Harmonic Drive HA-680 Series User manual

AC Servo Driver for

24 VDC Power Supply

HA-680 Series Manual

(

For FHA-8C, 11C, 14C/RSF-3C,5B/8B,11B, and 14B

)

●Thank you very much for your purchasing our HA-680 series AC

servo driver for 24 VDC power supply.

●Parameter setting for this servo driver requires dedicated

communication software PSF-520.

(The dedicated communication software can be downloaded from our website at

http://www.hds.co.jp/.)

●Be sure to use sufficient safety measures when installing and

operating the equipment so as to prevent an accident resulting in

a serious physical injury damaged by a malfunction or improper

operation.

●Product specifications are subject to change without notice for

improvement purposes.

●Keep this manual in a convenient location and refer to it

whenever necessary in operating or maintaining the units.

●The end user of the driver should have a copy of this manual.

SOFTWARE Ver.1.0

ISO14001

ISO9001

SAFETY GUIDE

For FHA series, RSF series, HA series

manufactured by Harmonic Drive Systems, Inc

Read this manual thoroughly before designing the application, installation, maintenance or inspection of the actuator.

Indicates a potentially hazardous situation,

which, if not avoided, could result in death

or serious personal injury.

Indicates a potentially hazardous situation, which, if

not avoided, may result in minor or moderate personal

injury and/or damage to the equipment.

LIMITATION OF APPLICATIONS:

The equipment listed in this document may not be used for the applications listed below:

Space equipment

Automobile, automotive parts

Aircraft, aeronautic equipment

Amusement equipment, sport equipment, game machines

Nuclear equipment

Machine or devices acting directly on the human body

Household apparatus

Instruments or devices to transport or carry people

Vacuum equipment

Apparatus or devices used in special environments

If the above list includes your intending application for our products, please consult us.

Safety measures are essential to prevent accidents resulting in death, injury or damage of the equipment due to

malfunction or faulty operation.

CAUTIONS FOR ACTUATORS AT APPLICATION DESIGNING

Always use under followings conditions:

-Ambient temperature: 0°C to 40°C

-Ambient humidity: 20% to 80%RH (Non-condensation)

-Vibration: Max 24.5 m/S2

-No contamination by water, oil

-No corrosive or explosive gas

Follow exactly the instructions in the relating

manuals to install the actuator in the equipment.

-Ensure exact alignment of motor shaft center and

corresponding center in the application.

Failure to observe this caution may lead to vibration,

resulting in damage of output elements.

CAUTION FOR ACTUATORS IN OPERATIONS

Keep limited torques of the actuator.

-Keep limited torques of the actuator.

-Be aware, that if arms attached to output element hits

by accident an solid, the output element may be

uncontrollable.

Never connect cables directly to a power supply

socket.

-Each actuator must be operated with a proper driver.

-Failure to observe this caution may lead to injury, fire or

damage of the actuator.

Do not apply impacts and shocks

-Do not use a hammer during installation

-Failure to observe this caution could damage the

encoder and may cause uncontrollable operation.

Avoid handling of actuators by cables.

-Failure to observe this caution may damage the wiring,

causing uncontrollable or faulty operation.

CAUTIONS FOR DRIVERS AT APPLICATION DESIGNING

Always use drivers under followings conditions:

-Mount in a vertical position keeping sufficient distance

to other devices to let heat generated by the driver

radiate freely.

-Ambient temperature: 0°C to 50°C

-

Ambient humidity: less than 95% RH (Non

condensation)

-No vibration or physical shock

-No contamination by water, oil or foreign matters

-No corrosive, inflammable or explosive gas

Use sufficient noise suppressing means and safe

grounding.

-Keep signal and power leads separated.

-Keep leads as short as possible.

-Ground actuator and driver at one single point, minimum

ground resistance class: D (less than 100 ohms)

-Do not use a power line filter in the motor circuit.

Pay attention to negative torque by inverse load.

–Inverse load may cause damages of drivers.

-Please consult our sales office, if you intent to apply

products for inverse load.

Use a fast-response type ground-fault detector

designed for PWM inverters.

-Do not use a time-delay-type ground-fault detector.

CAUTION FOR DRIVERS IN OPERATIONS

Never change wiring while power is active.

-Make sure of power non-active before servicing the

products.

-Failure to observe this caution may result in electric

shock or personal injury.

Do not touch terminals or inspect products at least

5 minutes after turning OFF power.

-Otherwise residual electric charges may result in electric

shock.

-Make installation of products not easy to touch their inner

electric components.

Do not make a voltage resistance test.

-Failure to observe this caution may result in damage of

the control unit.

-Please consult our sales office, if you intent to make a

voltage resistance test.

Do not operate control units by means of power

ON/OFF switching.

-

Start/stop operation should be performed via input

signals.

Failure to observe this caution may result in deterioration

of electronic parts.

DISPOSAL OF AN ACTUATOR, A MOTOR, A CONTROL UNIT AND/OR THEIR PARTS

All products or parts have to be disposed of as industrial waste.

-Since the case or the box of drivers have a material indication, classify parts and dispose them separately.

