Power Fist 8492910 User manual

V1.0 8492910

Please read and understand all instructions before use. Retain this manual for

future reference.

This page is intentionally left blank.

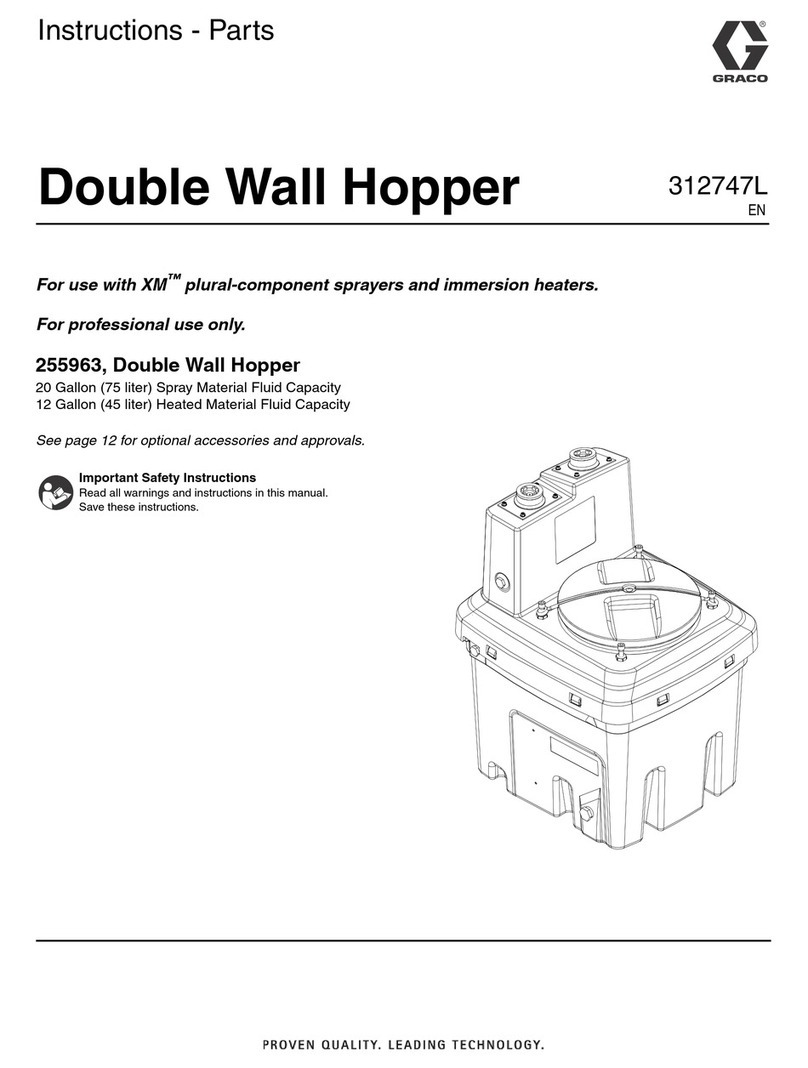

SPECIFICATIONS

Pressure Range 40 PSI

Flow Rate 2.4 CFM

Voltage Rating AC 120V

Amperage Rating 10A

Frequency Rating 60HZ

Wattage 1,200W

Fluid Delivery Type Air

Nozzle Size 0.9/1.8 mm

Cup Capacity 1 litre

Number of Spray Settings 3

Hose Size 15 feet (4.5 metres)

Cup Material Polypropylene

INTRODUCTION

This paint spray system applies lacquers, stains, water-based nishes and oil-

based paints with minimal overspray. It features a unique turbine system that

delivers airow directly to the spray gun, eliminating the need for an air

compressor. An adjustable spray nozzle allows for horizontal, vertical and

round at patterns.

SAFETY

WARNING! Read and understand all instructions before using this tool.

The operator must follow basic precautions to reduce the risk of

personal injury and/or damage to the equipment.

HAZARD DEFINITIONS

Please familiarize yourself with the hazard notices found in this manual. A

notice is an alert that there is a possibility of property damage, injury or death

if certain instructions are not followed.

DANGER! This notice indicates an immediate and specic hazard that will result in severe

personal injury or death if the proper precautions are not taken.

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 3 www.princessauto.com / 1-800-665-8685

WARNING! This notice indicates a specic hazard or unsafe practice that could result in a

serious injury if the proper precautions are not taken.

CAUTION! This notice indicates a potentially hazardous situation that may result in minor

or moderate injury if proper practices are not taken.

