Harmonic Drive KDU Series User manual

Direct Drive Motor

KDU Series Manual

ISO14001

ISO9001

Introduction

Introduction

Thank you very much for purchasing our KDU Series Direct Drive Motor.

Wrong handling or use of this product may result in unexpected accidents or shorter life of the product.

Read this manual carefully and use the product correctly so that the product can be used safely for

many years.

Product specifications are subject to change without notice for improvement purposes.

Keep this manual in a convenient location and refer to it whenever necessary in operating or

maintaining the units.

The end user of the motor should have a copy of this manual.

SAFETY GUIDE

1

SAFETY GUIDE

To use this product safely and correctly, be sure to read the SAFETY GUIDE and other parts of this

document carefully and fully understand the information provided herein before using the driver.

Notation

Important safety information you must note is provided herein. Be sure to observe these instructions.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious personal injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate personal injury and/or damage to the equipment.

Indicates what should be performed or avoided to prevent non-operation or

malfunction of the product or negative effects on its performance or function.

LIMITATION OF APPLICATIONS

The equipment listed in this document may not be used for the applications listed below:

・Space equipment

・Aircraft, aeronautic equipment

・Nuclear equipment

・Household apparatus

・Vacuum equipment

・Automobile, automotive parts

・Amusement equipment, sport equipment, game machines

・Machine or devices acting directly on the human body

・Instruments or devices to transport or carry people

・Apparatus or devices used in special environments

If the above list includes your intending application for our products, please consult us.

If this product is utilized in any facility in which human life is

at stake or that may incur material losses, install safety

devices so that accidents will not occur even when the

output control is disabled due to damage.

WARNING

CAUTION

CAUTION

SAFETY GUIDE

2

SAFETY NOTE

ITEMS YOU SHOULD NOTE WHEN USING THE MOTOR

NOTICES ON DESIGN

Always use them under the followings conditions:

The motor is designed to be used indoors. Observe the following conditions:

・Ambient temperature: 10 to 30℃

・Ambient humidity: 20 to 80%RH (No condensation)

・Under the environment with no vibration or physical shock

・No contamination by water, oil

・No corrosive or explosive gas

Follow exactly the instructions in the relating manuals to

install the motor in the equipment.

・Ensure exact alignment of the motor shaft center and corresponding center

as per the manual.

・Failure to observe this caution may lead to vibration, resulting in damage of

output shafts.

OPERATIONAL PRECAUTIONS

Never connect cables directly to a power supply socket.

・Each motor must be operated with a proper driver.

・Do not directly apply a commercial power supply. Failure to observe this

caution may lead to fire or damage to the motor.

Do not apply impacts and shocks.

・Because the motor is directly connected to the encoder with high accuracy,

do not apply any impact on it.

・Failure to observe this caution could damage the encoder and may cause

uncontrollable operation.

Avoid handling of motor by cables.

・Rough handling of cables may damage connectors, leading to uncontrolled

operation of the motor.

Keep limited torques of the motor.

・Keep limited torques of the motor.

・When installing a load on the output shaft, keep the weight well balanced.

CAUTION

SAFETY GUIDE

3

ITEMS YOU SHOULD NOTE WHEN USING THE DRIVER

NOTICES ON DESIGN

Always use them under followings conditions:

The driver generates heat. Take extra caution for radiation and use it under the

following conditions.

・Mount in a vertical position keeping sufficient distance to other devices to

let heat generated by the driver radiate freely.

・0 to 50℃, 95% RH or below (No condensation)

・No vibration or physical shock

・No corrosive, inflammable or explosive gas

Use sufficient noise suppressing means and safe grounding.

Any noise generated on a signal wire will cause vibration or improper motion.

Be sure to observe the following conditions.

・Keep signal and power leads separated.

・Keep leads as short as possible.

・Ground motor and driver at one single point, minimum ground resistance

class: D (less than 100 ohms)

・Do not use a power line filter in the motor circuit.

Pay attention to negative torque by inverse load.

・Inverse load may cause damages to the drivers.

・Please consult our sales office, if you intend to make a voltage resistance

test.

