling: ..... Built-in constant pressure regulator allows user to take up to four

simultaneous tube samples at different ow rates up to 500 ml/min

each (maximum total combined ow 1350 ml/min) using the adjust-

able low ow holder.

Flow and

Low Battery Fault: ............... If the pump is unable to compensate due to excessive back pres-

sure or if a low battery condition exists, the pump enters fault.

During fault, the pump shuts down, the LCD indicates a ow or low

battery fault, timing functions pause, and time display is retained.

Battery Test: ........................ LCD shows battery condition prior to sampling.

Time Display: ....................... LCD shows sampler run time in minutes for sampling period

elapsed time, pump run time, or total elapsed time including de-

layed start time.

3

Timing Accuracy: ............ ± 0.05% (± 45 seconds per day)

Sampling Pause: ............ Allows user to temporarily halt sampling without loss of timing data.

Restart does not require resetting time.

Timed Shutdown: ........... Allows user to select minutes of operation before automatic shutdown.

Timed shutdown maximum is 9999 minutes (7 days).

Delay On: ..........................

Allows user to select minutes to delay test up to 9999 minutes (7 days).

Intermittent Sampling: ... Programmable to allow user to extend short-term samples over an ex-

tended period of time to meet time weighted average (TWA) require-

ments with a reduced number of samples. Elapsed time maximum is

9999 minutes (7 days), at which time the sample pump shuts down.

RFI/EMI Shielding

Performance: ................ Complies with requirements of EN 55022, FCC Part 15 Class B, EN

50082-1; frequency range of the radiated susceptibility test was 27

MHz to 1000 MHz. CE marked.

Intrinsic Safety: ............... MSHA approved to 30 CFR, section 18; approval no. 2G-4036-0.

Tested for use in methane-air mixtures only.

Intrinsic safety and other approvals may be void if SKC pumps are not

repaired by SKC or authorized SKC repair centers.

Replacing parts with non-SKC parts or parts not approved for use with

this pump model can void intrinsic safety approvals and the manufacturer

warranty.

4

Operation

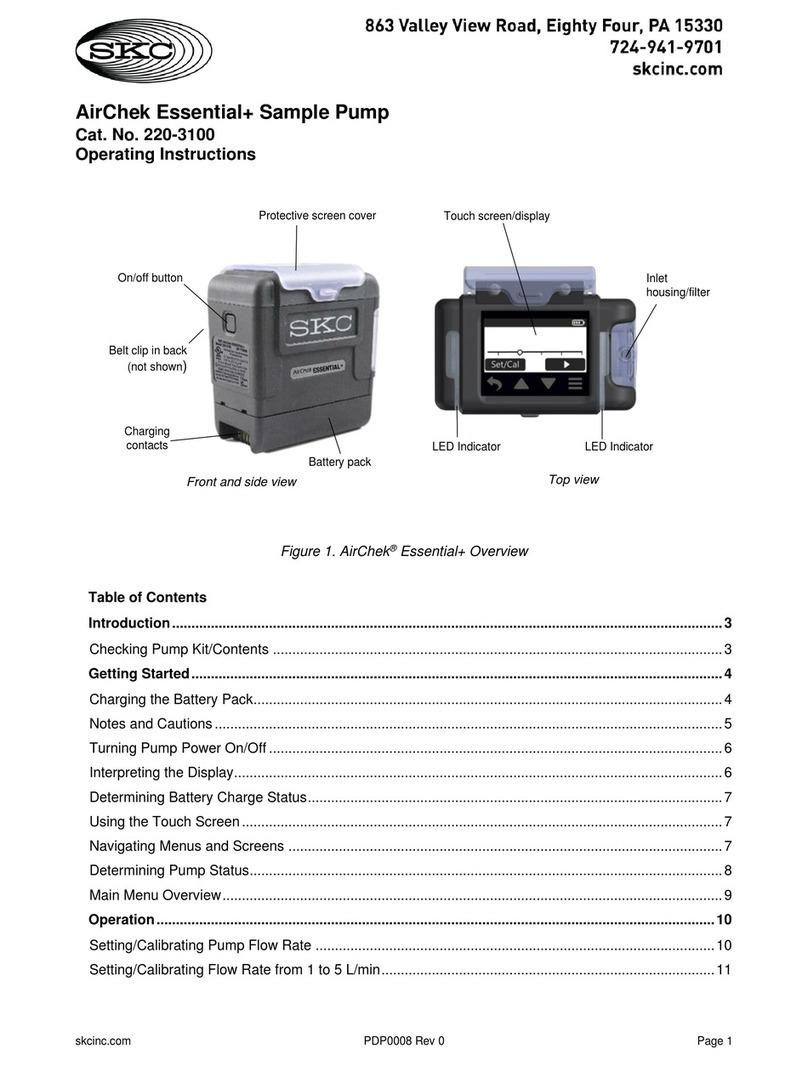

High Flow Applications (1000 to 3000 ml/min)