NOTICE! This notice indicates that a specic hazard or unsafe practice will result in

equipment or property damage, but not personal injury.

WORK AREA

1. Operate in a safe work environment. Keep your work area clean, well-lit

and free of distractions. Place lights so you are not working in a shadow.

2. Keep anyone not wearing the appropriate safety equipment away from

the work area.

3. Store unused tools properly in a dry, safe and secure location to prevent

rust, damage or misuse.

4. Do not install or use in the presence of ammable gases, dust or liquids.

5. Always make sure that the area is well ventilated when using indoors.

6. Observe the wind direction when using the paint spray gun outdoors.

PERSONAL SAFETY

WARNING! Wear personal protective equipment approved by the

Canadian Standards Association (CSA) or American National Standards

Institute (ANSI).

PERSONAL PROTECTIVE EQUIPMENT

1. Always wear impact safety goggles that provide front and side protection

for the eyes. Eye protection equipment should comply with CSA Z94.3-07

or ANSI Z87.1 standards based on the type of work performed.

2. The tool may contain high pressure. Use safety glasses and gloves for

protection during operation. Keep hands clear of the exposed rubber

portions of the hose.

3. Wear protective clothing and gloves designed for the work environment,

materials and tools.

4. The air source used with this tool may cause hearing damage. Wear ear

protection gear to eliminate or reduce the noise.

5. Wear the appropriate rated dust mask or respirator. Wear a NIOSH

approved respirator when working on materials that produce hazardous

fumes, dust or particulate matter.

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 4

PERSONAL PRECAUTIONS

Control the tool, personal movement and the work environment to avoid

personal injury or damage to tool.

1. Do not operate any tool when tired or under the inuence of drugs,

alcohol or medications.

2. Do not overreach when operating a tool. Proper footing and balance

enables better control in unexpected situations.

3. Keep your ngers away from the trigger/switch while carrying the tool,

attaching an air hose or an accessory. Lock the trigger/switch safety if

available.

4. Avoid unintentional starts. Be sure that the regulator/throttle switch is in

the neutral or OFF position when not in use and before connecting it to

any air source.

5. Never point the air stream or tool at any point of your body, other people

or animals. Debris and dust ejected at high speed can cause an injury.

SPECIFIC SAFETY

WARNING! DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to the tool safety rules. If you use

this tool unsafely or incorrectly, you can suer serious personal injury.

WARNING! Do not use a paint or a solvent containing halogenated

hydrocarbons (HHC) such as methylene chloride or trichloroethane.

Inhaled or ingested, HHC can cause serious lung or internal injury.

1. Use the correct tool for the job. This tool was designed for a specic

function. Do not modify or alter this tool or use it for an unintended

purpose.

a. Only use a nozzle tip specied for this tool.

2. Know the contents of the paints and solvents being sprayed. Read all

Safety Data Sheets (SDS) and container labels provided with the paints

and solvents.

a. Do not use paint or solvents such as HHC, thinners, paint removers or

acidic cleaning uids. They may react with electroplated components

and promote corrosion in the tool.

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 5 www.princessauto.com / 1-800-665-8685

3. Tightly recap all containers immediately after mixing and store in another

location to minimize vapours in the spray area and eliminate the potential

for spills.

4. Verify that all connections are secure before operating the paint spray

gun.

5. Do not operate the HVLP turbine in the presence of open containers or

spillage.

a. Make sure all vapours have dispersed prior to turning the HVLP

sprayer on.

6. Do not allow the spray to strike you and do not spray toward people or

animals. Do not spray the tool itself or any electrical sources.

7. Do not leave the spray gun under pressure while unattended. Turn the

HVLP turbine o and relieve the pressure in the paint spray gun.

8. Paint or solvent owing through the equipment is able to produce static

electricity. Static electricity creates a risk of re or explosion in the

presence of paint or solvent fumes. All parts of the spray system,

including the pump, spray gun and any objects in and around the spray

area shall be properly grounded to protect against static discharge and

sparks.

9. Have a working re extinguisher present while operating the spray paint

gun.

10. This paint spray gun is intended for household use only.

11. Do not leave the air tool unattended with its compressed air supply on.

Turn o the compressed air supply and bleed the air tool of any remaining

compressed air before leaving the air tool unattended.

12. Serious injury may occur from loose debris being propelled at high speeds

from the compressed air stream. Always wear OSHA approved safety

glasses to protect the eyes during operation of the air compressor.

