Electro-Craft BRU-200 User manual

BRU-200

and

BRU-500

Brushless

Drives

Instruction

Manual

Electro-Craft®

Servo

Products

Electro-Craft

BRU-200

and

BRU-500

Brushless

Drives

Instruction

Manual

P/N

0013-1028-001

Revision

B

Reliance

Motion

Control,

Inc.

6950

Washington

Avenue

South

Eden

Prairie,

MN

55344

612-942-3600

Technical

Support:

800-328-3983

ONLY

QUALIFIFED

ELECTRICAL

PERSONNEL

FAMILIAR

WITH

THE

CONSTRUCTION

AND

OPERATION

OF

THIS

EQUIPMENT

AND

THE

HAZARDS

INVOLVED

SHOULD

INSTALL,

ADJUST,

OPERATE

OR

SERVICE

THIS

EQUIPMENT.

READ

AND

UNDERSTAND

THIS

MANUAL

AND

OTHER

APPLICABLE

MANUALS

IN

THEIR

ENTIRETY

BEFORE

PROCEEDING.

FAILURE

TO

OBSERVE

THIS

PRECAUTION

COULD

RESULT

IN

SEVERE

BODILY

INJURY

OR

LOSS

OF

LIFE.

WARNING

THE

USER

MUST

PROVIDE

AN

EXTERNAL,

HARDWIRED

EMERGENCY

STOP

CIRCUIT

OUTSIDE

THE

CONTROLLER

CIRCUITRY.

THIS

CIRCUIT

MUST

DISABLE

THE

SYSTEM

IN

CASE

OF

IMPROPER

OPERATION.

UNCONTROLLED

MACHINE

OPERATION

MAY

RESULT

IF

THIS

PROCEDURE

IS

NOT

FOLLOWED.

FAILURE

TO

OBSERVE

THIS

PRECAUTION

COULD

RESULT

IN

SEVERE

BODILY

INJURY.

Copyright

©

Reliance

Motion

Control,

Inc.

1995.

All

mghts

reserved.

The

information

contained

in

this

manual

is

subject

to

change

without

notice.

Electro-Craft

is

a

registered

trademark

of

Reliance

Electric

Company

or

its

subsidianes.

Tandy

is

a

registered

trademark

of

Tandy

Corporation.

IBM

is

a

registered

trademark

of

Intemational

Business

Machines

Corporation.

INTEL

is

a

trademark

of

Intel

Corporation,

AMP

is

a

trademark

of

AMP

Incorporated.

Molex

is

a

registered

trademark

of

Molex

Incorporated.

Table

of

Contents

TABLE

OF

CONTENTS

SECTION

|

-

INTRODUCTION

V7

PUPPOSC

oo

eee

eceeeee

nee

n

ee

nnetee

pee

ceeeseceuevee

HnMAcHensHenRO

Hea

Enea

LdCAnSOnNAcucaNSA

Ene

LOE

CCEA

CnEOH

SHEE

CnEEH

ALU

DRREEAAAESReud

HE

SEDREREE

EEO

EA RE

1.2

Product

Description...

.

sea

eee

tease

teeeeceecavceneancoeennepeseenneee

vet

ne

set

sagee

peta

nseates

ene

1.2.1

Power

Supply

Modules

(BRU-

500

Only)...

dacneeeseveceescaecenecsessesnesetnsanenersnatengesaneseesutssntenteesnnees

&

1.2.2

Drive

Modules...

ccc

ccccercseceescueesareeseceseecescaeeseeseeesseserensesecoegse

seadsguaggessansaasasapeamasensaeasebenenenens

1.2.3

Motors

amid

Encoders.i....cccccccsscecesetcesecececeaseseseceecasascecnsseseecsecsenssnnaensenecauaneeassrepenenésedeeseestaseoeese

se

1.2.4

Transformers

...

pence

ceneaeacceneneag

cae

cncetsaeseenetinereesenseereaerbeddeaeseseabieeasaaneees

1.2.5

Auxiliary

Power

‘Supply

(BRU-

500

Only)...

enue

sus

cesuassesesceneasseseeccsscecaesatansesaesssaessetuaseaeeseceasvansstesenacates

3

SECTION

II

-

SPECIFICATIONS

2.1

Drive

Module

Specifications

«oes

cc

cececcneeeceeeeeeseoceseecaesoeneseneneeeetersecrereceesecess

or

ttsaviseeameaqsseneeaseneansees

2.2

Power

Supply

Module

Specifications

(BRU-500

Only)...

cece

cee

ccee

cee

nesee

rece

enesvanseerenasinaeesenererersnenas

Dl

2.3

S-Series

Motor

Specifications

TTENV)

.......c:ccecssescesssssseeesessesseesesessseeseessceseseecsevasseeeeecavavisasersasrensertacesissese

O

2.4

F-Series

Motor

Specifications

(TENV)........cccsscsceccscsssnecnensestsscecnesecescensavsveceesseseecscoesnsnetecesstsatpensetsncesnnee

B

25

I-Series

Motor

Specifications

(BRU-5SO0

Only)...

ccsccesssssssssesecesssseesessesescessseseeesecueenteenesceereerseecenesceneneaees

7

2.6

Encoder

Specifications

............cccscceccccecssseescscsnesnesseestesesscenensessecsceascnesscenseseeessenecaessenenenssueqeeteteratencesiyeateneees

2.7

Transformer

Spechications.......0.1..ccccsccecccsessscscssesescsesenesssenensusasevenesseeenscoatvaceusausaaceusersteteseenseseeterecgeeenes

B

2.8

Maximum

Power

LOSS@S.