Setup

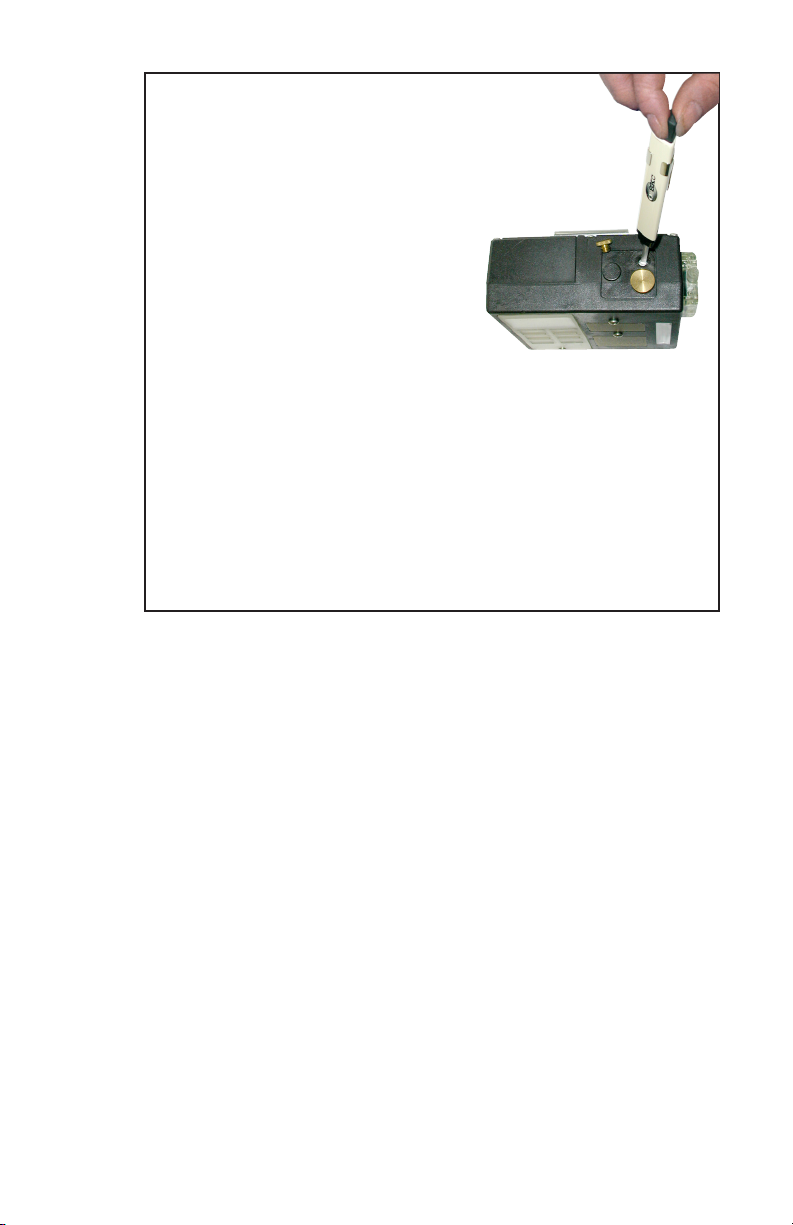

Ensure pump is not running. Charge the

battery by connecting the charger plug

to the sampler charging jack (Figure

1, #22). Ensure that the battery is fully

charged before sampling.

Do not charge or operate pump from

charger in hazardous locations.

Charge in fresh air only.

Use only an SKC-approved charger

designated for this model to ensure

reliable performance and to maintain

the SKC warranty.

Ensure proper orientation of charging cable before plugging it

into the charging jack. Improper orientation/contact will short-

circuit the battery.

Short-circuiting the battery pack will render it immediately

inoperative.

1

Charger and battery

pack connected

13

AIRCHEK

SAMPLER

5

4

3

2

1

SAMPLE PERIOD — MINUTES

START

HOLD

FLOW

AND

BATTERY

CHECK

DIGIT

SET

PUMP

RUN

TIME

DIGIT

SELECT

TOTAL

ELAPSED

TIME

SET-UP MODE

FLOW

ADJ

ON

AIRCHEK SAMPLER

MODEL 224-PCXR8M

11

22

18

BACK

TOP

FRONT

12

8

7

6

5

4

3

2

2 Flow and Battery Check Key

3 Start/Hold Key

4 Mode Key

5 Set-up Key

6 Digit Set/Pump Run Time Key

7 Digit Select/Total Elapsed

Time Key

8 On/Off Switch

11 Flow Adjust Screw

12 Accessory Mounting Screws (2)

13 Intake/Filter Housing

18 Cap Screw to Regulator

22 Charging Jack

Figure 1

Front, back, and top views of PCXR8M Sampler

For additional drawings, see pages 25 and 27.