Use a fast-response type ground-fault detector designed for

PWM inverters.

When using a fast-response type ground-fault detector, use one that is

designed for PWM inverters. Do not use a time-delay-type ground-fault

detector.

If this product is utilized in any facility in which human life is

at stake or that may incur material losses, install safety

devices so that accidents will not occur even when the

output control is disabled due to damage.

OPERATIONAL PRECAUTIONS

Never change wiring while the power is active.

Make sure that power is non-active before servicing the products. Failure to

observe this caution may result in electric shock or uncontrollable operation.

Do not touch terminals or inspect products at least 15

minutes after turning OFF power.

・Even after the power supply is turned OFF, electric charge remains in the

driver. In order to prevent electric shock, perform inspections 15 minutes

after the power supply is turned OFF.

・Make installation of products not easy to touch their inner electric

components.

CAUTION

WARNING

SAFETY GUIDE

4

Do not make a voltage resistance test.

・Do not perform a megger test or voltage resistance test. Failure to observe

this caution may result in damage to the control circuit of the driver.

・Please consult our sales office, if you intent to make a voltage resistance

test.

Do not operate control units by means of power ON/OFF

switching.

・Frequent power ON/OFF operations may cause deterioration of circuit

elements inside the driver.

・Start/stop operation should be performed via input signals.

DISPOSAL

All products or parts have to be disposed of as industrial

waste.

Since the case or the box of drivers have a material indication, classify parts

and dispose of them separately.

CAUTION

CAUTION

Structure of this document

5

Structure of this document

Chapter 1

Overviews

This chapter explains overviews of motor models, specifications,

external dimensions, etc.

Chapter 2

Installation

This chapter explains how to install the motor.

Chapter 3

Option

This chapter explains options.

Appendix

This chapter explains unit conversion and method of calculating inertia

moment.

6

Contents

SAFETY GUIDE ................................................................................................... 1

Notation..................................................................................................................1

LIMITATION OF APPLICATIONS............................................................................1

SAFETY NOTE ......................................................................................................2

Structure of this document...................................................................................... 5

Contents ................................................................................................... 6

Chapter 1

1-1 Overviews ................................................................................................... 1

Main features..........................................................................................................1

1-2 Model ................................................................................................... 2

1-3 Combination with driver ................................................................................ 3

1-4 Specifications................................................................................................ 4

1-5 External dimensions...................................................................................... 6

1-6 External drawing ........................................................................................... 8

1-7 Absolute positional accuracy ........................................................................ 9

1-8 Repeatability ............................................................................................... 10

1-9 Moment stiffness......................................................................................... 11

1-10 Axial load and moment load...................................................................... 12

1-11 Rotation direction ...................................................................................... 13

1-12 Resistance to vibration and impact ........................................................... 14

1-13 Allowable load inertia moment .................................................................. 15

1-14 Operable range ......................................................................................... 16

1-15 Cable specifications .................................................................................. 17

Chapter 2

2-1 Receiving inspection..................................................................................... 1

2-2 Notices on handling ...................................................................................... 2

2-3 Installation location and installation............................................................... 3

Contents

7

Environmental conditions of installation location.....................................................3

Installation ..............................................................................................................5

Chapter 3

3-1 Extension cable............................................................................................. 1

3-2 Communication cable ................................................................................... 2

3-3 Standard combination ................................................................................... 3

Appendix

Appendix-1 Unit conversion.......................................................................... 1

Appendix-2 Inertia moment calculation......................................................... 3

1. Formula of mass and inertia moment...............................................................3

2.Inertia moment of cylinder.................................................................................6

Contents

8

Memo

Chapter 1

Overviews

Overviews of motor models, specifications, external dimensions, etc., are explained in

this chapter.

