Hardy Process Solutions HI 2160RC PLUS Specification sheet

HI 2160RCPLUS

Rate Controller

Operation and Installation Manual

Table of Contents

i

Table of Contents

Table of Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i

Table of Illustrations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I

Chapter 1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

About Chapter 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

About Hardy Manuals - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Description- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

ALARMS- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Capabilities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Automatic Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Manual Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Continuous or Batch Modes - - - - - - - - - - - - - - - - - - - - - - - 1-3

Automatic Refill - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Manual Refill - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Automatic Tuning (Auto Rate Calibration) - - - - - - - - - - - - - - - - - 1-3

Operation Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Secure Memory Module - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Control Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Serial Communications- - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Hardy Link Communications - - - - - - - - - - - - - - - - - - - - - - - 1-4

Self Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Reports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

C2® Second Generation Calibration - - - - - - - - - - - - - - - - - - - 1-4

Remote Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Multiple Configuration Storage - - - - - - - - - - - - - - - - - - - - - - 1-4

Two Sigma- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Interpreting the Model Code Number - - - - - - - - - - - - - - - - - - - - - 1-4

Model Code Breakdown - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Chapter 2 Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

About Chapter 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

HI 2160RCPLUS Specifications - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Instrument Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Remote Control Options - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Alarms (Relays) - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Analog to Digital Specifications - - - - - - - - - - - - - - - - - - - - - - 2-1

Output Display Specifications- - - - - - - - - - - - - - - - - - - - - - - 2-2

Reports - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Power and Utility Requirements - - - - - - - - - - - - - - - - - - - - - 2-2

Environmental Requirements - - - - - - - - - - - - - - - - - - - - - - - 2-2

Physical Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Enclosure Rating- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Remote Set Point Input Option - Basic Function- - - - - - - - - - - - 2-2

RS422/485 (Serial Port Option) - Basic Function - - - - - - - - - - - 2-2

ALLEN BRADLEY Remote I/O Option - Basic Function - - - - - - - - 2-3

PROFIBUS Interface Option Card - - - - - - - - - - - - - - - - - - 2-3

HI 2160RCPLUS MANUAL

ii

Quad Option Expander Box - Basic Function - - - - - - - - - - - - - 2-3

Analog Output Option Card - - - - - - - - - - -- - - - - - - - - - - 2-3

RS-232 to RS-422 Converter Board Option - - - - - - - - - - - - - - 2-4

Chapter 3 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

About Chapter 3 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

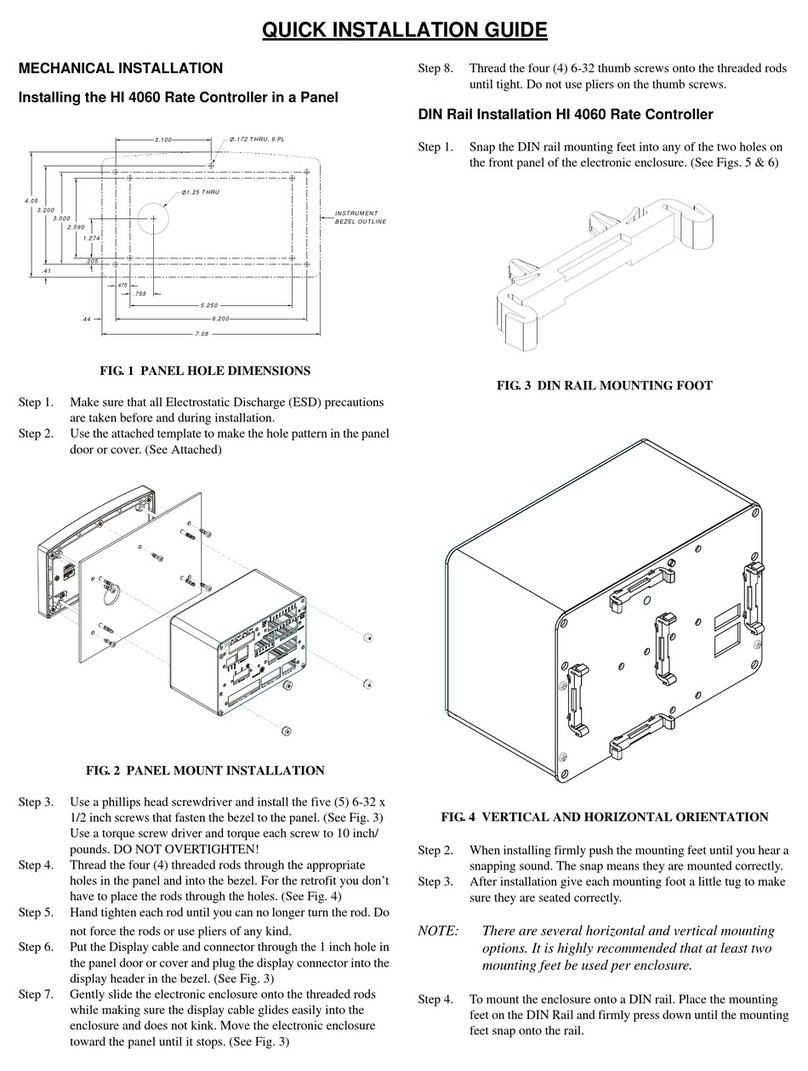

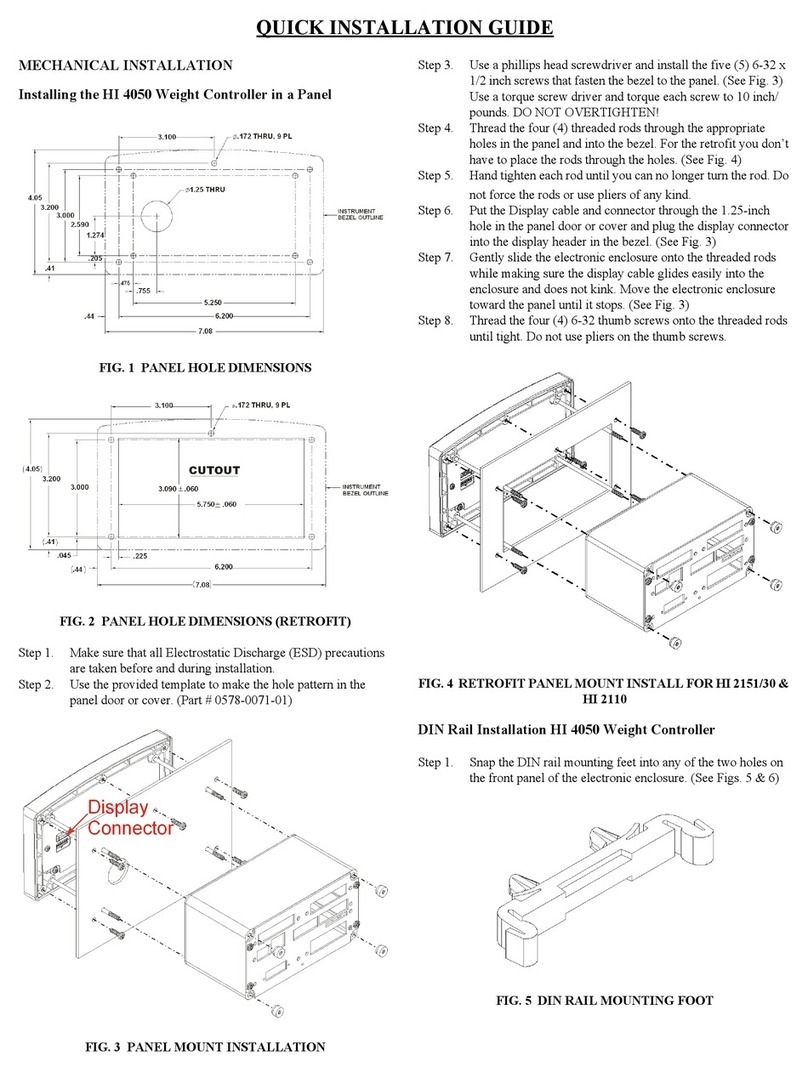

Installing the HI 2160RC PLUS in a Panel- - - - - - - - - - - - - - - - - - - 3-2