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

SYSTEMS

®

HA-680 series servo driver manual

- Contents 1 -

Contents

Chapter 1 Outlines of HA-680 driver ................................................................... 1

1-1 Main features...............................................................................................................1

1-2 Model of HA-680 driver ............................................................................................... 2

1-3 Combinations with actuators ....................................................................................... 2

1-4 Specifications of HA-680 drivers ................................................................................. 3

1-5 External drawing of the HA-680 drivers ...................................................................... 4

1-6 Names and functions of parts...................................................................................... 5

1-7 Outlines of I/O ports..................................................................................................... 7

1-7-1 TB2: Power supply connection terminal...................................................................... 7

1-7-2 TB1: Actuator connection terminal .............................................................................. 7

1-7-3 CN1: Encoder connector ............................................................................................. 7

1-7-4 CN3: Serial port connector .......................................................................................... 8

1-7-5 CN4: CAN connector................................................................................................... 8

1-8 CN2: Overview of I/O signal ........................................................................................ 9

1-9 LED display ................................................................................................................11

1-10 Outline of protective functions ....................................................................................11

1-11 Protective functions ................................................................................................... 12

Chapter 2 I/O ports ............................................................................................. 15

2-1 Assignment of I/O signals.......................................................................................... 15

2-1-1 Assignment of input signals....................................................................................... 15

2-1-2 Assignment of output signals .................................................................................... 16

2-1-3 Type of I/O signal connector CN2 ............................................................................. 16

2-2 Position control .......................................................................................................... 17

2-2-1 I/O port layout ............................................................................................................ 17

2-2-2 I/O port connections in the position control ............................................................... 18

2-2-3 I/O port functions in the position control .................................................................... 19

2-2-4 Connection examples in the position control............................................................. 27

2-3 Speed control............................................................................................................. 33

2-3-1 Pin numbers and names of I/O signals ..................................................................... 33

2-3-2 I/O port connections in the speed control.................................................................. 34

2-3-3 I/O port functions in the speed control....................................................................... 35

2-3-4 Connection examples in the speed control ............................................................... 43

2-4 Torque control............................................................................................................ 46

2-4-1 Pin numbers and names of I/O signals ..................................................................... 46

2-4-2 I/O port connections in torque control ....................................................................... 47

2-4-3 I/O port functions in torque control ............................................................................ 48

2-4-4 Connection examples in torque control..................................................................... 55

HA-680 series servo driver manual

- Contents 2 -

Chapter 3 Installing HA-680 driver ................................................................... 58

3-1 Receiving Inspection ................................................................................................. 58

3-2 Notices on handling................................................................................................... 59

3-3 Location and installation............................................................................................ 60

3-3-1 Environment of location............................................................................................. 60

3-3-2 Notices on installation................................................................................................ 60

3-3-3 Installing .................................................................................................................... 61

3-4 Suppressing noise..................................................................................................... 61

3-4-1 Devices for grounding ............................................................................................... 61

3-4-2 Installing noise filters ................................................................................................. 62

3-4-3 Instructions for cabling .............................................................................................. 63

3-5 Connecting power cables .......................................................................................... 64

3-5-1 Instructions for power supply..................................................................................... 64

3-5-2 Allowable size of cables ............................................................................................ 64

3-5-3 Connecting power cables .......................................................................................... 65

3-6 Connecting the ground wire ...................................................................................... 66

3-7 Connecting motor and regeneration resistor cables ................................................. 66

3-8 Connecting regenerative absorption resistance / capacitors .................................... 67

3-9 Connecting cables for the encoder and the I/O......................................................... 69

3-9-1 Preparing the encoder cable and the I/ O cable........................................................ 69

3-9-2 Pin layout of encoder connector (CN1) ..................................................................... 69

3-9-3 Pin-layouts of the I/O signal connector (CN2)........................................................... 71

3-9-4 Connecting cables for the encoder and I/O signals .................................................. 72

3-9-5 EIA-232C (RS-232C) cable specifications ................................................................ 72

3-10 Power ON and OFF sequences ................................................................................ 73

3-10-1 Power ON / OFF sequence circuit............................................................................. 73

3-10-2 Frequency of power ON / OFF operation.................................................................. 73

3-10-3 Power on and off sequences..................................................................................... 73

Chapter4 Functions of dedicated communication software PSF-520........... 74

Chapter5 Operations ......................................................................................... 75

5-1 Trial run...................................................................................................................... 75

5-1-1 Driving actuator only.................................................................................................. 75

5-1-2 Setting parameters .................................................................................................... 77

5-1-3 End of trial run ........................................................................................................... 77

5-2 Normal operation ....................................................................................................... 78

5-2-1 Notices for daily operations ....................................................................................... 78

5-2-2 Daily maintenance ..................................................................................................... 78

Chapter 6 Setting up parameters ..................................................................... 79

6-1 Parameter list ............................................................................................................ 79

6-2 Function of the parameters ....................................................................................... 80

6-3 Default parameter list .............................................................................................. 101

HA-680 series servo driver manual

- Contents 3 -

Chapter 7 Troubleshooting .............................................................................. 109

7-1 Alarms and diagnostic tips ...................................................................................... 109

7-2 Troubleshooting for improper actuator motions....................................................... 121

7-2-1 Improper motions in position control ....................................................................... 121

7-2-2 Improper motions in speed and torque control........................................................ 125

Chapter 8 Options ........................................................................................... 129

8-1 Relay cables ............................................................................................................ 129

8-2 Connectors .............................................................................................................. 130

8-3 Dedicated communication software RSF-520 (free) ............................................... 130

HA-680 series servo driver manual

MEMO

Chapter 1 Outlines of the HA-680 driver

- 1-

Chapter 1 Outlines of HA-680 driver

The HA-680 driver for 24 VDC power supply is a dedicated driver designed to drive: the ultra-thin/hollow

shaft structure 24-VAC actuator FHA-C mini combining a ultra-thin/speed reducer HarmonicDrive®for

precision control and flat AC servo motor; the ultra-small AC Servo Actuator RSF supermini series

combining an ultra-small HarmonicDrive®and ultra-small AC servo motor; and the RSF-B mini series.

