Harger Ultraweld GD User manual

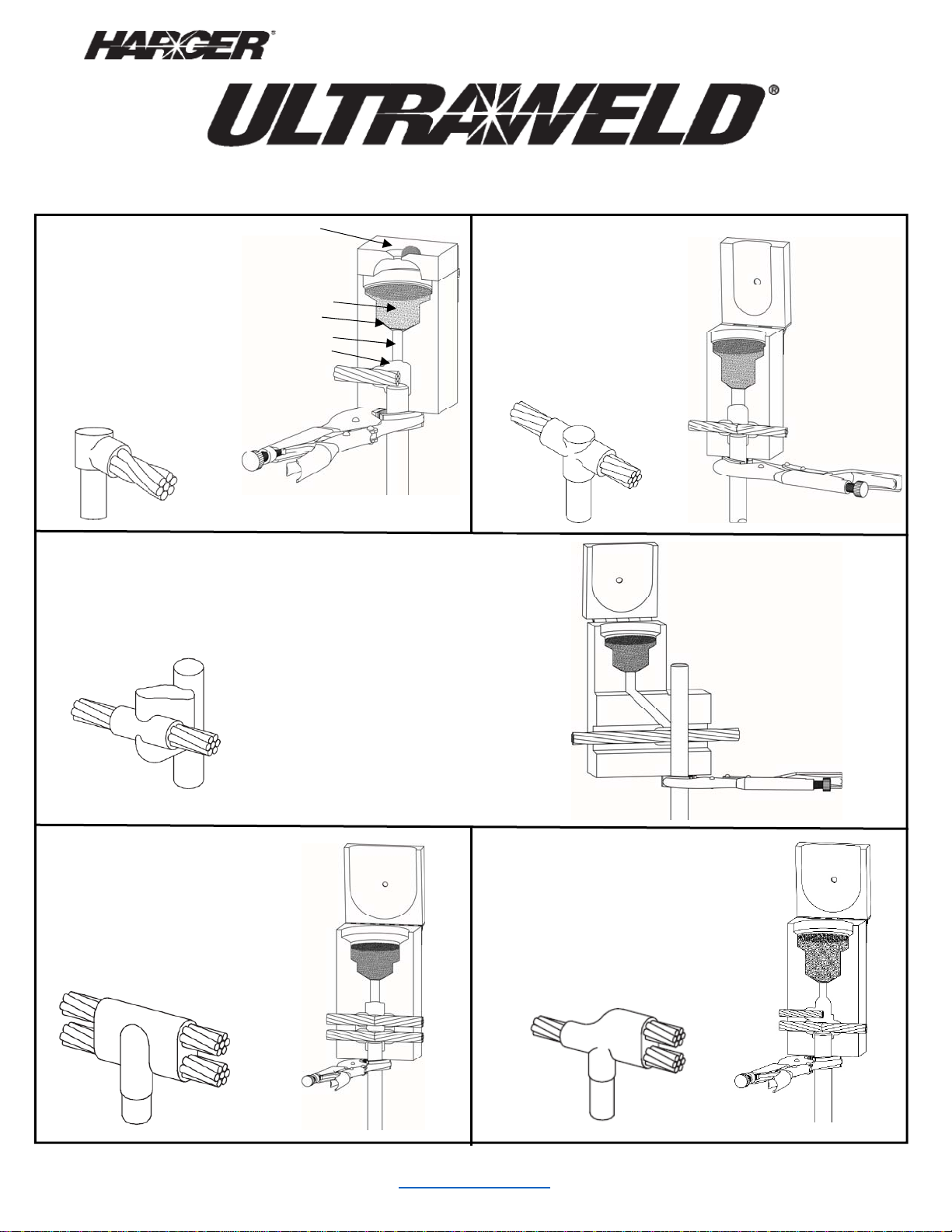

INSTRUCTIONS FOR ULTRAWELD® GROUNDING CONNECTIONS - CABLE TO GROUND ROD

GD

Place end of cable under

the center of the tap hole.