...........ccccccccccsce

ses

ceeeececeesceee

veseeceesessaeescaseserseeecseseseeessescencevesereerseeseeciesessnasevsanes

SECTION

Ill

-

INSTALLATION

3.1

Mounting

the

Power

Supply

and

Drive

Modules

«...........-.-c-cceseesecseeecceeesusceneaaeeseeenseeeceesenaeeesaecavaeceenseaeers

10

3.2

Power

Wiring...

venue

ceeenneeeseneneeeasinesecursapeeeesessgneeudegeegseqcennsessseesenseseeenetassctsaemesesnesanernte

TO

3.2.1

BRU

500

‘Power

Wiring...

cece

seecaneeesoueeeusesenceneseecassneccenepeesaaeesssscesenstessieseneveertestsamenteraseaneenees

TQ)

3.2.2

BRU-200

Power

Wiring....

besos

ta

caeeeeasesessacesnecae

sua

tasccnerensageeseeeceseeensenstsntennencsstereteriesacre

TT

3.3

Motor

Mounting

amd

Wiritig

nce.

csccsceesesssecesecececeecsesesesessesceseaesesesaeceneseseececesceeceeceseaceererscaeavasenetes

11

3.4

External

Shunt

Mounting

and

Wiring

(BRU-200

DM-30

Option

Only)

0.0...

ccccececeseetetetecsteeeseessenetane

TY

BRU-200/8RU-500

Brushless

Drives

instruction

Manual

iii

Table

of

Contents

SECTION

WV

-

INTERFACE

CIRCUITRY

4.1

Drive

Module

interface

Commectors........ccc

ccc

ee

ccceeecececoessasesseussucueceeessunnsesgueseeserecssgenneenrasesansnerecevens

4.2

Drive

Module

Interface

Signal

SpecifiCations

...........ccccccecccccsceeceeeceeecesuceseneecsuceenrceesaseeneees

4.3

Power

Supply

Module

interlace

Connector

(BRU-S00

Only)...

eeeccsee

teens

sssseencesseeeennarieerereaeeeee

rane

4.4

Power

Supply

Module

Interface

Signal

Specifications

(BRU-500

Only)

oo...

ee

cieceecrcsesereanseenssseeeensees

SECTION

V

-

START-UP

AND

ADJUSTMENTS

5.1

Initial

Start-Up

Procedure

...

§.1.1

Initial

Start-Up

Procedure

(BRU-

500)

...

5.1.2

Initial

Start-Up

Procedure

(BRU-200)

...

5.2

AGIUSTMONNS.

0.

eee

eetetec

eee

cneensareneeneseeenercnsonessseatanessusanaseenseessnecaneeetanenersseseasencesseesensenseeeeeeneeeesmaesareaaeaetaee

5.2.1

Power

Supply

Module

Adjustments

(BRU-500

Only)

oo...

ceceeeeeeseseeseseneesereseceersarteceanetaeararies

5.2.2

Drive

Module

Adjust

ments........---:cscsssrscsserssetavensenesessesseneseeesocecesaeedee

seeaeceeseceeaeees

see

caeeaneesenenates

5.2.3

Serial

Interface

Operation...

seaepeteesnevenaseanseaae

seeseeesescerasnaeceestveasaetseaesereaaeesseeeseeesereee

5.2.3.1

User

Terminal

Requirements

...

qevansuasaecesensesee

cssecenetacsusersucssatersscseeecesstecsevenes

ees

5.2.3.2

Operating

the

User

Terrminal................sccccccceccssesccecseeeceeeseeeaenansecenenanesensenaasececoeescneesrensess

§.2.3.2.1

Help

Page

oo...

csi

eceeceeccctee

cue

ce

ceacereee

esta

ceeeesacteunaecenaeneesgesanaaesestentanseraepenees

5.2.3,2.2

Status

PAGO...

ceeccccccccececcsseecetecessctassactecsennectacaecneaneconaesecegeaetacaaeveseeneeuseeeneras

5.2.3.2.3

S@tup

Page

wes

cceeessnsessceneseenssseneeseseescesssssscesscesseeescerssseeeecessanesssseseeseassae

5.2.3.3

Multi-Drop

Host

Mode

Serial

Protocol

«oo...

ceecnecececesceensa

so

eteveceatenceavecsaeeacssnen

5.3

Tuning

Procedure...

seccccscccceeeeens

ceseeaeedecestanetce

eeeseenesasteeaeseseeneeeueeseetesestaneenenyeeeiusnnnedsidaageas

cid

geneaseccnsenee

5.3.1

Usitig

Auto-Tune

Mode

.......eecsncesescscencenneeeseenereneeteegeecneensaeeseesenenseeaequen

nesteanaatsaaeneneaseesereass

5.3.2

USing

Tune

MOde

uc

ce

cseetsserecscesererssascesessscnenseeneneeseecsegteegeenemseseeestiess

pened

nadenasasatsunvonet

treeseneaan

5.4

Personality

Module

Installation...

cece

ccccseneteeeseesesrsneeenecevaneeeensrseseseeeaeeesassaeaeanassntaesansnsanseerneensesasens

SECTION

VI

-

TROUBLESHOOTING

AND

MAINTENANCE

B21

PR

OCUCHION

20...

ccecse

tee

eeseeesecesseensssansecescoeaeeesansececeaevecescnsgecesnaaesavensesstesescaseaseenesaceatatanaecacaneaeccnssaascaeeeenes

6.2

LED

Diagnostic

IMPOrMationi........e

eseeceeceeeseeecteesesseeetneneneeessoscesseccestesssuapestiesuaace

steam

tdededeecsdesuneeeeesssetereeas

6.2.1

Power

Supply

Module

LEDs

's

(BAU-500

Only)

eaventeseeusenneune

sarsesssessetantusseanersetenteauactrovenecsee

6.2.2

Drive

Module

LEDs...

ses

ca

secacceaecaaenaeeceaseace

ceases

sens

concesatessaseaceeeeneensanqecsatse

6.3

Serial

Link

Diagnostic

INfOrmMmation.

......--

ee

eeecccesccceceesecececoscsesecasenttesseneeses

coceneeuesastucessassnsesesesenaseceses

cate

15

.-

16

20

20

wre

2d

2

23

23

vel

wel

27

27

31

36

36

REE

iv

BRU-200/BRU-500

Brushless

Drives

instruction

Manual

7.1

7.2

7.3

7.4

8.1

9.1

9.2

9.3

9.4

9.5

9.6

9.7

GB

Transformers

.....