The HA-680 drivers provide many superior functions to allow the 24-VAC FHA-C mini type, RSF

supermini series, and RSF-B series to excel in performance.

1-1 Main features

◆Small and compact design

It is about half the size of a postcard, just the size of a card case. Its ultra-light design with a weight of

230 g is useful for small, space-saving devices.

◆Substantial functions

Position control, speed control, and torque control are provided as standard. It is compact and has

substantial functions at the same time.

◆Easy function setting

Parameters can be set easily using dedicated communication software PSF-520.

◆Wide range of operation state display

I/O signals, rotation speed, and deviation can be monitored using dedicated communication software

PSF-520.

Up to eight previous alarms are also indicated as alarm history that is helpful for diagnosis.

◆The main circuit power supply and the control power supply are separated.

Because the main circuit power supply and the control power supply are separated, safe diagnosis can

be performed in case of failure.

◆Easy test run adjustment

Adjustment can be performed using dedicated communication software PSF-520.

◆Electronic gear suitable for mechanical system

The electronic gear function adjusts commands to a feed pitch of a driven mechanism such as gears or

lead screws.

◆Three types of input signals for position commands

Three types of input signals for the position command are selectable: two-pulse train, single-pulse train,

and two-phase pulse train.

◆Regenerative circuit provided as standard

It incorporates a regenerative circuit as standard. You can use it in applications with a large moment of

inertia without worrying about regeneration.

Chapter 1 Outlines of the HA-680 driver

- 2-

1-2 Model of HA-680 driver

Model and sign of HA-680 driver are described as follows:

Note that the model varies depending on the actuator used.

◆HA-680 driver:

Optional

Extension cables: For FHA-Cmini 24VAC type (optional)

for HA-680

for a motor EWC - MB * * -A06 – TN2

for an encoder EWC - E * * -M06 - 3M14

for EIA-232C

HDM-RS232C (cable length: 1.5m)

* * means cable length: 03: 3m, 05: 5m, 10: 10m (three kinds of length are available.)

Extension cables: For RSF supermini series (optional)

(Require for connecting actuator and driver)

for HA-680

for a motor

EWA - M* * -JST04 – TN2

for an encoder

EWA - E * * -JST09 - 3M14

for EIA-232C

HDM-RS232C (cable length: 1.5m)

* * means cable length: 03: 3m, 05: 5m, 10: 10m (three kinds of length are available.)

Extension cables: For RSF-B mini series (optional)

(Require for connecting actuator and driver)

for HA-680

for a motor

EWC - MB* * -A06 – TN2

for an encoder + pole sensor

EWB - F * * -M0809 - 3M14

for EIA-232C HDM-RS232C (cable length: 1.5m)

* * means cable length: 03: 3m, 05: 5m, 10: 10m (three kinds of length are available.)

Connectors (optional): CNK-HA68-S1 / CNK-HA68-S2

Dedicated communication software (provided free of charge): PSF-520

Parameter setting and change can be performed using dedicated communication software PSF-520.

Dedicated communication software PSF-520 can be downloaded from our website at http://www.

hds.co.jp/.

If you do not have an environment to download it from the Internet, please ask one of our branch offices.

HA-680-4 □-200

AC servo driver

680 series

Nominal current

Input voltage

Corresponding

sign

4

4A

6

6A

None

For FHA-Cmini 24VAC type (FHA-8C,11C,14C)

B

For RSF supermini series (RSF-3C,5B)

For RSF-B series (RSF-8B,11B,14B)

24

24VDC

Chapter 1 Outlines of the HA-680 driver

- 3-

1-3 Combinations with actuators

Five HA-680 models are available for use with actuators dealing with their nominal current and encoder

systems. The correct combinations are as follows:

Model

HA-680-4-24 HA-680-6-24 HA-680-4B-24 HA-680-6B-24

Actuator model FHA-8C

FHA-11C FHA-14C

RSF-3C

RSF-5B

RSF-8B

RSF-11B

RSF-14B

1-4 Specifications of HA-680 drivers

Driver model

Item

HA-680-4-24

HA-680-6-24

HA-680-4B-24 HA-680-6B-24

Combined actuator FHA-8C FHA-11C FHA-14C RSF-3C RSF-5B RSF-8B RSF-11B RSF-14B

Allowable continuous

current (Arms)

note

2

1.8 3.9 6.0 0.7 1.2 2.0 5.0 4.9

Instantaneous max.

current (Arms)

note

3

3.4 8.4 16.5 1.5 2.3 3.9 15.8 17.2

Supply

voltage

Control circuit

power supply (CP)

DC24V(20~28V)

Main circuit power

supply (MP)