5

De-activating the Regulator

To ensure the pump is set for high ow,

remove the cap screw (Figure 1, #18)

covering the regulator valve and turn

the exposed screw clockwise until it

stops. (Do not overtighten.)

Replace the cap screw. The pump is

now set for high ow.

Setting or Verifying Flow Rate

Using 1/4-inch Tygon® tubing, connect the sampling medium to

the pump intake (Figure 1, #13).

Remove the tamper-resistant

cover. Start the pump

using the on/off switch

(Figure 1, #8). Press

Start/Hold (Figure 1, #3).

Press Flow and Battery

Check (Figure 1, #2).

Adjust the ow using the

ow adjust screw (Figure

1, #11) until the built-in

rotameter reads 2 L/min.

The LCD should indicate

BATT OK in the upper left cor-

ner (if it doesn’t, recharge the battery). Press Flow and Battery

Check to place the pump in Hold.

Connect a calibrator to the intake of the sampling medium.

Press Flow and Battery Check to start the pump, and set the ow

rate using the ow adjust screw (Figure 1, #11).

When the ow rate is set, press Flow and Battery Check to place

the pump in Hold. Disconnect the calibrator.

Replace the sampling medium used for calibration with unex-

posed medium for sample collection.

Calibration train with

lter cassette

2

3Flow

adjust

screw

On/Off

switch

Tubing

Calibrator

Sample

media

For high ow,

turn valve screw

clockwise.