13. Do not cover the air vents. Proper cooling of the motor is necessary to

ensure normal life of the tool.

AIR HOSE PRECAUTIONS

1. Inspect the tool's air hose for cracks, fraying or other faults before each

use. Discontinue use if the air hose is damaged or hissing is heard from

the air hose or couplers. Replace the defective air hose.

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 6

2. Do not allow people, mobile equipment or vehicles to pass over the

unprotected air hose. Position the air hose away from high trac areas, in

a reinforced conduit or place planks on both sides of the air hose to create

a protective trench.

3. Prevent damage to the air hose by observing the following:

a. Never carry the tool by the air hose.

b. Keep the air hose behind the tool and out of the tool's work path.

c. Keep the air hose away from heat, oil, sharp edges or moving parts.

d. Do not wrap the air hose around the tool as sharp edges may pierce

or crack the air hose. Gently coil the hose and either hang on a hook

or fasten with a device to keep hose together when storing.

4. A damaged or disconnected air hose under pressure may whip around and

inict personal injury or damage the work area. Secure the compressor's

air hose to a xed or permanent structure with clamps or cable ties.

ELECTRICAL SAFETY

WARNING! Do not touch or handle a live tool with any part of your body

that is wet or damp. Wet skin reduces resistance to electrical current,

increasing the danger of a serious or fatal shock.

1. Do not alter any parts of the tool or accessories. All parts and accessories

are designed with built-in safety features that may be compromised if

altered.

2. Protect yourself against electric shocks when working on electrical

equipment. Avoid body contact with grounded surfaces. There is an

increased chance of electrical shock if your body is grounded.

3. Do not expose the spray gun to rain, snow, frost or any other damp or wet

conditions. Water entering a tool will increase the risk of electric shock.

4. Do not disconnect the power cord in place of using the power switch. This

will prevent an accidental start-up when the power cord is plugged into

the power supply.

5. In the event of a power failure, turn o or unplug the machine as soon as

the power is interrupted. The possibility of accidental injury could occur if

the power returns and the unit is not switched o.

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 7 www.princessauto.com / 1-800-665-8685

6. Make certain the power source conforms to requirements of your

equipment (see Specications).

7. A polarized plug has two blades of dierent widths, allowing only one

way to insert the plug into the outlet. If the outlet does not accept a

polarized plug, contact a qualied electrician to install a polarized outlet.

Do not alter the plug, as this may compromise the built-in safety feature.

POWER TOOL PRECAUTIONS

1. Do not use any power tool with a malfunctioning power switch or control.

A power tool that fails to respond to the controls is dangerous and can

cause an injury. A qualied technician must repair and verify the power

tool is operating correctly, before it can be used.

2. Shut the power o and disconnect the spray gun from the power supply

(if possible) before making any adjustments, changing accessories,

cleaning, servicing or when storing. Such preventive safety measures

reduce the risk of starting the tool accidentally.

3. Never force the spray gun. Excessive pressure could break the tool,

resulting in damage to your workpiece or serious personal injury.

Excessive pressure is the cause if your tool runs smoothly under no load,

but roughly under load.

4. Check if the spray gun's moving parts are misaligned or binding before

each use. Correct the issue before using the spray gun to avoid an injury

or damage to the tool.

5. The material and the motor housing can get very hot during operation.

Stop work until the spray gun and the spray nozzle both cool down to a

safe temperature.

6. Do not cover the air vents. Proper cooling of the motor is necessary to

ensure normal life of the tool.

7. Avoid unintentional starts. Be sure that the regulator/throttle switch is in

the neutral or OFF position when not in use and before connecting it to

any air source.

8. Avoid unintentional starts. Make sure the power switch is set to OFF

before connecting the spray gun to a power supply.

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 8

UNPACKING

WARNING! Do not operate the tool if any part is missing. Replace the

missing part before operating. Failure to do so could result in a

malfunction and personal injury.

Remove the parts and accessories from the packaging and inspect for damage.

Contents:

• HVLP spray gun with sprayer station

• 15 ft ex paint hose

• Viscosity cup

• 0.9 and 1.8 mm tip and needle

IDENTIFICATION KEY

A. Main Housing

B. Screw

C. On/O Switch

D. Motor

E. Cord Holder

F. Power Cord

G. Hose Fixture

H. Motor Connector

I. Rubber Stand Set

J. Screw

K. Cover A

L. Cover B

M. Spray Gun

N. Fluid Adjustment

Knob

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 9 www.princessauto.com / 1-800-665-8685

ASSEMBLY & INSTALLATION

1. Push the hose tting onto the hose xture on

the HVLP unit and twist to lock it in place (Fig.