DC24V(20~28V)

Control method

Sinusoidal PWM control

switching frequency 12.5kHz

Encoder 4-line specification, serial transmission

method, line driver input

14-line specification

Line driver input

8-line specification

Line driver input

Pole sensor

8-line specification

Line driver input

I/O signal DI: 5 points (insulation with phto coupler) DO: 5 points (insulation with phto coupler)

Variable function assignment

Encoder monitor

Phase-A,B,Z line driver output Phase-Z open collector output (insulation with phto coupler)

Control mode

Speed, position and torque control

Display LED 2 points (green:1 point red:1 point)For power on, servo-on, alarm operation state display

Speed

control

Command voltage

DC0V~

±

10V/maxium speed

Input signal

FWD-enable, REV-enable, Alarm clear, Speed Command internal/external switch, Speed limiting, Current

limiting

Output signal

Attained speed, Alarm, ready, limiting speed, limiting current, Phase-Z open collector output

Speed control range

1:1000 or more

Position

control

Command pulse

interface Line driver: 500kp/s(max) open collector: 200kp/s(max)

Command

configuration

2- pulse (FWD/REV pulse train), 1 pulse method (sign+pulse train),

2-phase pulse method (90-degree phase difference 2-phase pulse train)

Input signal

FWD-inhibit, REV-inhibit, clear, Deviation clear, Speed limiting, Current limiting

Output signal

In-position, alarm, ready, limiting speed, limiting current, Phase-Z open collector output

Torque

control

Command voltage DC0V~±10V/Max. torque

Input signal FDW rotation start, REV rotation start, alarm clear, torque command internal/external switch, current limit

Output signal Attained speed, alarm, operation ready, limiting current, Phase-Z open collector output

Protection function

Overload, Max. deviation, Encoder break detection, encoder reception error, UVW error, regenerative error,

operating temperature error, system error, overcurrent, load short circuit, memory error, overspeed

Connector

I/O: 3M half-pitch 26-pin

encoder: 3M half-pitch 14-pin

RS-232C: Small-type 8-pin

CAN: RJ type

Regenerative absorption circuit

Incorporated (with an external capacitor/resistor installation terminal). The built-in resistance has a fuse.

Structure

Semi-covered type (aluminum base with plastic cover)

Installation method

Base mount (wall installation)

Mass

230g

Ambient conditions

Operating temp:0~50°CStorage temp:-20~85°C

Operating humidity/storage humidity:95%RH or less (no condensation)

No vibration or physical shock.

No powder dust, metal powder, corrosive gas, flammable gas, or oil mist.

No water or oil splashed.

To be used indoors. No direct sunlight.

Note 1: Parameter setting of this driver is performed depending on the actuator combined with it. It cannot be used

for any other actuator.

Note 2: This value may be limited depending on the combined actuator.

Chapter 1 Outlines of the HA-680 driver

- 4-

1-5 External drawing of the HA-680 drivers

The HA-680 driver model indication and the mark shown in this manual are as follows:

Unit: mm

When HA-680 drivers are installed in a cabinet, leave enough ventilation space for cooling as shown

below.

Air

Air

Control cabinet

Cooling fan

Wall mount

30mm or more

30mm or more

30mm

or more

50mm or

more

50mm or

more

Driver

Air

Air filter

Air

Cover

Ground mark

Specification indication plate

Software version No. seal

2-washer cross pan-head machine screw

(brass round) M3x6

Heat sink

Regenerative resistance

internal/external switch terminal

Chapter 1 Outlines of the HA-680 driver

- 5-

1-6 Names and functions of parts

LED display unit

Displays the operation state of the HA-680 driver with the green and red LEDs.

TB2: Power supply connection terminals

The terminals for power supply. These are divided into terminals for the control circuit power supply and

terminals for the main circuit power supply.

TB1: Actuator/external regenerative resistance connection terminal

The lead line of the actuator and an external regenerative resistance are connected here.

CN1: Encoder connector

The position detection encoder cable of the actuator is connected here.

CN2: Control I/O connector

This connector is for receiving control signals from the host controller.

•CN5: Not available (on the side)

•CN4: CAN connector

•CN3: EIA-232C serial

port connector

•CAN terminal resistance

switch jumper

•TB2: Power supply

connection terminal

•LED display

•Ground connection

terminal

•CN2: Control I/O

connector

•CN1: Encoder connector

•TB1: Actuator/external

regenerative resistance

connection terminal

•Regenerative resistance

switch jumper (on the side)

Chapter 1 Outlines of the HA-680 driver

- 6-

CN3: Serial port connector

The connector for connection with a PC. This is used for monitoring the output current and setting

parameters.

Connection with a PC requires dedicated communication cable “HDM-RS232C.”Parameter setting

requires dedicated communication software PSF-520.

CN4: CAN connector

Connector for CAN communication.

Note: Currently not available. For details, contact one of our branch offices.

CN5: Not available

This connector is for manufacture only. The customer should never use it.

Ground connection terminal

This terminal is for grounding. Connect the ground (earth) line here to prevent electric shock.

CAN terminal resistance switch jumper

Enables or disables the terminal resistance for CAN.

Note: Currently, the CAN function is not installed. Therefore, setting this jumper is meaningless.

Regenerative resistance switch jumper

Switches between the internal regenerative resistance and the external regenerative resistance.

