Hardinge 20C Operation manual

INSTRUCTIONS & PARTS LIST B -0009500-0067

20C DEAD-LENGTH®STEP CHUCK

Stop Rod

Spring Retainer

Nut Nut Outer Collet

Stop Body

Belleville Springs (2)

Coil Spring 1-1/8"

H

A

R

D

I

N

G

E

P

A

T

E

N

T

E

D

2

0

D

S

H

A

R

D

I

N

G

E

2

0

D

S

P

A

T

E

N

T

E

D

1-1/8"

Stop

Rod

Nut

S

t

o

p

B

o

d

y

D.L. Step Chuck

Stop

Rod

Drive Pin

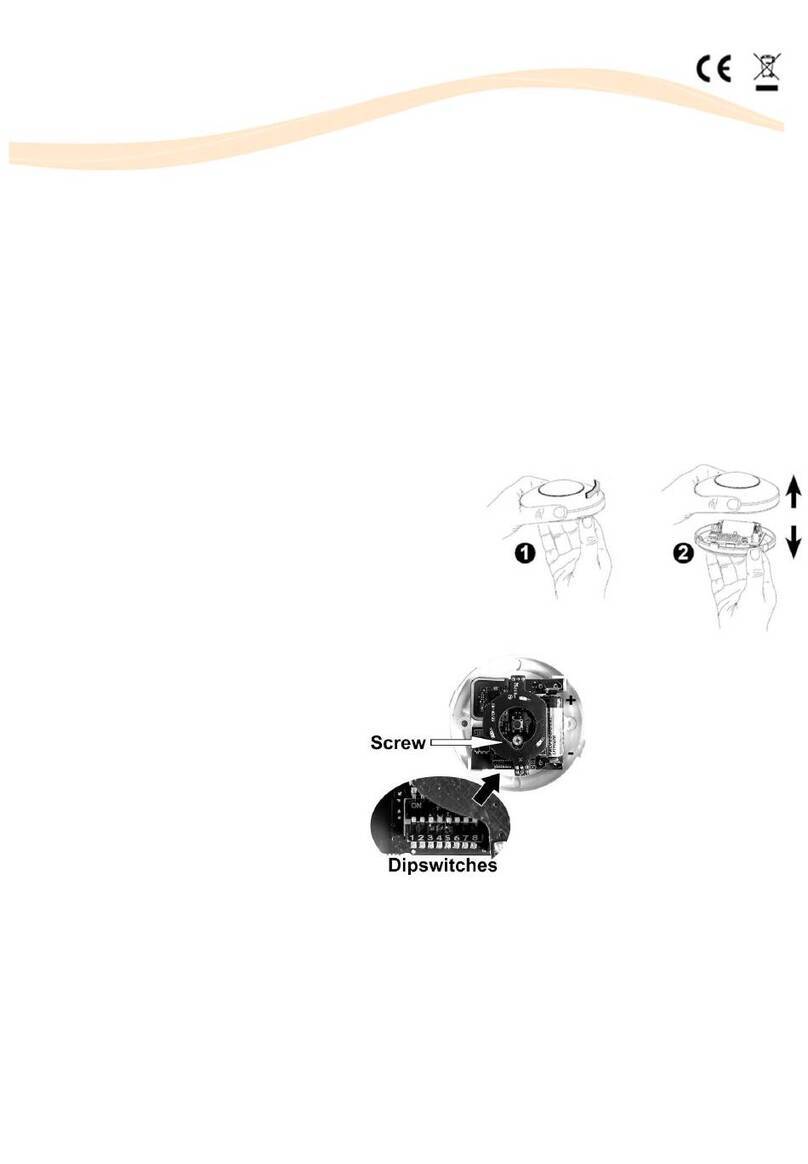

QUICK START

Quick Start instructions quickly guide

you through the procedure. Read the

main instructions first to thoroughly un-

derstand how to use the product.

•Clean parts & headstock

spindle

•Set face of Stop Rod 1-1/8"

from Stop Body face & secure

•Thread & Secure Stop Rod-

Body Assembly into D.L. Step

Chuck

•Coat Bearing surfaces with

Molybdenum Disulfide grease

•Assemble and secure Spring

Retainer into Outer Collet

•Insert D.L. Step Chuck-Stop

Assembly into Outer Collet

Aligning Pin with slot in Outer

Collet Face

•Slide Belleville Washer

Springs on Stop Rod

•Slide on the Coil Spring &

lock finger tight with the Nut,

fully compressing coil spring,

then back off one full turn

MAIN INSTRUCTIONS

•Clean the Lathe Spindle , Draw

Tube, and the parts of the 20C

Dead-Length Step Chuck

•Set the face of the Stop Rod 1-1/8"

from the face of the Stop Body. Secure with

the 1-1/4" Hex Nut. (This Dimension may

already be set from the factory.)