1-1).

2. Attach the other end of the hose to the back of

the spray gun (Fig. 1-2). Twist to lock into

place.

3. Attach the paint cup and make sure it is hand-

tight.

OPERATIONS

IMPORTANT! The recommended paint viscosity will vary according to

paint property and painting conditions.

Proper handling of the gun will allow you to achieve the desired paint coating.

1. Hold the paint spray

gun between 6 and 8 in.

from the workpiece.

The distance will vary

depending on the

atomization pressure

and work demand.

2. Grip the gun rmly and

keep it perpendicular to

the surface of the

workpiece at all times.

3. Move the gun in a straight horizontal line. Start and end the stroke

beyond the workpiece's edges to create a smooth coating of paint/varnish.

Fig. 1

Fig. 2

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 10

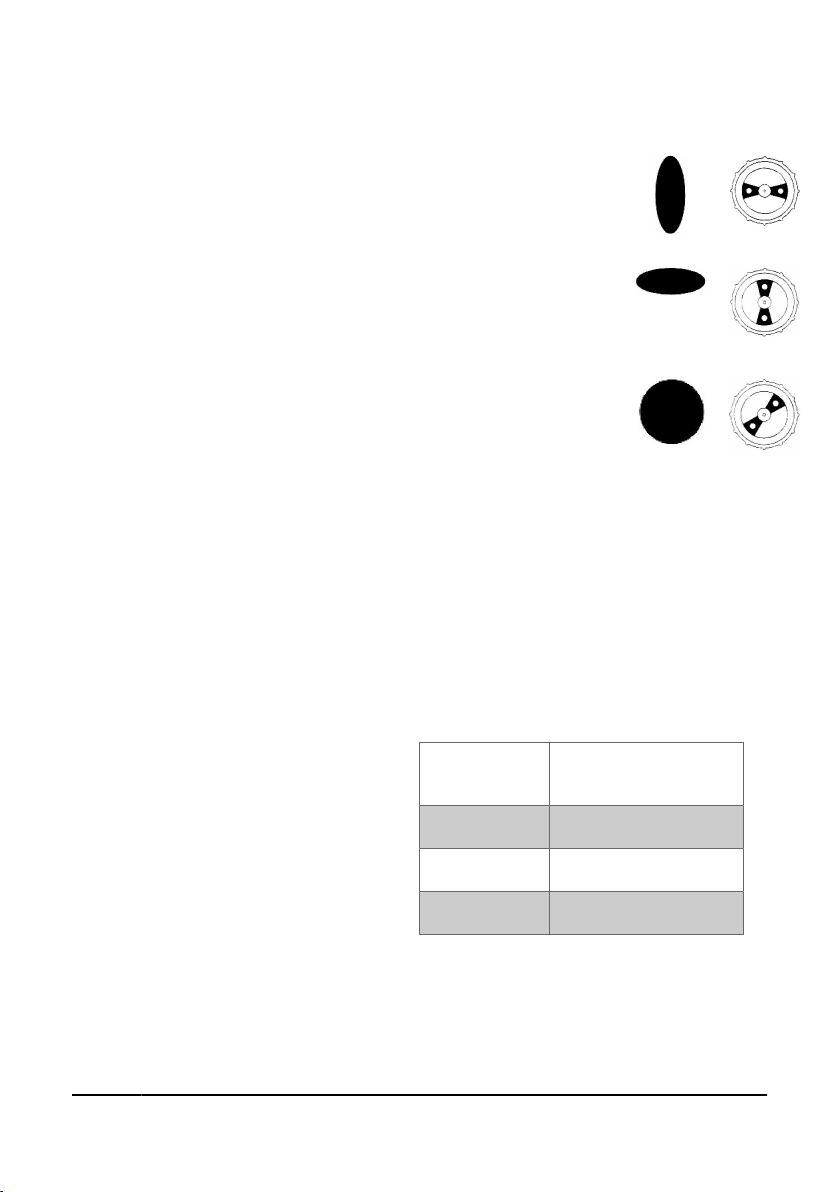

ADJUST THE SPRAY GUN

The HVLP spray gun has three dierent spray patterns.

Select the pattern by changing the air cap's angle.

1. Adjust the air cap so the ridges are horizontal in

relation to the spray gun body. This will create a

vertical, oval spray pattern.

2. Adjust the air cap so the ridges are vertical in relation

to the spray gun body. This will create a horizontal,

oval spray pattern.