Cable must sit on top of

ground rod. Use locking

pliers or a clamp on the

rod below the mold to

prevent it from slipping

when the mold is fired.

StartingPowder

WeldPowder

SteelDisc

TapHole

WeldCavity

Cable

GroundRod

GO

Place cable in the mold.

Cable must sit on top of

ground rod. Use locking

pliers or a clamp on the rod

below the mold to prevent it

from slipping when the

mold is fired.

GS

Place cable into mold and secure mold to ground rod with handle clamp.

Support mold to keep it from sliding down the ground rod

when welding with locking pliers or clamp below mold.

GF

Place cables in mold. Bottom

run cable must sit on top of the

ground rod. Use a pair of

locking pliers or a clamp below

mold on ground rod to support

the mold and prevent slipping.

GT

Place end of tap cable under

center of tap hole. Run cable

must sit on top of the ground

rod. Use a pair of locking pliers

or a clamp below mold on

ground rod to support the mold

and prevent slipping.

Revised1/3/2014 Visitourwebsiteatwww.harger.com forfurthertipsandvideos.

GENERALSAFETYINSTRUCTIONS

1. Alwayswearproperclothing,safetyglassesandgloveswhen

exothermicwelding.

2. Onlywelditemsthatthemoldisdesignedfor.

3. Donotusewornorbrokenmoldswhichcouldcauseleakage

ofmoltenweldmetal.

4. Alwaysuseproperhandleclampsorframeworkrequiredfor

themoldandmakesureitisadjustedproperlytoclosethe

moldcompletely.

5. Makesurethattheconductorsbeingweldedfitinthemold

properlyandthatthemoldwillclosetightlyaroundthem.

6. Donotaltermoldsoraccessorieswithoutfactory

authorization.

7. Avoidbreathingconcentrationsofsmoke,asitmaybe

hazardoustoyourhealth.

8. Avoidcontactwithhotmaterials.

9. Removeorprotectfirehazardsintheweldingarea.

10. Avoidmoistureandcontaminantsinthemoldandconductors

beingwelded.Contactofmoltenweldmetalwithmoistureor

contaminantsmaycauseweldmetaltospewoutofmold.

11. Whenweldingtopipeorvessels,youshouldconsiderthe

following:

A. theeffectweldingmayhaveonstructuralmembersand

thinwallpipeorvessels.

B. pipeorvesselsthatarepressurizedorcontain(orhave

contained)flammable,explosiveorhazardousmaterials

shouldbeevaluatedinthecaseofameltthroughorhot

moltenweldmetalcomingincontactwithany

flammable,explosiveorhazardousmaterials.

12. Failuretoabidebytheaboveandfollowweldingprocedures

mayresultinimproperwelds,damagetothematerialbeing

weldedorcreatehazardoussituationsfortheindividual.

PREPARATIONOFCABLE

1. Cablemustbebright,cleananddry.

2. Cablethatissaturatedwithoilorgreasemustbecleaned.

Cablemaybecleanedbyburningitoffwithapropaneor

oxy‐acetylenetorch.Afterburningoffoilorgrease,awire

brushshouldbeusedtoremoveresidue.Wetcablemustbe

driedout.Useahandpropanetorch.

3. Corrodedcablemustbecleaned.UsetheCCBRSH2cable

cleaningbrushorCCBRSH1cardclothbrush.Itisimportant

thattheendsoftheindividualstrandsareclean.Thiscan

bestbeaccomplishedbymakingafreshcutontheendof

thecable.

4. Cableshouldbestraightenedbeforeclampingmoldinplace.

Bentoroutofroundcablewillholdmoldopenandcause

leaks.

5. Removeinsulationfrominsulatedcablebeforecuttingwith

hacksaw.Otherwise,endsofstrandswillbecomecoated

withinsulatingmaterialwhichmaycausedefectivewelds.