Mechanical Installation - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Panel Cutout Specifications - - - - - - - - - - - - - - - - - - - - - 3-2

Enclosure Size Requirements. - - - - - - - - - - - - - - - - - - 3-2

Dimensions of the enclosure cutout (See Fig. 3-3) - - - - - - - - 3-2

Installing the HI 2160RCPLUS Panel Mount - - - - - - - - - - - - - - 3-2

Installation of HI 2160RCPLUS - RM Remote Panel Model - - - - - - - 3-8

Installation of the HI 216EX Quad Expander Box - - - - - - - - - - - 3-13

Electrical Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

Cabling and Interconnecting - - - - - - - - - - - - - - - - - - - - - - - 3-14

Recommended Installation Procedures - - - - - - - - - - - - - - - - 3-14

Output Relay Wiring Diagram- - - - - - - - - - - - - - - - - - - - - 3-15

Speed Control Output Wiring Diagram - - - - - - - - - - - - - - - - 3-15

Refill and Alarm Relays Diagram - - - - - - - - - - - - - - - - - - - 3-16

RS 232 Port Wiring Diagram - - - - - - - - -- - - - - - - - - - - - 3-16

Remote Functions Wiring Diagram - - - - - - - - - - - - - - - - - - 3-17

Input Power Wiring Diagram - - - - - - - - -- - - - - - - - - - - - 3-17

Remote Setpoint Option Wiring Diagram - - - - - - - - - - - - - - - 3-18

RS-422 Converter Option Wiring Diagram - - - - - - - - - - - - - - 3-18

Analog Output Option Wiring Diagram - - - - - - - - - - - - - - - - 3-18

Load Cell Wiring Diagram - - - - - - - - - - -- - - - - - - - - - - 3-20

Remote I/O Interface for the Allen Bradley Network - - - - - - - - - - - - - - 3-22

PROFIBUS Interface Option - - - - - - - - - - - - - - - - - - - - - - - - - 3-22

Interconnect Wiring Diagram - - - - - - - - - - - - - - - - - - - - - - - - - 3-23

Computer Clean Power Requirement - - - - - - - - - - - - - - - - - - - - - 3-24

Installing the Secure Memory Module - - - - - - - - - - - - - - - - - - - - - 3-24

Chapter 4 Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

About Chapter 4 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Output Relay Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Refill and Alarm Relays- - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Solid State Relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Dip Switch Configuration - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Speed Control Output Card (Prt. #0535-0406)- - - - - - - - - - - - - - - - - 4-2

Analog Output Card Option Configuration (Prt.# 0535-0406)- - - - - - - - - - 4-3

About the Analog Output Card Option- - - - - - - - - - - - - - - - - - - 4-3

Setting the Jumpers - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

Setting The Jumpers in the HI 2160RCPLUS- - - - - - - - - - - - - - 4-4

Setting the Jumpers in the Optional Quad Expander Box - - - - - - - 4-5

Jumper Configuration Chart - - - - - - - - - - - - - - - - - - - - - 4-6

Connector Pins for Current and Voltage Output - - - - - - - - - - - - - - 4-6

Remote Function Inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

Remote Set Point Input Option Card Configuration (Prt. #0535-0410) - - -- - 4-7

About Remote Set Point Input Option (Analog In) - - - - - - - - - - - - - 4-7

Setting the Jumpers - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

Setting the Jumpers in the HI 2160RCPLUS - - - - - - - - - - - - - - 4-8

Setting the Jumpers in the Optional Quad Expander Box - - - - - - - 4-8

Connector Pins for Input Voltage and Current Input - - - - - - - - - - 4-9

Grounding the Remote Pin to read the Remote Set Point Input - - - - 4-10

Remote I/O Interface for the Allen Bradley Network Option (-B2)- - - - - - - - 4-11

Table of Contents

iii

PROFIBUS Interface Option (-B4) - - - - - - - - - - - - - - - - - - - - - - 4-11

Changing the RS-422 Converter Port Option (-B1) - - - - - - - - - - - - - - 4-11

Setting the Dip Switches - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

Rear Panel Config. Option Dip Switch Settings - - - - - - - - - - - - - - - - 4-12

Option Configuration Dip Switch - - - - - - - - - - - - - - - - - - - - - 4-12

Power Up Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

Pre Power Up Check Procedures- - - - - - - - - - - - - - - - - - - - - 4-13

Proper Power Up Indicators - - - - - - - - - - - - - - - - - - - - - - - 4-13

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14

Effects of Vibration on a Scale - - - - - - - - - - - - - - - - - - - - - - 4-14

Configuring WAVERSAVER - - - - - - - - - - - - - - - - - - - - - - - 4-14

Some Things to Remember When Changing the Jumper Settings - - - - - 4-17

Chapter 5 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

About Chapter 5 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Pre-Calibration Procedures - - - - - - - - - - -- - - - - - - - - - - - - - - 5-1

Mechanical Check Procedures - - - - - - -- - - - - - - - - - - - - - - 5-1

Checking the Load Cell Installation - - -- - - - - - - - - - - - - - - 5-1

Check for Binding on the Load Cell - - -- - - - - - - - - - - - - - - 5-1

Check for Binding on Platform Scale/Feeder - - - - - - - - - - - - - 5-2

Electrical Check Procedures - - - - - - - - - - - - - - - - - - - - - - - 5-2

Load Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Weight Calibration Process - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Calibration Setup Procedures - - - - - - - - - - - - - - - - - - - - - - 5-3

Setting the Mass Units - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Setting the Time Units (Rate of Flow) - - - - - - - - - - - - - - - - - 5-4

Setting the Rate Decimal Points - - - - - - - - - - - - - - - - - - - 5-4

Setting the Batch Decimal Point - - -- - - - - - - - - - - - - - - - 5-4

Setting the Total Decimal Point - - - - - - - - - - - - - - - - - - - - 5-5

Setting the Graduations - - - - - - -- - - - - - - - - - - - - - - - 5-5

C2® Calibration Process - - - - - - - - -- - - - - - - - - - - - - - - - 5-6

Hard Calibration Process (With Calibrated Test Weights) - - - - - - - - - 5-7

ZERO Calibration Procedures - - - - - - - - - - - - - - - - - - - - 5-7

SPAN Calibration Procedures - - - - - - - - - - - - - - - - - - - - 5-7

Setting the Sticker Value - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

Rate Calibration Process - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

Feeder System Verification Procedures- - - - - - - - - - - - - - - - - - 5-9

Automatic Rate Calibration Procedures - - - - - - - - - - - - - - - - - - 5-14

Setting REC to Zero - - - - - - - - - - - - - - - - - - - - - - - - - 5-14

Enter the PAUSE TIME Value - - - - - - - - - - - - - - - - - - - - 5-14

Enter the PRIME TIME Value- - - - - - - - - - - - - - - - - - - - - 5-15

Enter the FEED TIME Value - - - - - - - - - - - - - - - - - - - - - 5-15

AUTO RATE CALIBRATION From the Front Panel - - - - - - - - - - 5-15

AUTO RATE CALIBRATION Using a Serial Command - - - - - - - - 5-15

The Instrument Does the Following - - -- - - - - - - - - - - - - - - 5-15

Manual Rate Calibration Procedures - - - - - - - - - - - - - - - - - - - 5-18

Gathering Rate Calibration Data Method #1- - - - - - - - - - - - - - 5-20

Materials Required - - - - - - - - -- - - - - - - - - - - - - - - 5-20

Gathering Rate Calibration Data Method #2- - - - - - - - - - - - - - 5-21

Materials Required - - - - - - - - -- - - - - - - - - - - - - - - 5-21

Slow Feed Rate - - - - - - - - - - - - - - - - - - - - - - - - - 5-21

High Feed Rate - - - - - - - - - - - - - - - - - - - - - - - - - 5-22

Entering the Calibration Values - - - - - - - - - - - - - - - - - - - - 5-22

Entering the rate data into the Rate Calibration sub-menu - - - - - 5-22

Entering the High Rate Calibration Data - - - - - - - - - - - - - 5-23

The Manual Rate Calibration is Complete- - - - - - - - - - - - - - - 5-23

HI 2160RCPLUS MANUAL

iv

Chapter 6 Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

About Chapter 6 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Display Menu Trees - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Display Menu Flow Chart with Standard Serial Port - - - - - - - - - - 6-1