2...

cececseececcececeesecnencesesceeeseesseecoesserssavaneaussesesensaauauessaaanansessseseevascensessasenessaseneneesecenstrerees

9.9

Motor

Mating

Conmectors...........

eect

ceecceccescsseeeeeeseneesaeessneaseessansanesatanaestensesoaeerasssscenensdevacaceetuqusaatcocetsense

9.10

Motor

Shaft

Seal

Kits...

esesessssseseeccnsneenversareenssuseusensensusavaneraseuseesssonnssessevarsueeanssstusauteateecengateateae

10.1

List

of

Drawings...

access

ceene

cece

cece

coevscaaeesauseessessseneesseeeeteeceneeseesasedseesiseteenasearsnsetsaneeeetenetones

SECTION

VIl

-

OPTIONAL

ACCESSORIES

PRO-Series

Controller

Kit

Installation

INStructions

......0..-:00::ccccaccessessesssesseesseeecsetensresenee

Spindfe

Orient

and

Auxiliary

Function

Card

Installation

Instructions

BRU-Series

Cortrol

Station

oo...

cceccecceescncseeecsrssvesceecneesceauecasseqensangesssteepeneusceseussessencareseuaeeevenssereneenees

RS232C0

/RS422

COMVOrter

we

cceecccccessessscecesececeesestesseseeneessasecaeesececcecaeeeedeqacneiesessenseceatseceaeeneertnestenees

SECTION

Vtll

-

APPLICATION

GUIDELINES

Torque

Sharing

Operation

of

BRU-Series

Drives...

ce

eeceece

ese

eees

cee

reses

ss

eeeenenneeeesnseneressnreneessseseneeeee

8.1.1

General

Description

...

8.1.2

Theory

of

Operation...

.:

8.1.2.1

Multiple

Slave

Drives...

8.1.2.2

Unequal

Torque

Staring...

8.1.3

Set-Up

Procedure...

eoseseecetereteeeteenensoeecoesansaerenenaneecaenes?

8.1.3.1

Wirng

Instructions...

8.1.3.2

Tuning...

SECTION

IX

-

REPLACEMENT

PARTS

Power

Supply

Modules

(BRU-500

Only)

oo...

ccsccscsssssssnsecsssssvanesaescseaseesscseeseessestaseceseaueaeessesdesnaceseesecseese

Drive

Modules...

ccc

cscs

cee

ceseseseecceeeeeceasnavenesssenssaaesens

veaesesesentesspesscneseasaseesccscarereessseseseeasaneeneseeeneneeetessetsaes

Personality

MOdUIGS.....

ec

cetcccenecesceeeecseesenessaneusesassaneuasensaeseeansessestersereseneeeteassteeseccsasaesanessanscaneetinesentees

MOLOrS.......

see

ecececaseeeceeseceeneeereesssepeeesesnsseenanenssesenesesiesscstnecsisesee

susseenbeseesnesersessvesteceatsseceeesseaeeatstanseeesseenannes

56

PRO-Series

Kits...

2...

.cccceccssecersesseeceeecceceseeteeescseeeacausesseeeseescseeueeestiesededieendseueeeeennscenscssrarcsesarenstecesegeeteeateenaes

Spindle

Orient

and

Auxiliary

Function

Card

(BRU-500

Only)...

eee

cee

eceeneneneeneeesteeeasareeeerneeesetasiegs

CADDIES

ccc

ecceccecceneteceseeneeeten

casas

crea

scntenten

sessed

etssenescasasessosceceusatudecesetendascenesansvevsseycecesusevaaucasessaneasanesaasas

SECTION

X

-

CUSTOMER

REFERENCE

DRAWINGS

Table

of

Contents

cave

nenaeveneeeteaenscaes

46

46

47

49

50

..

00

see

5

sed

52

vee

DL

wee

52

55

57

57

57

58

58

58

59

BRU-200/8RU-500

Brushless

Drives

instruction

Manual

Table

of

Contents

INDEX

OX

ooo

secccesesneenscesusscesnnuescsassnaseaessuessesesateeeereasanerssennuasunenreusnatesueaeeeseeaneesregdaesesececedsogeeeeaseneseceeeapeses

sesaenessteseecees

64

Figure

1-1

Figure

1-2

Figure

3-1

Figure

3-2

Figure

3-3

Figure

5-1

Figure

5-2

Figure

5-3

Figure

54

Figure

55

Figure

5-6

Figure

5-7

Figure

5-8

Figure

5-9

LIST

OF

FIGURES

BRU-500

Series

Servo

and

Spindle

Drives...

cece

ccceceesscceeneseacnesseasaeeaeteereanenessceneesssrasaatearaee

BRU-200

Series

Servo

Drives...

ec

ccccecccccscepeccsveceeesesacceensscaceees

suasceetaccuasenacesseseuaneqessseuessesaneesensaeees

S-Series

Motor

COnmmections..........

ccc

ceceeecerceeeseeneeccneeaneeecetaredeneersecheaesceeentetaunesessasecdcaeeeedssenanens

F-Series

Motor

Connections...

ec

scsessseessensensssessenerssenenecssseseuscauonsessusevarseneneansevensesangeaesasener

I-Series

Motor

Connections

«02...

ececescscecsesercereneeececesseneenesensenseeaeaneseresanensssnceresneseeesnesssennneneceecenees

PSM

Jumper

Locations...

cece

cee

eeeneneseteeaceseneee

nts

ceeenqessceaesecencatang

seeeeseensenaneeeeiresenee:eraneseneet

DM

Jumper

and

Personality

Module

Locations

«0...

ce

eececeeeeceseseeeeseene

nessa

see

sineeaeeeeen

ents

Serial

Terminal

HELP

PAGE...

eee

eeenscecrs

teens

tesccegsesees

teegsnenaecesenenetenensneaes

saaeeesensneasaeas

Software

and

Personality

Module

Identification...

eee

escsesceneceeceesaneaeeeseeeeeeeteseeeeteretacnenees

Serial

Terminal

STATUS

PAGE

..........cceceseceetssescserersessceeeereete

cesses

cr

cencea

erseceraneaeessterstsaseeeeeesenseaess

Serial

Terminal

STATUS

PAGE

After

FaUtt

.......ccscssssscecsssscseseceevsnsnstenseccesveteseseeesnsnnnustescurensereets

Serial

Terminal

SETUP

PAGE

(Velocity

Mode)

woeeceeed

see

netecovesestnseceonseeseeeteceareteseasssstsnensennisseaneetsat

Serial

Terminal

SETUP

PAGE

(Torque

Mode)