6. FLEXIBLECABLE:Asleevemustbeusedwhenwelding

flexiblecable.WRPSLVwrapsleevesarerecommendedfor

300MCMandsmallercable orcheckwithfactoryfor

premadesleeves.

PREPARATIONOFGROUNDRODSAND

GROUNDRECEPTACLES

1. Endsthatarethreaded,mushroomedfromdriving,or

drilledandtapped,mustbecutoffbeforeweldingtothe

end.Contactfactoryaboutgroundroddrivingsleeves.

2. Thesiteoftheweldonthegroundrodsandreceptacles

mustbeclean.Useacoarsefiletoremoverustandoxide

beforewelding

3. SlightlyUNDERSIZEDRODMAYBEBUILTUPWITHWRPSLV

WRAPSLEEVES.Thiswillnotworkforlargedifferencesin

size.

WELDINGPROCEDURE

1. Readallinstructionsandsafetywarningsbeforestarting.

2. Checkmoldtagforconductorstobeweldedandproper

weldmetalcartridgesizetouse.

3. Insertproperhandlesintothemoldandlockmoldshutif

applicable.

4. Makesureallsurfacesandconductorsareclean,dryand

arethepropersizesforthemold’sapplicationpermoldtag.

5. Moldscanbedriedbyheatingtoapproximately250°F.

Moldsmaybedriedwithahandoperatedpropanetorchor

byfiringachargeinthemoldbeforemakingthedesired

weld.

6. Positionconductor(s)intothemold.Seefrontofthissheet

forpositioningofconductorsintomold.Lockmoldwith

handleclampsorframe,whicheveristhecase.Checkto

makesuremoldiscompletelyclosed.

7. NuwTube:

A. Insertsteeldiskbeingsureitisdirectlycenteredover

thetaphole.Failuretoinsertdiskintomoldwillcreate

improperweldsandspewingofweldmetal.

B. Pourcartridgeorcartridgesintothecruciblebeing

carefulnottoupsetthesteeldisk.

C. RemoveOrangebottomlidinNuwTube toremove

startingpowder.Closelidandpourstartingpowder

intocupinthetopofthelid,allowingsometofallthru

theignitionholeinthelid.

D. Ignitestartingpowderwithflintgun.Pullflintgun

awayquicklytopreventfoulingflint.

8. UltraShot

A. InsertUltrashotcupintomoldcruciblealigningmetal

igniterwiththesmallgroveinthetopofthemold.

Closelid.

B. Insertmetaligniterintobatteryignitioncord.

C. Pressbothignitionbuttonsonbatterypackwhile

standingclearofexhaustportonmold.Moldshould

firerightaway.

9. Waitapproximately30secondsbeforeopeningmoldto

permitmetaltosolidify.

10. Tocleanthemold,useaMCBRSH1naturalbristlebrush,

softclothornewspaperbeforemakingnextweld.Do NOT

usewireorplasticbrushestocleanthemold!

11. Onhorizontallysplitmolds,useendofmoldcleaningspade,

asmalldiameterrod,orscrewdrivertoremoveslagfrom

taphole.Cautionshouldbeusedwhencleaningmoldsto

avoidburnsfromcontactwithhotmold.

NOTE:

1.Afouledflintgunmaybecleanedbysoakinginhouseholdammonia.

2.Properweldmetalcartridgesizeismarkedonmoldtagandshownonthecapofthecartridgetube.

3.Cartridgesizeistheapproximateweightofthepowderingrams.Whenthecartridgesizespecifiedisnotavailable,twoormore

smallercartridgesorpartofalargercartridgemaybeused.

4.HandleClampadjustmentsmaybemadebyremovingadjustingscrewandturningeyebolt180° clockwisetotightenor180° counter

clockwisetoloosen.

This manual suits for next models

4