Display Menu Flow Chart with Allen Bradley Remote I/O Option - - - - 6-2

Display Menu Flow Chart with PROFIBUS Interface Option - - - - - - 6-2

Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Function/Numeric Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Config/1 Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Security Sub-Menu - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Security Access Levels- - - - - - - - - - - - - - - - - - - - - - 6-3

Setting the Security Access Levels - - - - - - - - - - - - - - - - 6-5

Setting the Security Code Numbers- - - - - - - - - - - - - - - - 6-6

What to do if You Lose the HI Security Code Number - - - - - - - 6-7

When to Use the Select Button - - - - - - - - - - - - - - - - - - 6-7

When to Use the Clear Button - - - - - - - - - - - - - - - - - - 6-7

How to Exit a Sub-Menu Without Changing the Values - - - - - - - - 6-8

Tuning and Control Sub-Menu - - - - - - - - - - - - - - - - - - - - 6-8

Tuning/Control (Sec) Parameter Definitions - - - - - - - - - - - - 6-9

Manual (Calculating Parameters) Tuning Control Process - - - - - 6-12

Setting Up the Controller for Manual Tuning - - - - - - - - - - - 6-13

Set the OP% to 99.9% - - - - - - - - - - - - - - - - - - - - - - 6-15

Gathering Data- - - - - - - - - - - - - - - - - - - - - - - - - - 6-15

Calculate the K(pu) value (initial K(p) - - - - - - - - - - - - - - - 6-16

Calculate the Ultimate Oscillation Cycle Time (Tc) - - - - - - - - 6-16

Calculate the Time of Repeat (Tr) - - - - - - - - - - - - - - - - 6-16

Calculate the Three (3) Control Constants: K(p), K(i) and K(d) - - - 6-16

Enter the new Control Constants - - - - - - - - - - - - - - - - - 6-16

Manual Tuning Control Process (Cont’d) - - - - - - - - - - - - - 6-17

Rate Tolerance Sub-Menu - - - - - - - - - - - - - - - - - - - - - - 6-19

Setting the LO ALARM Tolerance - - - - - - - - - - - - - - - - 6-19

Setting the HI ALARM Tolerance - - - - - - - - - - - - - - - - - 6-20

Setting the ALARM TIME (Sec.) - - - - - - - - - - - - - - - - - 6-20

Setting the HI and LO Shutoff - - - - - - - - - - - - - - - - - - 6-21

Setting the Shutoff Out Percentage - - - - - - - - - - - - - - - - 6-22

Process Example using Rate Tolerances - - - - - - - - - - - - - 6-23

Auto Refill Sub-Menu- - - - - - - - - - - - - - - - - - - - - - - - - 6-24

About the Auto Refill Sub-Menu - - - - - - - - - - - - - - - - - 6-24

Selecting the Auto Refill Function - - - - - - - - - - - - - - - - - 6-25

Setting the START (LO) and STOP (HI) Parameters - - - - - - - 6-26

Setting the LO SHUTOFF and HI SHUTOFF Alarm Weight

Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - 6-26

Selecting the Initial Fill Function - - - - - - - - - - - - - - - - - 6-28

About the Refill Correction Factor- - - - - - - - - - - - - - - - - 6-28

Force Refill- - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

Time and Date Sub-Menu - - - - - - - - - - - - - - - - - - - - - - 6-30

Setting the Time - - - - - - - - - - - - - - - - - - - - - - - - - 6-30

Setting the Date - - - - - - - - - - - - - - - - - - - - - - - - - 6-31

Serial Communications/Serial Port #1 Sub-Menu (For RS-232C

Specifications See Chapter 2) - - - - - - - - - - - - - - - - - - - 6-31

Disabling the Front Panel Print Button - - - - - - - - - - - - - - 6-34

Printing Batch Reports - - - - - - - - - - - - - - - - - - - - - - 6-35

Bi-Directional Port Setup - - - - - - - - - - - - - - - - - - - - - 6-36

Saving to the Secure Memory Module (SMM) - - - - - - - - - - - - - - - - - 6-37

When to Save - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - 6-37

Saving to the Secure Memory Module (SMM) - - - - - - - - - - - - - - - 6-37

Data Saved in the Secure Memory Module - - - - - - - - - - - - - - - - 6-39

Table of Contents

v

Restoring Data Saved in the Secure Memory Module - - - - - - - - - - - - - 6-39

Data Recall Procedures - - - - - - - - - - - - - - - - - - - - - - - - - 6-39

Setting the Control Out LO% and Control Out HI% - - - - - - - - - - - - - - 6-40

Setting the Control Out LO% - - - - - - - - - - - - - - - - - - - - - - - 6-40

Setting Control Out HI% - - - - - - - - - - - - - - - - - - - - - - - - - 6-43

Setting Up the Analog Output Option - - - - - - - - - - - - - - - - - - - - - 6-45

Analog Output Main - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-46

The Information Type Parameter Setting - - - - - - - - - - - - - - - - - 6-47

ZERO Output Reference Voltage and Current - - - - - - - - - - - - - - 6-47

SPAN Output Reference Voltage and Current- - - - - - - - - - - - - - - 6-47

Chapter 7 Serial Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

About Chapter 7 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Host Functions - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Serial Protocol - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Hardy Link - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Multidrop Configuration- - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Serial Commands - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

Serial Command Lists - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

Data Transmission Format - - - - - - - - - - - - - - - - - - - - - - - - 7-5

Command Sets - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

X (Xmit) Command- - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

S (Set) Command - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

Error Codes - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

Chapter 8 Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-1

About Chapter 8 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-1

Operational Displays - - -- - - - - - - - - - - - - - - - - - - - - - - - - - 8-1

Selecting Operational Displays - - - - - - - - - - - - - - - - - - - - - - 8-1

There are three Continuous Rate Displays - - - - - - - - - - - - - - 8-1

The Rate Section - - - - - - - - - - - - - - - - - - - - - - - - 8-3

The Weight Section - - - - - - -- - - - - - - - - - - - - - - - 8-3

Current Weight Total Display - - - - - - - - - - - - - - - - - - - 8-4

Batch Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

Selecting Batch Displays - - - - - - -- - - - - - - - - - - - - - - - 8-5

Display Parameters - - - - - - - - - - - - -- - - - - - - - - - - - - - - - 8-8

Rate\Current Weight Display Parameters -- - - - - - - - - - - - - - - 8-8

Current\Total Weight Display Parameters - - - - - - - - - - - - - - - - - 8-9

Clearing the Total Register (Totalizer) from the

Front Panel - - - - - - - - - - -- - - - - - - - - - - - - - - 8-9

Clearing the Total Register from the Rear Panel - - - - - - - - - 8-10

Setting the Flow Rate - - - - - - - - - - - - -- - - - - - - - - - - - - - - 8-11

Rate Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-11

Setting the Manual Rate Control Mode (Volumetric Mode)- - - - - - - 8-11

Increasing/Decreasing the OP% output signal by

increments of .1% - - - - - - - - - - - - - - - - - - - - - - - 8-13

Set the Operating Percentage for 10% increments - - - - - - - - 8-14

Setting the Remote Set Point Input Mode - - - - - - - - - - - - - 8-14

Setting the Automatic Rate Control Mode (Gravimetric Mode) - - - - - 8-15

Amount Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-16

Setting the Set Point Amount Batch Mode - - - - - - - - - - - - - - 8-16

Setting the Continuous Operation Mode - - - - - - - - - - - - - - - 8-18

Ratio Control (Master/Slave) - - - - - - - - - - - - - - - - - - - - - - - - - 8-18