1-1 Overviews···········································································1

1-2 Model ················································································2

1-3 Combination with driver ·························································3

1-4 Specifications ······································································4

1-5 External dimensions······························································6

1-6 External drawing ··································································8

1-7 Absolute positional accuracy ···················································9

1-8 Repeatability ····································································· 10

1-9 Moment stiffness ································································ 11

1-10 Axial load and moment load ·················································· 12

1-11 Rotation direction ······························································· 13

1-12 Resistance to vibration and impact ········································· 14

1-13 Allowable load inertia moment ··············································· 15

1-14 Operable range ·································································· 16

1-15 Cable specifications ···························································· 17

1-1 Overviews

1

Overviews

付

11

10

9

8

7

6

5

4

1

1-1 Overviews

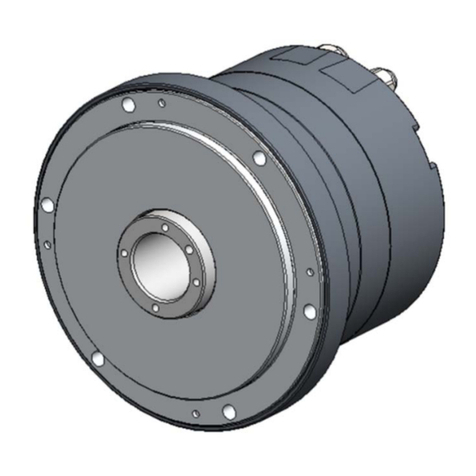

KDU Series Direct Drive Motor offers high precision positioning with super high resolution.

The KDU Series dedicated HA-770 driver is a servo drive units that can control position by command

communication command and pulse command.The small, multi-functional drivers control the

operations of KDU Series motors with great accuracy and precision.

The KDU Series plays an important role in ultra-precision measuring devices, driving ultra-precision

positioning mechanisms for semi-conductor and semi-conductor LCD devices, and various other

factory automation equipment.

Main features

Super high resolution

It achieves ultra-high resolution of 11,840,000 pulse/rev. This makes possible smooth indexing

operations and precise indexing positioning for ultra-high accuracy measuring devices, ultra-precise

semiconductor manufacturing devices, etc.

High positional accuracy

Achieves absolute positional accuracy of 10 s (with position correction control) and highly accurate

repeatability of ±0.5 s.

Large hollow diameter

It has a large hollow structure that has a diameter of 50. A through-hole is provided in the motor,

through which energy can be supplied to drive sections of machines and devices and through which

signals can be exchanged.

Unique motor structure

The unique motor structure (patent received) achieves superior torque/weight ratios. This delivers

more compact and lighter devices.

Mechanical accuracy

The high stiffness, high accuracy cross roller bearing configuration achieves an output shaft surface

runout accuracy of 2 µm.

1-2 Model

2

付

11

10

9

8

7

6

5

4

3

2

1

Overviews

付

11

10

1-2 Model

The KDU Series Direct Drive Motor functions in combination with the HA-770 AC Servo Driver.

The model names for the system and how to read the symbols are explained below.

Model names for the KDU Series Direct Drive Motors and how to read the symbols are explained

below.

KDU-13S B-E 10-□

Model: KDU Series Direct Drive Motor

Model No.: 13S, 13W

Encoder resolution

10: 11,840,000 p/rev

Version symbol

Encoder type

E: Incremental encoder

Specification symbol

No symbol :

Standard specification

product

SP :Special specification product

KDU-13SB-D3-100-□

Motor model: KDU Series Direct Drive Motor

KDU-13SB :KDU-13SB-E10

KDU-13WB :KDU-13WB-E10

System designation

Combined with the HA-770-2 AC Servo Driver

Specification symbol

No symbol :

Standard specification

product

Input voltage

100: 100V AC

200: 200V AC

1-3 Combination with driver

3

Overviews

付

11

10

9

8

7

6

5

4

1

1-3 Combination with driver

Model names for motors and systems combined with a HA-770 driver are shown below.

Input voltage

System model name

Motor model name

Driver model name

100V KDU-13SB-D3-100 KDU-13SB-E10

HA-770-2

KDU-13WB-D3-100 KDU-13WB-E10

200V KDU-13SB-D3-200 KDU-13SB-E10

KDU-13WB-D3-200 KDU-13WB-E10

.

Use the KDU Series motor combined with a driver as a set.

The KDU Series motor's absolute positional accuracy of 10 seconds is

based on correction data from the driver memory. If you use a motor

and driver combination that is not shown, the absolute positional

accuracy cannot be guaranteed.

