Harken Industrial CMC CLUTCH Installation instructions

Inspection Procedure

CMC CLUTCH™ by Harken Industrial™

1

Purpose / Intent

This procedure outlines the relevant checks of a detailed inspection for Personal Protective Equipment (PPE).

The detailed inspection should be performed at least once every 12 months and after any exceptional event(s)

that may occur during use of the product.

The inspector should be a competent person and have read and understood all parts of the Inspection

Procedure, Periodic PPE Inspection Form and User Manual.

The inspector should also stay informed of any changes to inspection requirements, the product and any related

recalls, and this documentation.

Required Materials to Perform the Inspection

CLUTCH User Manual

CLUTCH Periodic PPE Inspection Form

CLUTCH Inspection Procedure (this document)

A new, unused CLUTCH for comparison

2m of rope within the acceptable parameters for the CLUTCH (see inside of Moving Side Plate or CLUTCH User

Manual)

Documentation of product history from the user

Product History

The user should provide information regarding the lifecycle of the device. Of special importance are:

Date of purchase.

Date of first use.

Usage conditions and amount of use.

Reports on any exceptional event that the device may have experienced. Exceptional events include the

following:

oDynamic events such as falls or fall arrest

oOverloading or improper use cases

oImproper storage, cleaning or transport

oModifications made by parties other than the manufacturer

oOther exceptional events

Any PPE exhibiting unexpected wear or degradation must be quarantined and undergo a detailed inspection.

Inspection Procedure

CMC CLUTCH™ by Harken Industrial™

2

1. Visual Inspection

Ensure the presence and legibility of the device markings.

Ensure that the product number is located and is legible on the backside of the Chassis in the area covered

by the Control Handle when it is in the Stop position.

Ensure that the CE certification mark is located and is legible on the inside surface of the Moving Side Plate.

Visually compare the device with a new device and check to make sure that there are no missing or modified

parts.

Carefully inspect the entire device for signs of damage such as dents, deep scratches, cracks, yielding or

excessive wear. Check for any sharp edges, especially in the areas of the rope path. Take extra care to

inspect attachment points such as the Attachment Eye and the Becket for signs of damage or deformation.

Inspect the Sheave, Tension Rope Guide, and Friction Shoe for wear. The Tension Rope Guide and Friction

Shoe are shown in blue and the Sheave wear indicators (3) are shown in orange in the images below.

Inspection Procedure

CMC CLUTCH™ by Harken Industrial™

3

If the wear indicators have been worn away, the unit must be retired.

2. Functional Checks

2.1 Sheave Movement

Open the device and perform the following checks on the Sheave:

Ensure that the Sheave is able to rotate anti-clockwise and emits an audible clicking sound.

Check that the Sheave is not able to rotate clockwise.

Check that the Sheave is firmly attached to the Sheave Swing Arm without excessive axial movement,

i.e. >2mm.

2.2 Sheave Swing Arm Movement

With the device open, start with the Control Handle in the Stop position. Press the Sheave into the pinch

area and check that the Sheave is able to swing into the Chassis and make contact with the stainless

steel Friction Shoe.

Release the Sheave and move the Control Handle to the Stand By position while observing the position

of the Sheave and Sheave Swing Arm. The Sheave and Sheave Swing Arm should move to the left,

rotating anticlockwise until the rope-path laser etching becomes visible on the inner surface of the

Chassis.

With the Control Handle in the Stand By position, press on the Sheave and check that the Sheave is able

to swing into the Chassis and make contact with the stainless steel Friction Shoe.

Check that the Sheave Swing Arm is firmly attached to the Chassis and inspect the rivet on both sides for

damages.

Inspection Procedure

CMC CLUTCH™ by Harken Industrial™

4

2.3 Control Handle Movement

With the device closed, rotate the Control Handle through its range of motion from Stop to Anti-panic,

ensuring there is no excessive drag.

Rotate the Control Handle to the Stand By position and feel for a well-defined holding force at Stand By.

Rotate the device back and forth in this configuration and check that the Control Handle stays in the

Stand By position.

Hold the device in the left hand with the Moving Side Plate facing the palm. Use your fingers to press

the Sheave into the Chassis. While holding the Sheave into the Chassis, use your right hand to rotate the

Control Handle from Stand By to Release (Range) position. Continue to rotate the Control Handle

through the Release (Range) position and check that this action drives the Sheave away from the

Chassis, i.e. overcomes the pressure applied with the left hand.

Continue to rotate the Control Handle beyond the Release (Range) position while maintaining pressure

on the Sheave with the left hand until the Anti-panic position is reached. Check that the Sheave releases

and is once again able to be pressed into the Chassis.

Inspect the rivet in the center of the Control Handle for damage.

Ensure that the Control Handle is firmly attached to the Chassis and has minimal clearance with the

Chassis.