Description of a Ratio Controlled System - - - - - - - - - - - - - - - - - 8-18

Ratio Process Control System - - - - - - - - - - - - - - - - - - - - - - 8-18

Remote Set Points Option for Ratio Control Applications - - - - - - - - - 8-19

Ratio Control Application Example - - - - - - - - - - - - - - - - - - - - 8-25

HI 2160RCPLUS MANUAL

vi

Application - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-25

Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-25

Down Loading Rate Set Points Via Analog Signal for PLC's that

are not Equipped with PROFIBUS or Allen Bradley Remote I/O - - - - - 8-26

Rate Exception Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-28

Definition- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-28

Test Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-30

Sigma Test - Definition - - - - - - - - - - - - - - - - - - - - - - - - - - 8-30

Sigma Data - About 2 Sigma Data - - - - - - - - - - - - - - - - - - - - 8-34

Chapter 9 Troubleshooting and Repair - - - - - - - - - - - - - - - - - - - - - - - - 9-1

About Chapter 9 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-1

Disassembly and Reassembly Notes & Cautions - - - - - - - - - - - - - - - 9-1

Start Up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

Auto Clear Ram Memory Procedures - - - - - - - - - - - - - - - - - - - 9-2

System Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

Drift - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

Checking if Drift Problem is Internal or External - - - - - - - - - - - - 9-3

System Lock Ups - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

Weights Displayed are Incorrect - - - - - - - - - - - - - - - - - - - - - - - 9-7

After Calibration Display Weight Reading is Incorrect - - - - - - - - - - - 9-7

Feeder Motor Won't Start - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-9

Erratic Actual Rate Readings - - - - - - - - - - - - - - - - - - - - - - - - - 9-12

Rate Exception Control (REC) Alarm Appears too Often- - - - - - - - - - - - 9-12

Readings on the Display are Not Correct - - - - - - - - - - - - - - - - - - - 9-13

Remote Setpoint Input Card - - - - - - - - - - - - - - - - - - - - - - - - - 9-14

Allen-Bradley RIO error codes for C2 Calibration - - - - - - - - - - - - - - - 9-15

Allen-Bradley RIO Error Codes for Rate Calibration - - - - - - - - - - - - - - 9-15

PROFIBUS Error Codes for C2 Calibration - - - - - - - - - - - - - - - - - - 9-15

PROFIBUS Error Codes for Rate Calibration - - - - - - - - - - - - - - - - - 9-16

HI 2160RCPLUS Error Messages - - - - - - - - - - - - - - - - - - - - - - - 9-16

Operational Display Messages - - - - - - - - - - - - - - - - - - - - - - - - 9-18