CAUTION

1-4 Specifications

4

付

11

10

9

8

7

6

5

4

3

2

1

Overviews

付

11

10

1-4 Specifications

Below is the specifications of the KDU Series motors.

Model

Item

KDU

-13SB

-13WB

Max. torque Note 2

Nm

7.0

15.0

kgfm

0.7

1.5

Max. rotational speed

r/min

127

127

Torque constant

N m/A 3.1 6.5

kgfm/A 0.32 0.66

Input power supply

V

AC100/AC200

EMF constant

V/(r/min) 0.33 0.68

Line resistance

Ω(20℃)9.1 14.0

Line inductance

mH 19 35

Inertia

moment

(GD

2

/4) kgm

2

0.0047 0.0065

(J) kgfcms

2

0.048 0.066

Moment stiffness

Nm/rad

2.4

×

105

kgfm/rad

0.2

×

104

Motor position detector

pulse/rev

Incremental encoder

Square wave of Phases A and B:11,840,000

Pulse signal of Phase Z

Repeatability: Note 3

arc sec

±

0.5

Absolute positional accuracy:

Note 3 arc sec 10 (angular position correction): Note 4

Mass

kg

4.0

5.0

Protection structure

Totally enclosed self-cooled type (equivalent to IP40)

Environmental conditions

Service temperature: 10 to 30℃/Storage temperature: -10 to

60

℃ (Note 3)

Service/storage humidity: 20 to 80%RH (no condensation)

Resistance to vibration while transporting or mounting the

motor: 25 m/s2 (frequency: 10 to 400Hz)

Resistance to impact while transporting or mounting the

motor: 300 m/s2

No dust, metal powder, corrosive gas, inflammable gas, or oil

mist.

To be used indoors, no direct sunlight.

Altitude: less than1,000 m above sea level

Motor insulation

Insulation resistance: 100MΩ or more (by DC500V insulation

tester)

Dielectric strength: AC1,500V/1 min

Insulation class: B

Mounting direction

Output shaft facing up

Note 1: The table above shows the values for the output shaft.

Note 2: The values in the table are obtained when connected to the HA-770 Servo Driver

Note 3: The values for repeatability and absolute positional accuracy are measured with the mounting direction of

the output shaft facing up, and in an environment at a temperature of 23±0.3℃, with 50%humidity. Refer to

the "Notices for maintaining accuracy" on the next page when you use the motor.

Note 4: These values are after the angular position of the servo driver is corrected.

In order to enable angular position correction, it is always necessary to execute the originating operation by

the servo driver.

1-4 Specifications

5

Overviews

付

11

10

9

8

7

6

5

4

1

Notices for maintaining accuracy

To maintain accuracy, observe the following notices when using the motor.

Use the product in an appropriate environment.

The environmental conditions for our accuracy measurement are a temperature of

23±0.3℃and relative humidity of 50%.When using the motor in a device that

requires high accuracy positioning control, please take into account the stiffness of the

mechanism for temperature change of up to ±3˚C, the coefficient of expansion for

each part, external vibration, etc.

Periodically rotate the output shaft at least 90˚.

In order to prevent uneven wear due to the cross roller bearing grease running out, for

devices used in operation environments with fine operations, periodically rotate the

output shaft at least 90˚ in order to maintain accuracy.

Mounting direction check

The mounting condition for our accuracy measurement is to have the output shaft

facing up.

When using the motor with the output shaft not facing up, contact us for more

information.

Accuracy cannot be guaranteed in environments subject to vibration

and impact.

The resistance to vibration and impact in the specifications table are standard values

for the vibration and impact that occur while transporting or mounting the motor. While

transporting or mounting the motor, do not subject the motor to any vibration or impact.

In order to use the motor with high accuracy, use it in an environment with no impact

or vibration.

1-5 External dimensions

6

付

11

10

9

8

7

6

5

4

3

2

1

Overviews

付

11

10

1-5 External dimensions

The external dimensions of the KDU Series are shown below.