6

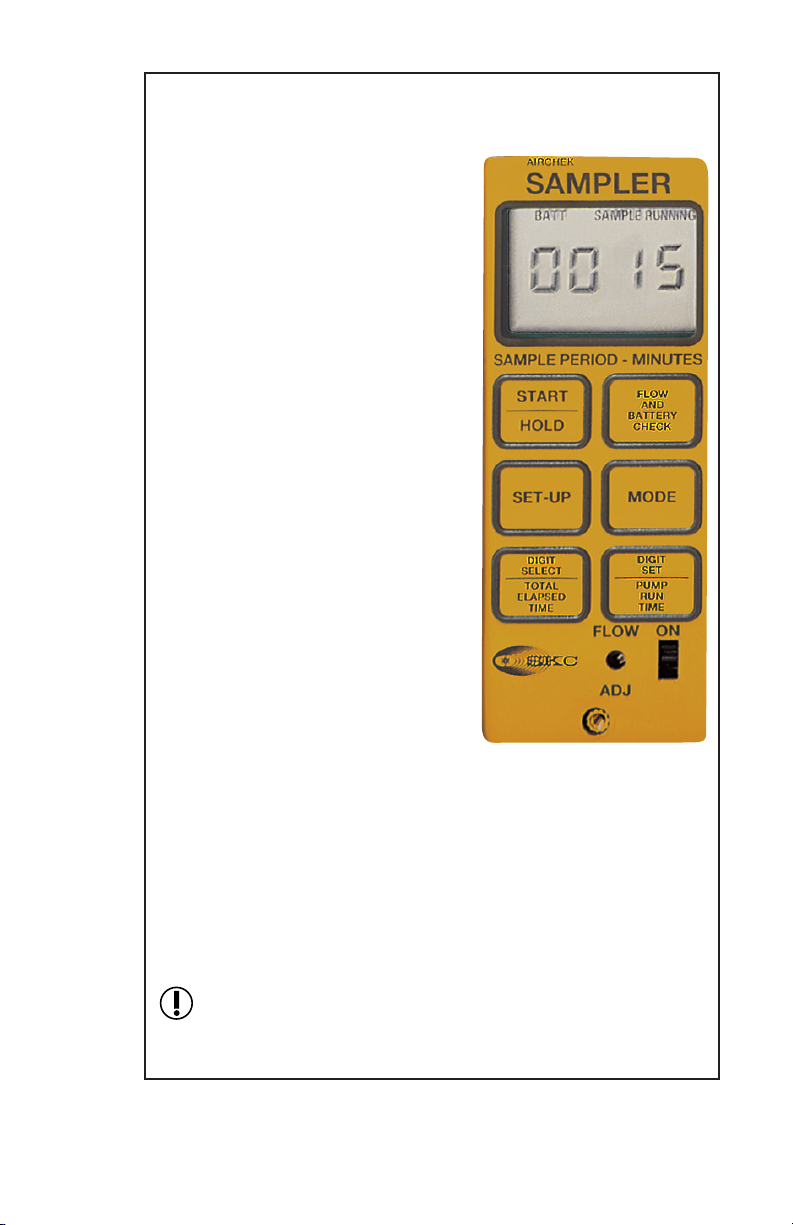

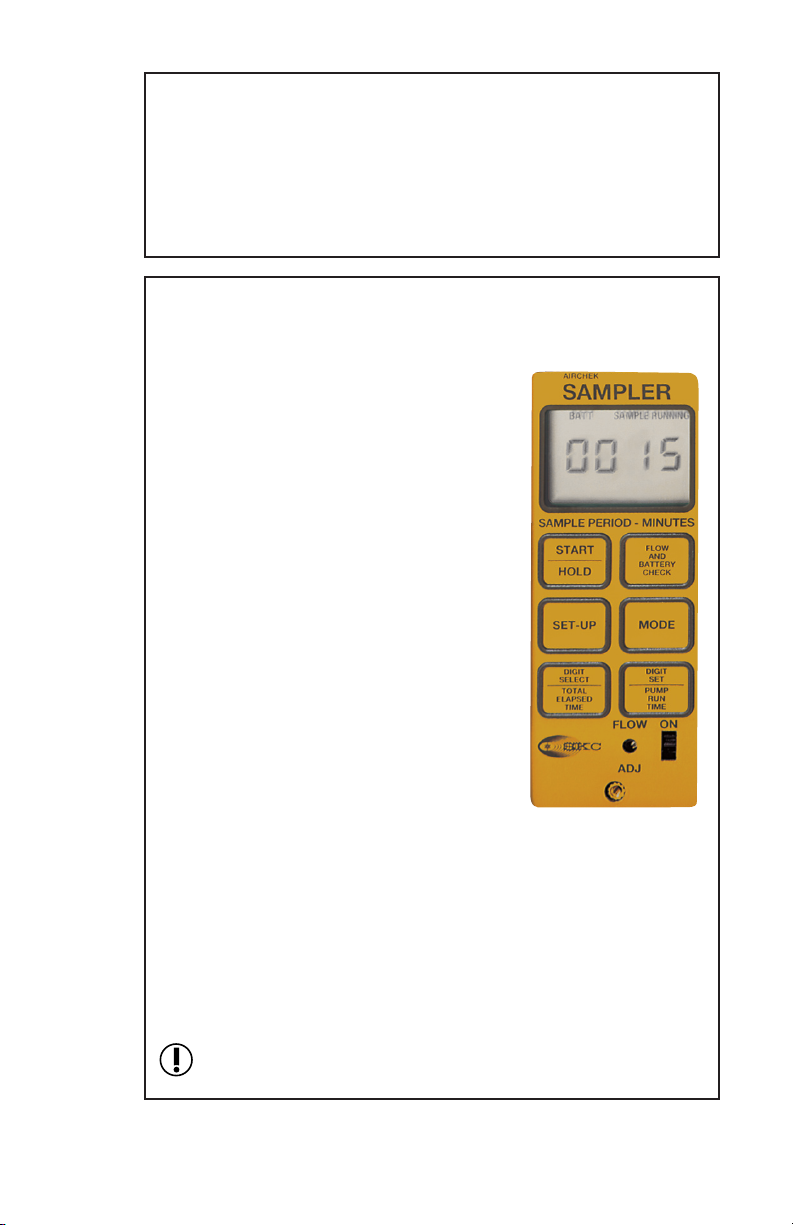

Programming Delayed and Intermittent

Sampling

To enter Delayed Start Mode:

From Hold, press Setup. Enter

the number of minutes delay (up

to 9999) before the sampling

period begins by pressing Digit

Select and Digit Set. Digit Select

advances the ashing digit and

Digit Set increases the value of the

ashing digit.

To enter Sample Period Mode:

Press Mode. Press Digit Select

and Digit Set to enter the sampling

time period in minutes (up to

9999). Note: The sample period is

the total period in which sampling

is performed and not the pump run

time.

To enter Pump Period Mode:

Press Mode. This is the actual run-

ning time of the pump. Use Digit

Select and Digit Set to enter the

pump run time in minutes (up to

9999).

If intermittent sampling is not

desired, set the sampling period

to equal the pump period. If the

pump running time is less than

the sampling period, the pump will automatically calculate and

control on/off cycling to complete the pump run time during the

sampling period.

Pressing Mode will scroll through the program sequence.

For intermittent sampling, the elapsed time maximum is 9999

minutes (7 days), at which time the sample pump will shut

down.