Index

System Data Work-

sheets

Table of Illustrations

I

Table of Illustrations

CHAPTER 1 OVERVIEW - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

FIG. 1-1 HI 2160RCPLUS RATE CONTROLLER - - - - - - - - - - - - - - 1-3

FIG. 1-2 MODEL CODE BREAKDOWN - - - - - - - - - - - - - - - - - - 1-5

FIG. 1-3 OPTIONAL EXPANDER BOX (NON-FM) - - - - - - - - - - - - - 1-6

CHAPTER 3 INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

FIG. 3-1 2” CLEARANCE REQUIREMENT - - - - - - - - - - - - - - - - - 3-2

FIG. 3-2 1” CLEARANCE REQUIRE AROUND BEZEL - - - - - - - - - - - 3-3

FIG. 3-3 PANEL CUTOUT DIMENSIONS - - - - - - - - - - - - - - - - - 3-3

FIG. 3-4 MOUNTING CONTROLLER IN PANEL - - - - - - - - - - - - - - 3-4

FIG. 3-5 NEMA 4 GASKET FLUSH AGAINST THE FRONT PANEL - - - - 3-4

FIG. 3-6 CONTROLLER FLUSH TO FRONT PANEL/FRONT VIEW - - - - 3-5

FIG. 3-7 CONTROLLER FLUSH TO FRONT PANEL/REAR VIEW - - - - - 3-5

FIG. 3-8 INSTALLING MOUNTING BARS - - - - - - - - - - - - -- - - - 3-6

FIG. 3-9 INSTALLING 6-32 MACHINE SCREWS - - - - - - - - - -- - - - 3-6

FIG. 3-10 NEMA 4 GASKET BEFORE AND AFTER TIGHTENING

THE MOUNTING BAR FASTENERS - - - - - - - - - - -- - - - 3-7

FIG. 3-11 MOUNTING BARS AND MACHINE SCREWS INSTALLED - - - - 3-8

FIG. 3-12 FRONT PANEL WITH BRACKETS FROM FACTORY - - - - - - - 3-9

FIG. 3-13 BEZEL INSTALLATION DIAGRAM - - - - - - - - - - -- - - - - 3-9

FIG. 3-14 SLIDING BEZEL INTO THE PANEL CUTOUT- - - - - - - - - - - 3-10

FIG. 3-15 REMOTE PANEL INSTALLED - - - - - - - - - - - - -- - - - - 3-11

FIG. 3-16 ELECTRONICS MOUNTED TO ENCLOSURE REAR PANEL - - - 3-12

FIG. 3-17 DIMENSIONS DIAGRAM FOR REMOTE MOUNT- - - - - - - - - 3-12

FIG. 3-18 PIN CABLE ASSEMBLY HI 2160PLUS REMOTE PANEL - - - - - 3-13

FIG. 3-19 QUAD EXPANDER INSTALLED - - - - - - - - - - - - - - - - - 3-14

FIG. 3-20 REAR PANEL - - - - - - - - - - -- - - - - - - - - - - - - - - 3-15

FIG. 3-21 OUTPUT RELAY CONNECTION - - - - - - - - - - - - - - - - - 3-15

FIG. 3-22 MOTOR CONTROL OUTPUT- - - -- - - - - - - - - - - - - - - 3-16

FIG. 3-23 REFILL AND ALARM RELAYS - - -- - - - - - - - - - - - - - - 3-16

FIG. 3-24 RS 232 WIRING DIAGRAM - - - - -- - - - - - - - - - - - - - - 3-16

FIG. 3-25 REMOTE FUNCTIONS WIRING DIAGRAM - - - - - - - - - - - - 3-17

FIG. 3-26 POWER CONNECTION WIRING DIAGRAM - - - - - - - - - - - 3-18

FIG. 3-27 REMOTE SETPOINT OPTION WIRING DIAGRAM - - - - - - - - 3-19

FIG. 3-28 RS-422 CONVERTER OPTION WIRING DIAGRAM - - - - - - - - 3-19

FIG. 3-29 ANALOG OUTPUT OPTION WIRING DIAGRAM - - - - - - - - - 3-19

FIG. 3-30 C2 LOAD CELL WIRING DIAGRAM- - - - - - - - - - - - - - - - 3-21

FIG. 3-31 4 CONDUCTOR LOAD CELL WIRING DIAGRAM

(NON C2 LOAD CELLS) - - - - - - - - - - - - - - - - - - - - - 3-21

FIG. 3-32 6 CONDUCTOR LOAD CELL WIRING DIAGRAM

(NON-C2 LOAD CELLS) - - - - - - - - - - - - - - - - - - - - - 3-22

FIG. 3-33 INTERCONNECT WIRING DIAGRAM - - - - - - - - - - - - - - 3-23

FIG. 3-34 COMPUTER CLEAN POWER DIAGRAM - - - - - - - - - - - - - 3-24

FIG. 3-35 SECURE MEMORY MODULE - - - - - - - - - - - - - - - - - - 3-25

FIG. 3-36 INSTALLING/REMOVING SECURE MEMORY MODULE - - - - - 3-25

CHAPTER 4 CONFIGURATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

FIG. 4-1 SOLID STATE RELAY DIP SWITCHES (PRT. #0535-0417) - - - - 4-1

FIG. 4-2 JUMPER SETTINGS FOR CONTROL OUTPUT BOARD - - - - - 4-3

FIG. 4-3 REMOVAL OF REAR PANEL - - - - - - - - - - - - - - - - - - - 4-5

FIG. 4-4 REMOVAL OF TOP PANEL- - - - - - - - - - - - - - - - - - - - 4-5

FIG. 4-5 REMOVING REAR PANEL IN QUAD EXPANDER BOX - - - - - - 4-5

FIG. 4-6 ANALOG OUTPUT OPTION CARD - - - - - - - - - - - - - - - - 4-6

HI 2151/30WC MANUAL

II

FIG. 4-7 REMOTE FUNCTION OPTION - - - - - - - - - - - - - - - - - - 4-7

FIG. 4-8 JUMPER SETTINGS FOR ANALOG INPUT PWA AND F1 FUSE - 4-9

FIG. 4-9 CONNECTOR PINS FOR ANALOG INPUT PWA - - - - - - - - - 4-10

FIG. 4-10 GROUND JUMPER TO READ ANALOG INPUT- - - - - - - - - - 4-11

FIG. 4-11 RS-422 CONVERTER DIP SWITCHES - - - - - - - - - - - - - - 4-12

FIG. 4-12 CONFIG. DIP SWITCHES REAR PANEL - - - - - - - - - - - - - 4-13

FIG. 4-13 OPERATIONAL DISPLAY #1 CURRENT WEIGHT - - - - - - - - 4-14

FIG. 4-14 REMOVAL OF REAR PANEL - - - - - - -- - - - - - - - - - - - 4-15

FIG. 4-15 REMOVAL OF TOP PANEL- - - - - - - -- - - - - - - - - - - - 4-15

FIG. 4-16 SETTING WAVERSAVER JUMPERS - - - - - - - - - - - - - - - 4-16

CHAPTER 5 CALIBRATION- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

FIG. 5-1 PROPERLY INSTALLED LOAD CELL W/NO BINDING - - - - - - 5-2

FIG. 5-2 OPERATIONAL DISPLAY/NOT RUNNING - - - - - - - - - - - - 5-10

FIG. 5-3 OPERATIONAL DISPLAY RUNNING - - - - - - - - - - - - - - - 5-11

FIG. 5-4 OUTPUT SIGNAL IN 00.1% INCREMENTS - - - - - - - - - - - - 5-11

FIG. 5-5 OUTPUT SIGNAL IN 10% INCREMENTS - - - - - - - - - - - - - 5-12

FIG. 5-6 OPERATIONAL DISPLAY UNIT PAUSED - - - - - - - - - - - - - 5-13

FIG. 5-7 OPERATIONAL DISPLAY OFF - - - - - - - - - - - - - - - - - - 5-13

FIG. 5-8 AUTO RATE CALIBRATION PASSED - - - - - - - - - - - - - - 5-16

FIG. 5-9 AUTO RATE CALIBRATION FAILED - - - - - - - - - - - - - - - 5-17

FIG. 5-10 OPERATIONAL DISPLAY #1 CURRENT WEIGHT - - - - - - - - 5-19

FIG. 5-11 SCALE DISPLAY - - - - - - - - - - - - - - - - - - - - - - - - - 5-19

CHAPTER 6 SETUP- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

FIG. 6-1 PRESS CONFIG/1 BUTTON TO GET TO THE MAIN MENU- - - - 6-4

FIG. 6-2 SECURITY CODE ENTRY DISPLAY - - - - - - - - - - - - - - - 6-4

FIG. 6-3 SELECTING SECURITY SUB-MENU - - - - - - - - - - - - - - - 6-5

FIG. 6-4 SECURITY MENU, SELECTING ACCESS LEVELS - - - - - - - - 6-5

FIG. 6-5 SECURITY MENU, ENTERING LEVEL VALUES - - - - - - - - - 6-7

FIG. 6-6 ACT BLANK TIMEBASE ERROR - - - - - - - - - - - - - - - - - 6-9

FIG. 6-7 DERIVED LOSS OF WEIGHT SLOPE (INTERPRETED AS

GAIN-IN-FIGWEIGHT)- - - - - - - - - -- - - - - - - - - - - - 6-10

FIG. 6-8 DERIVED LOSS OF WEIGHT SLOPE (INTERPRETED AS

NO CHANGE-IN-WEIGHT) - - - - - - - - - - - - - - - - - - - - 6-10

FIG. 6-9 DERIVED LOSS OF WEIGHT SLOPE (INTERPRETED AS

LOSS-IN-WEIGHT - - - - - - - - - - - - - - - - - - - - - - - - 6-11

FIG. 6-10 ENTERING TIMEBASE PARAMETER - - - - - - - - - - - - - - 6-13

FIG. 6-11 SETTING THE AVRG AND REC LEVELS - - - - - - - - - - - - - 6-14

FIG. 6-12 OPERATING DISPLAY TOTAL WEIGHT - - - - - - - - - - - - - 6-15

FIG. 6-13 ENTERING CALCULATED CONSTANT VALUES - - - - - - - - - 6-17

FIG. 6-14 OPERATIONAL DISPLAY/REC STATUS - - - - - - - - - - - - - 6-18

FIG. 6-15 GROUNDING THE “A” PIN TO CLEAR ALARM - - - - - - - - - - 6-21

FIG. 6-16 RATE TOLERANCES MENU/SHUTOFF SETTINGS - - - - - - - 6-22

FIG. 6-17 PROCESS GRAPH USING RATE TOLERANCES - - - - - - - - - 6-23

FIG. 6-18 AUTO REFILL OUTPUT RELAY - - - - - - - - - - - - - - - - - 6-24

FIG. 6-19 AUTO REFILL MENU/START AND STOP SETTINGS - - - - - - - 6-25

FIG. 6-20 AUTO REFILL MENU/LO SHUTOFF SETTINGS - - - - - - - - - 6-27

FIG. 6-21 AUTO REFILL MENU/HI SHUTOFF SETTINGS - - - - - - - - - - 6-28

FIG. 6-22 AUTO REFILL MENU/SETTING THE REFILL CORRECTION

FACTOR- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

FIG. 6-23 GROUNDING REFILL FOR FORCED REFILL- - - - - - - - - - - 6-30

FIG. 6-24 MAIN MENU/SETTING TIME AND DATE - - - - - - - - - - - - - 6-30

