English version 2/21

CONTENTS

1. Introduction...................................................................................................... 3

1.1 Introduction..................................................................................................... 3

2. Safety Instructions........................................................................................... 4

2.1 Use of machine...............................................................................................4

2.2 Clothing........................................................................................................... 4

2.3 Personal protective equipment ....................................................................... 4

2.4 Fluids: ............................................................................................................. 5

2.4.1 Water based wood protection:............................................................................................5

2.4.2 Oil based paint....................................................................................................................5

2.5 Room temperature.......................................................................................... 5

2.6 Ventilation....................................................................................................... 5

2.7 Risks during use .............................................................................................5

2.8 Moving the machine........................................................................................ 5

3. Technical data.................................................................................................. 7

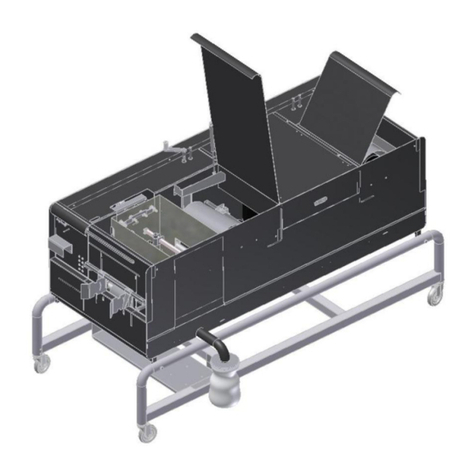

4. Preparing the machine for use....................................................................... 8

5. Adjusting the machine..................................................................................... 9

6. Cleaning.......................................................................................................... 12

6.1 After use of water based products................................................................12

6.2 After using oil based products....................................................................... 13

7. Maintenance ................................................................................................... 15

7.1 V-belts, belts and toothed belts..................................................................... 15

7.2 Motor v-belt –intermediate shaft I (item 575)...............................................15

7.3 Intermediate shaft I v-belt –vertical brushes (item 523)...............................15

7.4 V-belts for vertical brushes (item 524) .......................................................... 15

7.5 Forward drive toothed belt (item 526)........................................................... 15

7.6 Chain to horizontal brushes (item 555).........................................................15

7.7 Resetting the brush arms.............................................................................. 15

7.8 Belts in the brushes arrangement.................................................................15

7.9 Pumps (Item 720).........................................................................................15

8. Replacing spare parts ................................................................................... 16

9. Trouble shooting............................................................................................ 17

10. Spare parts lists............................................................................................. 18

11. Accessories.................................................................................................... 21

12. Production address....................................................................................... 21