3. Ajust the air cap so it is at a 45° angle in relation to the

spray gun body. This will create a round spray pattern.

4. Adjust the amount of material that is sprayed by

turning the uid adjustment knob.

a. For more material, turn the knob to the right.

b. For less material, turn the knob to the left.

MEASURING PAINT VISCOSITY

Paints come in a variety of viscosities and may require dilution to obtain the

best spraying results, as the paint is normally made for brush or roller

applications.

1. Pour the paint or lacquer into a bucket or other container.

2. Consult the Paint/Solvent Ratio

table and add a solvent

appropriate for the paint/

lacquer. Check the

manufacturer’s label for the

specic type of thinner

required. The ratios are

approximate.

3. Stir to mix the paint and

thinner.

4. Fill the included measuring cup with the paint mixture and pour it back

into the container. The mixture is thin enough when it takes 8 to 20

seconds to empty the cup.

Fig. 3

Fig. 4

Fig. 5

Oil-base

interior enamel

paint

1 part solvent to 4 parts

paint

Outdoor oil-

base paint

1 part solvent to 3 parts

paint

Lacquers 1 part solvent to 2 parts

lacquer

Stains and

Varnishes

Generally no thinning is

required

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 11 www.princessauto.com / 1-800-665-8685

5. Add more thinner if the mixture is too thick or paint if the mixture is too

thin. Repeat steps 3 and 4 until you are satised with the thickness.

6. Stir the thinned-paint each time before relling the paint cup. Remove

lumps or a 'surface skin' by straining the paint mixture through

cheesecloth, nylon stocking material or a commercial paint strainer with a

60-mesh.

CARE & MAINTENANCE

1. Maintain the tool with care. A tool in good condition is ecient, easier to

control and will have fewer problems.

2. Inspect the tool components periodically. Repair or replace damaged or

worn components.. Only use identical replacement parts when servicing.

3. Only use accessories intended for use with this tool. Follow instructions

for changing accessories.

4. Keep the tool handles or gripping surfaces clean and dry.

5. Maintain the tool’s labels and name plates. These carry important

information. If unreadable or missing, contact Princess Auto Ltd. for

replacements.

WARNING! Only qualied service personnel should repair the tool. An

improperly repaired tool may present a hazard to the user and/or others.

CLEAN THE SPRAY GUN

1. Turn o the air source.

2. Disconnect the paint cup from the spray gun and empty out the remaining

contents.

3. Add a small amount of the appropriate solvent. Check paint

manufacturer’s recommendations.

4. Reattach the paint cup.

5. Turn on the air source to the lowest volume.

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 12

6. Aim the spray gun into a container and continue spraying until the solvent

is clean.

a. Repeat steps 1 to 5 until the sprayed solvent is clean.

b. Immerse the paint cup in solvent for up to 24 hours if the solvent is

not removing the built-up paint.

7. Empty the remaining solvent out of the paint cup. Dispose of the waste

solvent safely. Consult the solvent manufacturer’s Safety Data Sheet.