Installing the jumper between the center pin and left pin selects the internal regenerative resistance, and

installing the jumper between the center pin and right pin selects the external regenerative resistance.

For details, refer to 3-8 Connecting regenerative absorption resistances/capacitors.

Chapter 1 Outlines of the HA-680 driver

- 7-

1-7 Outlines of I/O ports

1-7-1 TB2: Power supply connection terminal

Pin No.

Signal name

Description

1

CP+

Control circuit power supply + (DC+24V)

For details, refer to 3-5.

2

CP-

Control circuit power supply −(0V)

3

MP+

Main circuit power supply + (DC+24V)

4

MP-

Main circuit power supply −(0V)

5

NC

Do not connect

1-7-2 TB1: Actuator connection terminal

Pin No.

Signal name

Description

1

VM

External capacitor connection terminal

For details, refer to 3-8.2 R External regenerative resistance connection terminal

3

GND

External capacitor/regenerative resistance connection terminal

4

U

Actuator U-side connection terminal

For details, refer to 3-7.5 V Actuator V-side connection terminal

6

W

Actuator W-side connection terminal

1-7-3(1) CN1: Encoder connector (For FHA-Cmini 24VAC-type actuators)

Pin No.

Signal name

Description

1 Vcc

The power is supplied from the inside of the servo amplifier with the +5 V power

supplied to the encoder.

2

NC Do not connect.

3

4

5

SD+

Input terminal for the encoder data input signal from the actuator

6 NC Do not connect.

7

SD-

Input terminal for the encoder data input signal from the actuator

8

GND

Common terminal of the +5 V power supplied to the encoder

9

NC Do not connect.

10

11

12

13

14

(2) CN1: Encoder connector (For RSF supermini series actuators)

Pin No.

Signal name

Description

1 Vcc The power is supplied from the inside of the servo amplifier with the +5 V power

supplied to the encoder.

2 B+ Phase-B signal input+(LD)

3

Z+

Phase-Z signal input +(LD)

4

B-

Phase-B signal input -(LD)

5 A+ Phase-A signal input +(LD)

6

Z-

Phase-Z signal input -(LD)

7

A-

Phase-A signal input +(LD)

8

GND

Common terminal of the +5 V power supplied to the encoder

9

U+

Phase-A signal input +(LD)

10

U-

Phase-Z signal input -(LD)

11

V+

Phase-A signal input +(LD)

12 V- Phase-B signal input -(LD)

13

W+

Phase-A signal input +(LD)

14

W-

Phase-Z signal input -(LD)

Note 1: LD indicates the line driver.

Chapter 1 Outlines of the HA-680 driver

- 8-

(3) CN1: Encoder connector (For RSF-B mini series actuators)

Pin No.

Signal name

Description

1 Vcc

The +5V power supply to the encoder and pole sensor is used to supply power

from inside the servo amplifier.

2

B+

Phase-B signal input+(LD)

3 Z+ Phase-Z signal input +(LD)

4

B-

Phase-B signal input -(LD)

5

A+

Phase-A signal input +(LD)

6 Z- Phase-Z signal input -(LD)

7

A-

Phase-A signal input +(LD)

8 GND

This is a common terminal of the +5V power supply to the

encoder and pole sensor.

9 U+ Phase-A signal input +(LD)

10

U-

Phase-Z signal input -(LD)

11

V+

Phase-A signal input +(LD)

12 V- Phase-B signal input -(LD)

13

W+

Phase-A signal input +(LD)

14

W-

Phase-Z signal input -(LD)

1-7-4 CN3: Serial port connector

Pin No.

Signal name

Description

1 FG Frame ground

2

RXD

Transmission data

3

TXD

Reception data

4

DTR

Data terminal ready

5

GND

Signal ground

6

DSR

Data set ready

7

NC

Do not connect.

8

NC

Do not connect.

(Dedicated communication cable “HDM-RS232C” is required.)

1-7-5 CN4: CAN connector

Pin No.

Signal name

Description

1

CANH

CAN-High signal

2

CANL

CAN-Low signal

3

NC

Do not connect.

4 NC Do not connect.

5

NC

Do not connect.

6

NC

Do not connect.

7

NC

Do not connect.

8

NC

Do not connect.

Note: Currently not available.

Chapter 1 Outlines of the HA-680 driver

- 9-

1-8 CN2: Overview of I/O signal

The CN2 connector performs input and output of control signals with the host control device. The

connector has 26 pins, which are assigned for “position control,” “speed control,” and “torque control” as

shown in the table below.

Position control

Speed control

Pin

No.

Signal Symbol I/O

Pin

No.