4

PCXR8M Keypad

7

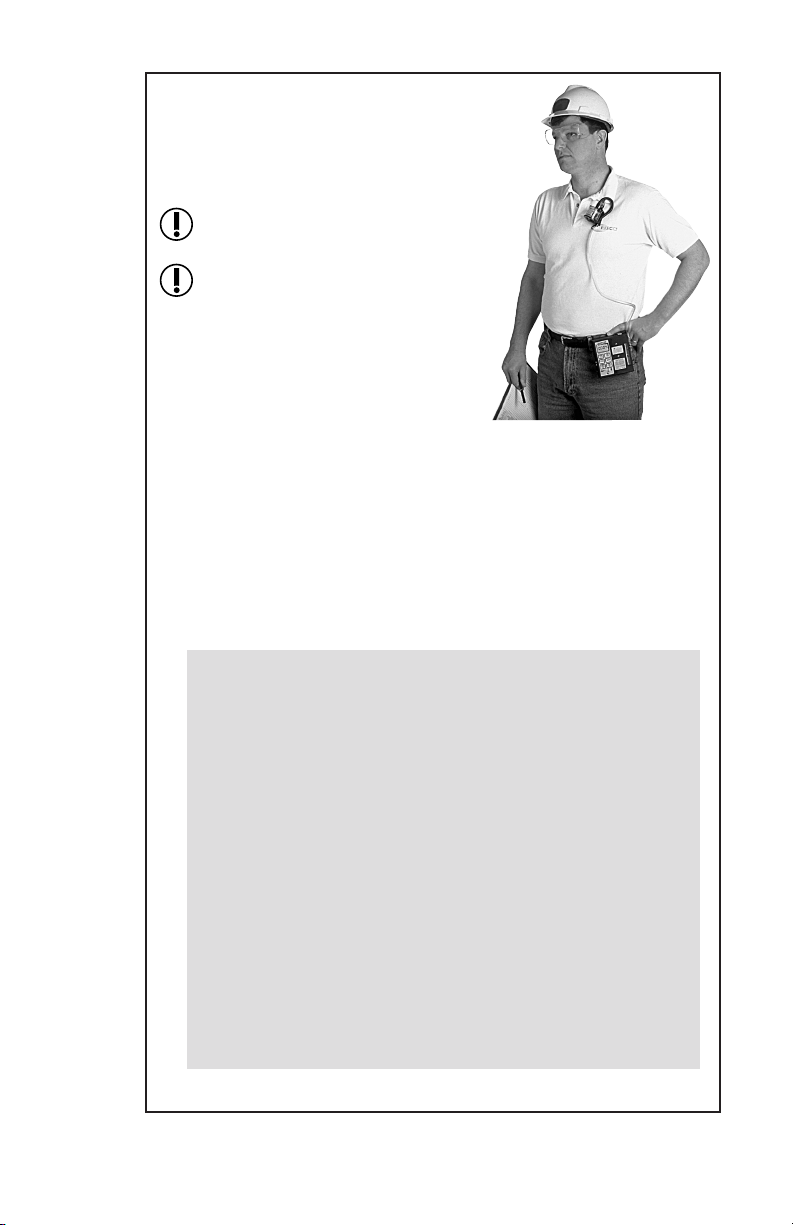

Sampling

For personal sampling, clip the sample

collection medium to the worker in the

breathing zone.

Protect sample pump from weather

when in use outdoors.

Use of any device other than the

approved battery pack to power

the pump voids MSHA approval.

While the LCD displays HOLD, start

sampling by pressing Start/Hold. If

a time delay has been programmed,

DELAYED START will ash on the

LCD and the amount of time remain-

ing until sampling starts will appear.

SAMPLE RUNNING will display when the delay sequence has

ended. The LCD will automatically track sampling period time

elapsed.

At the end of the sampling period, press Start/Hold and record

the stop time.

User Options During Sampling

Pause - Pause (shutdown) the pump by pressing Start/Hold. All

timing data will freeze. To resume sampling, press Start/Hold;

timing data will resume.

Flow or Battery Fault Shutdown - During restricted ow or

low battery conditions, the sampler will shut down. HOLD

will display on the LCD and timing functions will pause. LO

BATT or FLOW FAULT will display on the LCD depending

on the cause of the shutdown. To restart from ow fault, correct

the blockage and press Start/Hold. If LO BATT is displayed,

recharge the battery before sampling.

Display Times - Elapsed sampling period is continuously dis-

played on the LCD. Press and hold Pump Run Time (Figure

1, #6) to display pump run time. Press and hold Total Elapsed

Time (Figure 1, #7) to display total elapsed time, including

delayed start time.

Clip sample medium to

worker and pump to belt.

continued on page 8

5

8

Sampling with Impingers

When using impingers, place an

in-line trap between the pump and

the impinger to protect the sam-

pler from liquid or vapors. The

impinger and trap can be mounted

to the sampler using the accessory

mounting screws (Figure 1, #12) or

placed in a holster at the worker’s

waist.

Failure to use the impinger trap

voids the warranty.

Protect sample pump from

weather when in use outdoors.