© Hardinge Inc. 1996

H

A

R

D

I

N

G

E

P

A

T

E

N

T

E

D

2

0

D

S

S

p

r

i

n

g

R

e

t

a

i

n

e

r

Outer Collet

• Thread the Spring Retainer into the

Outer Collet and firmly tighten.

will insure maximum life of the mating parts.

angle of the Outer Collet with Molybdenum Disulfide grease (Moly-Lub). This

Step Chuck, the internal bearing diameter and collet head

•Coat the external bearing diameter of the Dead-Length

• Thread the Stop Rod/Body Sub-

Assembly into the Dead-Length

Step Chuck and tighten securely.

• Hold 1-1/4" Hex Nut of theStop Rod Sub- Assem-

bly in a vise and tighten D.L. Step Chuck using a

20C Inner Collet Spanner Wrench and turning clock-wise.

CAUTION: Do Not grip any part of the Step Chuck body in the

vise. The Step Chuck may be permanently distorted or break.

(Hold the Collet with the 20C Collet Wrench [ Part No.

CL-0011759-A] and use a 1-1/4" open end wrench to tighten the

Spring Retainer.)

TOOLS NEEDED

2 ea. 1-1/4 Open End Wrenches

1 ea. 20C Collet Wrench

1 ea. Machinist Vise

1 ea. Moly-Lub Grease

H

A

R

D

I

N

G

E

2

0

D

S

P

A

T

E

N

T

E

D

D

e

a

d

L

e

n

g

t

h

S

t

e

p

C

h

u

c

k

H

A

R

D

I

N

G

E

P

A

T

E

N

T

E

D

2

0

D

S

H

A

R

D

I

N

G

E

2

0

D

S

P

A

T

E

N

T

E

D

Nut

Boring Out the Dead-Length

Step Chuck on the Lathe

QUICK START

Boring Out -D.L. Step Chuck

• Insert Dead Length Step Chuck & Stop Sub-Assembly

into the Outer Collet & Spring Retainer Sub-Assembly.

Align the Drive Pin (shown on front page, 1st Figure) in the Step

chuck with the Slot in the face of the Outer Collet.

•Slide the 2 Belleville Spring Washers on the Threaded

Stop Rod with the small end of the first washer towards

the Spring Retainer and the Large end of the second

washer flush with the large end of the first washer, as

Illustrated.

•Slide the compression Coil Spring on to the Stop Rod up

against the Belleville Spring Washer.

•Thread the Hex Nut on the Stop Rod by hand to completely

compress the Coil Spring, then back the Nut off one full turn.

•Place the three 1/8" diameter x 3/4" long

pins in the holes on the face of the Dead-

Length Step Chuck. (A small amount of

grease on each pin will hold them in

place.)

•Activate Closer to Open Position

•Slide the Dead-Length assembly into the

spindle of the machine aligning the

spindle key with the keyway on the Outer

Collet.

H

A

R

D

I

N

G

E

P

A

T

E

N

T

E

D

2

0

D

S

H

A

R

D

I

N

G

E

2

0

D

S

P

A

T

E

N

T

E

D

Nut

Coil

Spring

Beleville Springs (2)

Outer Collet & Spring

Retainer Sub-Assembly

Dead Length Step Chuck

& Stop Sub-Assembly

Slot

•Place 3 Pins in face of step

chuck

•With closer in "Open" position,

slide D.L. Step Chuck into

spindle aligning Key

•Adjust Closer until back face of

D.L. Step Chuck just Contacts

spindle face

•Turn Closer 1/2 Turn more &

Continue to next screw hole.

•Tighten Screws in Closer

•Adjust pressure: Low to Moder-

ate force - Approx. 3,000 Lbs.

•Drill, rough bore ,and finish bore

for the workpiece

•Remove & thoroughly clean

•Remount & Adjust Pressure on

the workpiece: Max. 5,000 Lbs.

MAIN INSTRUCTIONS (Continued)

H

A

R

D

I

N

G

E

2

0

D

S

P

A

T

E

N

T

E

D

Pins

Maximum Accuracy and Repeatability:

Bore out to a dimension .001" Greater Than the

O.D. of the workpiece.

Maximum Holding Power:

Bore out to a dimension .001" to

.002" Less Than the O.D. of the

workpiece.

When a stepped type bore is required, finish bore to the

proper size and then face the bottom of the bore to provide a square

shoulder. It is recommended that the corner where the bore and

shoulder meet be undercut to insure that the workpiece fully seats

against the face of the step.

•Using the Illustration as a guide for Maximum Diameters and Depths, Drill, Rough Bore and then Finish Bore the Step

Chuck out to the proper size for the workpiece.

1-1/8"

Stop

Rod

Nut

S

t

o

p

B

o

d

y

1/2"-20

TPI

• The Stop Rod is set at a 1-1/8" dimension from the face of the Stop

Body. The Stop Rod can be machined to decrease its length.

Custom Stop Rod Extensions can be made that are threaded into

the 1/2"-20 TPI internal thread in the Stop Rod.