Signal Symbol I/O

1 Output 1 (in-position ready) IN-POS Output 1

Output 1(Attained speed

Output)

HI-SPD Output

2

Output 2(Alarm Output)

ALARM

Output

2

Output 2 (Alarm Output)

ALARM

Output

3 Output 3 ―Output 3 Output 3 ―Output

4 Output 4 ―Output 4 Output 4 ―Output

5 Output 5 (Phase-Z OC

Output)

Z Output 5 Output 5 (Phase-Z OC

Output)

Z Output

6

Output signal common

OUT-COM

Output

6

Output signal common

OUT-COM

Output

7

Input 1 (Servo-ON)

S-ON

Input

7

Input 1 (Servo-ON)

S-ON

Input

8

Input 2

―

Input

8

Input 2 (FWD start)

FWD-EN

Input

9

Input 3

―

Input

9

Input 3 (REV start)

REV-EN

Input

10 Input 4 ―Input 10 Input 4 ―Input

11 Input 5 ―Input 11 Input 5 ―Input

12

Input signal common

IN-COM

Input

12

Input signal common

IN-COM

Input

13

Encoder monitor GND

MON-GND

Output

13

Encoder monitor GND

MON-GND

Input

14

FWD pulse +

FWD+

Input

14

―――

15

FWD pulse -

FWD-

Input

15

―

―

―

16 REV pulse + REV+ Input 16 ―――

17 REV pulse - REV- Input 17 ―――

18 +24v +24v Input 18 ―――

19 ―――19 Speed command SPD-CMD Input

20

―

―

―

20

Speed command ground

SPD-GND

Input

21

Phase-A Output + (LD)

A+

Output

21

Phase-A Output + (LD)

A+

Output

22

Phase-A Output - (LD)

A-

Output

22

Phase-A Output - (LD)

A-

Output

23 Phase-B Output + (LD) B+ Output 23 Phase-B Output + (LD) B+ Output

24

Phase-B Output - (LD)

B-

Output

24

Phase-B Output - (LD)

B-

Output

25

Phase-Z Output + (LD)

Z+

Output

25

Phase-Z Output + (LD)

Z+

Output

26 Phase-Z Output - (LD) Z- Output 26 Phase-Z Output - (LD) Z- Output

Note 1: OC indicates the open collector. LD indicates the line driver.

Note 2: For terminals without a signal name for input and output, function assignment can be changed in

parameter setting. For details, refer to 2-1.

Do not connect the pins with “-” in the Signal column to the external

device.

If you do, failure may occur because it is connected to the internal circuit.

CAUTION

Chapter 1 Outlines of the HA-680 driver

- 10 -

Torque control

Pin No.

Signal

Symbol

I/O

1

Output 1 (Attained speed)

HI-SPD

Output

2 Output 2 (Alarm) ALARM Output

3

Output 3 (operation ready)

READY

Output

4

Output 4 (limiting current)

CUR-LMT-M

Output

5 Output 5 (Phase-Z Output OC) Z Output

6

Output signal common

OUT-COM

Output

7

Input 1(Servo-ON)

S-ON

Input

8 Input 2 (FWD start) FWD-EN Input

9

Input 3 (REV start)

REV-EN

Input

10 Input 4 ―

Input

11 Input 5 ―

Input

12

Input signal common

IN-COM

Input

13 Encoder monitor GND MON-GND Output

14 ―――

15

―

―

―

16 ―

―

―

17 ―

―

―

18

―――

19

Torque command

TRQ-CMD

Input

20 Torque command ground TRQ-GND Input

21

Phase-A Output + (LD)

A+

Output

22

Phase-A Output - (LD)

A-

Output

23 Phase-B Output + (LD) B+ Output

24

Phase-B Output - (LD)

B-

Output

25

Phase-Z Output + (LD)

Z+

Output

26

Phase-Z Output - (LD)

Z-

Output

Note 1: OC indicates the open collector. LD indicates the line driver.

Note 2: For Input 4 and Input 5, function assignment can be changed in parameter setting. For details,

refer to 2-1.

Do not connect the pins with “-” in the Signal column to the external

device.

If you do, failure may occur because it is connected to the internal circuit.

CAUTION

Chapter 1 Outlines of the HA-680 driver

- 11 -

1-9 LED display

The 2 LEDs (green and red) indicate the state of the HA-680 driver.

State

LED green

LED red

Remarks

Control power ON

ON

OFF

The connected actuator and the actuator set to

the driver are different.

Blinking OFF

Servo-ON

ON

ON

Alarm (*1) ON Blinking

The number of times it blinks varies

depending on the alarm. Refer to 1-10.

CPU error

Blinking

Blinking

The green and red LEDs blink alternately.

*1 If two or more alarms occur, only the latest alarm is displayed.

1-10 Outline of protective functions

The HA-680 driver has various types of protection function. When an error occurs in the system, it

immediately turns off the servo, and outputs an “alarm” signal to the host device.

When these protection functions trip, driving of the actuator is stopped (the motor becomes servo-off),

and the display LED blinks at 0.5-second intervals. (It illuminates in green and blinks in red: The number

of times it blinks varies depending on the alarm. See below.)

If two or more alarms occur, only the latest alarm is displayed. Up to 8 latest alarms are recorded.

Recorded alarms can be checked with “Alarm History” of dedicated communication software PSF-520.

Alarm code Description No. of times

LED blinks Releasing

Overload Electronic thermal detected an overload state. 1 Available *1

Deviation counter

overflow

The value of the deviation counter exceeded the parameter

setting value.

2 Available *1

Encoder break

detection

The encoder line was broken. 3 Not available *2

Encoder reception

error

Serial encoder data could not be received 10 times in a row. 4

Not available *2

Serial encoder data could not be received over an extended time

period, and encoder monitor could not be outputted successfully.

5

UVW error All UVW signals of the encoder became the same level. 6 Not available *2

Regenerative error The main circuit voltage detection circuit detected overvoltage. 7 Not available *2

Operation

temperature error

The temperature of the HA-680 main unit tripped the temperature

rise sensor.