Use of any device other than the approved battery pack

to power the pump voids MSHA approval.

Impinger holder on pump

with impinger and trap

5

(cont’d)

9

Setup

Ensure pump is not running. Charge the

battery by connecting the charger plug to the

sampler charging jack (Figure 1, #22). En-

sure that the battery is fully charged before

sampling.

Do not charge or operate pump from

charger in hazardous locations. Charge

in fresh air only.

Use only an SKC-approved charger

designated for this model to ensure

reliable performance and to maintain

the SKC warranty.

Ensure proper orientation of charging cable before plugging it

into the charging jack. Improper orientation/contact will short-

circuit the battery.

Short-circuiting the battery pack will render it immediately

inoperative.

1Charger and battery

pack connected

Low Flow Applications (5 to 500 ml/min)

Using Single Adjustable Low Flow Holder

13

AIRCHEK

SAMPLER

5

4

3

2

1

SAMPLE PERIOD — MINUTES

START

HOLD

FLOW

AND

BATTERY

CHECK

DIGIT

SET

PUMP

RUN

TIME

DIGIT

SELECT

TOTAL

ELAPSED

TIME

SET-UP MODE

FLOW

ADJ

ON

AIRCHEK SAMPLER

MODEL 224-PCXR8M

11

22

18

BACK

TOP

FRONT

12

8

7

6

5

4

3

2

2 Flow and Battery Check Key

3 Start/Hold Key

4 Mode Key

5 Setup Key

6 Digit Set/Pump Run Time Key

7 Digit Select/Total Elapsed

Time Key

8 On/Off Switch

11 Flow Adjust Screw

12 Accessory Mounting Screws (2)

13 Intake/Filter Housing

18 Cap Screw to Regulator

22 Charging Jack

Figure 1

Front, back, and top views of PCXR8M Sampler

For additional drawings, see pages 25 and 27.

10

Activating the Regulator

Remove the tamper-resistant

cover. Start the pump using the

on/off switch (Figure 1, #8). Press

Start/Hold (Figure 1, #3). Press

Flow and Battery Check (Figure

1, #2). Adjust the ow using the

ow adjust screw (Figure 1, #11)

until the built-in rotameter reads

1.5 L/min. The LCD should indi-

cate BATT OK in the upper left

corner (if it doesn’t, recharge the

battery). Press Flow and Battery

Check to place the pump in Hold.

Remove the cap screw covering the regulator valve (Figure 1,

#18) and turn the exposed screw four to ve turns counterclock-

wise.

Replace the cap screw. The pump is now set for low ow.

For low ow,

turn valve screw

counterclockwise.

