Tuba Installation Guide Table of Contents

MAN-TUBIG (Ver. 1.503) 6

3.4.4. Feedback and Control Cable Assemblies....................................................... 30

3.4.5. Main Feedback Cable (Feedback A)...............................................................30

3.4.6. Main and Auxiliary Feedback Combinations .................................................39

3.4.7. Auxiliary Feedback (FEEDBACK B).................................................................. 41

3.4.7.1. Main Encoder Buffered Outputs or Emulated Encoder Outputs

Option on FEEDBACK B (YA[4]=4) ................................................. 41

3.4.7.2. Differential Auxiliary Encoder Input Option on FEEDBACK B

(YA[4]=2) ....................................................................................... 43

3.4.7.3. Single-Ended Auxiliary Input Option on FEEDBACK B -(YA[4]=2) 45

3.4.7.4. Pulse-and-Direction Input Option on FEEDBACK B - (YA[4]=0) ....47

3.4.8. I/O Cables ......................................................................................................50

3.4.8.1. Analog Inputs................................................................................ 50

3.4.8.2. Digital Inputs (on the GENERAL I/O Port) ..................................... 51

3.4.8.3. Digital Outputs (on the COMMITTED I/O Port) ............................ 54

3.4.9. Communication Cables.................................................................................. 56

3.4.9.1. RS-232 Communication (on the COMM.1 Port) ........................... 56

3.4.9.2. CAN Communication (on the COMM.2 Ports)..............................57

3.5. Powering Up ................................................................................................................. 59

3.6. Initializing the System................................................................................................... 59

Chapter 4: Technical Specifications ................................................................................ 60

4.1. Features........................................................................................................................ 60

4.1.1. Motion Control Modes ..................................................................................60

4.1.2. Advanced Positioning Motion Control Modes .............................................. 60

4.1.3. Advanced Filters and Gain Scheduling........................................................... 60

4.1.4. Fully Programmable....................................................................................... 60

4.1.5. Feedback Options .......................................................................................... 61

4.1.6. Input/Output ................................................................................................. 61

4.1.7. Built-In Protection .........................................................................................62

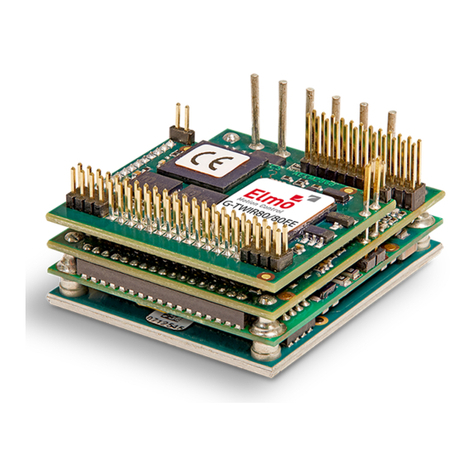

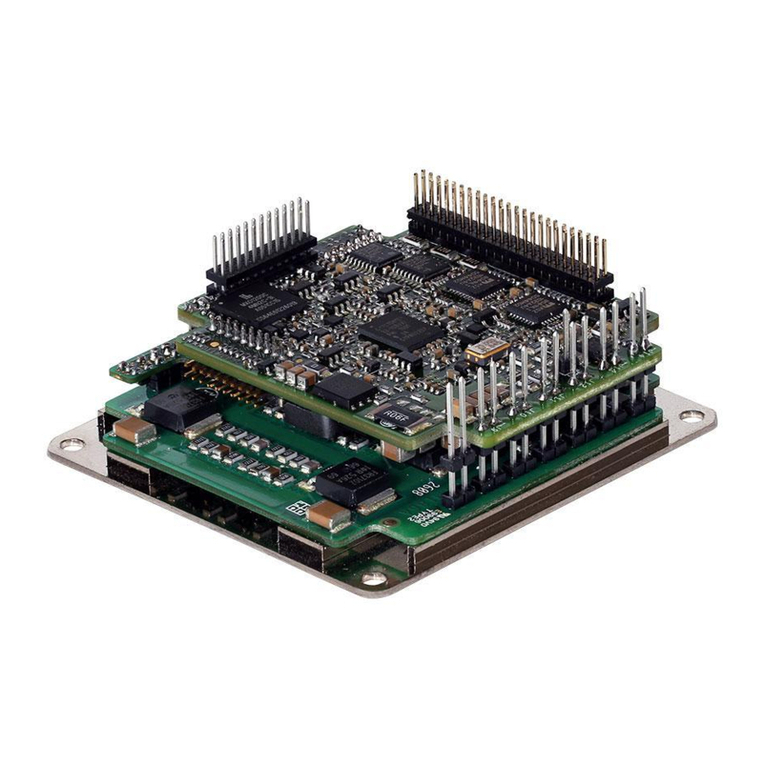

4.2. Tuba Dimensions .......................................................................................................... 63

4.3. Mounting Dimensions .................................................................................................. 64

4.4. Mechanical Specifications ............................................................................................ 64

4.5. Power Ratings...............................................................................................................65

4.6. Environmental Conditions............................................................................................ 65

4.7. Tuba Connections ......................................................................................................... 66

4.7.1. Auxiliary Supply .............................................................................................67

4.8. Control Specifications...................................................................................................67

4.8.1. Current Loop.................................................................................................. 67

4.8.2. Velocity Loop ................................................................................................. 68

4.8.3. Position Loop .................................................................................................68

4.9. Feedbacks ..................................................................................................................... 69

4.9.1. Feedback Supply Voltage...............................................................................69

4.9.2. Incremental Encoder Input............................................................................69

4.9.3. Digital Halls .................................................................................................... 70

4.9.4. Interpolated Analog (Sine/Cosine) Encoder .................................................. 70