8 Not available *2

System error An error of the current detection circuit was detected. 9 Not available *2

Overcurrent The current detection circuit detected excessive current. 10 Not available *2

Load short circuit Excessive current flowed through the FET. 11 Not available *2

Memory error Read/write of EEPROM failed. 12 Not available *2

Overspeed The motor axis speed exceeded the maximum rotation speed

+100 rpm for 0.5 s or longer. 13 Not available *2

*1 The servo does not turn on unless the S-ON signal is entered again after the alarm is cleared with the

CLR signal.

*2: Shut off the power supply after remedying a cause of the alarm that releasing is impossible. Then

turn on the power supply.

Chapter 1 Outlines of the HA-680 driver

- 12 -

The following example illustrates how the LED blinks in case of an alarm.

0.5s 0.5s 0.5s 2s 0.5s 0.5 s 0.5s

In the above example, the LED blinks 4 times at 0.5-s intervals, which indicates an “encoder reception

error.”

1-11 Protective functions

HA-680 drivers provide the following protective functions and show the alarm displays on 1-10.

◆Overload

The driver always monitors the motor current, and if the current exceeds the curve in the figure below,

the overload alarm occurs. Occurrence of the overload alarm varies depending on the actuator.

FHA-C mini AC24V type

(1)

The alarm occurs when a current of more than

1.25 times the allowable continuous current of

the actuator flows for about 170 seconds.

(2)

The alarm occurs when a current of 3 times the

allowable continuous current of the actuator

flows for about 16 seconds.

RSF supermini series (RSF-5B)

(1) The alarm occurs when a current of more than

1.2 times the allowable continuous current of

the actuator flows for about 35(45) seconds.

(2)

The alarm occurs when a current of 2 times the

allowable continuous current of the actuator

flows for about 5(6) seconds.

HA-680過負荷アラーム検出時間

0

5

10

15

20

25

30

35

40

45

50

50 100 150 200 250 300

出力トルク[%}

検出時間[s]

RSF-3C

RSF-5B

Detection time [s]

Output torque [%] The rated torque is 100%.

RSF supermini series

Overload alarm occurrence time

( )The inside is RSF-3C

0

20

40

60

80

100

120

140

160

180

200

0 50 100 150 200 250 300

出力トルク [%] 定格を100%とする

検出時間 [s]

Output torque [%] The rated torque is 100%.

Detection time [s]

FHA-C mini AC24V type

Chapter 1 Outlines of the HA-680 driver

- 13 -

RSF-11B

(1)

The alarm occurs when a current of more than

1.2 times the allowable continuous current of the

actuator flows for about 23 seconds.

(2)

The alarm occurs when a current of 1.5 times

the allowable continuous current of the actuator

flows for about 10 seconds.

It is possible to clear the alarm by inputting ON signal to [CN2 Clear or Alarm clear] if it is not overload,

again.

◆Deviation counter overflow

The alarm occurs when the value of the deviation counter exceeds the parameter setting value

(PSF-520 No.21 Allowable position deviation). This alarm can be reset by inputting an ON signal to

“CN2 Alarm Clear: ALM-CLR” after inputting an ON signal to “CN2 Clear: CLEAR” or “CN2 Deviation

Clear: DEV-CLR.”

◆Encoder break detection

This alarm occurs when the signal from the encoder is lost. To reset the alarm, you must shut down the

power and turn it on again after diagnosing the cause.

◆Encoder reception error

This alarm occurs when data cannot be received from the encoder successfully, or encoder signal output

cannot be performed.

◆UVW error

An alarm occurs if encoder or pole sensor phase UVW signals become abnormal. To reset the alarm,

you must shut down the power and turn it on again after diagnosing the cause.

To clear the alarm after troubleshooting, shut off the control power once and turn it on again.

RSF-8B

(1) The alarm occurs when a current of more than

1.2 times the allowable continuous current of the

actuator flows for about 13 seconds.

(2) The alarm occurs when a current of 1.5 times

the allowable continuous current of the actuator

flows for about 6 seconds.

RSF-14B

(1)

The alarm occurs when a current of more than

1.2 times the allowable continuous current of the

actuator flows for about 45 seconds.

(2)

The alarm occurs when a current of 2.5 times

the allowable continuous current of the actuator

flows for about 5 seconds.

RSF シリーズ

0

5

10

15

20

25

30

35

40

45

50

50 100 150 200 250 300

出力トルク [%]

検出時間 [s]

RSF-14B

RSF-8B

RSF-11B

RSF-B mini series

Detection time [s]

Output torque [%] The rated torque is 100%.

Chapter 1 Outlines of the HA-680 driver

- 14 -

◆Regenerative error

The alarm occurs when the voltage of the main circuit exceeds 50 V. If the moment of inertia of the load

is large, the main circuit voltage increases due to the energy generated during deceleration of the

actuator.

The regenerative resistance of the regenerative absorption circuit incorporates a fuse. When the

temperature of the regenerative resistance increases due to excessive regeneration and the fuse is

blown, the regenerative circuit no longer works, and the main circuit voltage increases. If the

regenerative error occurs immediately the control circuit power is shut down and turned on again, it may

be due to a blown fuse. In this case, connect the external regenerative resistance and switch the jumper

setting.