2

11

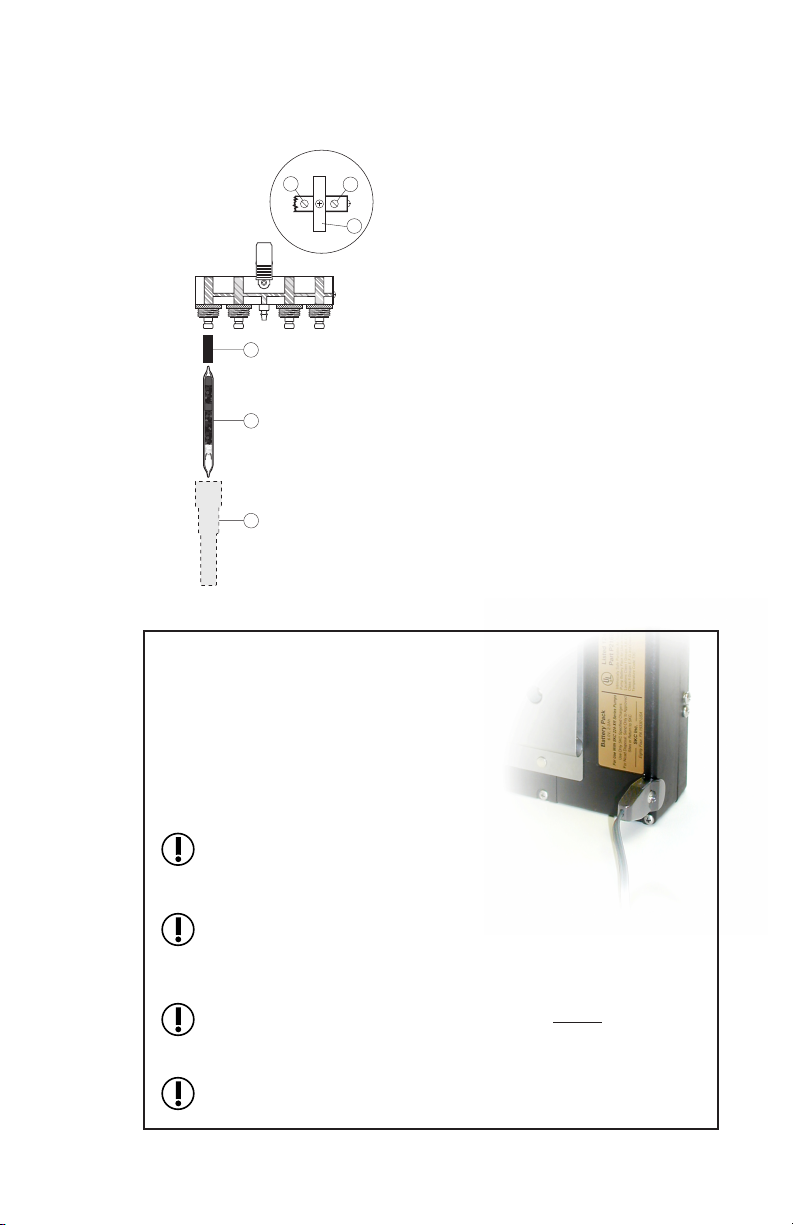

Figure 2

Single Adjustable

Low Flow Holder

with sample tube

1 Flow Adjust Screw

2 Rubber Sleeve

3 Sorbent Tube

Airow

Setting or Verifying Flow Rate

For a diagram of the pump, see Figure 1, page 9.

Connect a single adjustable low ow holder (Figure 2) to the

pump intake (Figure 1, #13) using 1/4-inch Tygon tubing.

Insert an opened sorbent tube

(Figure 2, #3) into the rubber

sleeve (Figure 2, #2) of the low

ow holder with the arrow on the

tube pointing toward the holder.

Connect a calibrator to the exposed

end of the sorbent tube.

Loosen the brass ow adjust screw on the low ow holder. Acti-

vate the pump by pressing Flow and Battery Check.

Adjust the ow rate by turning the

ow adjust screw (Figure 2, #1)

on the holder until the calibrator

indicates the desired ow.

Do not adjust the ow on the

pump. Adjust the ow only by us-

ing the ow adjust screw on the low

ow holder.

3Calibration train

with tube in low ow

holder

Turn screw on

low ow holder to

adjust ow.

Flow adjust

screw

continued on page 12

12

When the desired ow is set, place the pump in Hold by press-

ing Flow and Battery Check. Disconnect the calibrator. Replace

the sorbent tube used for setting the ow with a new unexposed

sorbent tube for sample collection.

Place the appropriate size tube cover over the tube, and screw it

into place on the low ow holder.

Programming Delayed and Intermittent

Sampling

To enter Delayed Start Mode: From

Hold, press Set-up. Enter the number

of minutes delay (up to 9999) before

the sampling period begins by pressing

Digit Select and Digit Set. Digit Select

advances the ashing digit and Digit Set

increases the value of the ashing digit.

To enter Sample Period Mode: Press

Mode. Press Digit Select and Digit Set to

enter the sampling time period in minutes

(up to 9999). Note: The sample period

is the total period in which sampling is

performed and not the pump run time.

To enter Pump Period Mode: Press

Mode. This is the actual running time of

the pump. Use Digit Select and Digit Set

to enter the pump run time in minutes (up

to 9999).

If intermittent sampling is not desired, set

the sampling period to equal the pump

period. If the pump running time is less

than the sampling period, the pump will automatically calculate

and control on/off cycling to complete the pump run time during

the sampling period.

Pressing Mode will scroll through the program sequence.

For intermittent sampling, the elapsed time maximum is 9999

minutes (7 days), at which time the sample pump will shut down.

4

PCXR8M Keypad

3

(cont’d)

13

Sampling

For personal sampling, clip the low ow

holder to the worker in the breathing zone.

Protect sample pump from weather when

in use outdoors.

Use of any device other than the approved

battery pack to power the pump voids

MSHA approval.

While the LCD displays HOLD, start sam-

pling by pressing Start/Hold. If a time delay

has been programmed, DELAYED START

will ash on the LCD and the amount of time remaining until

sampling starts will appear. SAMPLE RUNNING will display

when the delay sequence has ended. The LCD will automatically

track sampling period time elapsed.

At the end of the sampling period, press Start/Hold and record

the stop time.

To return to high ow, remove the low ow holder and

de-activate the regulator (see page 5).

For user options during sampling, see page 7.

Sampling with Long-duration Color Detector Tubes

Long-duration Color Detector Tubes re-

quire a special tube cover that accommo-

dates an in-line trap tube. The trap tube

protects the pump from caustic fumes

which are often released from detector

tubes. Closely read all precautions when

using these tubes.

Failure to use the necessary traps

will damage the pump and void the

warranty.

Clip holder to worker

and pump to belt.