.......ccccccssescecsstesecsesseesssuacenesacsnceatersececaencavenaacassaeaes

Serial

Terminal

SETUP

PAGE

(Tune

Mode)

0.0...

eececesesecsseconecenserscesencaecareoternsnsseneneasanesensneness

Figure

5-10

Serial

Terminal

SETUP

PAGE

(Auto-Tune

Mode)

..........-..ecsscceccoeecoteseecoeceenereceneeserersuaeececenenenetes

Figure

5-14

Control

Block

Diagrams

of

Operating

MOde@S

.............-cescccceececceceeeceneea

ces

ceecesesenentenseceaneeseaeeseseoes

Figure

5-12

Typical

Small-Signa!

Response

for

Well-Tuned

Systerm...........cccccscscceesescesseeseteerseseeneevensersesesess

Figure

5-13

Personality

Module

Installation

oo...

ccc

cesses

sseeeecsteceeseeseessesuceuessecaeersseresegecbaressnardetacateceseasates

Figure

7-1

Figure

7-2

Spindle

Orient

and

Auxiliary

Function

Application

(BRU-500

Only)...

cesses

cs

eeecnessseseeeacees

BRU-Series

Control

Station...

cece

cesses

ceceeeseececo

eevee

nsseaus

en

sees

saeevecsarsnseenessebayeneusssesererenense

wd

2

12

-13

14

25

26

28

28

31

32

32

32

39

42

43

46

47

Figure

7-3

BRU-Senes

Control

Station

Connection

Diagram

........

cc

cecscccescaececeeseueccrscetecetaceceeeecarentaneeeats

48

vi

BRU-200/BRU-500

Brushiess

Drives

Insiruction

Manual

Table

of

Contents

LIST

OF

FIGURES

(Cont.)

Figure

8-1

Examples

of

Torque

Sharing

Operation...

cc

ceeesesessecseneeserseeeseeresseeeeesseserscenssensasaneenes

peesseaneates

51

Figure

8-2

Recommended

Wiring

for

Torque

Sharing

when

Motors

Rotate

in

Same

Direction...

ccscsssseecsses

creer

cecececee

sesceeseeseseeessaneasasearscsssaseeasasneneseee

53

Figure

8-3

Recommended

Wiring

for

Torque

Sharing

when

Slave

Motors

Rotate

Opposite

of

Master

MOtor

...........cccccccceescsescecsesceueececeaeeseecuescecseeeseeeanssenererteeeatsenanaesena

ees

54

56

Figure

9-1

Personality

Module

Model

Number

Description

...0.....cccccc

eects

eeeeee

tence

tee

reese

ebeenecenereentnacaeaense

Figure

9-2

Motor

Model

Number

Description

.......

eect

cerreee

eee

teens

testeeneessernnrereseneaceaesserenetitecasser

eases:

OG

LIST

OF

APPENDICES

APPENDIX

A

-

Getting

Started

With

the

Tandy

102

Termiitial

...........c:c-ce:cccseceeceeececeeccenececeneesraneseascateatcovenenenes

60

APPENDIX

B

-

User

Terminal

Communication

Codes

...0....:.ccccccccssesscseescssssseceseneeseeseneneneet’

venavensesasesanansaceesees

6t

APPENDIX

C

Getting

Started

With

an

IBC

PC

Terminal...

ccccccccccceccsccsessessecscecesanneaescaesaseraeeeetnseeeseseeeees

62

APPENDIX

D

Communication

Problems

and

Possible

Cures

.00....0....cccccccecscesesseesceseeneststeneeceesssseesseetareeees

BS

BRU-200/8RU-500

Brushless

Drives

instruction

Manual

vii

4)

3393

9992992992393

2

introduction

SECTION

|

-

INTRODUCTION

1.1

Purpose

This

manual

describes

the

Electro-Craft

BRU-Senies

brushless

servo

drives

and

spindle

drives

along

with

standard

Electro-Craft

motors

recommended

for

use

with

the

BRU-Series

drives.

The

manual

is

intended

for

use

by

qualified

engineers

or

technicians

directly

involved

in

the

installation,

operation,

and

field

ievel

maintenance

of

the

drives

and

motors.

1.2

Product

Description

The

BRU-500

is

a high

performance

sinusoidal

brushless

industrial

drive

employing

a

modular

package

suited

to

single

or

multtaxis

applications.

The

drive

modules

can

power

S-Series

and

F-Series

permanent

magnet

synchronous

motors

as

servo

drives

or

!-Series

squirrel

cage

induction

motors

as

spindle

drives.

All

drives

share a

common

power

supply

to

achieve

the

most

economical

system

package.

