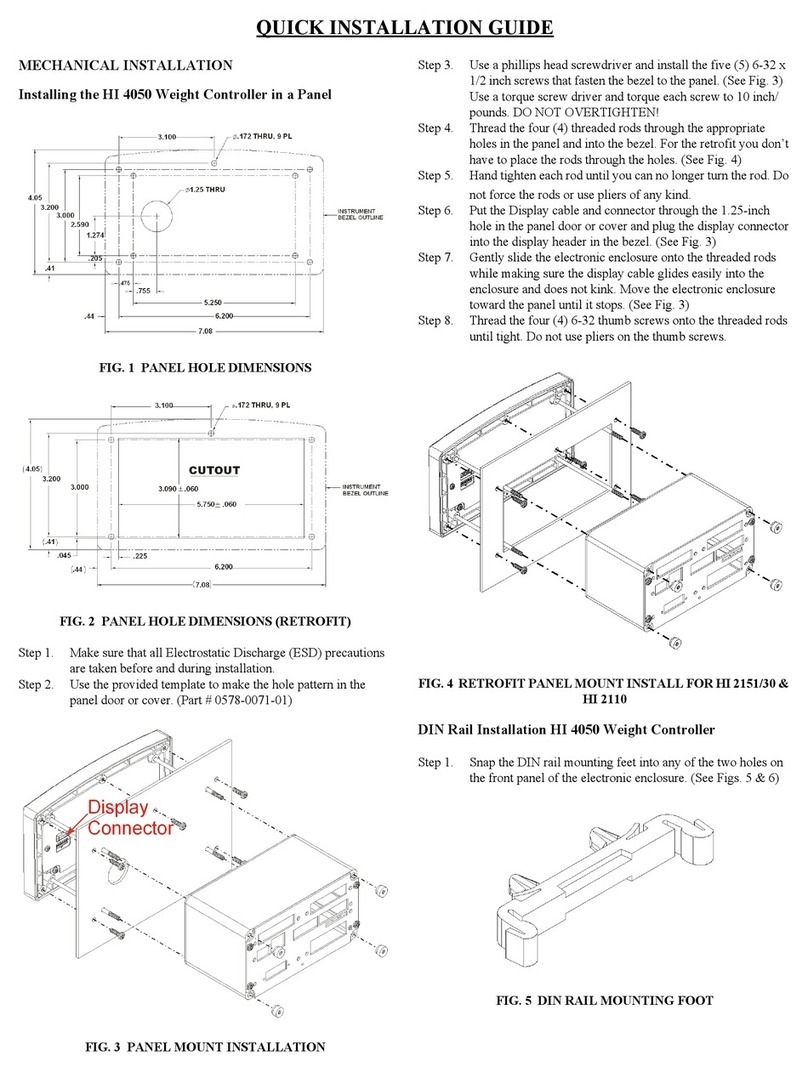

Step 5. To remove the mounting feet use a finger on the clip and gen-

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

FIG. 6

C2®Load Point Connection

Cable color Code for C2 Load Points (left to right facing the rear panel):

• Shield Ground Wire

• C2- Violet

•C2+ Grey

•EXC- Black

•SEN- Brown

•SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

Step 1. Remove the factory installed jumpers from the terminal block

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel terminal

block according to the cable color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Load Point connection,

consult the HI 4060 User Guide.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code for your Non-C2 load point. Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that includes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or per manu-

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

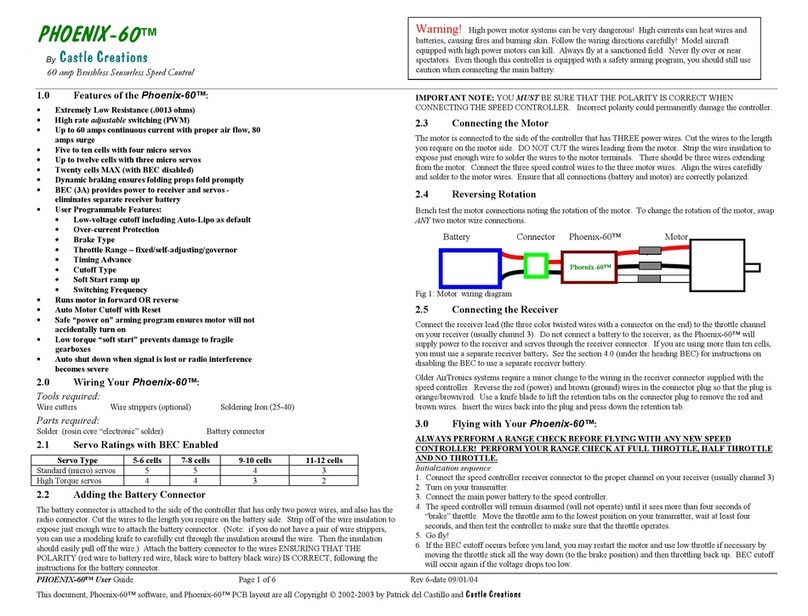

INPUT POWER WIRING

WARNING: DONOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. TODO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

WARNING: IF ALITHIUM BATTERY IS REPLACED WITH AN

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: IFAN AUTOMATIC DISCONNECT DEVICE IS USED

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN ADOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

• The AC power should be supplied by a “clean” pri-

mary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and should be supplied with a mini-

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

Step 1. The HI 4060 is configured with a universal power supply rated

from 110 to 240 VAC.

Step 2. Make sure the VAC power is shut off before installing the

wires to the connector.

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3-pin ter-

minal block connector.

nalog InputsDigital Inputs

Relay Outputs

nalog InputsDigital Inputs