FIG. 6-25 TIME AND DATE MENU/SETTING TIME AND DATE - - - - - - - 6-31

FIG. 6-26 MAIN MENU/SELECTING SERIAL PORT #1 - - - - - - - - - - - 6-32

Table of Illustrations

III

FIG. 6-27 SERIAL PORT #1 CONFIGURATION - - - - - - - - - - - - - - - 6-32

FIG. 6-28 SERIAL PORT #1 CONFIGURATION - - - - - - - - - - - - - - - 6-33

FIG. 6-29 OPERATIONAL MENU - - - - - - - - - - - - - - - - - - - - - - 6-33

FIG. 6-30 DISABLING THE PRINT FUNCTION - - - - - - - - - - - - - - - 6-35

FIG. 6-31 CONFIG DIP SWITCH #3/DISABLING BATCH REPORT PRINTING

FUNCTION - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-36

FIG. 6-32 SAVING TO SECURE MEMORY MODULE - - - - - - - - - - - - 6-38

FIG. 6-33 SAVE/RECALL MENU - - - - - - - - - - - - - - - - - - - - - - 6-38

FIG. 6-34 RECALL SUB-MENU - - - - - - - - - - - - - - - - - - - - - - - 6-40

FIG. 6-35 CONTROL OUT% GRAPH - - - - - - - - - - - - - - - - - - - - 6-41

FIG. 6-36 TUNING/CONTROL MENU/SETTING CONTROL OUT LO

PERCENTAGE - - - - - - - - - - - - - - - - - - - - - - - - - 6-42

FIG. 6-37 TUNING/CONTROL MENU/ SETTING CONTROL OUT LO

PERCENTAGE TO 26 - - - - - - - - - - - - - - - - - - - - - - 6-43

FIG. 6-38 TUNING/CONTROL MENU/SETTING CONTROL OUT HI

PERCENTAGES- - - - - - - - - - - - - - - - - - - - - - - - - 6-44

FIG. 6-39 TUNING/CONTROL MENU/SETTING CONTROL OUT HI

PERCENTAGE/74 - - - - - - - - - - - - - - - - - - - - - - - - 6-45

FIG. 6-40 MAIN MENU/ANALOG OUTPUT - - - - - - - - - - - - - - - - - 6-46

FIG. 6-41 ANALOG OUTPUT MENU - - - - - - - - - - - - - - - - - - - - 6-46

FIG. 6-42 ANALOG OUTPUT MENU/ZERO AND SPAN VOLTAGE

SETTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-48

CHAPTER 7 SERIAL COMMUNICATIONS - - - - - - - - - - - - - - - - - - - - - - - - 7-1

FIG. 7-1 MULTIDROP CONFIGURATION WITH HOST AND

CONTROLLERS - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

CHAPTER 8 OPERATION- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-1

FIG. 8-1 RATE & CURRENT WEIGHT DISPLAY (DEFAULT DISPLAY)- - - 8-1

FIG. 8-2 RATE & TOTAL WEIGHT DISPLAY - - - - - - - - - - - - - - - - 8-2

FIG. 8-3 CURRENT TOTAL WEIGHT DISPLAY - - - - - - - - - - - - - - 8-2

FIG. 8-4 RATE DISPLAY - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

FIG. 8-5 TOTAL ACCUMULATED WEIGHT - - - - - - - - - - - - - - - - 8-4

FIG. 8-6 CURRENT AND ACCUMULATED TOTAL WEIGHT DISPLAY - - - 8-5

FIG. 8-7 SET POINT MENU/SELECTING BATCH MODE - - - - - - - - - 8-5

FIG. 8-8 BATCH AMOUNT AND RATE DISPLAY - - - - - - - - - - - - - 8-6

FIG. 8-9 BATCH AMOUNT/CURRENT WEIGHT DISPLAY - - - - - - - - - 8-7

FIG. 8-10 BATCH AMOUNT AND TOTAL WEIGHT DISPLAY - - - - - - - - 8-8

FIG. 8-11 SET RATE/CURRENT WEIGHT DISPLAY PARAMETERS - - - - 8-8

FIG. 8-12 CURRENT/TOTAL WEIGHT DISPLAY PARAMETERS - - - - - - 8-9

FIG. 8-13 CLEARING THE TOTAL REGISTER FROM THE FRONT PANEL - 8-10

FIG. 8-14 CLEARING TOTAL REGISTER FROM THE REAR PANEL - - - - 8-10

FIG. 8-15 OPERATIONAL DISPLAY RUNNING - - - - - - - - - - - - - - - 8-12

FIG. 8-16 OUTPUT SIGNAL IN 00.1% INCREMENTS - - - - - - - - - - - - 8-13

FIG. 8-17 OUTPUT SIGNAL IN 10% INCREMENTS - - - - - - - - -- - - - 8-14

FIG. 8-18 SELECTING THE REMOTE MODE OF OPERATION - - - - - - - 8-15

FIG. 8-19 SETPOINT MENU/SELECTING AUTOMATIC MODE - - -- - - - 8-16

FIG. 8-20 SETPOINT MENU/CONTINUOUS AMOUNT MODE- - - - - - - - 8-17

FIG. 8-21 SETPOINT MENU/SET POINT AMOUNT BATCHING - - - - - - - 8-17

FIG. 8-22 PROCESS CONTROL SYSTEM/RATIO CONTROL - - - - - - - - 8-19

FIG. 8-23 REMOTE SET POINT JUMPER- - - - - - - - - - - - - -- - - - 8-20

FIG. 8-24 SETTING LO AND HI SIGNAL OUTPUT PARAMETERS - - - - - 8-21

FIG. 8-25 REMOTE SETPOINT MENU/SETTING AVERAGING - - - - - - - 8-22

FIG. 8-26 REMOTE SETPOINT MENU/SETTIN SPL & SPH - - - - - - - - - 8-23

FIG. 8-27 ANALOG SIGNAL CONFIGURATION DIAGRAM - - - - - - - - - 8-27

FIG. 8-28 DOWNLOADING SET POINTS, RELAY WIRING

HI 2151/30WC MANUAL

IV

CONFIGURATION - - - - - - - - - - - - - - - - - - - - - - - - 8-28

FIG. 8-29 SELECTING TEST MENU - - - - - - - - - - - - - - - - - - - - 8-30

FIG. 8-30 TEST MENU - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-31

FIG. 8-31 2 SIGMA TEST MENU - - - - - - - - - - - - - - - - - - - - - - 8-31

FIG. 8-32 2 SIGMA TEST MENU/SELECTING THE TEST - - - - - - - - - - 8-32

FIG. 8-33 2 SIGMA TEST MENU/SELECTING YES - - - - - - - - - - - - - 8-33

FIG. 8-34 SELECTING RUNNING 2 SIGMA DISPLAY - - - - - - - - - - - - 8-34

FIG. 8-35 SELECTING 2 SIGMA DATA - - - - - - - - - - - - - - - - - - - 8-35

FIG. 8-36 2 SIGMA DATA DISPLAYED - - - - - - - - - - - - - - - - - - - 8-35

CHAPTER 9 TROUBLESHOOTING AND REPAIR- - - - - - - - - - - - - - - - - - - - - 9-1

FIG. 9-1 RESISTOR SHUNT BRIDGE DIAGRAM - - - - - - - - - - - - - 9-3

FIG. 9-2 SURGE SUPPRESSION RESISTIVE/CAPACITIVE CIRCUIT

PRT. #4802-0002 - - - - - - - - - - - - - - - - - - - - - - - - 9-6

FIG. 9-3 TEST SUB-MENU/CHECKING CURRENT COUNT - - - - - - - - 9-8

FIG. 9-4 USING A VOLTMETER TO CHECK LOAD CELL VOLTAGE- - - - 9-9

FIG. 9-5 CONNECTOR WIRING DIAGRAM FOR CONTROL OUTPUT

CARD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

FIG. 9-6 JUMPER SETTINGS FOR CONTROL OUTPUT CARD - - - - - - 9-11

Chapter 1 - Overview

1-1

CHAPTER 1 - OVERVIEW

About Chapter 1 This manual provides the user and service personnel with a description

of the operating procedures, specifications, installation procedures,

setup and configuration, maintenance and troubleshooting procedures

for the Hardy Process Solutions HI 2160RCPLUS Rate Controller

with WAVERSAVER®(A Registered Trademark of Hardy Process

Solutions) To get the maximum service life from this product, users

should use this instrument in accordance with recommended practices

either implied or contained in this manual. The user and maintenance

person-nel should read and understand all cautions, warnings, and

safety pro-cedures, referenced or explicitly stated in this manual, to

ensure the safe operation of this product. Hardy Process Solutions

appreciates your business. Should you not understand any information

in this manual or experience any problems with the product, please

contact our Customer Service Department at:

Phone: (858) 278-2900

Web Site: www.hardysolutions.com

Support e-mail address: hardysupport@hardysolutions.com

About Hardy Manuals Every Hardy Installation and Operation manual is organized into easily

referenced chapters, that are almost always the same:

•Chapter One - Provides an introduction to the instrument and an

Overview of the equipment and its capabilities.

•Chapter Two - Provides a complete list of Specifications.

•Chapter Three - Contains information needed to Install the HI

2160RCPLUS (both standard equipment and optional equipment) and

the HI 215IT series Junction Box.

•Chapter Four - Provides complete hardware Configuration

instructions for setting dipswitches and jumpers.

•Chapter Five - Pertains to the firmware Setup and preparation pro-

cedures to calibrate and operate the instrument.

•Chapter Six - Provides Calibration instructions.

•Chapter Seven - pertains to the Operation of the HI 2160RC PLUS.

•Chapter Eight - Pertains to the Troubleshooting procedures for

repair of the instrument.