For connection of an external regenerative resistance and change of the jumper setting, refer to 3-8.

◆Operating temperature error

The alarm occurs when the temperature of the HA-680 main unit increases and the temperature sensor

trips. To reset the alarm, you must shut down the power and turn it on again after diagnosing the cause.

◆System error

This alarm occurs when an error of the motor current detection circuit is detected. To reset the alarm,

you must shut down the power and turn it on again after diagnosing the cause.

◆Overcurrent

This alarm occurs when overcurrent is detected by the motor current detection circuit. To reset the alarm,

you must shut down the power and turn it on again after diagnosing the cause.

◆Load short circuit

The alarm occurs when excessive current flows through the FET. To reset the alarm, you must shut

down the power and turn it on again after diagnosing the cause.

◆Memory error

The alarm occurs when read/write fails due to failure of the EEPROM memory of the driver. It can be

reset by shutting down the power and turning it on again. However, if the same phenomenon persists, it

may be due to failure. Contact one of our branch offices.

◆Overspeed

The alarm occurs when the rotation speed of the actuator exceeds the motor axis maximum rotation

speed +100 rpm for 0.5 s or longer. To clear the alarm, shut off the control power once and turn it on

again.

This manual suits for next models

4

Table of contents

Other Harmonic Drive Servo Drive manuals

Harmonic Drive

Harmonic Drive LAH Series User manual

Harmonic Drive

Harmonic Drive HA-675 Series User manual

Harmonic Drive

Harmonic Drive HMA Series User manual

Harmonic Drive

Harmonic Drive HS-360 Series User manual

Harmonic Drive

Harmonic Drive H A - 800A User manual

Harmonic Drive

Harmonic Drive HA-520 Series User manual

Popular Servo Drive manuals by other brands

Technosoft

Technosoft Micro 4803 SX Technical reference

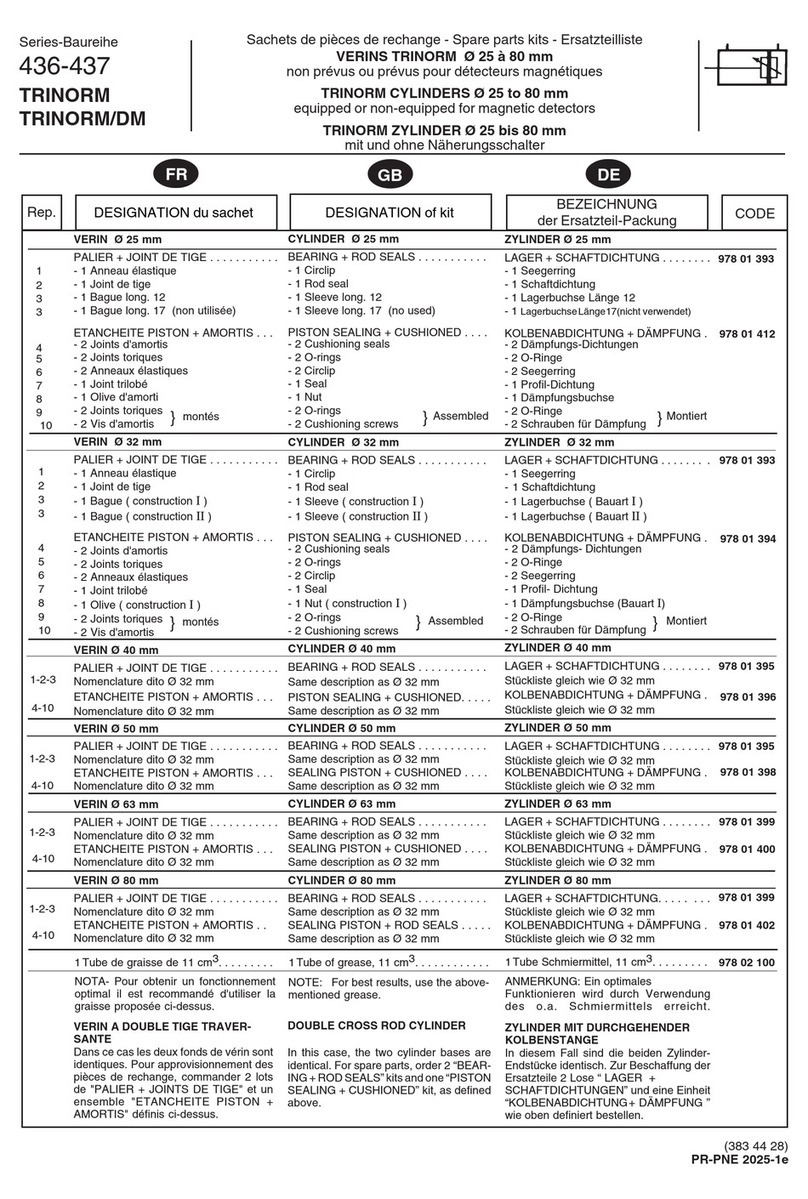

Emerson

Emerson TRINORM 436 Series instruction manual

Omron

Omron R88M-K Series user manual

Inovance

Inovance SV660N Series Advanced user's guide

Xinje

Xinje DS3 series servo user manual

Danfoss

Danfoss VLT 6002-6011 Installation, operation and maintenance manual