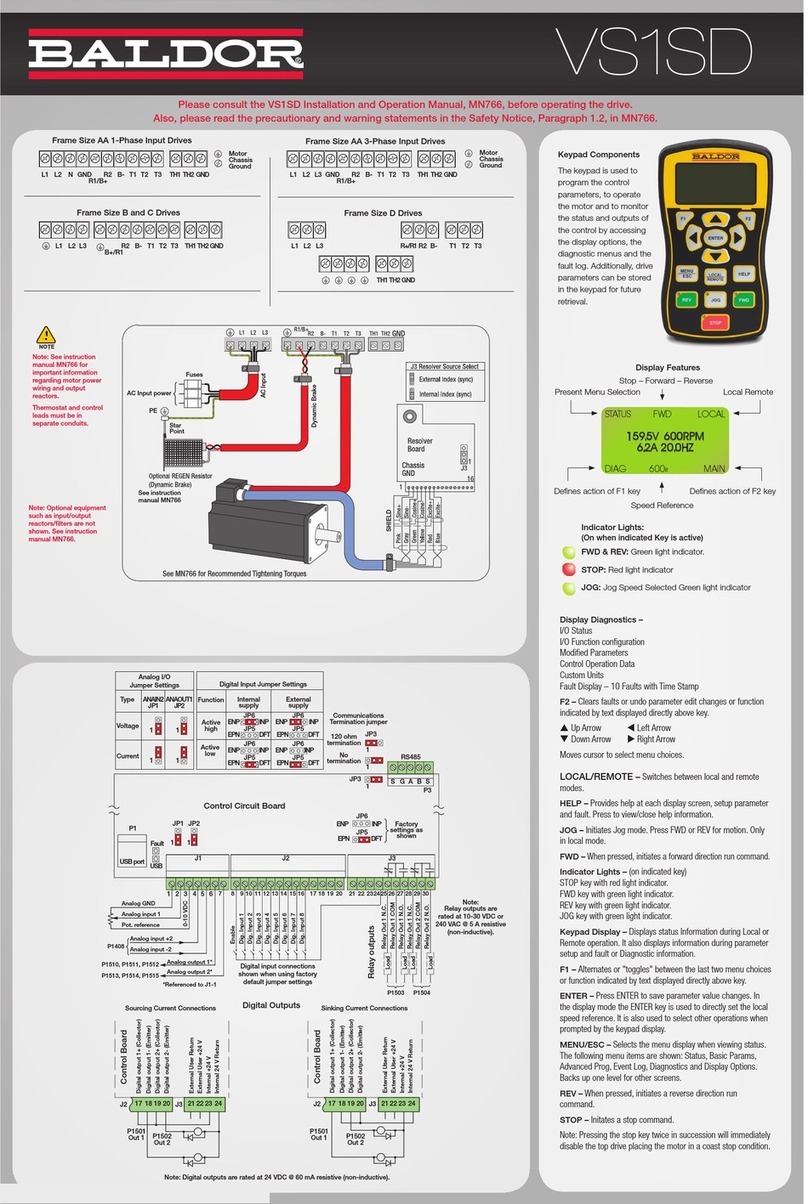

Figure

1-1

shows

the

standard

BRU-500

components.

The

BRU-200

is

a

high

performance

sinusoidal

brushless

industrial

drive

employing

a

modular

package

suited

to

single

or

multi-axis

applications.

The

drive

modules

power

S-Series

and

F-Series

permanent

magnet

synchronous

motors.

Figure

1-2

shows

the

standard

BRU-200

components.

For

single

axis

positioning

applications,

the

Electro-Craft

PRO-Senes

controller

cards

are

available

as

PRO-

Senes

Controller

Kits

to

be

integrated

into

the

BRU-Series

drive

module.

This

eliminates

the

need

for

a

separate

controller

package.

a

AF

a

ls

eh

Le

Figure

1-1

BRU-500

Series

Servo

and

Spindle

Drives

BRU-200/BRU-500

Brushless

Drives

instruction

Manual

1

introduction

Figure

1-2

BRU-200

Series

Servo

Drives

A

brief

descnption

of

the

BRU-Series

major

components

follows.

1.2.1

Power

Supply

Modules

(BRU-500

Only)

The

power

supply

module

(PSM)

can

supply

DC

power

to

as

many

as

six

servo

or

spindle

drive

modules.

The

AC

voltage

input

to

the

PSM

is

non-isclated

or

isolated

three

phase

power.

The

output,

which

is

daisy-

chained

to

the

drive

modules,

is

a

two

wire

DC

bus.

The

PSM

requires

no

adjustments,

protects

itself,

Provides

trouble-shooting

diagnostics,

and

has

a

built-in

solid-state

"soft

charge”

of

the

DC

bus

capacitors

to

reduce

AC

inrush

currents.

It

also

includes

a

built-in

dissipative

shunt

regulator

that

provides

quick

discharge

of

the

DC

bus

capacitors

and

doubles

as

an

emergency

synchronous

motor

dynamic

brake.

1.2.2

Drive

Modules

The

drive

modules

(DM)

provide

control

and

power

for

either

S-Series

and

F-Series

permanent

magnet

synchronous

motors

or

t-Series

squirrel

cage

induction

motors

(BRU-500

only).

The

DMs

are

available

in

a

range

of

current

ratings

to

best

complement

the

vanety

of

avaiable

motors.

The

DM

control

circuitry

utilizes

a

16

bit

microprocessor

to

provide

high

performance

and

a

simple

serial

interface

from

a

host

computer

or

user

programming

terminal

to

the

servo

drive.

All

set-up

and

tuning

is

periormed

by

a

personality

module

(PM}

which

plugs

into

the

DM.

The

PM

customizes

the

DM

for

each

specific

motor

and

encoder

type.

The

standard

decimal

line

count

encoders

are

factory-installed

on

the

motors.

2

BRU-200/BRU-500

Brushless

Drives

instruction

Manual

Introduction

A

standard

RS-232/RS-422

serial

interface

is

used

to

modify

tuning,

change

limit

values,

or

monitor

variables/status

in

the

BRU-Senes

drive

modules.

Any

changes

made

through

the

serial

interface

can

then be

stored

in

the

PM.

A

VT-52

compatible

serial

terminal

is

required

for

the

easy-to-use

menus.

Refer

to

Section

5.2.3.4

for

user

terminal

requirements.

Alternatively,

a

multi-drop

host

mode

communication

protocol

is

aiso

available

for

direct

connection

to

computer

hosts.

Refer

to

Section

5.2.3.3.

1.2.3

Motors

and

Encoders

A

wide

range

of

Electro-Craft

S-Series

and

F-Series

permanent

magnet

synchronous

motors

and

I-

Series

induction

motors

are

available

for

use

with

BRU-Series

drives.

Each

motor

includes

an

internally

mounted

encoder.

The

BRU-Series

also

provides

the

encoder

signals

for

the

position

controlier

to

use

for

the

most

economical

system.

Most

motors

are

available

with optional

spring-Set

brake,

optional

shaft

oi]

seals,

and/or

optional

fanpack.

The

synchronous

motors

have

a

rear

shaft

available

for

mounting

optional

feedback

devices.

1.2.4

Transformers

Multi-tap

three

phase

isclation

transformers

are

avaiiable

in

a

variety

of

power

ratings

for

line

voltage

matching

for

the

BRU-500.