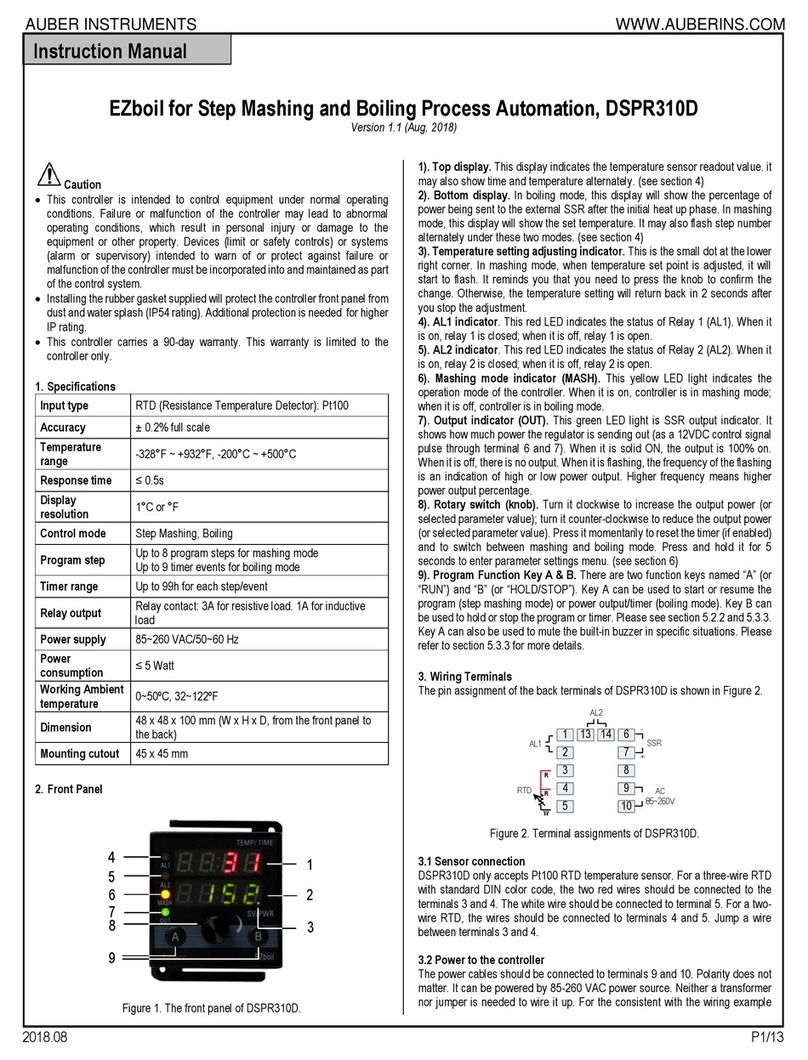

Description The HI 2160RCPLUS is a compact, single ingredient Loss-In-Weight

controller. The rate controller is used in a variety of material flow appli-

cations for example auger, belt, and vibration based feeders. The HI

2160RCPLUS measures the flow rate from a feeding device located on a

process weighing scale. The rate is measured by calculating the loss of

weight over a very short period of time. The rate controller compares

the actual rate of flow to the desired rate of flow, computes the appro-

priate change(s) and transmits a signal (0-30 Millivolts) to either speed

HI 2160RCPLUS MANUAL

1-2

up or slow down the driver of the feeding device thereby achieving the

desired flow rate. The user simply enters the flow parameters via the

key touch pad (See Fig. 1-1) or standard bi-directional serial port or

optional Interface and the HI 2160RCPLUS rate control algorithm auto-

matically calculates and adjusts the tuning parameters thereby main-

taining the desired flow rate. The analog to digital converter in the rate

controller is capable of greater than 1,000,000 counts of resolution,

detecting the smallest fluctuations in rate of flow.

NOTE: Manual adjustment of the tuning parameters is typically not necessary, but can be

done.

WAVERSAVER®Typically, mechanical noise (from the feeders and plant environment)

is always present and much larger when compared with the detection

and control of small changes in weight. The HI 2160RCPLUS is fitted

with WAVERSAVER®technology which ignores mechanical noise

present in all material flow applications. WAVERSAVER®enables the

rate controller to decipher actual weight data from mechanical noise

and blocks the mechanical noise transmitted from the load cell.

ALARMS The HI 2160RC LUS is fitted with two alarms to detect exceptions to the

desired flow rate. The Rate Tolerance Alarm is configured to monitor

a tight guard band around the desired flow rate. The guard band is user

selectable. The alarm is triggered when the desired flow rate exceeds

the selected guard band tolerance for a selected period of time. The

Rate Tolerance alarm is connected to a relay which can activate a visual

or sound alarm. This alarm is used for small changes in the desired flow

rates. The Rate Exception Control (REC) Alarm uses a broader

guard band tolerance then the Rate Tolerance Alarm. The alarm is trig-

gered by an out of tolerance flow rate. The controller in REC Alarm

state continues to control the flow rate while trying to bring the excep-

tional flow rate into tolerance. The REC is a user selectable alarm

which can display an "REC" at the bottom left corner of the controller

display and/or shut down the feeder system.

Chapter 1 - Overview

1-3

FIG. 1-1 HI 2160RCPLUS RATE CONTROLLER

Capabilities

Automatic Control

Mode

Automatically corrects for variations in desired flow rates.

WAVERSAVER®Ignores plant and process vibration for more accurate measurement of

feed rates.

Manual Control

Mode

Use the up and down arrows to manually control the flow rate. Convert

to automatic mode when proper flow rate is achieved.

Continuous or

Batch Modes

User selectable operating modes for continuous or batch processing.

Automatic Refill User selectable refill points to start and stop the refill process. HI and

LO alarms to detect a refill failure.

Manual Refill Allows for manual refill at anytime.

Automatic Tuning

(Auto Rate

Calibration)

Provides the user with automatically calculated parameters or the user

can manually enter their own derived values.

Operation Displays Single button selection of Predefined operating displays such as, Rate,

Current Weight, Totalized Weight, and Batch data.

Secure Memory

Module

Provides for stored critical data to be transferred to a replacement HI

2160RC PLUS. Conveniently located on the rear panel, replacement

HI 2160RCPLUS MANUAL

1-4

takes only a few seconds. Does not require recalibration of the scale.

Maximizes up time for the feed systems.

Control Output Electrically and optically isolated, user selectable 0-20 mA, 4-20 mA,

0-5 VDC, or 0-10 VDC output.

Front Panel 5" x 7" Waterproof when mounted in a NEMA 4 enclosure.

Serial

Communications

Bi-directional serial port (RS 232) allows reading of data and down-

loading of feed rate instructions.

Hardy Link

Communications

Assigns addresses to each instrument so they can share the same Serial

Chain.

Self Test User can easily troubleshoot the controller by implementing the inter-

nal self test.

Reports Automatically prepares batch performance reports.

C2®Second

Generation

Calibration

Electronic method for calibrating a scale.

Remote Operation The HI 2160RCPLUS is fitted with a bi-directional serial port, an

optional Allen Bradley I/O card or PROFIBUS Interface, which allow

for remote operation of the controller.

Multiple

Configuration

Storage

Stores up to twelve different complete system configurations allowing

fast and easy transition to a new material, auger or entire feeder.

Two Sigma The 2 Sigma Test feature is used to measure the feed rate performance

for any given feeder system. The 2 Sigma Test can be run on demand

during all feed cycles.

Interpreting the Model

Code Number

Model Code

Breakdown

• The model code number can be found on a label that is attached to

the top panel of the HI 2160RC PLUS.