8. Wipe the paint cup with a lint-free cloth.

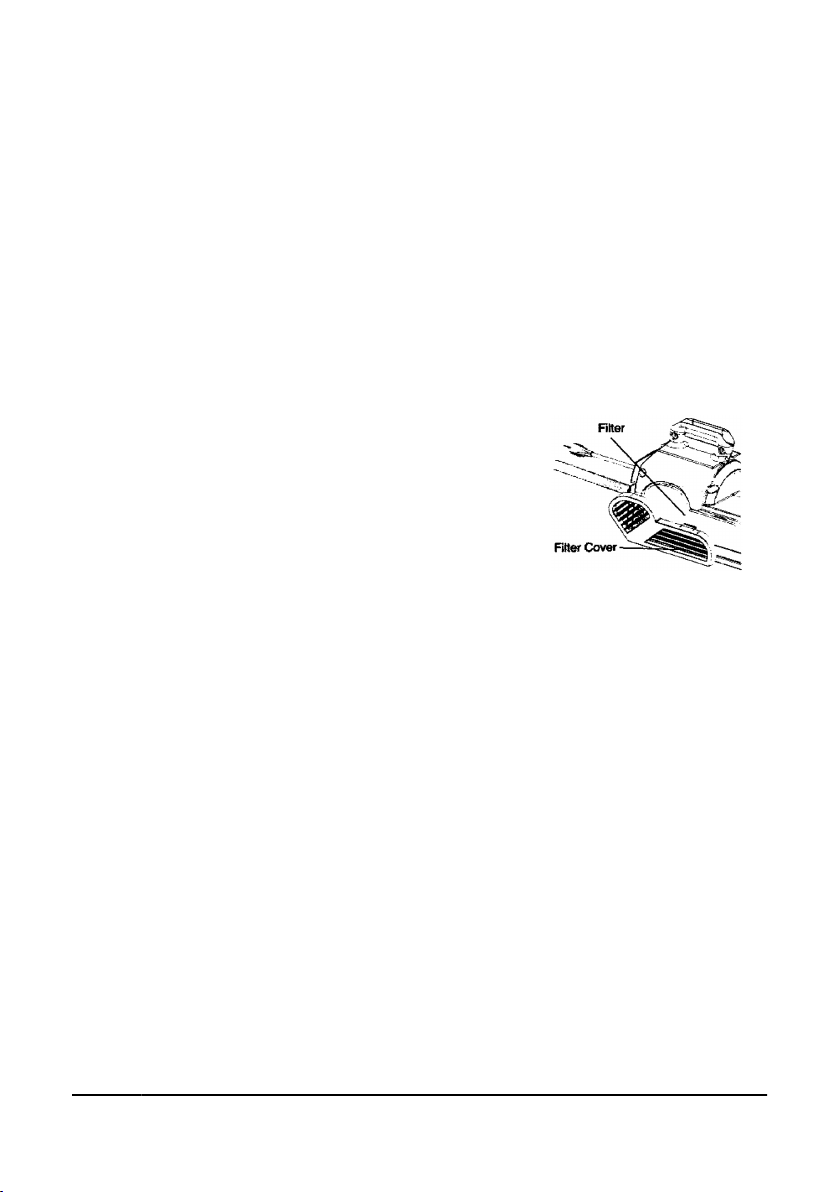

CLEAN THE FILTER

1. Pull the lter grill o to reveal the lter.

Remove the air lter from the air lter cover.

Be sure that the air lter is clean. A dirty air

lter restricts airow and can cause the motor

to overheat.

2. Clean the air lter:

a. Clean latex (water-based) coatings from

the lter with mild soapy water. Remove

excess water with a soft cloth. Allow to dry at before reinstalling

the lter.

b. Replace the lter if it becomes built-up with paint, or if using oil-

based (solvent-based) coatings.

c. Keep the unit at the maximum distance from the spray area to

extend lter life.

DISPOSAL

Recycle a tool damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws for

electronic devices, batteries, oil or other toxic liquids.

Fig. 6

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 13 www.princessauto.com / 1-800-665-8685

TROUBLESHOOTING

Visit a Princess Auto Ltd. location for a solution if the tool does not function

properly or parts are missing. If unable to do so, have a qualied technician

service the tool.

