Table of contents

Section 1 Introduction.......................................................................3

This manual........................................................................................3

Intended audience..............................................................................3

Product documentation.......................................................................4

Product documentation set............................................................4

Document revision history.............................................................5

Related documentation..................................................................6

Symbols and conventions...................................................................6

Safety indication symbols..............................................................6

Manual conventions.......................................................................7

Functions, codes and symbols......................................................7

Section 2 REM630 overview..........................................................11

Overview...........................................................................................11

Product version history................................................................11

PCM600 and IED connectivity package version..........................11

Operation functionality......................................................................12

Product variants...........................................................................12

Optional functions........................................................................12

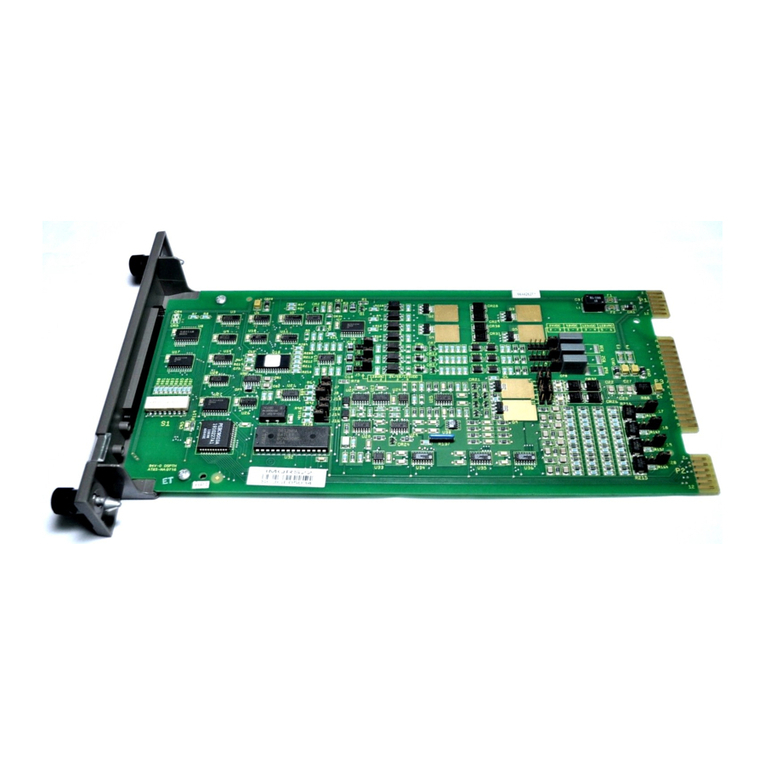

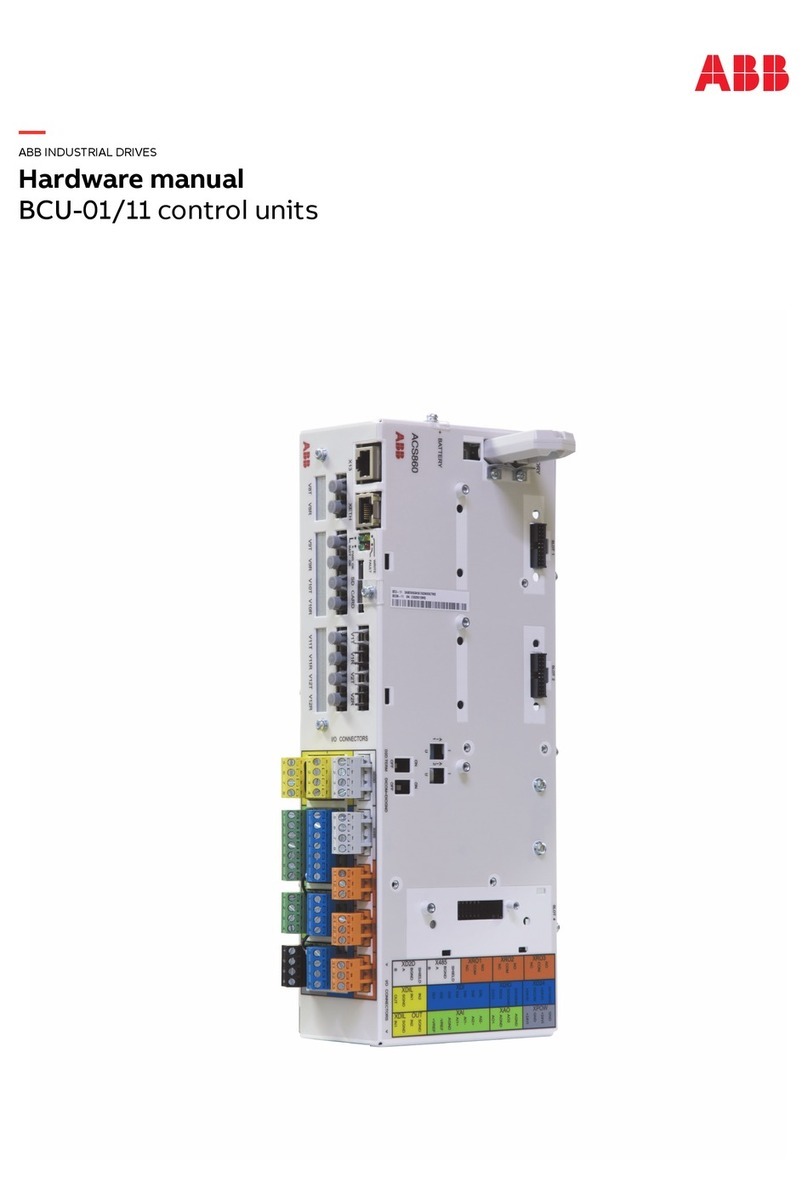

Physical hardware............................................................................12

Local HMI.........................................................................................14

LCD.............................................................................................14

LEDs............................................................................................17

Keypad........................................................................................17

Web HMI...........................................................................................17

Authorization.....................................................................................18

Communication.................................................................................19

Section 3 REM630 variants............................................................21

Presentation of preconfigurations.....................................................21

Preconfigurations.........................................................................22

Preconfiguration A for asynchronous motor.....................................23

Application...................................................................................23

Functions.....................................................................................24

Input/output signal interfaces.......................................................26

Preprocessing blocks and fixed signals ......................................27

Control functions..........................................................................28

Motor bay control QCCBAY...................................................28

Apparatus control SCILO, GNRLCSWI, DAXCBR,

DAXSWI.................................................................................28

Table of contents

REM630 1

Application Manual