A

multitap

single

phase

isolation

transformer

is

available

for

line

voltage

matching

for

the

BRU-200.

1.2.5

Auxiliary

Power

Supply

An

auxiliary

power

supply

module

(PSM-AU)

is

available

to

supply

DC

power

to

the

logic

supplies

of

up

to

four

DMs

if

the

PSM

is

tumed

off.

The

PSM-AUX

uses

single

phase

115

VAC

power

as

the

input.

The

PSM-AUX

option

is

used

if

DM

logic

power

must

stay

on

even

when

the

motor

supply

(the

PSM}

is

turned

off.

Absolute

positioning

with

PRO-Series

controller

kits

is

one

example

where

the

PSM-AUX

would

be

used.

Another

example

would

be

maintaining

DM

logic

power

so

that

the

DM

serial

interface

could

be

used

for

trouble-shooting

and

diagnostics.

See

drawing

9101-0134

in

Section

X

for

additional

information

on

use

of

the

PSM-AUX

and

the

optional

PSM-AUxX

isolation

transformer.

The

auxiliary

power

supply

is

built

into

the

BRU-200

drive

modules

as

standard

equipment.

See

drawing

9101-1329

in

Section

X

for

additional

information.

BRU-200/BRU-500

Brushless

Drives

Instruction

Manual 3

Specifications

SECTION

Il

-

SPECIFICATIONS

2.1

Drive

Module

Specifications

BRU-500

Model

DM-25

DM-50

DM-100

DM-150

DM-150X

Continuous

20 40

50 65

85

Amps[1]

Peak

Amps/[1]

25

50

100

150

150

Bus

Voltage

125-375

VDC

(325

VDC

with

230

VAC

input)

Command

Signal

+10

VDC

(13.3k

Ohms

impedance)

input

Range

Ambient

Temp.

32°-122°F

(0°-50°C)

Weight

24.2

tbs

(11.0

kg)

BRU-200

Model

DM-10 DM-20

DM-30

Continuous

5

10

15

Amps

[1]

Peak

Amps

[1]

10

20

30

Input

Volts

100-240

VAC

RMS

(Single

Phase)

Internal

DC

141-340

VDC

Bus

Voitage

(325

VDC

with

230

VAC

Input)

Command

Signal

+10

VDC

(13.3k

Ohms

impedance)

Input

Range

Continuous

50

W

Shunt

Power

[2]

Peak

Shunt

Power

4.5

kW

[2]

Ambient

Temp.

32°-122°F

(0°-50°C)

Weight

15

lbs

(6.8

kg}

f1]

peak

vaiue

of

sine

wave

per

phase

[2]

DM-30

has

provision

for

optional

external

shunt

resistor

that

provides

200

W

continuous

and

6000

W

peak

shunt

power.

See

drawing

9101-1328

in

Section

X

for

additional

details.

BRU-200/BRU-500

Brushiess

Doves

Instruction

Manual

Specifications

2.2

Power

Supply

Module

Specifications

(BRU-500

Only)

BRU-500

Model

PSM-50

PSM-125

input

Volts

88-265

VAC

RMS

(Three

Phase)

Output

Volts

125-375

VDC

(325

VDC

with

230

VAC

Input)

Continuous

Amps

(DC}

50

100

Peak

Amps

(DC)

150

450

Continuous

600

W

1200

W

Shunt

Power

Peak

Shunt

Power

20

kW

40

kW

Ambient

Temp.

32°

-122°

F

(0°

-50°

C)

Weight

26.2

Ibs

(11-9 kg)

BRU-200/BRU-500

Brushless

Drives

Instruction

Manual

Specifications

2.3

S-Series

Motor

Specifications

(TENV)

[5]

woda)

s-2003

s-2005

s-3007

5-3016|

s-a030|

s-a050|

s-4075 s-6400

56200

s~ca00

S-a350}

S-a500

Stalk

Torque

2.7

5.0

7.0

20

30 60 a0

1oo

200 325

350

450

b-in)

oe

0.30

0.58 0.79

2.26 3.39

6.78 s0.2 44.3

22.6

35.7

39.5

so.a

speed

@

tepm)

6000

so00g

Seco

Sooo

ao0o

4p00

3000

3000

3000

3000

2000

2000

a

poteyy

247

4-47

2.5

28

aa aa

67

oo

S.8

G2

7.6

82

(n/a

0.43

0.13

0.28 0.28

0.50

0.50

0.76

o.6a

o.66

0.70

9.86

9.92

a

ewekeoa)

i6

46

24

24

60 &0

30

a2

ao 85

104

442

a

lottee)

7.3

26

6.6

4.3

20

0.6

0.9

o.49

ose

o.c2

0.93

0.40

L

a

(a

9.7

4.4

42.0

a4

9.0

aa

sia

aa

2.2

ae]

as

aca

J

tip-in-s4i

|/0.00007]

0.00043]

0¢.00027/0.00072|

0.0022

o.0041/

9.006

o.0a2

0.024

0.030

0.056

0.083

ikg-m2)

.o00008

19.

co0028/0.00003

6.00008

0.00025/9.09046/0.00068|

0.0023

0.0024

0.0034

0.0063

0.0094

saesoo

—

_

oe25

om-25

om-25

o50

ce-So

ne-SO

Oe-s00|

OM-450

OM-4100

OM~250

pa-200

ov10

on-ao

oxic

ow-20

ceo

o30

oso]

—

_

_

__ __

[1]

(2)

[3]

[4]

[5]

maximum

continuous

operating

speed

peak

amps

of

per

phase

sine

wave

peak

volts

of

line

to

jine

sine

wave

phase

to

phase

totally

enclosed

nonventilated

BRU-200/BRU-500

Brushless

Drives

instruction

Manual

2.4

F-Series

Motor

Specifications

(TENV)

[5]

|

Nedet

F

4030

F-4050

F-4075 F-S100

F-sz00

F-£300

Stati

s

(tb-

I?