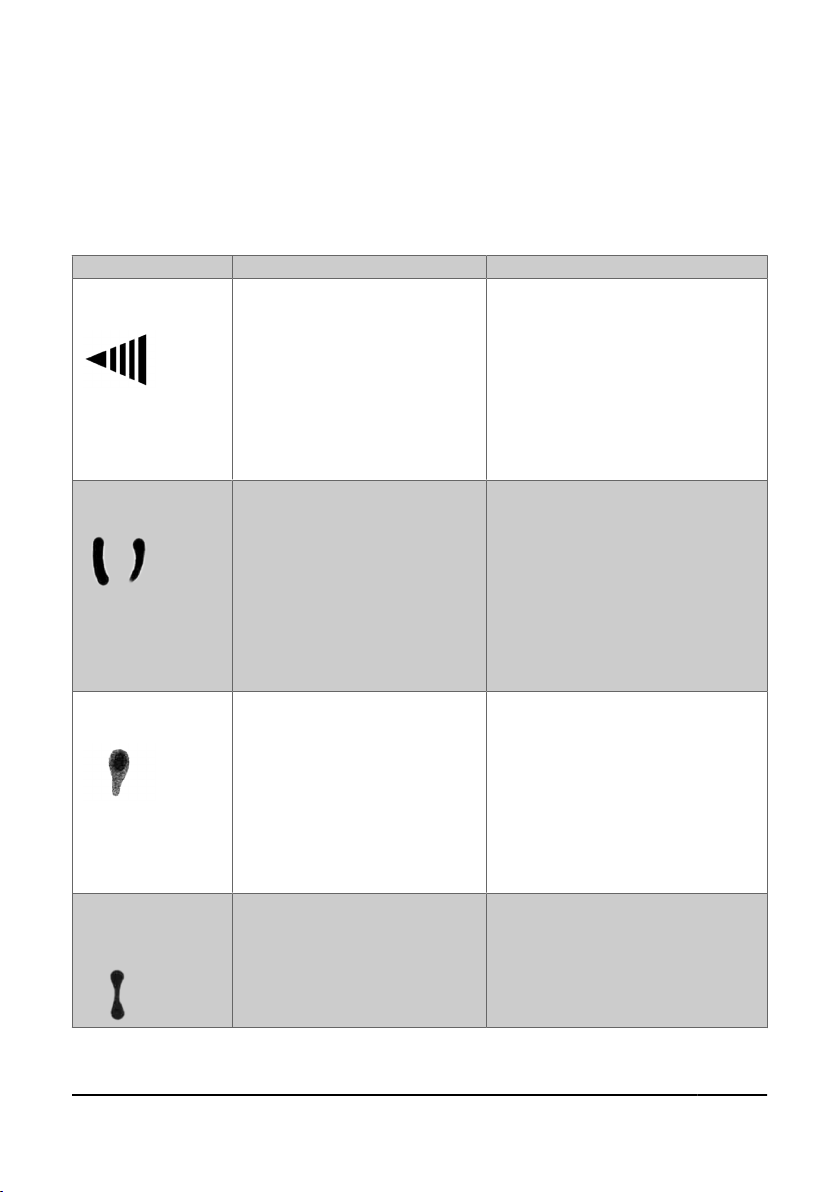

Problem(s) Possible Cause Suggested solution

The spray pattern

is intermittent.

Presence of air in the paint

circuit.

1. Tighten the nozzle with a

wrench.

2. Check the amount of uid in

the container.

3. Ensure that none of the

connector holes are obstructed.

4. Tighten all ttings around the

paint circuit.

The spray pattern

is arched.

1. Material residue in the

holes is obstructing the

passage of material.

2. The nozzle is dirty or

malfunctioning.

3. The atomization cap is dirty

or damaged.

1. Submerge the head in solvent.

2. Clean and open all closed holes

with a jet of compressed air or

a toothpick.

a. Do not use pointed metal

objects for this purpose,

as you may deform the

hole at the end of the

head.

The spray pattern

is uneven.

1. Material has built up on the

outside of the uid nozzle

tip or center hole or

partially clogged the nozzle

orice.

2. The uid nozzle is loose.

1. Clean the head and the nozzle.

2. Ensure that the centering

between the head and nozzle is

precise.

a. Check that the tip of the

pin is not ruined.

b. Replace the head and

nozzle if necessary.

The center of the

pattern is too

narrow.

1. The atomization of the air

pressure is too high.

2. The working material is too

thin.

Reduce the quantity of air and

increase the ow of paint.

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 14

Problem(s) Possible Cause Suggested solution

There is poor

atomization with

the spray

concentrated in the

center.

The ow of paint is greater than

the pressure and quantity of air

supplied.

1. Clean the head and the nozzle.

2. Ensure that the paint is not too

dense and dilute if necessary.

There is little to no

paint output.

1. The uid passage is clogged

with dirt or the air holes in

the cover are blocked.

2. Fluid needle stroke is too

small.

1. Remove any obstructions.

2. Adjust uid needle stroke.

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 15 www.princessauto.com / 1-800-665-8685