5

(See Optional Accessories, page 28)

Pump with

Tandem Tube

Cover

Long-duration

detector tube

Trap Tube

14

Low Flow Applications (5 to 500 ml/min)

Using Multiple-tube Adjustable Low Flow Holder

Figure 3

Quad Adjustable Low Flow Holder

1 Anti-tamper Cover

2 Flow Adjust Screws

3 Rubber Sleeve

4 Sorbent Sample Tube

5 Protective Cover

Top view of adjust

screws

1

Charger and battery

pack connected

Setup

For a diagram of the pump, see Figure 1, page 9.

Ensure pump is not running. Charge

the battery by connecting the charger

plug to the sampler charging jack

(Figure 1, #22). Ensure that the battery

is fully charged before sampling.

Do not charge or operate pump from

charger in hazardous locations.

Charge in fresh air only.

Use only an SKC-approved charger

designated for this model to ensure

reliable performance and to maintain

the SKC warranty.

Ensure proper orientation of charging cable before plugging it

into the charging jack. Improper orientation/contact will short-

circuit the battery.

Short-circuiting the battery pack will render it immediately

inoperative.

22

1

3

5

4

15

continued on page 16

Setting or Verifying Flow Rate

If performing multiple-tube sampling using an adjustable low

ow holder (dual, tri, or quad), the ow rate of the pump must

be greater than the sum of the ow rates through the tubes; the

ow rate through any one tube cannot exceed 500 ml/min and

maximum total combined ow is 1350 ml/min.

Ensure the pump is set for low ow (see Activating the Regulator,

page 10).

Connect the adjustable low ow holder (Figure 3, page 14) to the

pump intake (Figure 1, #13) using 1/4-inch Tygon tubing.

Insert an opened sorbent tube into each rubber sleeve of the low

ow holder (Figure 3, # 3 and 4) with the arrow on the tube

pointing toward the holder.

If sampling with fewer tubes than number of ports, insert un-

opened sorbent tubes in the empty ports to seal them.

Note the ow rates specied by each sampling method and add

them together. Set the pump to a ow rate that is greater than the

sum. Do not exceed 1350 ml/min.

Connect a calibrator to the exposed end of a sorbent tube, loosen

the ow adjust screw on the low ow holder, and activate the

pump by pressing Flow and Battery Check.

Turn the ow adjust screw (Figure 3, #2) on the low ow holder

until the desired ow rate is achieved. Turn clockwise to de-

crease the ow.

Do not adjust the ow on the pump. Adjust the ow only by us-

ing the ow adjust screw on the low ow holder.

Do not exceed 500 ml/min ow rate per tube and 1350 ml/min

total ow rate for pump.

Connect holder to pump

intake and tube inlet to

calibrator.

2

16

When the desired ow is set on the

initial tube, place the pump in Hold

by pressing Flow and Battery Check.

Remove the calibrator from the tube

and connect to the exposed end of

the next sorbent tube. Press Flow and

Battery Check and repeat the ow

adjustment process until all tubes are

ow calibrated. Changing the ow on one tube will not affect the

ow rate through the remaining tubes.

Do not exceed 500 ml/min ow rate per tube and 1350 ml/min

total ow rate for pump.

For tri and quad models, rst rotate each anti-tamper cover (Fig-

ures 3 and 4) to expose the ow adjust screw, then adjust until the

calibrator indicates the desired ow.

When the ow rate is set for each tube, press Flow and Battery

Check to place the pump in Hold and disconnect the calibrator.

Replace the sampling media used for calibration with unexposed

media for sample collection. Use a protective tube cover to pre-

vent tube breakage.

If sampling with fewer tubes than number of ports, insert un-

opened sorbent tubes in the empty ports to seal them.

2

(cont’d)

Screw Screw

Figure 4

Cut-away of Tri/Quad Low

Flow Holder

Table of contents

Other SKC Water Pump manuals

SKC

SKC AirChek ESSENTIAL User manual

SKC

SKC Pocket Pump TOUCH User manual

SKC

SKC 224-50MH User manual

SKC

SKC 220 Series User manual

SKC

SKC Quick Take 15 User manual

SKC

SKC Leland Legacy User manual

SKC

SKC Flite 2 User manual

SKC

SKC AirChek 52 User manual

SKC

SKC TOUCH Operating instructions

SKC

SKC AirLite 110-100-T User manual

SKC

SKC 224-44XR User manual

SKC

SKC Leland Legacy User manual

SKC

SKC AirChek XR5000 User manual

SKC

SKC 224-44MTX User manual

SKC

SKC Vac-U-Go 228-9605 User manual

SKC

SKC AirChek 220-3100 User manual

SKC

SKC AirChek XR5000 User manual

SKC

SKC 224-PCXR4 User manual

SKC

SKC 210-1002MTX User manual

SKC

SKC AirChek 3000 User manual