C=

as

69

93

13.0

19.8

27.8

at 61

a2

a5

i7S 245

@m

Kt

4.8

4.8 6.5

6.3

6.2 6.5

(iva

Clea)

0.54 0.54 0.79

o.71

0.70

6.79

ke

™)

gg

5S

ag

&

gs ag

O/irpa)

a)

cote

224

0-69

|

0,98

0.st

0.28

0.18

L

#

cdo

se

33

34 3a

1?

oat

J

(lb-inea*?||

0.009

0.019

0.029

0.057 0.095

O.144

tkg-m

27

0.001

0.00z7

0.0032 0.0084

0.0107

0.0162

{1]

maximum

continuous

operating

speed

[2]

peak

amps

of

per

phase

sine

wave

[3]

peak

volts

of

line

to

line

sine

wave

[4]

phase

to

phase

[5]

totally

enclosed

nonventilated

2.5

I-Series

Motor

Specifications

(BRU-500

Only)

Specifications

i

Rotor

Cont.

30

Min.

Base

Max.

.

.

.

Model

|

Power

|

Rating

|

Speed Speed

Inert

a

teign

t

ra

r

dule

kW/HP

kW/HP

RPM

RPM

goer

t2|

Ke7tbs

Lb-in

I-5300

0.031/

TeA0,,

5°5/7-4

7.8710.0]

1500

|

6000

}

‘ogg

|

70/154

|

DH-100

I1-6690

0.073/

Teag,,

1714-7

|

18720

|

1800

sooo

|

Oe"

|

108/238

|

DM-150x

(1}

totally

enclosed

air

over

(TEAO)

BRU-200/BAU-500

Brushless

Drives

Instruction

Manual

Specifications

2.6

Encoder

Specifications

Motor

Type

I-Series

S-Series

F-Series

Line

Count

1000

[1]

2000

[1]

2000

[1]

Supply

5

¥DC

5

VDC

(190mA

DC

max}

5

VDC

(245mA

DC

max)

Line

Driver

26L531

26LS31

[1}

standard

line

count

CAUTION

THE

ENCODERS

MOUNTED

INSIDE

THE

S-SERIES

AND

F-SERIES

SYNCHRONOUS

MOTORS

ARE

FACTORY

ALIGNED

AND

MUST

NOT

BE

MOVED OR

IMPROPER

OPERATION

MAY

RESULT.

HOWEVER,

THE

ENCODERS

MOUNTED

ON

THE

I-SERIES

INDUCTION

MOTORS

MAY

BE

MECHANICALLY

REALIGNED

TO

ANY

ARBITRARY

POSITION

IF

DESIRED.

2.7

Transformer

Specifications

BRU-500

-Rating

(kVA)

3.0 6.0

12.0

18.0

Input

208/230

/240

/380/460

/480

VAC

RMS

(Three

Phase)

Output

115/230

VAC

RMS

(Three

Phase)

Ambient

Temp.

32°

-122°

F

(0°

-50°

C}

Weight

86

ibs

135

Ibs

200

Ibs

325

Ibs

(39

kg)

(61

kg)

(91

kg)

(148

kg}

Refer

to

drawing

9101-0131

and

drawing

9101-0132

in

Section

X

for

transformer

outline

drawings

and

load

regulation

data.

BRU-200

Rating(kVA)

3.0

Input

220/230/240/440/460/480

VAC

RMS

(Singie

Phase}

Output

115/230

VAC

RMS

(Single

Phase)

Ambient

Temp.

32°

-122°

F

(0°

-50°

C}

Weight

62

Ibs

(28 kg)

Refer

to

drawing

9101-1056

and

drawing

9101-1057

in

Section

X

for

transformer

outline

drawing

and

load

regulation

data.

&

BRU-200/BRU-500

Brushless

Drives

Instruction

Manual

2.8

Maximum

Power

Losses

Model

DM-10

DM-20

DM-30

3

KVA

Transformer

(1

Phase)

DM-25

DM-50

DM-100

DM-150

DM-150X

PSM-50

PSM-125

3

kVA

transformer

(3

Phase}

6

kVA

transformer

(3

Phase)

12

kVA

transformer

(3

Phase)

18

kVA

transformer

(3

Phase)

specifications

Maximum

Watts

Loss

50

+

dissipative

shunt

100

+

dissipative

shunt

150

+

dissipative

shunt

350

120

180

275

300

110

+

dissipative

shunt

240

+

dissipative

shunt

350

600

950

1200

The

maximum

power

losses

are

shown

to

help

in

sizing

a

NEMA

12

(or

equivalent)

enclosure

and

any

required

ventilation.

Typical

power

losses

are

about

one-half

maximum

power

losses.

As

an

additional

aid

in

sizing

an

enclosure

with

no

active

method

of

heat

dissipation,

the

following

approximate

equation

is

used:

T

=

4.08*(Q/A)

+

1.1

where

T

is

the

temperature

difference

between

inside

air

and

outside

ambient

(°

F),

Q

is

heat

generated

in

enclosure

(watts),

and

A

is

enclosure

surface

area

(Ft).

The

exterior

surface

of

all

six

sides

of

an

enclosure

is

calculated

as:

A=

(2dw +

2dh

+

2wh)/144

where

d

(depth),

w

(width),

and

h

(height)

are

in

inches.

BRU-200/BRU-500

Brushless

Drives

Instruction

Manual

9

installation

SECTION

Ill

-

INSTALLATION

3.1

Mounting

the

Power

Supply

and

Drive

Modules

The

BRU-500

power

supply

and

drive

modules

and

BRU-200

drive

modules

are

designed

for

simple

installation

on

a

flat

surface

such

as

the

back

wall

or

plate

of

an

enclosure.

The

environment

in

the

enclosure

must

be

clean

and

free

of

oil

mist,

coolant

mist,

conductive

particles,

and

corrosive

chemicais.

For

industrial

applications,

a

NEMA

12

or

equivalent

enclosure

is

recommended.

The

enclosure

must

also

be

properly

sized

(and

ventilated

if

required)

to

insure

that

the

BRU-500

and

BRU-200

maximum

ambient

temperature

is

not

exceeded.

Drawings

9101-0409

and

9101-0410

illustrates

a

typical

BRU-500

installation

showing

space

requirements

between

modules

for

cover

removal

and

around

modules

for

wiring

and

air

flow.

The

power

supply

module

should

be

centrally

located

to

minimize

the

distance

between

it

and

the

drive

modules.