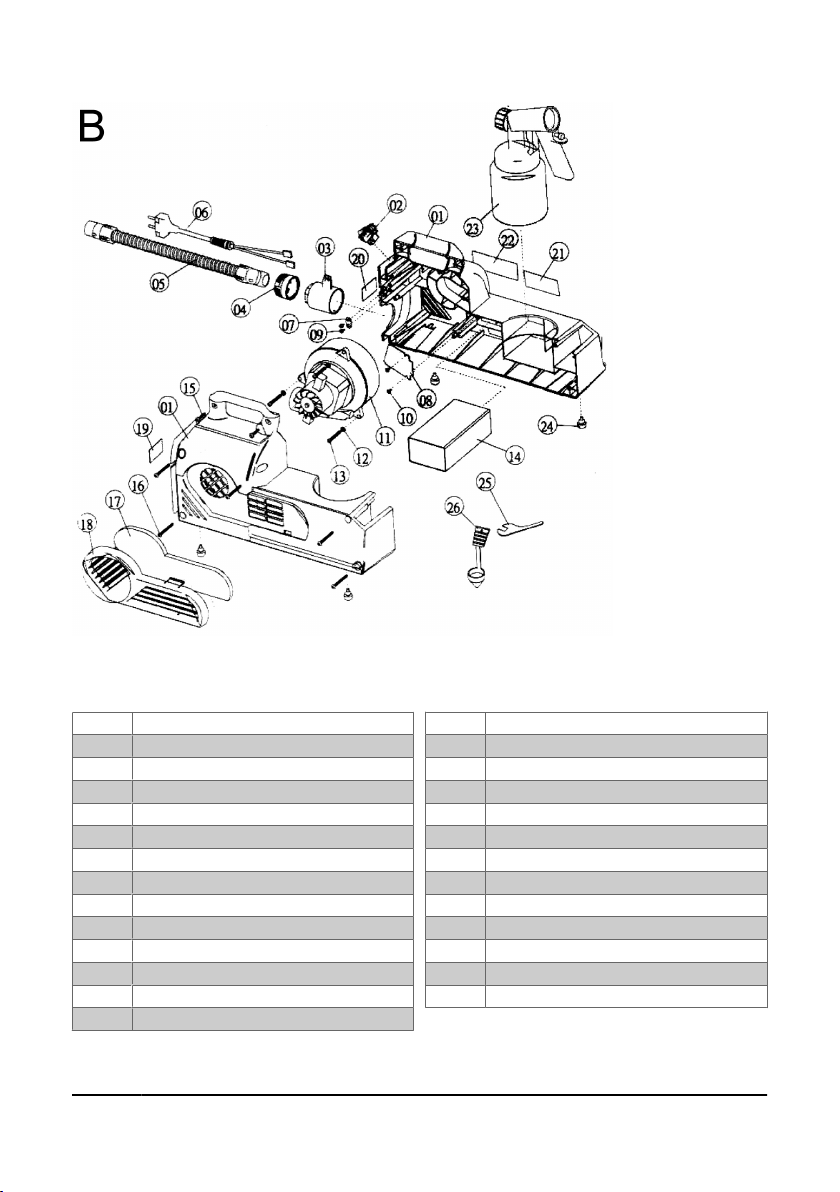

PARTS BREAKDOWN

PARTS LIST

# DESCRIPTION

A2 Fluid Needle Assembly

A3 Spring

A4 Fluid Adjustment Knob

A5 Gun Body

A6 Airow

A7 Fluid Tip

A8 Air Cap

A9 Lock Ring

A10 Fluid Tube

A11 Container Gasket

A12 Container

A13 Fluid Needle Packing

A14 Needle Packing Screw

A15 Trigger

A16 Trigger Pin

A17 Nozzle Washer

8492910 HVLP ELECTRIC PAINT SPRAY SYSTEM V1.0

www.princessauto.com / 1-800-665-8685 Page 16

PARTS LIST

#DESCRIPTION

B1 Main Housing

B2 Switch

B3 Motor Connector

B4 Hose Fixture

B5 Hose

B6 Power Cord

B7 Tube Cover A

B8 Tube Cover B

B9 Screw

B10 Screw

B11 Motor

B12 Washer

B13 Screw

B14 Airow Tube

B15 Screw

B16 Housing Screw

B17 Air Filter

B18 Filter Cover

B19 Pointing Label

B20 Hose Connector Pointing Label

B21 Warning Label

B22 Main Label

B23 Paint Spray Gun

B24 Rubber Stand Set

B25 Wrench

B26 Viscosity cup

V1.0 HVLP ELECTRIC PAINT SPRAY SYSTEM 8492910

Page 17 www.princessauto.com / 1-800-665-8685

This page is intentionally left blank.

V1,0 8492910

Vous devez lire et comprendre toutes les instructions avant d'utiliser l'appareil.

Conservez ce manuel afin de pouvoir le consulter plus tard.

Cette page a été laissée blanche intentionnellement.

Table of contents

Languages:

Other Power Fist Paint Sprayer manuals

Power Fist

Power Fist 8604530 User manual

Power Fist

Power Fist 8059833 User manual

Power Fist

Power Fist 0432344 User manual

Power Fist

Power Fist 8059851 User manual

Power Fist

Power Fist 0450071 User manual

Power Fist

Power Fist 8006577 User manual

Power Fist

Power Fist 8160657 User manual

Power Fist

Power Fist 8006578 User manual

Power Fist

Power Fist 8006581 User manual

Power Fist

Power Fist HVLP User manual