2.4 Side Plate Release Latch and Moving Side Plate Movement and Function

2.5 Check the Side Plate Release Latch for functionality by actuating it two times to open the Moving Side Plate.

Inspect the rivet of the Side Plate Release Latch for damages. Ensure that the Side Plate Release Latch is

firmly attached to the Moving Side Plate.

Check the (2) latch pins in the Chassis. Check that they are flush with the surface of the Chassis and

ensure they are not excessively worn in the area of engagement with the Side Plate Release Latch.

Close the Moving Side Plate by pushing it into the closed position. The Side Plate Release Latch should

make two successive clicks and securely lock the Moving Side Plate.

Re-open the Moving Side Plate and close it again, making sure that it is accurately guided into the

correct position.

Inspection Procedure

CMC CLUTCH™ by Harken Industrial™

5

2.6 Function Check

Install a rope within the acceptable size range into the device as indicated on the inside of the Moving

Side Plate or in the CLUTCH User Manual.

1. Move the Control Handle to the Stand By position and give a quick pull on the Tension Side

(Load/Anchor) of the rope. Check that the CLUTCH locks up and prevents the rope from exiting the

device.

2. Gradually apply a load to the device (rope taut, Control Handle in the Stand By position). Gradually move

the Control Handle to the Release (Range) position to allow rope through the device. Check that it is

possible to move rope through the device.

3. While maintaining load on the device, release the Control Handle and check that the device locks up and

holds the rope.

4. While maintaining load on the device, quickly pull the Control Handle through the Release (Range)

position and into the Anti-panic position. Check that the device locks up and prevents any more rope

from releasing.

Inspection Procedure

CMC CLUTCH™ by Harken Industrial™

6

5. Pull rope through the device as if using it to haul. Check that the Sheave turns and emits an audible

clicking sound.

Disposition

Use the criteria outlined in the inspection checklist to properly disposition the device. If one or more inspection points

are marked as Monitor, then the device should be dispositioned as Monitor. If one or more inspection points are marked

as Fail, then the device should be dispositioned as Fail.

Disposition States:

Pass –Continue to use, next required periodic check in 12 months.

Monitor –Use with caution, next required periodic check in <12 months (document date on Periodic PPE Inspection

Form).

Fail –Do not use, render device useless before disposal to prevent further use.

CMC Rescue, Inc.

6740 Cortona Drive

Goleta, CA 93117, USA

805-562-9120 / 800-235-5741

cmcpro.com

ISO 9001 Certified

©2019 CMC Rescue, In. All rights reserved.

CMC and are registered marks of CMC Rescue, Inc.