It

is

also

recommended

that

the higher

current

rating

drive

modules

be

located

closest

to

the

power

Supply

module.

Drawing

9101-1300

shows

the

BRU-200

drive

module

dimensions

including

space

requirements

around

the drive

module

for

wiring

and

air

flow.

3.2

Power

Wiring

3.2.1

BRU-500

Power

Wiring

WARNING

DANGER

OF

ELECTRICAL

SHOCK

OR

BURN.

ONLY

QUALIFIED

INDIVIDUALS

SHOULD

WORK

ON

THIS

EQUIPMENT.

DISCONNECT

ALL

POWER

BEFORE

WORKING

ON

EQUIPMENT.

DANGEROUS

VOLTAGES

MAY

EXIST

AFTER

POWER

IS

REMOVED!

CHECK

DC BUS

VOLTAGE

OF

BRU-500

EACH

TIME

POWER

IS

REMOVED

BEFORE

WORKING

ON

EQUIPMENT.

Drawing

9101-0411

illustrates

the

only

required

power

wiring

for

a

typical

four

axis

installation.

The

phasing

of

the

three

phase

input

L1,

L2,

and

L3

to

the

power

supply

module

is

arbitrary,

but

the

DC

bus

+

and

-

polarities

must

be

connected

as

shown.

Also,

the

phasing

of

the

three

phase

drive

module

outputs

R, S,

and

T

must

conform

to

the

motor

R,

S,

and

T

leads

for

proper

operation.

Connect

the

earth

ground

as

shown

to

insure

a

safe

and

proper

installation.

The

DC

bus

connection

wires

(substitution

not

permitted)

are

provided

with

each

drive

module.

Selection

of

transformer,

line

fuses,

and

wire

gauges

is

covered

in

drawing

9101-0411.

The

optional

auxiliary

power

supply

wiring

is

covered

in

drawing

9101-0134.

10

BRU-200/BRU-500

Brushiess

Drives

instruction

Manual

Installation

3.2.2

BRU-200

Power

Wiring

WARNING

DANGER

OF

ELECTRICAL

SHOCK

OR

BURN.

ONLY

QUALIFIED

INDIVIDUALS

SHOULD

WORK

ON

THIS

EQUIPMENT.

DISCONNECT

ALL

POWER

BEFORE

WORKING

ON

EQUIPMENT.

DANGEROUS

VOLTAGES

MAY

EXIST

AFTER

POWER

IS

REMOVED!

Drawing

9101-1329

illustrates

the

only

required

power

wiring

for

a

typical

installation.

The

phasing

of

the

three

phase

drive

module

outputs

R,

S,

and

T

must

conform

to

the

motor

R,

S,

and

T

leads

for

proper

operation.

Connect

the earth

ground

as

shown

to

insure

a

safe

and

proper

installation.

The

AC-AUX

auxiliary

power

input

is

used

if

DM

logic

power

must

stay

on

when

the

motor

supply

is

tumed

off.

Absolute

positioning

with

PRO-Series

controller

kits

is

one

example

where

this

would

be

used.

Another

example

would

be

maintaining

DM

logic

power

so

that

the

DM

serial

interface

could

be

used

for

trouble-shooting

and

diagnostics.

The

auxiliary

AC

input

must

be

isolated

or

be

the

same

phase

as

the

main

AC

power

to

the

drive

module

or

damage

can

result.

if

multiple

BRU-200

drive

modules

are

used,

and

AC

power

is

distributed

from

more

than

one

phase,

the

AC

auxiliary

input

for

each

drive

must

be from

the

same

phase

as

the

main

power

for

that

drive.

You

may

not

use

a

single

auxiliary

AC

source

for

drives

on

more

than

one

supply

phase,

even

if

the

auxiliary

AC

source

is

isolated.

See

drawing

9101-

1329

for

additional

information

and

examples

showing

use

of the

AC-AUX

power

input.

Selection

of

transformer,

liné

fuses,

and

wire

gauges

is

covered

in

drawing

9161-1329,

3.3

Motor

Mounting

and

Wiring

Motor

outline

drawings

for

the

S-Series, F-Series,

and

!-Series

motors

are

shown

in

drawings

9101-0129,

9101-0332,

and

9101-0130

respectively.

Some

motor

mounting

considerations

are

as

follows:

1)

Bo

not run

motor

unmounted.

Attach

all

motor

cables

after

motor

is

mounted.

2,)

Mount

motor

with

connectors

pointing

downward

to

keep

liquids

flowing

away

from

connectors

and

use

a

drip-loop

in

cables

to

allow

liquids

to

flow

away

from

connectors.

3.)

Consider

motor

case

temperature

if

necessary

to

safeguard

operator

and

maintenance

staff.

Maximum

case

temperature

is

about

100°C

(212°F)

for

a

motor

used

at

continuous

rating

in

a

40°C

ambient.

Motor

connections

are

shown

in

Figure

3-1,

Figure

3-2,

and

Figure

3-3.

3.4

External

Shunt

Mounting

and

Wiring

(BRU-200

Option

Only)

The

External

Shunt

is

designed

to

be

mounted

on

flat

surface.

The

same

mounting

restrictions

apply

to

the

External

Shunt

as

to

the

BRU-200.

Drawing

9101-1328

shows

the

Extemai

Shunt

Resistor

dimensions

and

connection

diagram.

Note

that

the

jumper

between

pins

1

and

2

of

TB2

on

the

DM

connects

the

internal

shunt

resistor

when

an

External

Shunt

Resistor

is

not

being

used.

BRU-200/BRU-500

Brushless

Drives

instruction

Manual

11

This manual suits for next models

11

Table of contents

Other Electro-Craft Servo Drive manuals

Electro-Craft

Electro-Craft CompletePower Plus CPP-A12V80A-SA-USB Use and care manual

Electro-Craft

Electro-Craft SCA-LE-30-03 User manual

Electro-Craft

Electro-Craft CompletePower Plus CPP-A24V80A-SA-CAN User manual

Electro-Craft

Electro-Craft SCA-SE-30-06 User manual

Electro-Craft

Electro-Craft MAX-430 User manual