• The model code number starts with the base model number (HI

2160RC PLUS). The dash alphanumeric designations indicate the

capabilities of the rate controller. For example: A model HI

2160RC-PM-A1-B1 is a Panel Mount controller with 4-20 milli-

amp control output and RS-232 to RS-422 converter. (See Fig. 1-2)

HI 2160RC-PM-A1-B1-C1-D1-E1

PM - PANEL MOUNT

RM - REMOTE

DISPLAY

MOUNTING

A1 - CONTROL OUTPUT

4-20 MILLIAMPS

A2 - CONTROL OUTPUT

0-20 MILLIAMPS

A3 - CONTROL OUTPUT

0-5 VDC

A4 - CONTROL OUTPUT

0-10 VDC

B1 - RS-232 TO 422 CONVERTER

B3 - REMOTE I/0 INTERFACE FOR

ALLEN-BRADLEY NETWORK

B2 - 240 VAC OPERATION

Power: 240 VAC 10%

"Refill" and "Alarm" relays:

240 VAC, 3 Amps

Solid State Outputs:

240 VAC 4 Amps

+

-

B4 - PROFIBUS INTERFACE CARD

C1 - CURRENT INPUT (4-20 MILLIAMPS)

REMOTE SETPOINT INPUT CARDS

C2 - CURRENT INPUT (0-20 MILLIAMPS)

C3 - VOLTAGE INPUT (0-10 VOLTS)

C4 - VOLTAGE INPUT (0-5 VOLTS)

D1 - ANALOG OUTPUT OF 4-20 MILLIAMPS

OPTIONAL ANALOG OUTPUTS

D2 - ANALOG OUTPUT OF 0-20 MILLIAMPS

D3 - ANALOG OUTPUT OF 0-5 VOLTS

D4 - ANALOG OUTPUT OF 0-10 VOLTS

E1 - OPTION EXPANDER CARD (Non FM)

Chapter 1 - Overview

1-5

FIG. 1-2 MODEL CODE BREAKDOWN

HI 2160RCPLUS MANUAL

1-6

• Optional Expander Box (Non FM) (See Fig. 1-3)

The dash number for the expander box is:

-HI216EX

If the expander box is configured for 240 VAC Opera-

tion the dash number is:

-B2

NOTE: Requires the -E1 option expander card to be installed in the main rate controller.

FIG. 1-3 OPTIONAL EXPANDER BOX (NON-FM)

Chapter 2 - Specifications

2-1

CHAPTER 2 - SPECIFICATIONS

About Chapter 2 Chapter 2 lists the specifications for the HI 2160RCPLUS rate controller.

Specifications are listed for the standard instrument and for instruments

fitted with optional equipment. The specifications listed are designed to

assist in the installation, operation and troubleshooting of the instru-

ment. All service personnel should be familiar with this section before

attempting an installation or repair of the instrument

HI 2160RC PLUS

Specifications

Input Up to 4 (four) 350 ohm load cells (10 volt excitation)

Full Wheatstone Bridge, Strain Gauge Load Cells

Output Control Out - Isolated Outputs, user selectable

• 4-20 Milliamp

• 0-20 Milliamp

•0-5VoltDC

• 0-10 Volt DC

Storage • Battery Backed RAM

• Secure Memory Module Calibration Data

Instrument

Resolution

• Display: 1:985,000 (for 3 mv/v)

• Internal: 1:1,048,576

Remote Control

Options

• Allen Bradley Programmable Logic Controller (PLC)

• Profibus (Various PLCs)

• Serial Port - RS-232C (Standard)

• Serial Port - RS 422/485

• Remote Set Point (Analog)

Alarms (Relays) • Rate Tolerance Alarms

• Refill Alarms

• Rate Exception Control Alarm (REC)

• Shut Off

•ON/OFF

Analog to Digital

Specifications

• Conversion Rate: 20 updates per second

• Averages: 1 to 200 selectable in increments of 1

• Rate of Change Time Base: 1, 2, 3, 4, 5, 6, 8, 10, 12, 15, 20, 30, 40,

50, 60, 100, 120 (seconds)

• Non-Linearity: 0.0015% of Full Scale

• Common Mode Rejection: 100 dB at or below 60Hz

• Common Mode Voltage: 300 VAC or VDC maximum (with respect

to earth ground)

HI 2160RCPLUS MANUAL

2-2

Output Display

Specifications

• Liquid Crystal Display (LCD) - 80 characters

• Display Format: 4 line x 20 character full ASCII (5 x 7 dot matrix)

• Display Increments: 1,2,5,10,20,50,100,200,500 counts selectable

by keypad. Corresponding weight is dependent on decimal point

location.

NOTE: Only the weight display increments are effected by graduations

Reports • Automatic Batch Reports

• Print Screen Available

• Two Sigma

Power and Utility

Requirements

• 120 VAC (47-63 Hz) Standard from factory.

• 240 VAC (47-63 Hz) (Optional) Installed at factory with power and

relay modifications.

Environmental

Requirements

• Operating Temperature Range: -10 to 50 C (14 to 122 F)

• Storage Temperature Range: -20 to 85 C (-4 to 185 F)

• Temperature Coefficient: Less than 0.005% of full scale per degree

C for zero and span.

Physical

Characteristics

• Overall Size - 7"W x 4.88"H x 10.04"L

• Weight: 6 pounds (2.72 Kilograms)

Enclosure Rating • NEMA 4 & 4x Seal when placed in a NEMA 4 & 4X Enclosure.

Approvals • UL Certification

• CSA Certification

• Factory Mutual (FM) Approval

Connectors • Relays: Phoenix 12 pin connector

• RS-232: Phoenix 6 pin connector (Standard)

• Alarm Relays: Phoenix 6 pin connectors

• Load Sensors: Phoenix 8 pin connectors

Options

Remote Set Point

Input Option - Basic

Function

1. Reads analog input signals from a master controller, Program-

mable Logic Controller (PLC), or from a main ingredient flow

meter device.

2. Changes the rate of flow set point to proportionally track the

master controller's flow rate.

3. Changes the rate of flow set point to a new fixed rate, down-

loaded by the PLC via analog signal, if the input trigger is

pulsed

4. Interface to the 2160 Rate Controller - Selectable 0-20 mA, 4-

20 mA, 0-5 VDC, 0-10 VDC analog input signal.

RS422/485 (Serial

Port Option) - Basic

Function

1. Converts the Standard Serial Port from RS 232 to RS 422/485

signals.

Chapter 2 - Specifications

2-3

2. Same function as standard serial port but with the capability to

run in multidrop mode and handle long distance (50-1000 ft.)

communications.

3. Interfaces to the 2160 Rate Controller - RS422/485 serial com-

munications with a comprehensive ASCII command set for bi-

directional and multidrop communications over a long range.

ALLEN BRADLEY

Remote I/O Option -

Basic Function

1. Allows the Allen Bradley PLC to fully configure, monitor, and

control the HI2160RC via the AB Remote I/O Interface.

2. Processes both Discrete and Block Transfer commands.

3. Interfaces to the 2160 Rate Controller - Communications on the

Allen Bradley (AB Remote I/O network utilizing a complete

and comprehensive discrete and block transfer command set.

Uses three-wire "Blue Hose" cable to interface with Allen Brad-

ley.

PROFIBUS

Interface Option

Card

1. Allows the Profibus to fully configure, monitor and control the

HI 2160RC PLUS.

2. Interfaces to the HI 2160RC PLUS rate controller. Enables

communications on the Profibus network utilizing comprehen-

sive block and operator selectable output.

Quad Option

Expander Box -

Basic Function (See

Fig. 1-3)

1. Expands the capability of the HI 2160RC PLUS.

2. Houses up to four option cards in its own enclosure.

3. Interfaces to the 2160 Rate Controller - TTL interfacing

between the HI 2160RC PLUS and the quad option box via

quad interface card, installed in the HI 2160RC PLUS option

slot, and a 40 pin ribbon cable.

Analog Output

Option Card

The analog output option outputs Gross, Batch, Rate of Change (ROC),

and total weight as 0-5 V, 0-10V, 0-20 mA or 4-20 mA (or the reverse

of these values via the front panel). The analog output option makes it

possible to span these ranges over a portion of the weight data.

• Resolution:16,000 counts or limited by the resolution calibrated on

the display.

• Voltage Out

Maximum Volts: 0-5 or 0-10

Temperature Stability

10 ppm/C or 5 mV total from 30 to 120 F

• Current Out

Maximum Current:

0-20mA or 4-20mA

Temperature Stability:

20 ppm/C or 20 microampere total from 30 to 120 F

Table of contents

Other Hardy Process Solutions Controllers manuals

Popular Controllers manuals by other brands

Eurotherm

Eurotherm 2132 operating instructions

Chromalox

Chromalox Chroma-FP-OD Series Installation and operating manual

Atlas Copco

Atlas Copco EBL Drive Configuration manual

Desoutter

Desoutter ESP1-A Original instructions

PMA

PMA KS 45 manual

Equalizer Systems

Equalizer Systems Auto Level Basic Troubleshooting