•Remove the Dead-Length Step Chuck Assembly from the spindle and thoroughly clean out chips from the slots

and the bore. Debur the edges of the machined surfaces.

BORING OUT (Continued)

•Draw the assembly into the spindle by adjusting the collet closer draw tube until the back face of the Step

Chuck just contacts the face of the spindle. A very noticeable increase in resistance will be felt at this point.

•Further tighten the draw tube 1/2 turn and then continue turning until the next screw hole lines up.

•Tighten the Screws on the collet closer.

•Make certain that the three 1/8" Diameter pins are fully bottomed in the Dead-Length Step Chuck.

CAUTION: Do not actuate the lathe's collet closer without either the three pins in the face of the Dead-

Length Step Chuck or a workpiece in place. If the unit is closed without the pins or workpiece

in place, both the Dead-Length Step Chuck and the Outer Collet will be permanently distorted

and have to be replaced.

•Close the Step chuck using a low to moderate chucking force, approximately 3000 Lbs.

3-1/2"

1-3/4"

.250

.5

3-1/2"

1-1/8"

All specifications are subject to change without notice.

All marks indicated by ® and ™ are trademarks of Hardinge Brothers, Inc.

Mounting a Machined Dead-Length®Step Chuck in the Lathe

Litho in U.S.A.

April 1996

Form No. B-67A

Part No. BA -0009500-0067

QUICK START

Mounting-D.L. Step Chuck

•Clean Spindle & D.L. Step

Chuck

•Open the Collet Closer

•Slide DL Step Chuck into

spindle aligning Key with Key-

way

•Put the workpiece in the Dead-

Length Step Chuck

•Adjust Closer until back face

of DL Step Chuck just Con-

tacts spindle face

•Turn Closer 1/2 Turn more &

Continue to next screw hole.

•Tighten Screws in Closer

•Do not exceed a chucking

force of 5,000 pounds

•Clean the machine spindle & the Dead-Length Step Chuck.

•Activate Closer to its

"Open"

Position.

•Slide the complete assembly into the spindle of the machine aligning the spindle

key with the keyway on the Outer Collet.

•Place a workpiece in the bore of the Dead-Length Step Chuck.

•Draw the assembly into the spindle by adjusting the collet closer draw tube

until the back face of the Step Chuck just contacts the face of the spindle. A

very noticeable increase in resistance will be felt at this point.

•Further tighten the draw tube 1/2 turn and then continue turning until the next

screw hole lines up.

•Tighten the Screws on the collet closer.

•Close the collet closer.

•Adjust the collet closer to the proper closing force. Maximum Recommended

Force: 5,000 pounds.

PARTS LIST

Stop Rod

Spring Retainer

Nut Nut Outer Collet

D.L. Step Chuck

Stop Body

Belleville Springs (2)

Coil Spring 1-1/8"

Pin

Stop

Rod

Drive Pin

Description Hardinge Part Number Quantity

20C Dead-Length Step Chuck Assembly 2041-00-00-000000 1

– Emergency Dead Length Step Chuck 2037-00-00-000000 1

- Pin

(Used when machining out the step chuck) 7

731-00-00-000000 3

- Drive Pin 7734-00-00-000000 1

– Nut 1185-00-00-000000 2

– Outer Collet Body 2039-00-00-000000 1

– Spring - Coil 1187-00-00-000000 1

– Spring - Belleville AM-9011700 2

– Spring Retainer 1815-00-00-000000 1

– Stop Body 1813-00-00-000000 1

– Stop Rod 1271-00-00-000000 1

20C Collet Wrench

(For holding Outer Collet during assembly)

CL-0011759-A 1

20C Inner Collet Spanner Wrench 7897-00-00-0000001 1

Molybdenum Disulfide Grease (Moly-Lub,3 Oz.) VS-10440 1

HARDINGE INC.

One Hardinge Drive, PO Box 1507

Elmira, New York 14902-1507 USA

To Order call: 800-843-8801 • Canada : 800-468-5946 • Phone: 607-734-2281 • FAX: 607-734-3886

Table of contents

Popular Control Unit manuals by other brands

Sandpiper

Sandpiper Signature Series Service & operating manual

ABB

ABB Relion 630 Series Applications manual

HYDAC International

HYDAC International FCU 1000 Series Operating and maintenance instructions

Buderus

Buderus MP100 EMS plus installation instructions

YASKAWA

YASKAWA U1000 Series Technical manual

Xanavi Informatics Corporation

Xanavi Informatics Corporation HJZ0093 user manual

SSS Siedle

SSS Siedle FPM 600-0 Product information

WEG

WEG SSW900-CPDP-N Installation, configuration and operations guide

opticis

opticis M1-2R2VI-DU user manual

Siemens

Siemens SIMATIC S7-400H manual

LOVATO ELECTRIC

LOVATO ELECTRIC EXS0000 instruction manual

OJ Electronics

OJ Electronics WLM3-1AO instructions