KDU-13SB-E10

KDU-13WB-E10

Unit: mm (third angle)

Unit: mm (third angle projection)

Encoder

Interpolator

Interpolator

Motor connector

Hole for fixing the

stopper part

6-⌀5.5

Encoder

Interpolator

Interpolator

Motor connector

Tap for fixing the

rotating part

6-M5X8

Rotating part

Fixed part

Hollowshaft

diameter

Hollow shaft

diameter

Fixed part

Rotating part

Hole for fixing

the stopper part

6-⌀5.5

Tap for fixing the

rotating part

6-M5X8

1-5 External dimensions

7

Overviews

付

11

10

9

8

7

6

5

4

1

Encoder

Interpolator

Unit: mm (third angle projection)

1-6 External drawing

8

付

11

10

9

8

7

6

5

4

3

2

1

Overviews

付

11

10

1-6 External drawing

The mechanical accuracies of the output shaft and mounting flange are shown below for the KDU

Series motor:

unit: mm

Accuracy items

KDU-13

1. Output shaft surface runout

0.002

2. Deflection of output shaft

0.040

3. Parallelism b

etween the output shaft

end mounted surface

0.040

Note: All values are T.I.R. (Total Indicator Reading).

The measuring for the values are as follows:

(1) Output shaft surface runout

The dial gauge on the fixed part measures the axial

runout (maximum runout width) of the outermost

periphery of output shaft of the output rotary unit per

revolution.

(2) Output shaft surface runout

The dial gauge on the fixed part measures the radial

runout (maximum runout width) of output shaft of the

output rotary unit per revolution.

Reducing deflection of the output shaft

The specified deflection of output shaft value of 0.040 mm is due to the assembly error of the KDU

parts.

The method for reducing deflection of the output shaft is shown below.

1 When producing the mounted load (disk) at your

company, produce it with circularity of 1 µm or less.

2 Temporarily mount the load on the KDU output shaft.

3 Set the dial gauge on the side of the mounted load as

in (2).

4 While rotating the motor at low speed, adjust the

deflection of the mounted load to lower the reading

on the dial gauge.

5 After adjusting the deflection, tighten further to secure

the mounted load.

The operations above can secure shaft deflection accuracy of 4 µm or less.

(3) Parallelism between the output shaft and mounted surface

The dial gauge installed on the output rotary unit measures the axial runout (maximum runout width) of

the outermost periphery of the mounting surface (both on the output shaft side and opposite side) of

the output rotary unit per revolution.

2

A

B

1

3

B

2

A

B

1

3

B

2

A

B

1

3

B

2

A

B

1

3

B

(1)

(2)

(3)

1-7 Absolute positional accuracy

9

Overviews

付

11

10

9

8

7

6

5

4

1

1-7 Absolute positional accuracy

"Absolute positional accuracy"

The accuracy is measured with measurement comparing with a reference encoder. Rotating one

revolution with the Z signal as the datum point, the difference between the actual measured value at

each positioning point (the position actually moved to from the datum point) and the reference encoder

is found, and the value of (maximum – minimum) is shown as the absolute positional accuracy.

[Reference encoder]

Resolution: 57,600,000 pulse/rev

Absolute positional accuracy: 0.26 arc sec

"Absolute position compensation function"

The uni-directional positional accuracy means the maximum positional difference between the actual

rotated angle from the datum position and its theoretical rotational angle in one revolution when series

of positioning are performed in the same rotation direction.

The "absolute positional accuracy" is shown in the table below:

Model

Item

KDU-13

Absolute positional accuracy

(w/position correction function)

arc sec 10

Actual stop

position

Theoretical

position

Max. positioning

error

360°

0°

Z

This manual suits for next models

2

Table of contents

Other Harmonic Drive Engine manuals

Popular Engine manuals by other brands

Ironton

Ironton 190F owner's manual

Malaguti

Malaguti KYMCO 125 - KY - MA 12 manual

Vascat

Vascat MAC R Series Instruction and maintenance manual

Siemens

Siemens SIMOTICS FD 1LP1 operating instructions

Volvo

Volvo DH10A 245 Service manual

MOOG ANIMATICS

MOOG ANIMATICS SMARTMOTOR COMBITRONIC Installation and startup