Control No. PPE - 335011.00.10232019

1

2

3

4

5

Other manuals for CMC CLUTCH

3

Table of contents

Popular Security Sensor manuals by other brands

Honeywell

Honeywell Notifier FSP-951AUS Installation and maintenance instructions

Simon

Simon XTi quick guide

Winland Electronics

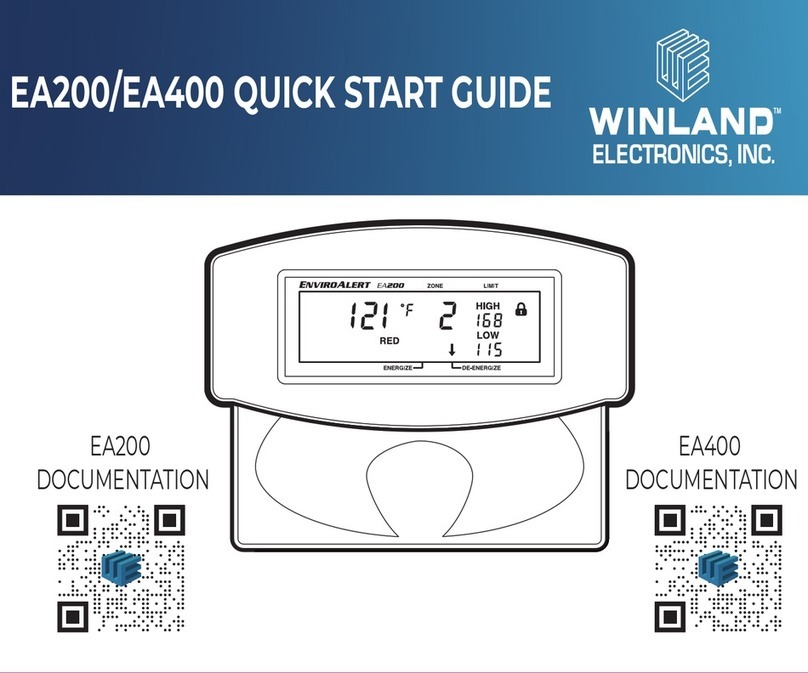

Winland Electronics ENVIROALERT EA200 quick start guide

System Sensor

System Sensor B116LP Installation and maintenance instructions

Feig Electronic

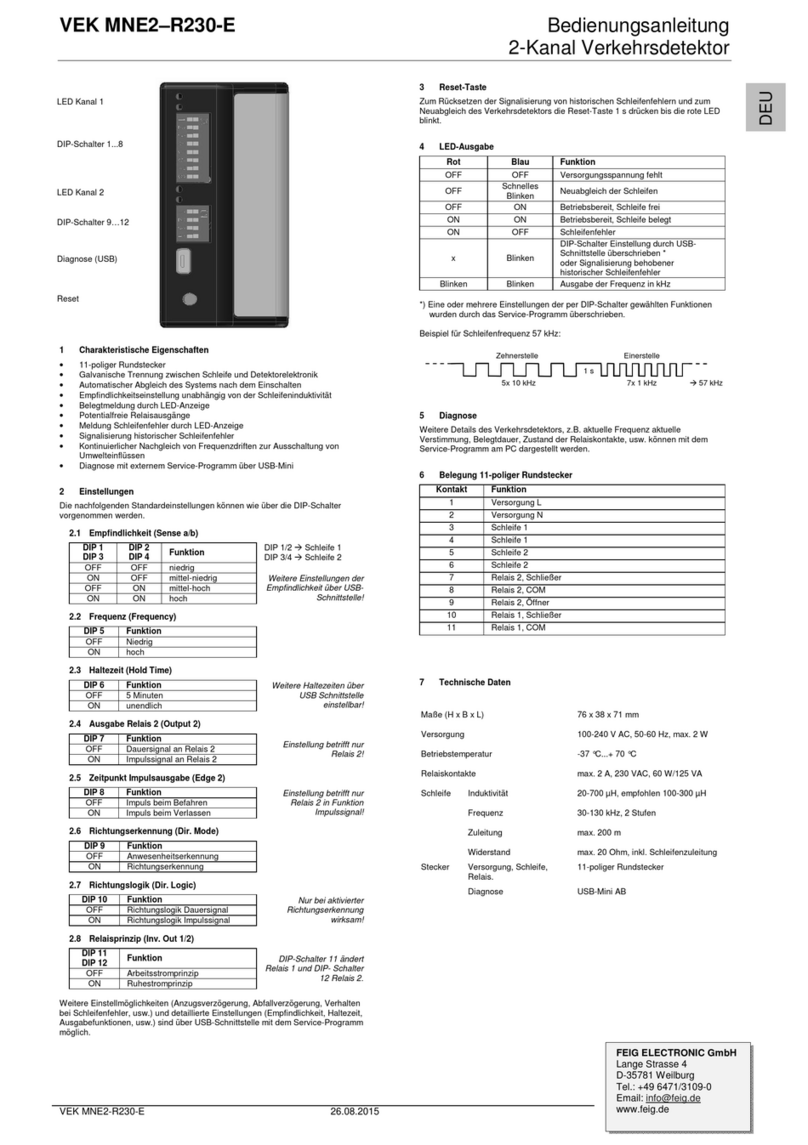

Feig Electronic VEK MNE2-R230-E operating instructions

STEINEL PROFESSIONAL

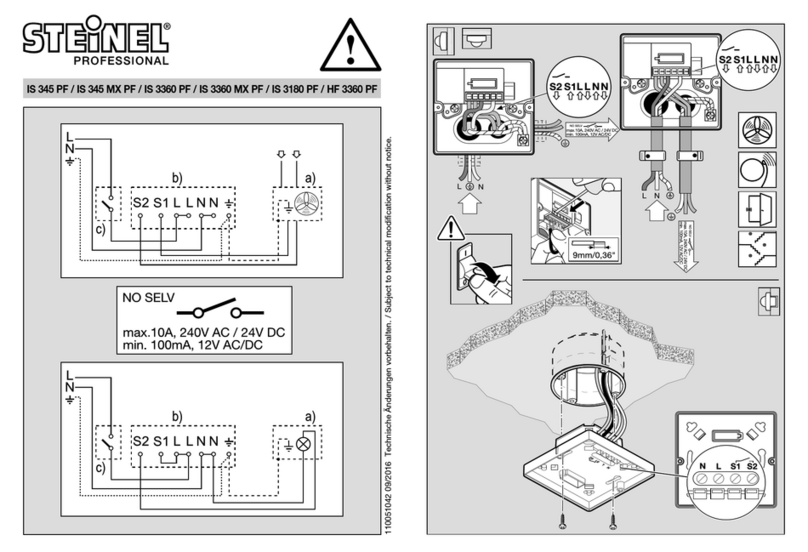

STEINEL PROFESSIONAL IS 345 MX PF manual